Use and maintenance manual

4

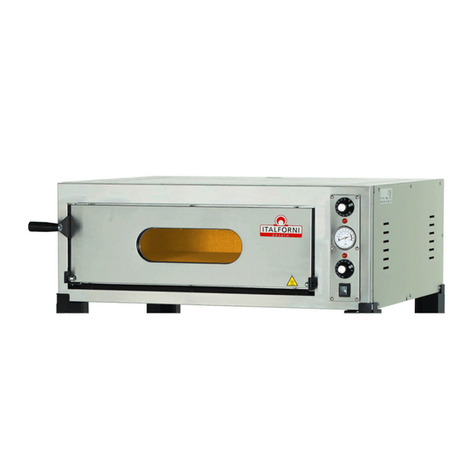

CHAP.1 - INTRODUCTION AND OVEN DESCRIPTION

All gas parts of the appliance are covered by warranty starting from the invoice date.

Any attempt to dismantle, alter or tamper with any part of the appliance shall invalidate the

warranty.

Improper use of the oven as well as any attempt to dismantle or alter it can lead to accidents and

therefore the manufacturer declines all responsibility for any damage to persons or property

caused by tampering. For any faults encountered, contact the nearest authorised service centre or

the manufacturer directly.

The manufacturer declines all responsibility in the following cases:

-Improper use of the oven by unsuitably trained staff.

-Use not complying with the regulations in force in the country of use.

-Lack of or incorrect routine maintenance.

-Use of non-original spare parts.

-Total or partial failure to comply with the instructions.

-Failure to send the warranty certificate.

The electric-gas-powered pizza ovens EGA/LE, EGA/T, EGA/C, EGA/L, EGA/LE2, EGA/T2, EGA/C2,

EGA/L2, EGB/LE, EGB/C, EGB/L, EGB/LE2, EGB/T2, EGB/C2, EGB/L2 all carry the CE symbol issued

by a Notified Body, entrusted with and responsible for assessing compliance with the essential

requisites set out by gas Directive 2009/142/EEC. The oven or the quality of the production system

are subject to periodic monitoring through inspection checks in order to ensure their compliance

with the type of certificate as stated in the above Directive.

The ovens comply with product standards EN 203-1, EN 203-2 and EN 437.

The appliance also complied with the following European Directives:

Low Voltage Directive 73/23/EEC.

Electromagnetic Compatibility Directive 89/336/EEC.

The appliance can be marketed in all European countries whose code is present on the technical

plate. It must be installed in accordance with the rules in force governing the installation of gas-

electric appliances for collective use, with the accessories and the adjustments required by the

country of use as described in the use and maintenance manuals printed in the original and official

languages of the different countries.

In particular, the oven must be installed on a suitable stand or sufficiently stable and fully

horizontal surface in a room with sufficient ventilation and must be used by specialised staff.

Connect a pipe of suitable diameter to the combusted exhaust gas flue collar in order to discharge

the cooking vapours and combustion fumes outside (directly in the flue or using an appropriate

interlocked extractor hood).