EDNord EXCELAM-Q 1670RS User manual

LEADERS IN LAMINATION TECHNOLOGY

Before operating the unit, please read this manual thoroughly and retain it for future reference.

www.gmp.com

USER’S GUIDE

EXCELAM-Q

1100RS/1670RS

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

3

2

WARNING

If you ignore this symbol, you could suffer serious injury or death.

This symbol means a prohibited action.

If you ignore a prohibited action, you could

suffer a personal injury and damage

the machine

This symbol means a required action.

If you don't follow this action, your safety is

not guaranteed.

Required action will be included in this symbol.

“Important Safety Instruction” is for the purpose of user’s safety and prevention of Property loss.

Read thoroughly and use rightly according to the manual.

Important Safety Instruction is classified as “Warning” and “Caution”, the meaning is as follows.

This symbol means that you could suffer personal injury and damage the machine.

CAUTION

If you ignore this symbol, you could receive a serious injury or loss of property.

WARNING

Do not overload a power supply.

Do not connect or disconnect with wet hands, as this will cause an electric shock.

Make sure plug is in the socket, as it could cause fire or an electric shock.

Do not use a damaged plug or lead, as this could cause a fire or an electric shock.

Do not use other voltage and power supply other than specified,

as this will cause a fire and an electric shock.

Do not dissemble, make repairs or convert the machine. Contact your dealer for repairs.

Do not use materials near a naked flame.

Do not use the flammable spray or flammable materials inside or outside the machine.

As this could cause a fire.

Do not allow children use of this equipment.

Do not spill any liquids on the laminator as this will cause damage and a possible electric shock.

Danger, Malfunction, loss of electricity could cause an electric shock.

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

When lamintor is not in use, you must turn off the power switch, disconnect the power plug from the

socket.

When moving the product, turn off the power switch, disconnect the power plug from the socket.

CAUTION

Please avoid installing near the following places :

*Gas stove, Ventilator or Air conditioner due the higher temperature or higher humidity.

*Dusty environment.

Do not place any materials on the top of the laminator as they could catch a fire.

Avoid touching the laminator and the film just after laminating as you could get burned.

Ensure all hair, neckties, necklaces, are kept free of the feeding table to avoid injury.

2 people are needed to carry this equipment to avoid personal injury or damage to the machine.

Danger - laminating blades are sharp and can cause injury

Keep gears and chains free of all materials.

Do not touch the roller and heating plate with your hand as you could be burnt.

Warnung

Wenn Sie dieses Symbol ignorieren, Sie können verletzen und sterben.

Dieser Sicherheitshinweise meint das

Verboten.

Wenn Sie nicht vorsichtig umgehen, das

Gerät kann die Zerstörungen sein, und Sie

können sich verletzen.

Dieser Sicherheitshinweise meint die Achtung.

Wenn Sie nicht vorsichtig umgehen, nicht

genug Sicherheit garantieren.

In dem Zirkus, Sie konnen die Achtung fur

Zeihen sehen.

Dieses Sicherheits-Zeichen markiert einen wichtigen Sicherheitshinweis in diesem

Bedienungshandbuch und auch an dem Gerät.

Lesen und beachten Sie diese Hinweise und die entsprechenden Anweisungen sorgfällig.

Es gibt zwei wichitige Sicherheitshinweise und sie meinen unter Folgende.

Vorsicht

Wenn Sie dieses Symbol ignorieren, Sie können verletzen und das Gerät kann

Zerstörungen sein.

5

4

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

7

6

Warnung

Vermeiden Sie viele Steckeren im eine Steckdose zu einstecken.

Es gibt das Risco eines elecktrischen Shlages und bricht ein Brand aus.

Vermeiden Sie die Stecker mit flußiges Hand im Kontakt.

Es gibt das Risiko eines elecktrischen Shlages.

Stecken Sie den Stecker im der Steckdose richtig ein.

Es gibt das Risiko eines elecktrischen Shlages und bricht ein Brand aus.

Verbinden Sie den Erdeschuß des Gerät fur die Sicherheits.

Nicht transformieren Sie den Stecker and die Steckdose.

Es gibt das Risiko eines elecktrischen Shlages und bricht ein Brand aus.

Nur benutzen Sie die richtige Stromsorgung.

Es gibt das Risco eines elecktrischen Shlages und bricht ein Brand aus.

Versuchen Sie niemals im Falle einer Betriebsstörung das Gerät selber zu reparieren oder den

Fehler innerhalb des Gerät zu suchen. Frangen Sie unbedingt qualifiziertes Service-Person.

Nicht benutzen Sie neben Brandstuffe.

Es gibt das Risiko eines elecktrischen Shlages und bricht ein Brand aus.

Wenn Sie das Gerät reinigungsarbeiten, Sie können nicht die brandstuffe benutzen.

Es bricht ein Brand aus.

Halten und installieren Sie das Gerät fern vom Kinder.

Es gibt das Risiko eines elecktrischen Shlages und Verbruhende.

Nicht liegt das Wasser oder Flußigkeit ober dem Gerat.

Das Gerat kann die Zerstorungen sein und es gibt das Risiko eines elecktrischen Shlages.

Nicht linken, schlagen und ziehen das Stromkabel.

Es gibt das Risiko eines elecktrischen Shlages und bricht ein Brand aus.

Under die Zerstörung des Gerät und das Krieshstrom, Es gibt das Risiko eines elecktrischen Schlages.

Wenn Sie nicht das Gerat langezeit benutzen, ausschalten Sie das Gerät and ziehen Sie den Stecker

aus der Steckdose.

Wenn Sie das Gerät in eine neue Position bewegen, ziehen Sie den Stecker aus der Steckdose und

halten Sie das Stromkabel bei sich.Wenn Stecker und Stromkabel beshadigt werden, gibt es das Risiko

eines elecktrischen Shlages und bricht ein Brand aus.

VORSICHT

Vermeiden Sie die Installation vom Gerate in der folgende platze.

-Neben dem heiße Gerät oder Klimaanlage. Hoch variation temperatur platz oder hoch Feuchtigplatz.

-Neben dem arbeitsplatz oder dampf Gerät ( die Brantquelle )

-Die sonnen Shein kommt direkt.

-Schmutzig und Schwingung Platz.

-Instabilität Platz.

Nicht einladen Sie Material ober das Gerat.

Das Material kann transformieren und das Gerät kann die Zerstörungen sein.

Halten Sie Ihre Hände fern von Foilen nach dem Laminierung und ober das Gerät.

Halten Sie Ihre Klabatt, lange Haare, und Halsketten vom foilen eingang im Gerät um verletzungen

zu vermeiden.

Das Gerät wird nur fur Laminieren benutzt.

Das Gerät kann die Zerstörungen sein.

Wenn Sie laminieren, das Arbeitsplazt wird unter Reinigungssituation sein.

Wenn Sie das Gerät entpacken oder in eine neue Position bewegen, bedarfen Sie die Hilfe

vom anderem Leute. Das Gerät kann die Zerstorungen sein, und Sie können sich verletzen.

Scharfe Messerklinge

Sie konnen sich verletzen, wenn Sie nicht vorsichtig mit der Schneidevorrichtung umgehen.

Halten Sie die Ihre Hande und Körfer, lockere Kleidungs stucke, langes Haar, Schmuck, z.B. lange Halsketten

fern von dem Kette oder Getriebe.Das Gerät kann die Zerstörungen sein, und Sie können sich verletzen.

Halten Sie Ihre Hände und Körfer fern von den vorderen heißen Walzen um verletzungen zu vermeiden.

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

9

8

Contents

Part name

Carriage & Installation

Control panel

Usage of the main device

Laminating procedure

Laminating guide

Product Maintenance

Trouble shooting

Specification

GMP Subsidiaries

SURELAMPLUS-PCR800DBS

2.5mm T Wrench 1EA

3mm, 4mm L Wrench 1EA User GuideFuse 5A 2EA

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

11

10

Q

Y

QQ

QS

S

X

QP

W

U

R

QT

V

QR

T

Front Panel

Pressure Plate

Safety Cover

Upper Sub-roller

Rewinder

Heat Roller

Upper Film

Bottom Film

Stretch Bar

Film Cutter

Pull Roller

Bottom Sub-Roller

Stand

Moving Wheels

Upper Film Rewinder Paper Pipe

Bottom Film

Foot Switch

Stand

Control Panel

Safety Cover

Roller Pressure

Bottom film tension handle

Front Panel

Power Cable

Power Switch

Foot Switch Cable

Bottom Film

Emergency Switch

Bottom Film Tension Handle

Back Trimmer

Pull Roller

Clutch Pressure Handle

Rewinder Pressurel handle

Rewinder

Emergency Switch

Separator

(Ultra-thin Film Sepa.)

Film Core

Pressure Plate

Safety Cover

Front Panel

Rewinder Shaft Rewinder Paper Pipe Rewinder Cap

Film Shaft Film Core

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

13

12

Power supply should be used AC 220V/20A above.

Necessarily Grounding is needed for your safety.

Grounding

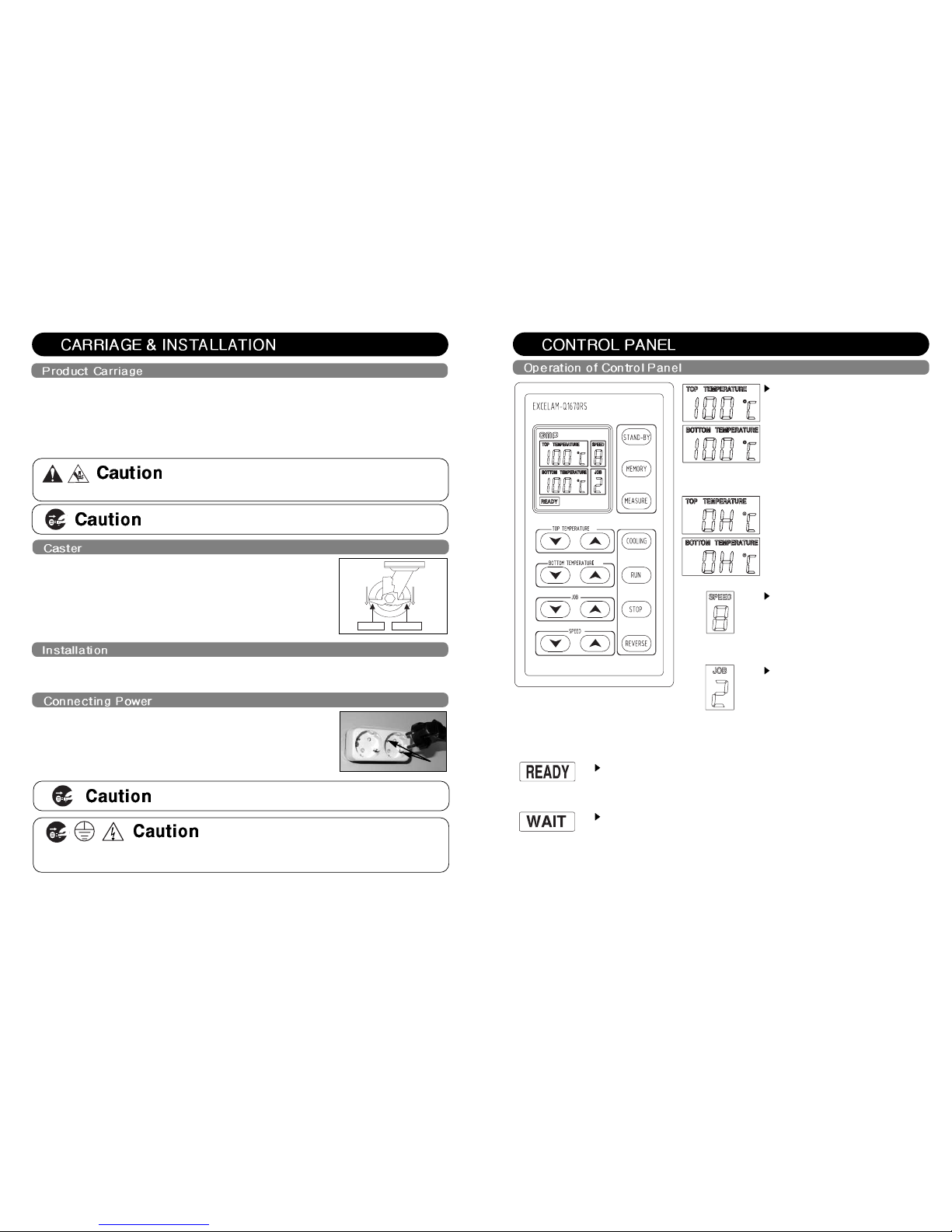

This product is easy to carry mainly due to the caster attached

At carrying product, push the “locker of a caster” toward “OFF” direction and the caster moves.

The product is too heavy, necessarily more than 2 persons should carry the product. On the condition of loading and

carrying the product, necessarily use the lift-truck.

After installing a product, push “locker of a caster” toward “ON” direction. The caster are fixed, it prevents from the

product’s movement.

The product is too heavy, therefore at the condition of carrying product,

necessarily more than 2persons carry. If you don't, it makes a product breakage

and personal injury

On carrying product, segregate the powerplug from the outlet, otherwise it makes an

electric shock

At the same place, carry and install the product in a short distance, use a caster.

At the caster, a locker is installed, on carrying product, you should unlock the locker

of a caster.

The caster's locking or unlocking is fixed when you push the “lock(ON)” just like the

right picture, the caster is locked and otherwise push “OFF” lever, the caster is

unlocked. After carrying the product, lock the caster.

Lock(ON) Unlock(OFF)

Unlock(OFF)Lock(ON)

Product installation should be installed on the hard and balanced floor. At the condition of unbalanced status, a laminating

quality can be down.

Grounding is necessary for your safety. If the grounding isn't good,

a static electricity happens excessively, it can be a main reason of a

malfunction on operating of a laminator. A malfunction and electric

leakage can make an electric shock.

Insert the powerplug inside firmly.

If you don't, it makes a fireflame by the overheating.

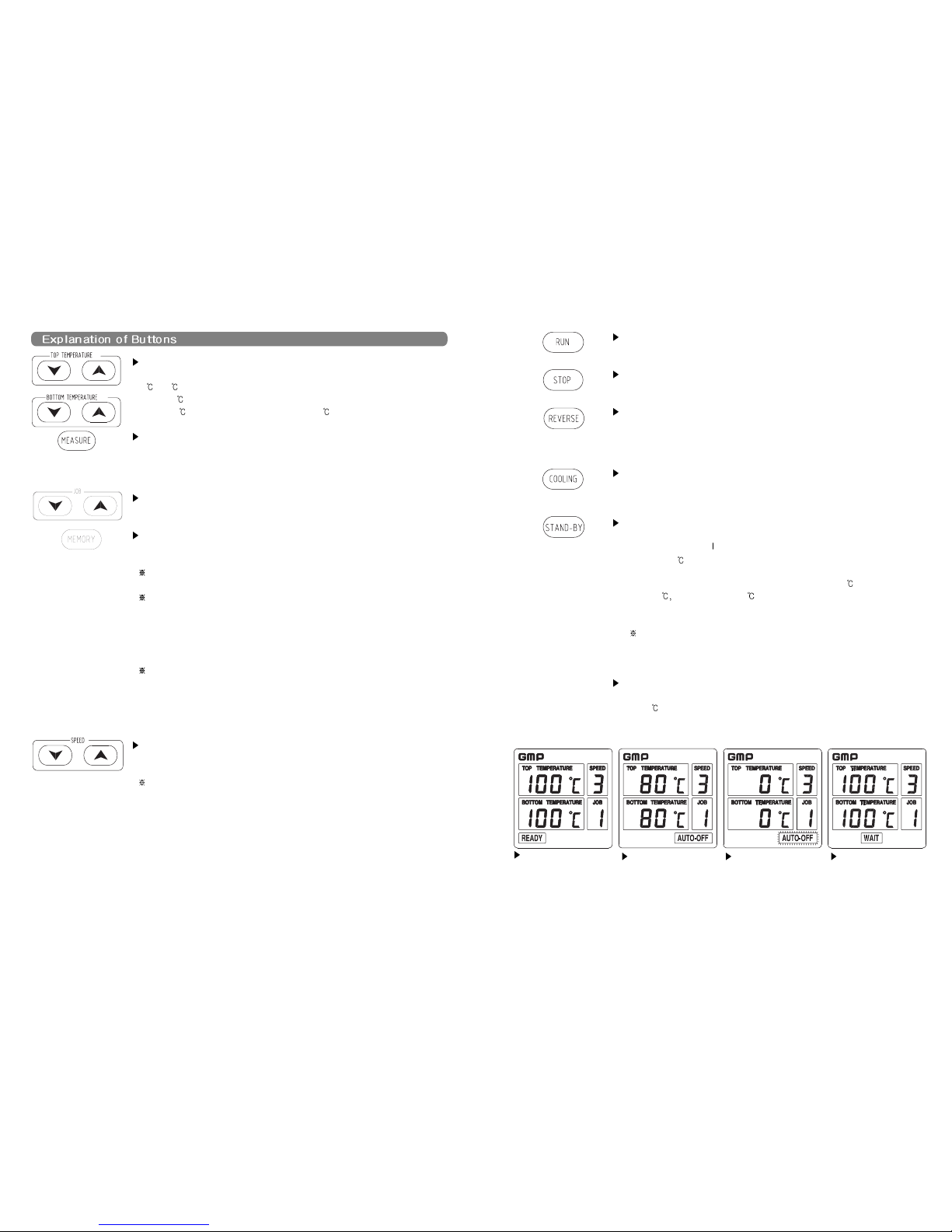

Upper Heating roller temperature

indication panel

Shows the setting temperature of Heating

roller and current temperature.

In the normal condition, setting temperature

diplays but if you press “Measure indication

button” of Function button, It shows the

current temperature. A setting temperature

change can be modified by pressing the top

button upwards or downwards.

This product has a self-detection system for

overheating. If a heater's temperature rises

too high, it displays “OH”, in this case you turn

off the power supply of machine, contact your

dealer.

Speed Display Window

It displays roller's rotation speed, Variation

speed is “1~9”. Roller's rotation speed is

modified by the “Speed setting button” being

adjusted up or down.

Job Mode Display Window

Can memorize the different working condition

from “1” to “9”, the displayed number means

that the working condition of included current

temp and speed memorized.

Working condition change can be adjusted by

“Job button”.

Working Mode Display Window

“READY” indicates that a heated roller's temperature has reached the laminating temperature.

When “READY” displays on the control panel, you can start laminating.

Heating Display Window

“WAIT” means that the roller's temperature is not right(temperaute is low) against setting

temperature. On the condition of “WAIT” displays, if you start laminating, a laminating can’t be

made. If “WAIT” on display window flickers, a roller's temperature is very high against a setting

temperature. When “WAIT” display flickers, at that time you start laminating, the laminating

result can have a crease, curving.

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

15

14

Temperature Setting Button

Is for the purpose of setting heated roller's temperature. The setting temperature range is

“0 ~130 ”. When you press the temperature setting button, the value on the display

increase “1 ” for the first time. If you press the button contineously, the temperature

increases 1 during 0.5 second, after two second, 10 increases quickly by one second.

MEAS Button

When you press the MEAS button. The machine beeps, the current temperature is flashed

in the “Temperature Window”. If you keep your fingers on the button, it displays a previous

set temperature.

Job mode button

Is for the purpose of setting JOB1~JOB9 level.

Memory Button

Is for memorizing of working condition.

JOB Mode Function

You can save 9 different working conditions from Job1 to Job 9.

Saving of Working condition

1) Select Number by using Job mode button.

(Selected Number displays on the Job mode display window)

2) You can set the temperature of the heated roller, speed with the temperature and speed

setting button.

3) If you press the “MEMORY”, setting value automatically is memorized.

Reference!!!

When you chang the temperature or speed, the changed number and current job number

flickers for 2senconds.

The flickering alarms that the setting value is correct and asks that saving the changed

contents to memorize at the job condition.

Speed Control Button

Is for the purpose of settting a roller rotation speed. Roller rotation speed can be increased /

decreased from 1 step to 9 step.

Change of roller’s rotating speed

1) When rollers rotate : by the change of speed, the roller rotates by the changed speed.

2) When rollers stop : At time of roller's stop, if you change the speed, only the number is

changed. Press the Run button if you want to rotate the roller.

RUN Button

Is for the purpose of roller rotation.

Stop Button

Is for the purpose of stopping a roller's rotation.

Reverse Button

This is for reverse rotation of the rollers. When pressed the “REVERSE” button will show a

speed flicker indication and the rollers will start to reverse. Remove fingers from the button to

stop reverse procedure.

Cooling button

Is for the purpose of starting a cooling motor.

Press once to start, once to stop.

STAND-BY

1) Setting by Users : For short time, if you does not operate the machine, it can be used.

At the normal condition. f you press the “STAND-BY” button, the setting temp. can be

changed to 80 automatically. (The operating condition stops)

2) Automatic setting by microprocessor : If you leave the machine for 3hours, micro-

processor installed in machine controls the roller temp. below 80 (If the setting temp is

below 80 it is controlled at the 0 ). At this time, stand-by display lamp is on, Job

display or Heater display window is cleared. And then one and half hour passed, Stand-

by Mode flickers and Power of heater is cut off."

At the above two condition, release of stanby mode is available by pressing “STAND-

BY” button again. If the saving mode is released, all conditions come back to the previous

status of stand-by mode.

Standby(Safety) Mode

In case of leaving the machine on for 3hours or longer, the temperature of roller will drop

below 80 and go to standby mode This is an automatic power-shut off function to prevent

an accident and save power.

Before Saving mode Saving mode Stand-by(safety) mode Releasing power

save/stand-by mode

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

17

16

Power Switch

Is for supplying or interrupting the power of machine, circuit breaker installed,

when the overloading or overflow of electricity happens, automatically shuts off

the power when pressing the switch “I”, the power is on, otherwise pressing “O”,

the power is “off”.

Emergency Switch

Is for stoping rollers' rotation and system operation on emergency.

When this switch pressed, the system does not operate for the cancellation of

emergency switch, turn the red handle right for one-third.

Feed table safety lever

Is a safety device for preventing the product's malfunction and user's safety.

Safety lever moves left/right, when installing front panel, pull the lever at the right

direction, install the front panel.

After installing front panel, leave the lever, it comes back to the original status by

the spring’s power.

If the safety lever is not fixed at the front fixing hole, the rollers does not operate.

Pressure plate

Is for speading over at feeding papers.

When you install the pressure plate, first pull the lever(positioned at left/right) to

arrow, install the feed table.

After installing, if you lay down the lever, it can be back to the original position by

spring.

Film tension handle

This controls the tension of the film.

Clockwise to increase film tension, ante clockwise to take off.

SEPARATOR - Option

Is a device for separating film from paper at working

with MICRONEX. When installation of separator

(positioned at the end of right/left) can be made by

pulling forwards to arrow direction and then, by the

back trimmer guide it can be installed.

After installation, if you lay down the lever, it can be

back to he original position by spring.

Rewinder tension handle

Is for the tension control of rewinder.

On the way of using it, if the tension is loose or too strong, adjust it.

Tension increases when turning the handle right, otherwise turn left, it decreases.

Clutch Handle

Clutch handle's pressure increases when turning the handle clockwise, otherwise

it decreases.

Generally, the clutch pressure is first fixed when delivery and recommend to

use it.

Back trimmer

Is for separating the laminating results from the laminator.

After laminating, at the condition of trimmer lever is pressed, push the trimmer

right(left), the film can be cut.

Foot switch

Is for mounting.

When you press the foot switch, the roller rotates. If you take off the foot switch,

the roller stops.

When the roller rotates by foot switch, be cautious

because the safety function does not work.

If you does not watch out, you can suffer a

personal injury.

Be cautious to the blade of trimmer.

laminating

heavy@gauge

QU@mount

HQU@ψڒࣹI

mount

HψڒࣹI

Main roller pressure lever

Is for the control of heating roller's pressure. The rightful pressure

can be selected by the laminating results. When the lever is

directed upwards, upper / lower roller are seperated, it is easy to

insert / remove a film or a paper.

At the time of roller not pressed, laminating does not happen.

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

19

18

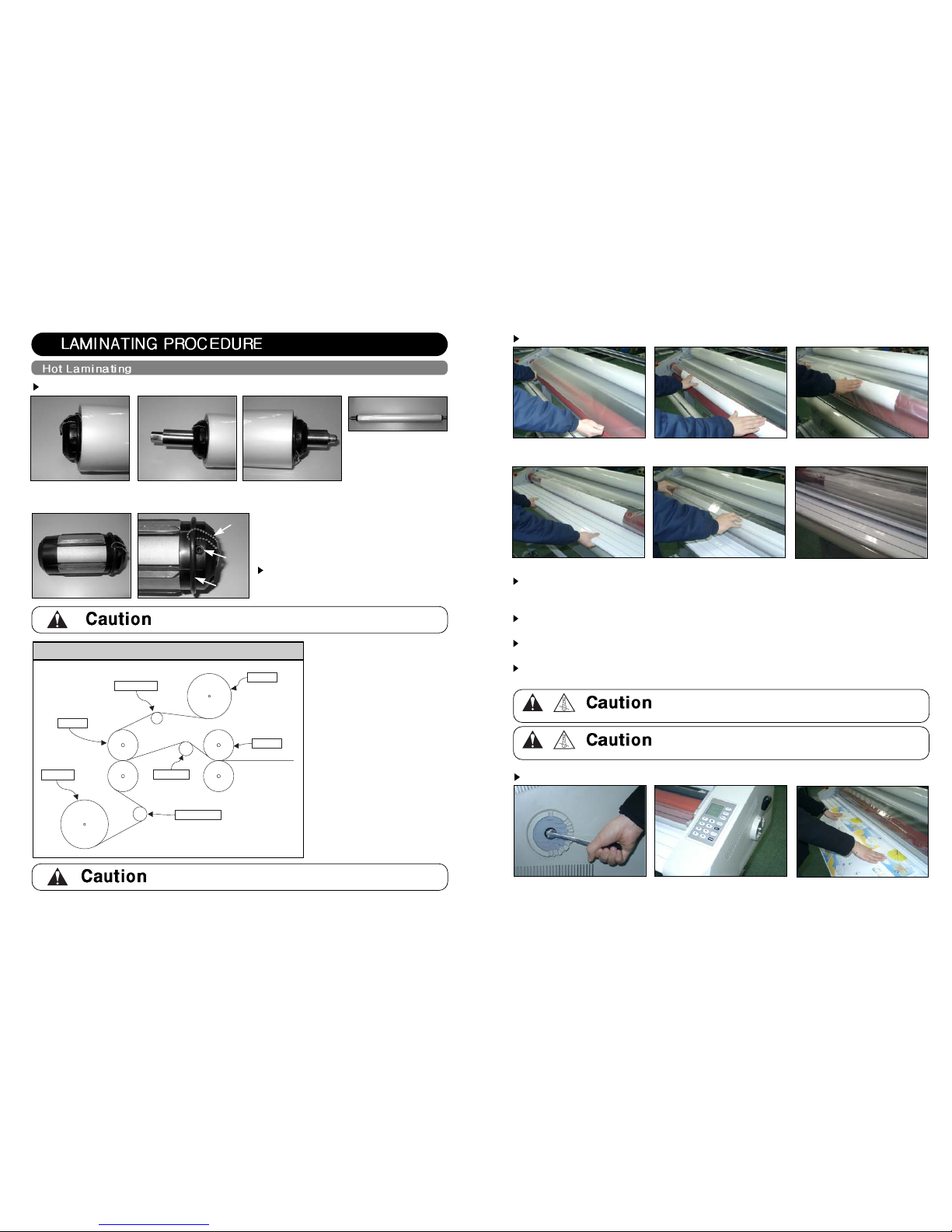

Stage 1 : Film Installation

1. Insert the film into film

core.

2. After film sheaft insertion,

lock it with fixing bolt.

3. After another film core

insertion, lock it with fixing bolt.

4. Reitherate sequence 1~3,

ready for another set.

When you exchange the film, first pull out the fixing

ring and take off it. After fixing ring thaking off, push

film shaft at the other direction, you can change it.

Fixing ring

Film fixing ring

Fixing core bolt

In the case of film width is above 1M or 25KG, More than 2persons is needed.

If you does not, you can suffer a personal injury.

Upper Film

Bottom Film

Pull Roller

Heat Roller

Upper Sub-Roller

Stretch Bar

Bottom Sub-Roller

Film Loading

At the condition of laminating status, temperature and speed adjusting is needed.

Stage 2 : Laminating Readiness

1. The edge of upper film should be

positioned at the upper roller.

2. The inserted paper between rollers,

should be sticked to upper film.

3. Bottom film should be sticked to

paper and bottom film.

4. Install the feed table. 5. Install the safety cover. 6. Install the pressure plate.

It is easy to work if you preheat the roller before readiness stage.

Necessarily film should be passed by sub-roller. (Refer to film loading)

If the film does not pass by sub-roller, it will cause a film crease.

Film tension is available to adjust according to the laminating results,

basically film tension is enough to spread over the film crease.

When paper width is smaller than the laminating film, the glue of film can contaminate the bottom roller.

It is possible to use the paper width larger than film width.

At the condition of roller stop, lay down the roller pressure handle to the preheating or stand-by. It is for preventing roller

damage.

Be cautious to the body touch to the heat plate at laminating.

It will cause a personal damage.

When you laminate and machine running, you shoud be careful not to touch

the hair,necktie, necklace with the machine. It will cause a personal injury.

1. Set the pressure control handle to

the right position.

2. Set the right speed and temp. 3. Load the paper on the feeding table

and insert the paper slightly.

Stage 3 : Laminating

Film Core

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

21

20

Do not laminate with following things

Stage 1 : Film Installation

Film installation is the same as the stage 1 of hot laminating.

Only the film should be placed at the upper end of the film core. MICRONEX is only for the single side laminator.

Film should be passed by the sub-roller. (Refer to the film loading)

If you does not like that, it will cause a film crease.

Stage 2 : Rewinder Paper Pipe Installation

1. Insert the paper core into

the rewinder paper pipe

2. Insert the paper pipe shaft

into the rewinder paper

pipge.

3. And then insert another

paper pipe core.

4. It is a figure of rewinder

installation finished.

Heat Roller Pull-Roller

Upper Film

Rewinder

Upper Sub-Roller

Film Loading

According to the laminating status, Temperature and Speed control is needed.

1. After Installing separator,

insert the paper to push

out.

2. It is the same as hot

laminating stage 2 of

sequence 2~6.

7. Rewind the film into the

rewinder paper pipe.

8. It is a readiness for ultra-

thin film laminating.

Stage 3. Readiness for laminating

Ultra-thin film necessarily should be used at the condition of bottom heat roller cooled down.

Stage 4 : Laminating

It is a same procedure just like the hot laminating stage 3.

When you handle the ultra-thin film, the caution to treat.

1. At the condition of no paper and roller stopping, roller pressure handle should be at the stand-by status.

2. On operating, necessarily use the cooling fan.

3. Below 80g paper is not separated.

Metal plate, Timber board,

Clothes

Credit card Things to be tarnished

easily by heat

Combustible things

After laminating paper printed by heat transfer printer, as time goes by, the paper may

be tarnished.

In the case of film width is above 1M or 25KG, More than 2persons is needed.

If you does not, you can suffer a personal injury.

Using a separator, separate the laminated Film

and paper.

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

23

22

Stage 1 : Film Installation

the same case as like the hot laminating stage 1.(Film installation)

Stage 2 : Rewinder Paper Pipe Installation

Rewinder paper pipe installation is the same as the ultra-thin film laminating stage 2.

Stage 3. Readiness for laminating

1. Install the paper liner on the

rewinder paper pipe.

2. Stick the paper to the bottom film. 3. It is a cold laminating readiness.

Paper size should be larger than the film size to prevent the film winding.

Film tenison is enough to spread over the film crease between the rollers.

Upper Sub-Roller

Upper Film

Rewinder

Pull Roller

Heat Roller

The rotating direction

of rewinder

Film Loading

According to the laminating status, Temperature and Speed control is needed.

Stage 4 Laminating

Is the same as the hot laminating stage 3

Caution at the cold laminating

Laminating should be made below 30

It is easy to work when you use the foot switch on cold laminating.

When the rollers rotate by foot switch, you have to take care because the safety

function does not activated. You can suffer a personal injury.

Mounting

1. Load the paper on the mounting board.

2. Feed the mounting board between rollers.

Direction

Liner

Heat Roller

Mounting Board

When you are ready to laminate, take care of non-touching your

body to the machine. You can suffer a personal injury

When laminating or machine operating, Do not wind the long-hair,

necktie, necklace into machine. It will cause a personal injury

In the case of film width is above 1M or 25KG, More than 2persons is needed.

If you does not, you can suffer a personal injury.

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

25

24

1. Always test your material before commencing ‘live’ jobs.

2. Thicker film require slower speeds and sometimes temperature adjustment.

3. Thinner film can be run at a faster speed.

4. Do not stop the machine with a ‘live’ job between the rollers as the hot roller will mark the paper.

5. If laminating result isn’t good, decrease the speed or increase the temperature.

6. For optimum results GMP laminating film is always recommended.

To increase product life.

- After laminating arrange “the roller pressure control handle” to the open position.

- If you leave the laminator not used for one hour, set the temperature on 0 .

* These requests are for the purpose of maintaining the safety of the roller and laminator, on saving power.

Below 38mic(1.5mil)

50~80mic(2~3.5mil)

100~150mic(4~6mil)

175~250mic7~10mil)

Below 38mic(1.5mil)

50~80mic(2~3.5mil)

100~150mic(4~6mil)

175~250mic7~10mil)

Below 38mic(1.5mil)

50~80mic(2~3.5mil)

100~150mic(4~6mil)

175~250mic7~10mil)

Below 38mic(1.5mil)

50~80mic(2~3.5mil)

100~150mic(4~6mil)

175~250mic7~10mil)

Below 100g

Above 100g ~ Below 150g

Above 150g ~ Below 300g

Above 300g ~ 1mm

Temp.

110

110

110

110

110

110

110

110

110

110

110

110

110

110

110

110

Speed

9

5

3

1

7

3

1

x

5

1

x

x

3

x

x

x

Max. Setting

Film Thickness Paper Type

When the laminating results are not good, adjust the speed.

If you does not cleanse the roller...

- Film can be wound with rollers.

- Laminating results have a stain.

* To prevent this status, roller cleansing is needed.

Roller’s cleansing

- After laminating when the heating roller’s temperature is belowe 80 , wipe the roller with a “linen” and “iso-prophilene

alcohol”.

- Remove front panel and open upper / bottom heat shoe and then cleanse a roller.

A main body's washing

A main body and cover should be brushed with a soft and dried linen.

* Follow the caution, when washing with a neutral detergent or chemical.

When cleansing roller, only should use Iso-prophillene alcohol.

Segregate the powerplug from the outlet. It is a main reason of a fireflame.

Do not use acetone, bezene, or that kinds of flamables at the washing. It is a main reason of a fireflame.

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

27

26

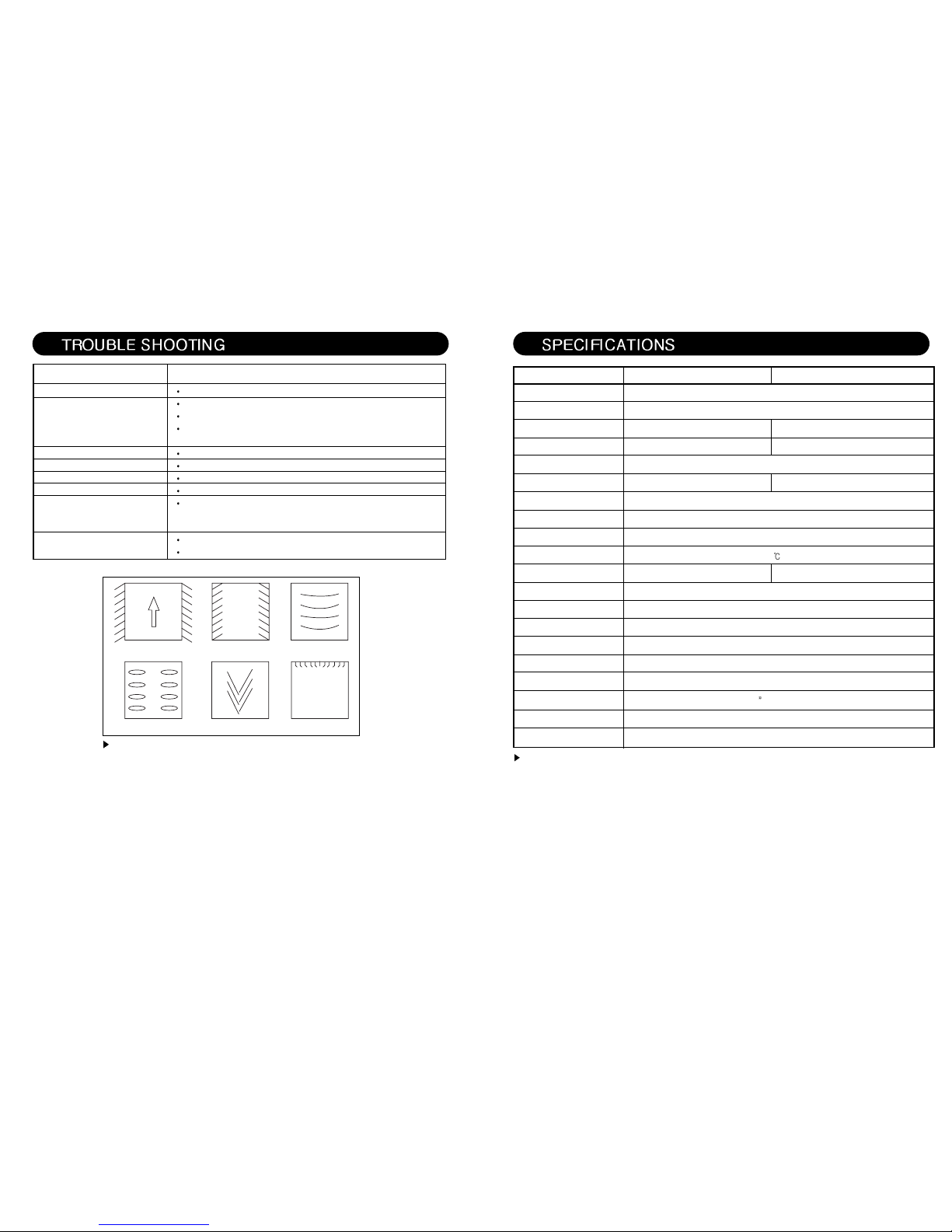

ABC

DEF

Picture A,B,C,D,E,F

Symptom Trouble shooting

Power supply problem

Rollers not turning

Symptom of picture "A"

Symptom of picture "B"

Symptom of picture "C"

Symptom of picture "D"

Symptom of picture "E"

Symptom of picture "F"

Check circuit breaker and disconnection of fuse. Contact dealer / engineer.

Check whether the front safety lever is fixed into fixing hole inside

Check safety cover is normally placed

Check roller pressure control lever position. Only when the roller pressured,

normally it works.

Increase roller pressure

Decrease roller pressure. Operate cooling fan.

Decrease roller pressure

Increase roller pressure

Operate cooling fan.

If not solved by cooling fan, cooling the laminator for about 30 minutes

This symptom caused by high temperature of pulling roller.

Operate cooling fan

Decrease roller temperature

Model Name EXCELAM-Q 1100RS EXCELAM-Q 1670RS

Power Requirements

Power Consumption

Dimensions(WxLxH)

Warm Up Time

Max Laminating Speed

Max Laminating Width

Laminating thickness

Max Mounting Height

Thickness of substrate(Paper)

Roller temperature

Weight

Heating System

Temperature Control

Temperature Adjustment

Speed Control

Type of Main Motor

Roller pressure control

Film Core

Cooling System

Rewinding Mothod

220~240V, 50/60Hz

3000W / 15A

3000mm/min

25~500mic

13mm

80~350g/m2

160

Infrared Heater

Key Pad

Time control

Key Pad

DC Motor

Manual

77mm(3 ) Bilateral core

AC Motor (Blower fan)

Link to Main Motor

Outerior design and Product specification can be changed without previous notice.

1500 x 710 x 1250mm

22 minute

1100mm

205kg

2000 x 710 x 1250mm

25 minute

1670mm

276kg

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

29

28

http://www.gmp.com

President & CEO Y P Kim

#472, Munbal-Ri Kyoha-Eup, Paju-Si, Kyoungki-Do, Korea

Trade Dept Tel No : +82-31-943-3600

Fax No : +82-31-943-4433

Total Laminating &

Graphic Systems Manufacturer

GMP Co (UK) LTD

Managing Director S G Ra

Sales & Marketing Director Annmarie McCaffrey

Address Unit 3, Network II Thorpe Way, Banbury Oxon,

OX16 4XS, United Kingdom

Sales [email protected]

Tel No. +44(0)1295-268833 Fax No. +44(0)1295-268835

GMP PROGRAPHICS Germany GmbH

EU Prographics Center for Distribution, Marketing,

Service and Training

Managing Director S G Ra

Sales Director Dieter Georgi

http://www.gmp-germany.de

Sales [email protected]

Address August-Horch Str. 19, 56751 Polch, Germany

Tel No. +49-2654-9490-0 Fax No. +49-2654-9490-90

European Lamination Service Center Tel No. +49-2654-950-540

GMP EUDC GmbH

Europe Distribution and Marketing Center

Managing Director S G Ra

Sales & Marketing Director Monika Georgi

http://www.gmp-germany.de

Sales [email protected]

Address Robert-Bosch-Str. 4, 56751 Polch, Germany

Tel No. +49-2654-9490-0 Fax No. +49-2654-8806-24

GERMANY

EUROPE

UNITED KINGDOM

EUROPE

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

This manual suits for next models

1

Table of contents

Other EDNord Laminator manuals