Edwards 3-PPS/M Assembly instructions

© 2014 UTC Fire & Security Americas Corporation, Inc. 1 / 4 P/N 270495-EN • REV 06 • ISS 10JUL14

Power Supplies

Installation Sheet

Description

This installation sheet applies to the following models:

•3-PPS/M(-230) Primary Power Supply

•3-BPS/M(-230) Booster Power Supply

•3-BBC/M(-230) Booster/Charger Supply

3-PPS/M(-230) Primary Power Supply

The 3-PPS/M(-230) Primary Power Supply provides the required

power and related supervision functions for the control panel. The

3-PPS/M(-230) comprises a heat sink assembly and a monitor module.

The monitor module plugs into the rail, and the heat sink and the heat

sink assembly mount onto the rail chassis.

The 3-PPS/M(-230) provides filtered, regulated power to the rail

chassis modules as well as 24 VDC for operating ancillary equipment.

AC power and battery connections are made to fixed terminals on the

heat sink assembly, away from the panel’s power-limited wiring.

The 3-PPS/M(-230) provides a dual rate constant current battery

charger circuit with automatic temperature compensation. To prevent

memory problems and total battery discharge, a battery monitor circuit

supervises the standby batteries and disconnects them when they

reach the low battery threshold.

The 3-PPS/M(-230) checks the AC input source and automatically

switches to battery power in the event of a brownout or loss of AC

power. In the event of a failure of one or more booster power supplies,

the 3-PPS/M(-230) determines its ability, along with the surviving

booster supplies, to supply the load. If the load exceeds the ability of

the primary and surviving booster supplies to meet the demand, the

3-PPS/M(-230) automatically switches in the standby batteries. The

3-PPS/M(-230) also switches in the standby batteries if an overload

causes the heat sink temperature to reach a high level.

The power supply monitor module provides the interface between the

3-PPS/M(-230) and the panel, making the required data and power

connections to and from the rail chassis. The monitor module requires

one rail space and is secured to the assembly using snap rivet

fasteners. The monitor module has a hinged front panel for mounting

displays or a blank protective faceplate.

3-BPS/M(-230) Booster Power Supply and 3-BBC/M(-230)

Booster/Charger Supply

The 3-BPS/M(-230) and 3-BBC/M(-230) booster power supplies are

used to provide additional power over and above that of the

3-PPS/M(-230). Each model is composed of a heat sink assembly and

a monitor module. The monitor module plugs into the rail and the heat

sink assembly mounts onto the rail chassis.

Depending on the size of the cabinet, up to three booster power

supplies can be added to make a total of 28 A available for both

internal and external applications. Each booster supply provides

filtered, regulated power to the rail chassis modules as well as 24 VDC

for operating ancillary equipment.

A 3-BPS/M(-230) supply can share a common set of standby batteries

with the 3-PPS/M(-230) or 3-BBC/M(-230). Each 3-BPS/M(-230)

supervises its own battery connection but does not have any battery

charging capability. The 3-BBC/M(-230) is capable of charging standby

batteries.

Each booster supply shares the panel's 24 VDC electrical load with the

3-PPS/M(-230). In the event of a booster power supply failure, a

trouble is annunciated, and the panel load is distributed among the

remaining operational power sources. Should the load ever exceed the

ability of the operable power sources to supply the power, as in the

event of an alarm, the system automatically switches to standby

batteries.

The booster supply monitor module provides the interface between the

booster power supply and the panel, making the required data and

power connections to and from the rail chassis. The monitor module

requires one rail space and is secured to the assembly using snap

rivet fasteners. The monitor module has a hinged front panel for

mounting displays or a blank protective faceplate.

Installation

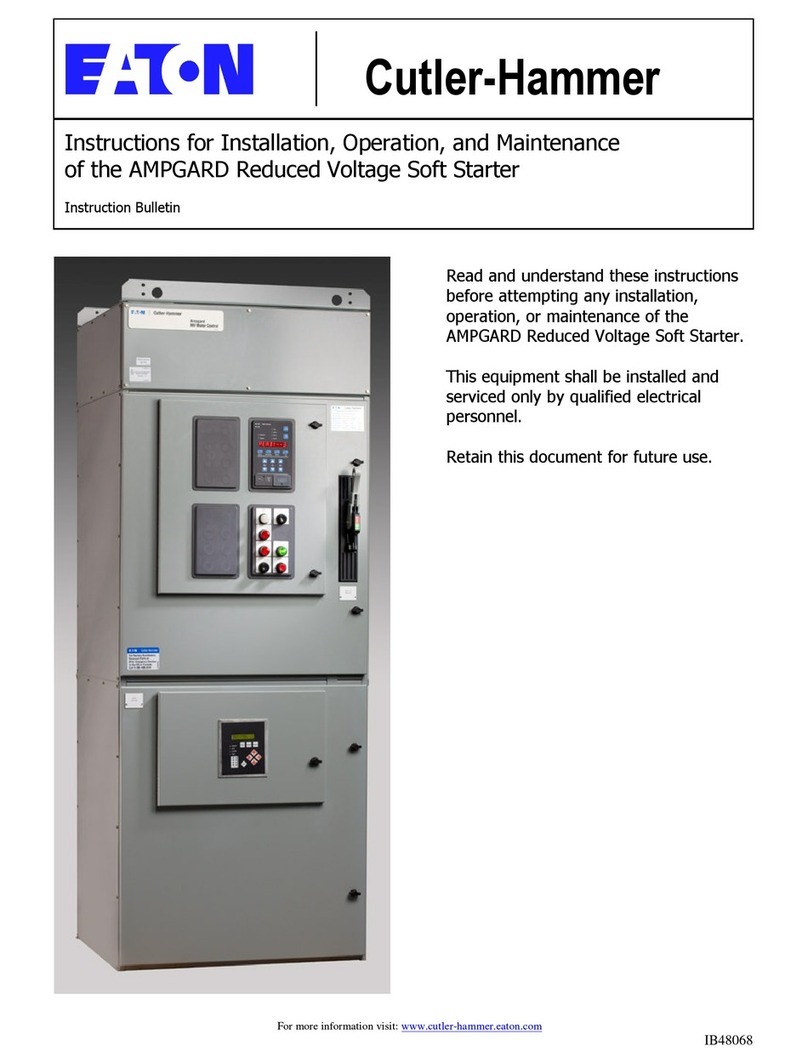

Installing a heat sink assembly

Heat sink assemblies are installed on the rail chassis behind the rail

module connectors. Refer to Figure 1.

To install a heat sink assembly:

1. Attach the heat sink assembly to the four threaded mounting studs

on the rail chassis using lock nuts provided in the hardware kit.

2. Secure the bottom edge of the heat sink assembly to the threaded

standoffs on the rail chassis using screws provided in the

hardware kit.

3. Secure the top edge of the heat sink assembly to the rail chassis

using the two threaded standoffs provided in the hardware kit.

4. Attach the AC terminal block cover to the threaded standoffs using

two #6-32 x 1/2 pan head screws.

Notes

•Always mount the heat sink assembly for the primary power supply

onto the left mounting space of the rail chassis in which the central

processor module is installed.

•Booster supplies, if installed, can be mounted on any rail chassis,

but no more than three booster supplies may be installed in the

same enclosure.

TB1

P3

TB2

P2

+BATTERY-MON

TEMP

TB1

AUXILIARY POWER

1 2

Heat sink

assembly

Monitor

module

2 / 4 P/N 270495-EN • REV 06 • ISS 10JUL14

Figure 1: Heat sink assembly installation

Installing a monitor module

Caution: Equipment damage hazard. This product is sensitive to

electrostatic discharge (ESD). To avoid damage, follow accepted ESD

handling procedures.

To install a monitor module:

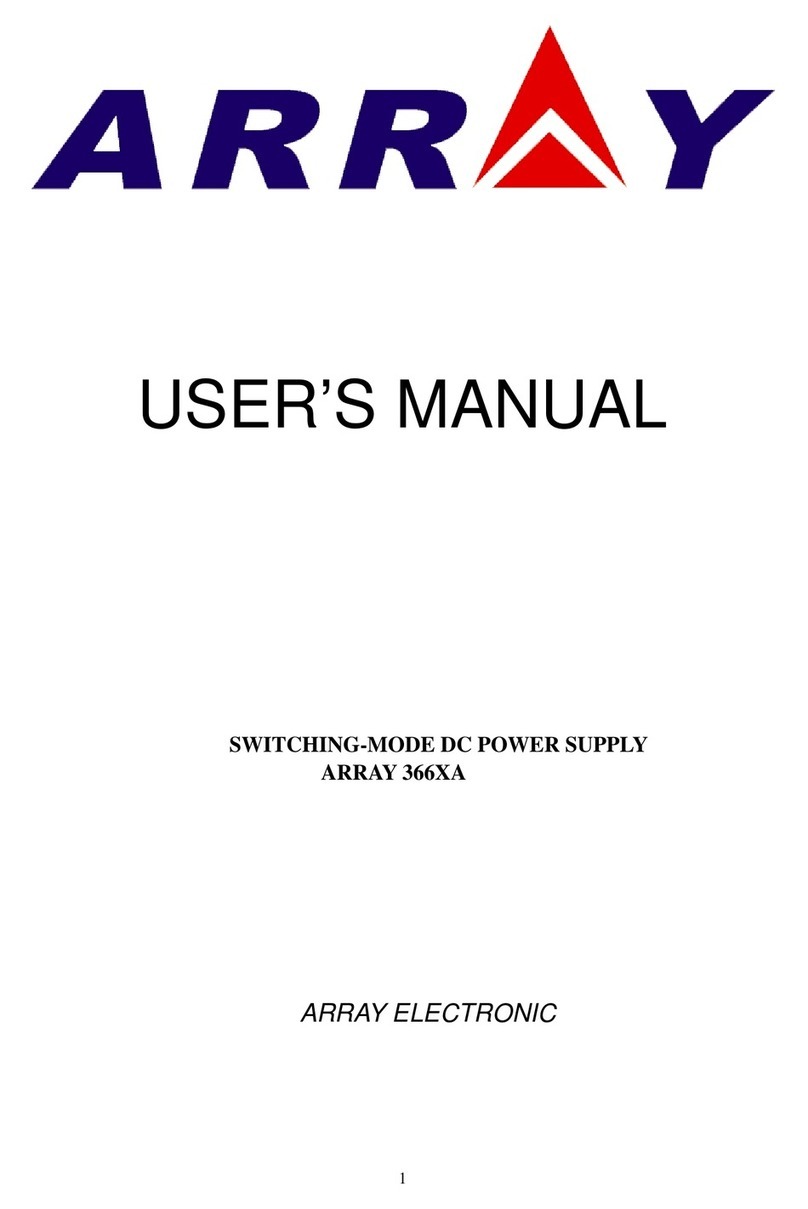

1. Plug the cable harness and ribbon cable into the monitor module

as shown in Figure 2. Ensure the cable connections are secure.

2. For a power supply monitor module, align the module to the guide

posts on slot 3 of the rail chassis.

For a booster supply monitor module, align the module to the

guide posts on slot 3 or slot 5 of the rail chassis, whichever is

closest to the heat sink assembly.

3. Route the cable harness over and behind the bottom rail and

connect it to P2 on the heat sink assembly. Push in until the

connector clicks.

4. Route the ribbon cable under the bottom rail and connect it to P3

on the heat sink assembly.

5. Plug the module into the rail connectors and lock it into place using

the snap rivet fasteners.

Figure 2: Power supply to monitor module cable connections

Figure 3 shows a primary power supply and booster power supply

installed in a chassis before they are wired.

Figure 3: Primary and booster power supplies installed in a

chassis

Wiring

Install and wire these power supplies in accordance with applicable

national and local codes, ordinances, and regulations.

Mains power wiring

Connect the mains power wiring after all power supplies have been

installed. No more than one primary power supply and three booster

supplies may be connected to a single mains AC circuit. All mains

power wiring must be double insulated.

WARNING: Electrocution hazard. To avoid personal injury or death

from electrocution, remove all sources of power and allow stored

energy to discharge before installing or removing equipment. Ensure

that the mains power cannot be inadvertently switched on.

#8-32 lock nut

(4 places)

#6-32 x 3/4 threaded standoff

(2 places)

#6-32 x 1/2 pan head screw

#6 lock washer

#6 flat washer

(2 places)

J8

J9

J10

J11

Right mounting area for installing

booster power supply

P2

TB1

H

120 VAC

GN

P3

TB2

P2

+BATTERY- MON

TEMP

P2

J4

P3

P6

Cable harness

(P/N 250187)

Ribbon cable

P/N 250189 (primary monitor module)

P/N 250188 (booster monitor module)

P3

P3

TB2

MON

TEMP

J8

J9

J10

J11

P/N 270495-EN • REV 06 • ISS 10JUL14 3 / 4

To connect the mains power wiring:

1. Ensure that the mains AC circuit is de-energized.

2. Connect the mains AC conductors from the dedicated mains

distribution circuit to TB1 on the power supplies (see Figure 4).

3. Secure the power supply cover to the standoffs on the top edge of

each power supply.

Figure 4: Mains power wiring

Auxiliary 24 VDC riser wiring

Connect the 24 VDC auxiliary power riser conductors to TB1 on the

power supply monitor module as shown in Figure 5.

Note: Current loads must be evenly distributed across all power

supplies.

Figure 5: 24 VDC riser wire connections

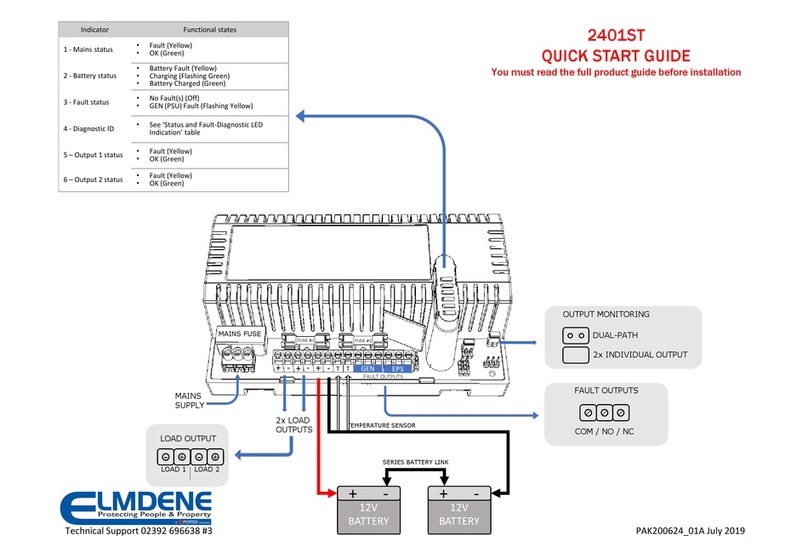

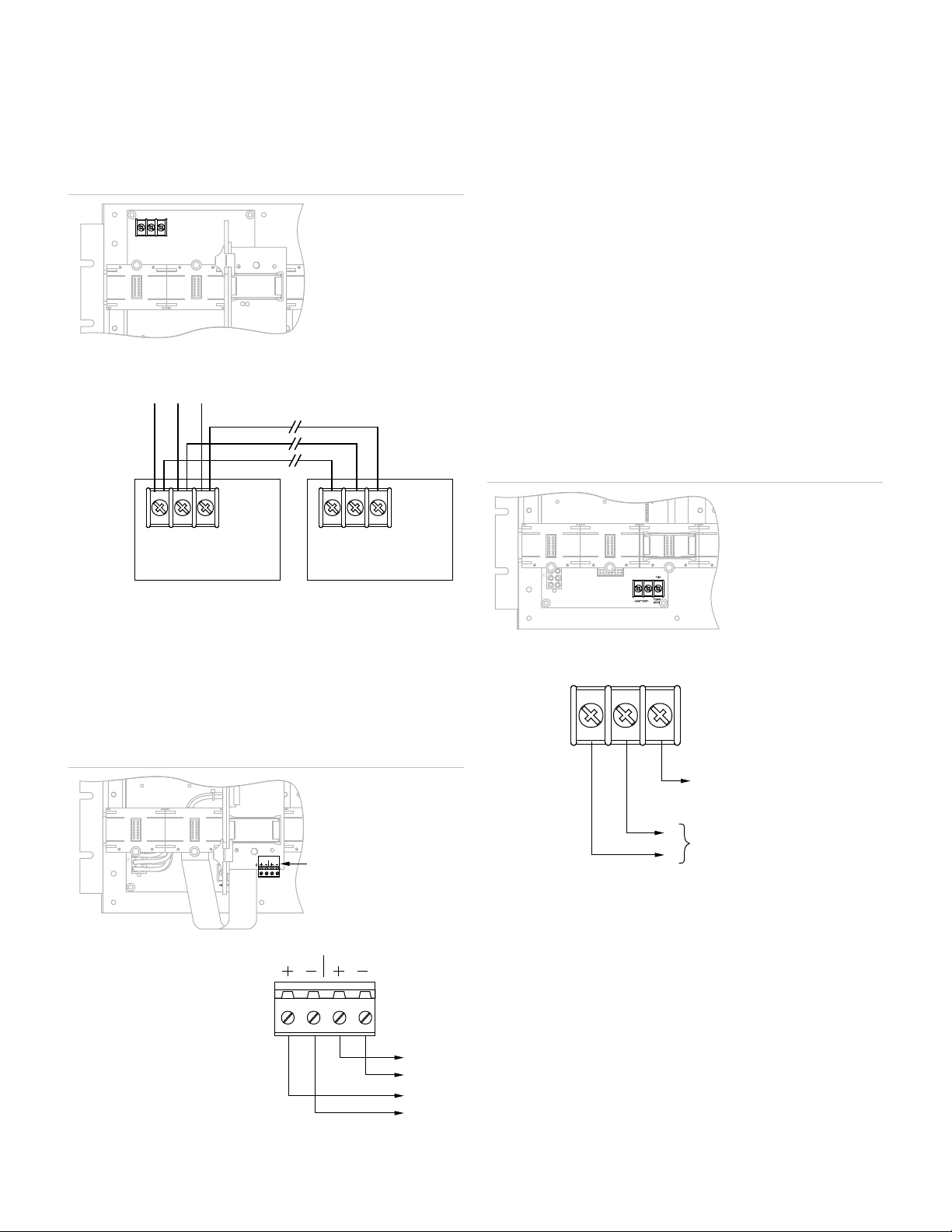

Standby battery wiring

Connect the standby batteries to TB2 on the heat sink assembly as

shown in Figure 6and according to the following requirements:

•Each set (pair) of batteries must be connected to a separate

battery charging circuit, either on a 3-PPS/M(-230) or on a

3-BBC/M(-230).

•Each power supply must be connected to only one set of batteries.

A 3-PPS/M(-230) and a 3-BPS/M(-230) can be wired to the same

set of batteries, as well as a 3-BBC/M(-230) and a 3-BPS/M(-230),

but never a 3-PPS/M(-230) and a 3-BBC/M(-230).

•Each power supply must have its own separate pair of wires

connecting it to a set of standby batteries. Daisy chaining battery

connections from power supply to power supply is not allowed.

•All battery wiring must be the same length and wire gauge.

•All batteries connected to the same control panel must have the

same ampere-hours rating, be from the same manufacturer, and

have the same manufacturing date code.

•Batteries greater than 17 Ah and any additional batteries must be

installed in an external battery cabinet.

•If an external battery cabinet is used to house standby batteries,

the cabinet must be installed within three feet and in the same

room as the control panel.

Figure 6: Standby battery wire connections

Table 1 lists typical battery and power supply combinations.

TB1

H

GN

TB1

120 VAC

L1

GL2 230 VAC

H

GN

TB1

120 VAC

L1

GL2 230 VAC

Dedicated 120 V or 230 V mains

power distribution circuit

Primary power supply Last booster supply

in the same cabinet

TB1

AUXILIARY POWER

1 2

AUXILIARY POWER

12

24 VDC

0 VDC

24 VDC

0 VDC

TB1

TB2

BATTERY TEMP

MON

Not used

To plus and minus terminals

on cabinet battery or to plus and

minus terminals on power

distribution bus in remote cabinet

+ −

−

+

TB2

4 / 4 P/N 270495-EN • REV 06 • ISS 10JUL14

Table 1: Typical battery and power supply combinations

Total current

Power supplies required Battery sets required

7A

1 3-PPS/M(-230) 1 set, 65 Ah max.

14 A

1 3-PPS/M(-230)

1 3-BPS/M(-230) 1 set, 65 Ah max.

1 3-PPS/M(-230)

1 3-BBC/M(-230) 2 sets, 65 Ah max.

21 A

1 3-PPS/M(-230)

2 3-BPS/M(-230) 1 set, 65 Ah max.

1 3-PPS/M(-230)

2 3-BBC/M(-230) 3 sets, 65 Ah max.

28 A

1 3-PPS/M(-230)

3 3-BPS/M(-230) 1 set, 65 Ah max.

1 3-PPS/M(-230)

3 3-BBC/M(-230) 4 sets, 65 Ah max.

Specifications

3-PPS/M(-230), 3-BPS/M(-230), and 3-BBC/M(-230)

Installation

Heat sink assembly

Monitor module

Mounts onto the rail chassis

Mounts in one rail space

Power input

120 VAC, +10%, −15%, 3.0 A, 50 to

60 Hz

230 VAC, +10%, −15%, 1.5 A, 50 to

60 Hz (-230 only)

Brownout level

≤ 102 VAC

≤ 195 VAC (-230 only)

Output ratings

Special application

s

Total

Internal DC

Auxiliary DC

R

egulated applications

Total

Auxiliary DC

24 VDC at 7.0 A (internal and auxiliary

outputs)

24 VDC at 7.0 A max.

Two 24 VDC at 3.5 A max.

Power-limited and supervised for ground

faults and shorts

For special applications, see the EST3

Compatibility List (P/N 3100427-EN)

24 VDC at 4.5 A (internal and auxiliary

outputs)

Two: one 24 VDC at 3.5 A max. for all

circuits except the regulated NAC; one

24 VDC at 1.0 A max. for regulated NACs

to 3-IDC8/4 modules only

Power-limited and supervised for ground

faults and shorts

Termination

AC input

Batteries

Internal DC output

Auxiliary DC output

Terminals on heat sink assembly

Terminals on heat sink assembly

LRM chassis rails via monitor module

Removable plug-in terminal strips on

monitor module

Current requirements

3-PPS/M(-230)

3-BPS/M(-230)

3-BBC/M(-230)

Included with CPU current requirements

Alarm: 50 mA

Standby: 50 mA

Alarm: 70 mA

Standby: 70 mA

Operating environment

Temperature

Relative humidity

32 to 120°F (0 to 49°C)

0 to 93% noncondensing

3-PPS/M(-230) and 3-BBC/M(-230)

Battery charging capacity

10 to 65 Ah

Type

Temperature compensated dual rate

(1.5 A and 3.0 A)

Supervision

Low AC

Low battery

High battery

Discharged battery

Ground fault

< 22.5 VDC

< 18 VDC

< 10 kΩ

3-BPS/M(-230) only

Supervision

Low AC

Low battery

Ground fault

< 22.5 VDC

< 10 kΩ

Contact information

For contact information, see www.edwardsutcfs.com.

This manual suits for next models

5

Other Edwards Power Supply manuals