Edson 220A Series User manual

Model 220A

Installation and Operations Manual

Page 1 Index

Page 2 Performance & Dimensions

Page 3 Installation Guidelines

Page 6 Operations Guidelines

Page 8 Maintenance & Repair

Page 9 Trouble Shooting

Page10 Parts

220ACA-150 Air Powered Diaphragm Base Mount Aluminum 1 1/2” Inlet and 1 1/2” Discharge

220ACB-150 Air Powered Diaphragm Base Mount Bronze 1 1/2” Inlet and 1 1/2” Discharge

Make sure the pump received is the pump ordered. Compare the pump with the packing list.

Make sure the parts list attached to this manual is the one for your pump.

Fill in the Serial No. and Model No.below

ENTER YOUR PUMP DATA HERE

SYSTEM SERIAL #

From Edson Serial # Sticker On Pump Frame

PUMP MODEL #

From Packing List i.e.. 220ACB-150

146 Duchaine Blvd., New Bedford, MA 02745-1292 Tel. 508-995-9711 Fax 508-995-5021 E-Mail pumps@edsonintl.com

P-220A-2012-04

146 DUCHAINE BLVD. , NEW BEDFORD, MA. 02745-1292 TEL. 508- 995-9711 FAX 5 08-995- 5021 E-MAIL pumps@edsonintl.com

Pump Performance Is Dependent On Cycle Rate of The Pump Air Cylinder & The Plumbing Head.

lVolume is expressed in GPM (gallons per minute) and LPM (liters per minute)

lA Cycle Rate is one up and down stroke of the cylinder. Maximum cycles rate for this pump

should not exceed 60 per minute. Over 60 cycles per minute the pump begins to cavitate.

lHead conditions are determined by the height, length and size of the installation plumbing

connected to the inlet and discharge of the pump base.

General Performance Specifications:

lStatic Head: Suction 20 ft / 6.1m Discharge 18 ft / 5.47m (1 1/2" Hose or Pipe)

lDry Suction Lift: 17 ft / 5.18m (1 1/2"ID Pipe or Hose)

lContinuous Duty Discharge Heads: Should be Limited to 10 ft. / 3m

lPerformance: 20 GPM / 75.7LPM at 5 ft Suction Lift and 0 Discharge at

60 Cycles per Min. w/ 1 1/2" Pipe

Volume Charts:

lUse the following charts as guides to determine the performance volume at different cycle rates

with the pump installed with a variety of suction and discharge plumbing conditions.

Dimensions

Page 2 Performance & Dimensions

Performance & Specifications P-220A-03

S

U

C

T

I

O

N

H

E

I

G

H

T

D I S C H A R G E H E I GH T

AT 56

Cycles

Per Min.

5 feet

1.5 meters

1 foot

.3 meters

10 feet

3 meters

17 feet

4.2 meters

5 feet

1.5 meters

18 gpm

68.4 lpm

1 7.5 gpm

66.5 lpm

1 6.5 gpm

62.7 lpm

6 gpm

22.8 lpm

17 gpm

64.6 lpm

17 gp m

64.6 lpm

15 gpm

57 lp m

5 gp m

19 lpm

17 gpm

64 .6 lp m

15 .5 g pm

59 lpm

1 3.5 gpm

51.3 lpm

4 gpm

15 .2 lp m

010 feet

3 meters

S

U

C

T

I

O

N

H

E

I

G

H

T

D I S C H A R G E H E I GH T

AT 40

Cycles

Per Min.

5 feet

1.5 meters

1 foot

.3 meters

10 feet

3 meters

17 feet

4.2 meters

5 feet

1.5 meters

12.9 gp m

49 lpm

12.5 gp m

47.5 lpm

11.8 gp m

44.8 lpm

5 gpm

19 lp m

12 .1 g pm

46 lpm

12 .1 g pm

46 lpm

10.7 gp m

40.7 lpm

4 gpm

15 lp m

12 .1 g pm

46 lpm

11 gpm

41 .8 lp m

9.6 gpm

36 .5 lp m

3 gpm

11 .5 lp m

010 feet

3 meters

S

U

C

T

I

O

N

H

E

I

G

H

T

D I S C H A R G E H EI GH T

AT 36

Cycles

Per Min.

5 feet

1.5 meters

1 foot

.3 meters

10 feet

3 meters

17 feet

4.2 meters

5 feet

1.5 meters

11.6 gpm

44.1 lpm

11.3 gpm

42.9 lpm

10.6 gpm

40.3 lpm

5 gpm

19 lp m

10.9 gpm

41.4 lpm

10.9 gpm

41.4 lp m

9.6 gp m

36.5 lpm

4 gpm

15 lp m

10.9 gpm

41.4 lpm

10 gpm

38 lp m

8.7 gpm

33 .1 lp m

3 gpm

11 .5 lp m

010 feet

3 meters

S

U

C

T

I

O

N

H

E

I

G

H

T

D I S C H A R G E H E I GH T

AT 30

Cycles

Per Min.

5 feet

1.5 meters

1 foot

.3 meters

10 feet

3 meters

17 feet

4.2 meters

5 feet

1.5 meters

7 gpm

26.5 lpm

6 gpm

22 .8 lp m

5.5 gpm

21 lpm

5 gpm

19 lp m

6 gpm

22.8 lpm

5.5 gpm

21 lpm

5 gpm

19 lp m

4 gp m

15 lp m

5 gp m

19 lp m

5 gpm

19 lpm

5 gpm

19 lpm

3 gpm

11 .5 lp m

010 feet

3 meters

S

U

C

T

I

O

N

H

E

I

G

H

T

D I S C H A R G E H E I GH T

AT 20

Cycles

Per Min.

5 feet

1.5 meters

1 foot

.3 meters

10 feet

3 meters

17 feet

4.2 meters

5 feet

1.5 meters

4.6 gpm

17.5 lpm

4 gpm

15.2 lpm

4 gpm

15.2 lpm

3.6 gpm

13.7 lpm

2.7 gpm

10 lpm

3.3 gpm

12 .5 lp m

2 gpm

7.6 lpm

010 feet

3 meters

3.3 gpm

12 .5 lp m

3.3 gpm

12 .5 lp m

3.3 gpm

12.5 lpm

3.3 gpm

12 .5 lp m

3.6 gpm

13 .7 lp m

S

U

C

T

I

O

N

H

E

I

G

H

T

D I S C H A R G E H EI GH T

AT 13

Cycles

Per Min.

5 feet

1.5 meters

1 foot

.3 meters

10 feet

3 meters

17 feet

4.2 meters

5 feet

1.5 meters

3 gpm

11.4 lpm

2.6 gpm

10 lpm

2.4 gpm

9.1 lpm

1.7 gpm

6.5 lpm

2.2 gpm

8.4 lpm

1.3 gpm

4.9 lpm

010 feet

3 meters

2.6 gpm

10 lpm

2.6 gpm

10 lpm

2.6 gpm

10 lpm

2.6 gpm

10 lpm

2.6 gpm

10 lpm

2.4 gpm

9.1 lpm

220ACA-150

220ACB-150

Installation Guidelines

Step 1 Check All Bolts - Make sure that all bolts on the pump are tight. Tools: 2ea. 9/16”, 1/2” and

7/16” Box Wrenches & 1 Allen Wrench.

7/16”

Upper Standard

& Head Ring

1/2”

Cylinder Mounting Nuts (Not Shown)

9/16”

Cylinder Rod

Locking Nut

Step 2 Place Pump - The pump must be installed so that the flapper valves will open and close. The drawings

below show how the pump can and can not be installed in relationship to its’ horizontal and vertical axis.

Page 3 Installation

P-220A-03

Step 4 Connect The Air Line - Air line should be at least 1/4” pipe or hose. It should deliver at least 8 ACFM and

regulated between 85 and 95 psi. The air line is connected to the 3/8” FNPT located between the two

exhaust regulator filters.

Step 5 Speed Control Muffler - The needle valve that is part of this exhaustPXIIOHU is used to adjust the speed of

the down stroke and up stroke of the cylinder. Using this adjustment the cycle rate of the pump was set to

60 cycles per minute

Important

Air Pumps are factory set to 60 cycles per minute with the input air

holding at 85 psi run pressure and no liquid being pumped.

Step 6 Practice Adjusting The Pump Cycle Rate - There are two ways to control the cycle rate. The first is by

adjusting the needle valves of the Exhaust Regulator Filter. The second is by using an air flow control valve

on the air line between the pressure regulator and the air cylinder. You can use either or a combination of

both adjustments to set the pump performance you need once the plumbing is installed and liquid is being

pumped.

1. Open the air line.

2. Set air line pressure to 90 psi.

3. Using a very small flat head screwdriver start closing (clockwise) the right hand solenoid needle valve. The

down stroke of the air cylinder should start slowing down.

4. Now close the upper needle valve. The up stroke of the air cylinder should start to slow.

5. Now reset the cycle rate to 60 cycles per minute by opening each needle valve till you are getting one

down stoke per second and you perceive that the timing on the up stroke and the down stroke is

approximately the same. Use a watch with a sweep second hand to time the cycle rate.

6. Now open and close the air flow control valve if you want to use one and note the change in cylinder

speed.

Page 4 Installation - Air Line

Important

Do not control pump cycle rate by increasing or decreasing air line pressure.

Air line pressure should always be kept between 85 and 95 psi.

3/8” Female NPT

Air Line Connection

Speed Control Muffler

Part No.161-A-2990

controls the speed of the

up stroke of the cylinder

Speed Control Muffler

Part No.161-A-2990

controls the speed of the

down stroke of the cylinder

P-220A-03

146 DUCHAINE BLVD. , NEW BEDFORD, MA. 02745-1292 TEL. 508- 995-9711 FAX 508-995- 5021 E-MAIL pumps@edsonintl.com

lDO NOT INSTALL THE PUMP AND PLUMBING

SO AIR WILL BE TRAPPED.

BECAUSE trapped air can completely restrict the

flow, or at the least require more work from the

pump resulting in early diaphragm failure. Install

pump and plumbing so any air introduced into the

plumbing will not be trapped but flow naturally

through liquid and out of the system.

lSHOULD NOT INSTALL PUMP WITH POSITIVE

HEAD ON THE INLET - Under standard operating

guidelines the pump should be above the liquid it is

being used to transfer.

BECAUSE of the flow through check valves,

stopping the pump will not stop the liquid from

flowing. Under the force of gravity liquid will pass

right through a diaphragm pump. Also consider a

diaphragm pump can not control a siphon

condition. They are used many times to start one.

lDISCHARGE FITTINGS, PIPE AND HOSE

SHOULD ALL BE THE SAME SIZE AND NEVER

BE SMALLER THAN THE INLET.

BECAUSE a smaller discharge line increases

work for the pump and increases the possibility

of clogging.

lUSE ONLY LONG RADIUS ELBOWS.

BECAUSE a they reduce back pressure and

wear on the pump diaphragm. When pumping liquid

with solids they help prevent clogs in the plumbing.

lINSURE ALL HOSE AND FITTINGS ARE AIR

TIGHT.

Because self priming performance depends on air

tight suction line. It prevents leaks

Discharge

1.5"ID

Inlet

2" ID

DON'T

Step 7 Install Plumbing - Good pump performance requires plumbing to be installed properly for this pump.

P-220A-03

OK OK

OK

Don’t

Don’t

OK

Air Tight

Against

Vacuum

Page 5 Installation - Plumbing

146 DUCHAINE BLVD. , NEW BEDFORD, MA. 02745-1292 TEL. 508- 995-9711 FAX 508-995- 5021 E-MAIL pumps@edsonintl.com

Running The Pump Dry:

This Pump will run dry indefinitely without damage.

Pumping Liquids with Suspended Solids:

lKEEP SOLIDS IN SUSPENSION - When the pump

is used to pump solid matter such as sludge at

the bottom of a tank, or to dredge out a section of a

lagoon make, sure the solids have enough liquid

mixed in to allow it to flow. Raking or stirring while

the pump is pumping will keep solids in

suspension. Rule of thumb in pumping viscous

liquids or combinations of liquids with solids, "If It

Will Not Flow Through A Line Under Gravity, The

Pump Will Most Likely Not Pump It."

lFLAPPER CHECK VALVES AND SOLIDS -

Solids trapped under the check valves will

prevent self priming. This is likely to occure when

the pump is used in sewage or sump pump out

applications . Flushing with water will generally

clear out the solid matter. Installing secondary

clear flapper check valves right at the inlet and

discharge will improve the dry suction start

performance of the pump and make clearing the

valves easy. Order Edson Clear Check Valves

69CL-150 (1.5").

lPUMPING AT THE PROPER SPEED - When

pumping liquid with solids the speed may be too

slow to keep the solids and the liquid combined.

The solids will stop moving and begin to clog the

line. Pumping at a faster rate or decreasing the

hose size to increase velocity may be the solution.

Check With Edson Customer Service.

lUSING A STRAINER ON THE INLET - If the

solids are too large they will block the inlet or get

stuck in the suction line. The end a suction hose

can become attached to a flat surface cutting off

all flow. Using an Edson strainer will prevent

these conditions. Order an Edson Shatterproof

Bronze Strainer 111BR - 150

lUSING A DISCHARGE LOOP - For sewage and

sump applications when the discharge drains

naturally down and away from the pump, installing

an 8” to 10” positive loop right on the discharge port

will improve the self priming feature. When you

stop pumping the loop traps some liquid against

the discharge valve improving the seal.

Operation Guidelines

Union Ball Valve

Union Check Valve

PVC Pipe Adapter

P-220A-03

Discharge Loop

Page 6 Operation Guidelines

146 DUCHAINE BLVD. , NEW BEDFORD, MA. 02745-1292 TEL. 508- 995-9711 FAX 508-995- 5021 E-MAIL pumps@edsonintl.com

How The Pump Works

lThe air cylinder housing raises and lowers the diaphragm.

lRaising the diaphragm creates a vacuum.

lThe vacuum forces the discharge valve assembly closed.

lAtmospheric pressure pushes liquid and/or air up the inlet plumbing to fill the vacuum.

lWhen the diaphragm is driven down the air and liquid under the diaphragm is compressed

closing the inlet check valve and forcing the air and liquid out the discharge.

lThe closing of the inlet valve assembly also prevents the liquid and air trapped in the

inlet line from dropping back down (to atmosphere).

Inlet Valve Assembly:

opens into the pump

Discharge Valve Assembly:

closes and seals on the valve

seat that is part of the pump

base under the discharge

chamber.

Suction Stroke Discharge Stroke

Discharge Valve Assembly:

opens away from the pump

Inlet Valve Assembly:

closes and seals on the valve

seat that is part of the inlet

chamber.

P-220A-03

lVolume Test -Tests overall performance of the pump installation.

1.Use a container with a known capacity of at least 2 gallons.

2.Empty the container using the suction side of the pump or fill it from the discharge.

When using the fill test make sure the pump is fully primed before filling the container.

3.Use a watch to record the time it takes. Repeat the test at least twice.

4.Establish GPM rate. Example 1: It took 10 seconds to fill a 5 gallon container. The

GPM rate is 30 Gallons Per Minute.(60 seconds divided by 10 seconds times 5 gal.)

Example 2: It took 10 seconds to empty a 2 gallon container. The GPM rate is 12

Gallons Per Minute.(60 seconds divided by 10 seconds times 2 gal.)

5.Record the cycle speed of the pump. Know the head conditions of your test and

compare the results of your test with the volume of the appropriate Volume Chart

on page 2. Every installation is different so use the charts as a guideline.

6.Example 1: The “fill test” at 30 GPM. The diaphragm is going up and down at 56

cycles per minute. The pump is approximately 6 ft. above the liquid. I disconnected the

installation discharge line and replaced it with a 3 ft. length of 2” hose so I could do the

fill test. Using the 56 cycle per minute Volume Chart from page 2, I know that at a

suction height of 5 ft. and a discharge height of between 0 and 5 ft. I should get

approximately 30 GPM. The installation is performing within the guidelines.

6.Example 2: The “empty test” at 12 GPM. The diaphragm is going up and down at 30

cycles per minute. The pump was approximately 5 ft. above the 2 gal. container and

the discharge line goes up 4 ft. From the 30 cycle per minute Volume Chart on page

2, I know that with a suction height of 5 ft. and a discharge height of 0 to 5 ft. I

should get approximately 17 GPM. The installation is performing below the

guidelines. See the Trouble Shooting section of this manual.

lVacuum Gauge Test - Tests the performance of the discharge valve and valve seat.

1.Attach a 5’ length of non-collapsing hose or pipe with a vacuum gauge installed

to the inlet of the pump. Make sure the line is completely sealed and air tight.

2.Turn on the pump and let it run till the gauge stabilizes. Record the reading.

3.Turn off the pump and watch the gauge.

4.If the discharge is working properly the gauge should build and hold at 10” to 12”hg.

Do not be concerned if the vacuum pressure slowly returns to 0 within a minute or so.

5.If you do not get any vacuum reading or if the gauge does not get to 10” hg and drops

off to 0 as soon as the pump stops, do the same thing again. Listen for air being

sucked in around the diaphragm. If you hear air movement, inspect for loose bolts or

worn diaphragm. If you hear no air movement, remove the discharge chamber and

inspect the valve assembly and valve seat. Clean or replace the valve and clean or

resurface the valve seat as appropriate. See Maintenance/Valve Assemblies

Pump Performance Tests:

Page 7 Operation Guidelines- Testing

146 DUCHAINE BLVD. , NEW BEDFORD, MA. 02745-1292 TEL. 508- 995-9711 FAX 508-995- 5021 E-MAIL pumps@edsonintl.com

Page 8 Maintenance

Maintenance

Diaphragm & Check Valves: Over time these parts wear and need to be replacement. The ability to

easily and quickly replace these inexpensive parts is one of the major advantages of an Edson diaphragm

pumps. Edson has packaged these parts as Spares Kits. See the parts list for the order #s.

lChange the diaphragm as required.

lInspection and testing on a regular basis is recommended. For continuous duty application,

inspect the pump daily until a life pattern is established.

lLook for leaks, cracks or splits on the surface of the diaphragm.

lLife expectancy is directly related to head conditions, run time and diaphragm material. The

higher the suction and discharge pressures the shorter the life.

lPressure Gauge Test - Tests the performance of the suction valve and valve seat.

1.Attach a 5’ length of non-collapsing hose or pipe with a 0 to 15 psi gauge installed

to the outlet of the pump. Make sure the line is completely sealed and air tight.

2.Turn on the pump and let it run till the gauge stabilizes. Record the reading.

3.If the suction valve is working properly the gage should build and pulse at 6 to 7 psi.

and when the pump is stopped the pressure may hold or slowly returns to 0.

4.If you do not get any pressure reading or if the gauge does not get to 4 psi and drops

off to 0 as soon as the pump stops, clean or replace the suction valve and clean or

resurface the valve seat as appropriate. See Maintenance/Valve Assemblies

lManual Test - Testing the pump valves and valve seats without the use of a gauge.

1.Remove all fittings from the inlet and discharge of the pump.

2.Turn on the pump.

3.Put your hand over the inlet. If the discharge valve is working properly, you should feel a

very strong pulsing suction. The pulsing coincides with the raising and loweringof the

diaphragm. If you do not feel any suction, do the same thing again and listen for

air being sucked in around the diaphragm. If you hear air movement, inspect for loose

bolts or worn diaphragm. If you hear no air movement, remove the discharge

chamber and inspect the valve assembly and valve seat. Clean or replace the valve

and clean or resurface the valve seat as appropriate.

4.Press your hand over the discharge. If the inlet valve is sealing properly, the

pressure of the pump down stroke should push your hand away. If it does not and the

air is forced out the inlet remove the inlet chamber and inspect the valve assembly

and valve seat. Clean or replace the valve and clean or resurface the valve seat as

appropriate. See Maintenance/Valve Assemblies

P-220A-03

146 DUCHAINE BLVD. , NEW BEDFORD, MA. 02745-1292 TEL. 508- 995-9711 FAX 508-995- 5021 E-MAIL pumps@edsonintl.com

Valve Assemblies & The Valve Seats: The sealing of the flapper valves are what makes the diaphragm

pump work. If the valves are not sealing properly, the pump will not be performing to full potential

or may not be pumping at all. The valves tend to last longer than the diaphragm. When you

change the diaphragm inspect the valves for cracks and delamination and the valve seats for

pitting and any build up that will prevent the valve rubber from sealing effectively. Testing the

pump is the best way to evaluate performance.

lChange the valve assemblies as required.

lInspection and testing on a regular bases is recommended. For continuous duty application,

inspect the pump daily until a life pattern is established.

lSee Pump Performance Tests .

P-220A-03

Page 9 Maintenance

Trouble Shooting

2.Problem

Air Cylinder is not going

up and down.

Possible Causes

a. Air pressure is low.

b. Discharge or suction line is

blocked.

c. Air cylinder is malfunctioning.

Action

If the cause is not obvious, isolate the source.

Check air line for pressue and flow. If ok, discon-

nect the inlet and discharge plumbing from the

pump and restart the pump. If pump cycles without

the plumbing connected, there could be a clog in

the lines. The back pressure caused by a com-

plete blockage in the inlet and discharge line will

stop the pump. If the pump cylinder still does not

cycle then the problem is in the air cylinder. See

air cylinder section.

1.Problem

Pump is running, liquid

is not moving.

Possible Causes

a. Suction line is blocked.

b. Suction line has air leak

between liquid and inlet of the

pump.

c. Discharge and/or suction

valves are not working.

d. Diaphragm has a leak.

e. Discharge or suction line is

to high.

Action

If the cause is not obvious, isolate the source.

Disconnect the inlet and discharge plumbing from

the pump and perform the Manual Test. If the

cause is not in the pump check for a block or an

air leak in the suction line. Suction air leaks can

be cumulative and can be as simple as one or two

fittings not being sealed properly. Review Plumbing

The Edson Air Powered Diaphragm Pump is very simple and problems are usually isolated to the following components:

l Suction and Discharge Plumbing

l The Diaphragm and Valves

l The Air Cylinder

146 DUCHAINE BLVD. , NEW BEDFORD, MA. 02745-1292 TEL. 508- 995-9711 FAX 508-995- 5021 E-MAIL pumps@edsonintl.com

Page 10 Parts

3.Problem

Diaphragm is wearing

out much earlier than

expected.

Possible Causes

a. Liquid being pumped is not

compatible with the

diaphragm material.

b. Discharge and/or suction

back pressure too high.

Action

Consult a chemical resistance chart. If material

being pumped is compatable with the diaphragm

being used, review the pump performance

specifications and installation guidelines in

respect to the installation. Diaghragm life will be

reduced with the increase in discharge and

suction head. Expected diaphragm life is different

based on the material and style of the diaphragm

used. Call Edson Customer Service for details.

4.Problem

Pump base and/or lines

keep filling with solids

Possible Causes

a. Line velocity is too slow to

keep the solids in suspen

sion.

b. The percent of solids is too

high.

Action

Speeding up the pump will help increase the

velocity. Using a strainer can reduce the size and

percent of solids. Diluting the slurry by increasing

the amount of liquid or by increasing the agitation

of the mix may solve the problem.

P-220A-03

Parts 220ACB-150

161 A-2994 Air Cylinder,QFOXGHV$6SHHG&RQWURO0XIIOHUV

161 B-387B

Adapter Frame

1/4-20 X 3/4” HHCS

160-A-1253 Sealing Washer

161-A-1008 Upper Standard

161-A-1006 Lower Standard

113N-18 Nitrile Diaphragm

1/4-20 X 2” HHCS w/Nut & Washer

10-32 X 3/4” PHMS w/Nut

5/16-24 Nut

160-A-1207 Valve Assembly

160-A-1207 Valve Assembly

160-B-374B Head Ring

160-B-375B

Suction Chamber

160-B-378B

Pump Base

160-B-376B

Discharge Chamber

10-32 X 3/4” PHMS

146 DUCHAINE BLVD. , NEW BEDFORD, MA. 02745-1292 TEL. 508- 995-9711 FAX 508-995- 5021 E-MAIL pumps@edsonintl.com

Pump Spares Kits:

161 A-2994 Air Cylinder,QFOXGHV$6SHHG&RQWURO0XIIOHUV

160- B-387B

Adapter Frame

1/4-20 X 3/4” HHCS

160-A-1253 Sealing Washer

161-A-1008 Upper Standard

161-A-1006 Lower Standard

113N-18 Nitrile Diaphragm

1/4-20 X 2” HHCS w/Nut & Washer

10-32 X 3/4” PHMS w/Nut

5/16-24 Nut

160-B-376A

Discharge Chamber

160-A-1207 Valve Assembly

160-A-1207 Valve Assembly

160-B-374B Head Ring

160-B-375A

Suction Chamber

160-B-378A

Pump Base

10-32 X 3/4” PHMS

Parts 220ACA-150

Viton

Order No. 114V 18-220

1 Diaphragm 113V - 18

2 Valve Assemblies 160 A-1207V

2 Sealing Washers 160 A-1253

Nitrile

Order No. 114N 18-220

1 Diaphragm 113N -18

2 Valve Assemblies 160 A-1207

2 Sealing Washers 160 A-1253

Viton

Order No. 114V 18-220

1 Diaphragm 113V - 18

2 Valve Assemblies 160 A-1207V

2 Sealing Washers 160 A-1253

Parts: Spares Kits

Page 11 Parts

P-220A-03

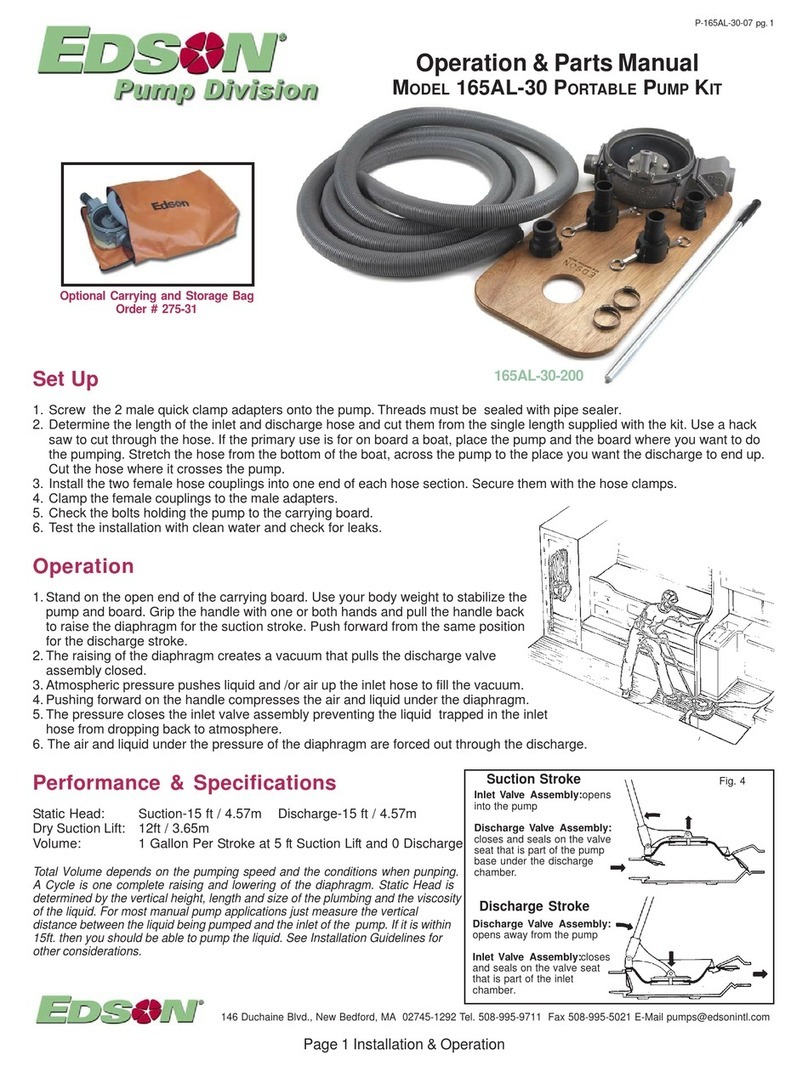

This manual suits for next models

2

Table of contents

Other Edson Water Pump manuals

Popular Water Pump manuals by other brands

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS 02K31-X2 3P Installation, operation, and maintenance manual with parts list

GORMAN-RUPP

GORMAN-RUPP 86B3-B Installation, operation, and maintenance manual with parts list

Sauer Danfoss

Sauer Danfoss 45 Series Service manual

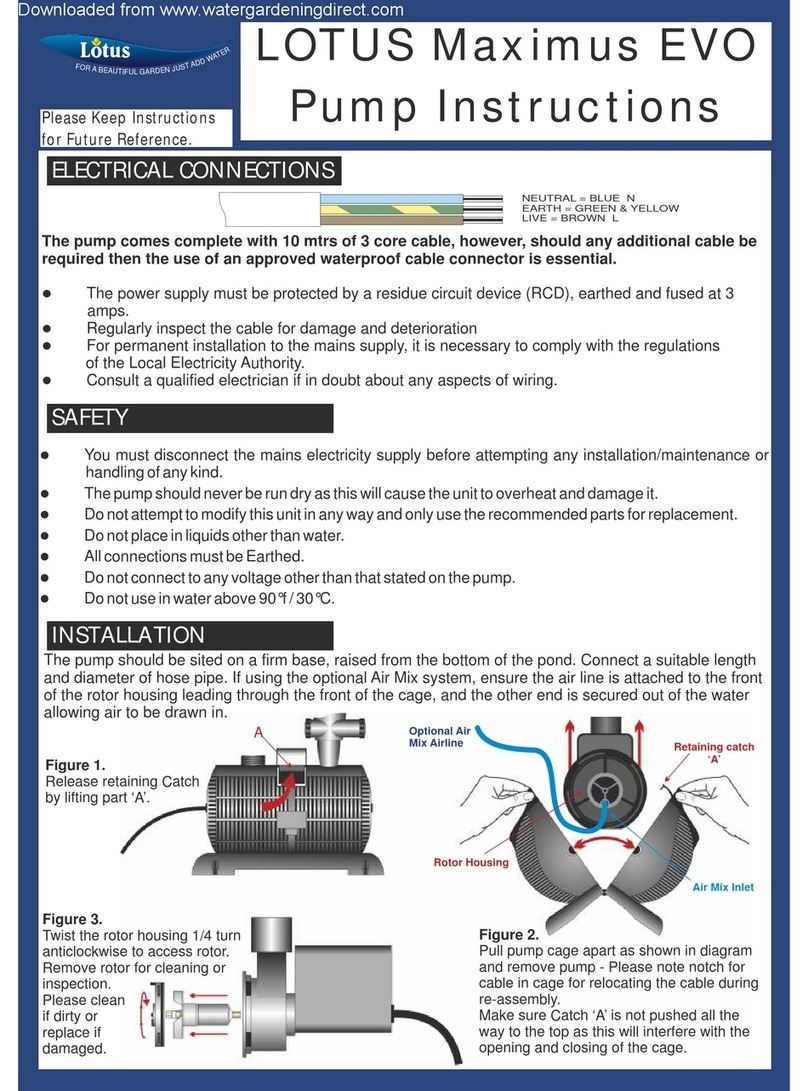

Lotus

Lotus Maximus EVO Series instructions

AL-KO

AL-KO TWIN 10000 combi manual

SFA

SFA SANICOM1 1332 manual