3

EDS - TECHNICAL INFORMATION

1.11 - When beign certain of the automatic spark

extinguishing is necessary or in important installations,

where security should be set at the highest level, we

suggest to install another detector (or detectors couple)

at a suitable distance from the detector or couple of

detectors already installed, for a forward confirmation of

the performed extinguishing. Ifextinguishing was performed

correctly this second detector will stay inactive, otherwise it

will activate and its output relay will be used to :

•activate a second sprinkler spraying nozzle for a

second extinguishing attempt

•close the output mounth of the pipe by means of an

automatic shutter before the materials are deployed

in the Silo

•activate a suitable acoustic alarm

2 - OPERATION

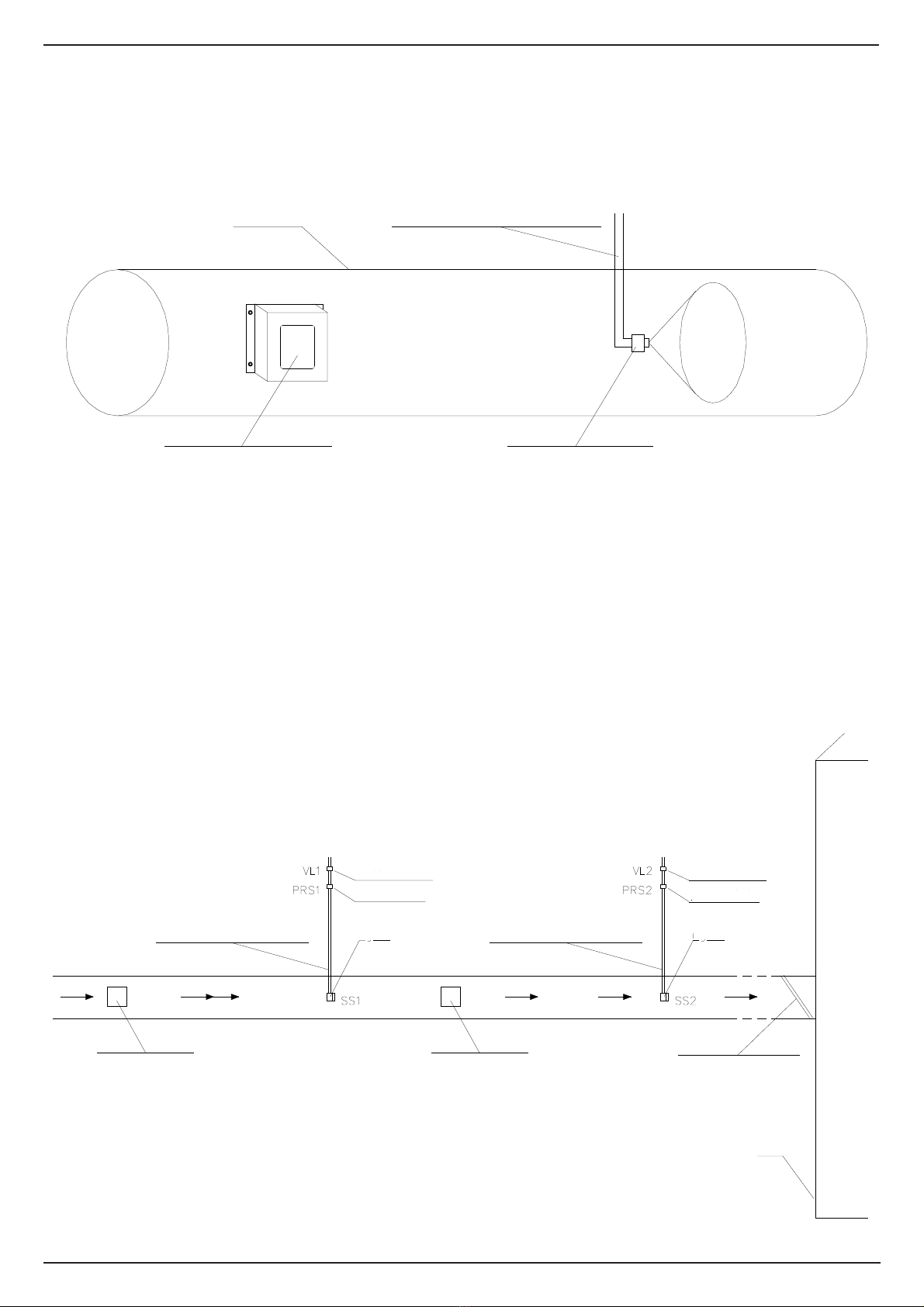

2.1 - With reference to fig. 5 about a 2 detectors

installation, if a burning spark passes through the first

detector's field of view, the EV395 detector gets in

alarm condition, its output relay immediately activates

and remains activated for a time duration equal to the

one set with P2 trimmer between 0 and 10 seconds.

The output contact of this relay will be used to drive

VL1 electrovalve that will activate the water spraying

by the SS1 noozle for a first extinguishing attempt.

2.2 - If the spark has been extinguished, the system

returns to normal operation, otherwise the spark,

continuing its ride, wil enter in the field of view of the

second EV395 detector.

This will activate its output relay. The contact of this

relay will drive VL2 electrovalve that will activate the

water spraying by the SS2 noozle for a second

extinguishing attempt.

3- RESPONSE TIME

3.1 - The times to evalauate during the designing

process of a spark detection system are the following:

T1 - response time of EV395 detector

T2 - response time of the detector's output relay

T3 - acquisition time of EV521 Control Unit and

response time of its relay

T4 - response time of extinguishing electrovalve VL

T5 - filling time of the part of pipe goig from the

electrovalve to the noozle SS and time of water

cone generation

If in the system there's no EV521 Control Unit

included the time relative to the Control Unit (T3)

shall not be counted.

The usual values of this times are:

T1 - 3 ms

T2 - 1 ms

T3 - 10 ms

T4 - 2 ms

T5 - depends on pipe lenght, pipe section and most

of all on water pressure

3.2 - For designing calculations the T1-T4 time can

be considered of 60 ms max.

The T5 time should be added to that. This time is

dependent on the pipe sectionand lenght, on water

presssure and on the used noozle. With a SP34F22

noozle and a water pressure of 3-4 bar a water

speed of 4-6 m/s is obtained. So if the piece of

pipe between electrovalve and noozle is 1 m long,

the transit time is around 0.2 s.

Therefore summing the T1-T5 times the result is

0,22 s.

This is the system response time.

4- NOZZLE POSITIONING

4.1 - The spaying noozle has the function of

extinguishing the spark.

Its position must be calculated taking in account the

times detailed in the previous chapter and the

speed of the fluid or materials flowing in the pipe.

For a calculation of the mean value, a simple

Physics formula can be used:

S = vt

where :

S= covered lenght in meters

v= speed of the fluid in the pipe m/s

t= response time of the security system

The fluid speed has to be measured in place.

Normally the following speed is measured:

•wood industry : 20-30 m/s

•textile industry : 10-20 m/s

For other applications a measurement is required.

So the calculation is simple knowing the 3

parameters of the formula.