Eelectron HORIZONE User manual

Eelectron Spa

IN00B02WEBFI00060134_MODBUS_MANUAL_IT

1/22

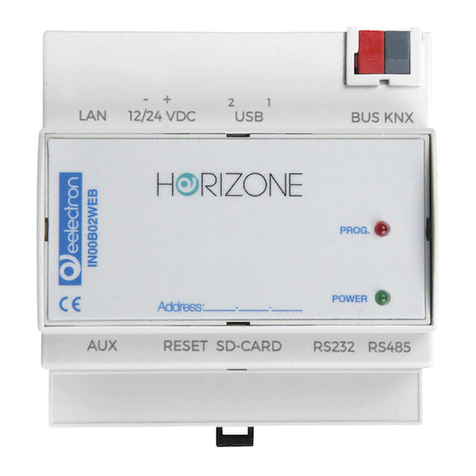

HORIZONE SERVER

IN00B02WEB

MODBUS MODULE MANUAL

Product: IN00B02WEB

Description: Horizone Server Modbus Module Manual

Date: 03/03/2020

Version: 1.3

Eelectron Spa

IN00B02WEBFI00060134_MODBUS_MANUAL_IT

2/22

Any information in this manual may be changed without notice.

This manual can be downloaded free of charge from the website: www.eelectron.com

Exclusion of responsibility:

Although the contents of this manual have been checked to ensure that they correspond to the

hardware and software indicated in the title, changes may, however, be made. Consequently,

Eelectron assumes no responsibility therein.

© 2020 Eelectron SpA. All rights reserved.

Microsoft, Windows, Windows 2000, Windows XP, Windows 2003, Windows Vista, and Internet

Explorer are either registered trademarks or trademarks of Microsoft Corporation in the USA and

other countries. Java is a trademark of Sun Microsystems, Inc. in the USA and other countries.

All other product names mentioned herein are trademarks or registered trademarks of their

respective manufacturers.

Eelectron Spa

IN00B02WEBFI00060134_MODBUS_MANUAL_IT

3/22

Summary

INTRODUCTION 4!

Safety Information 4!

Copyright 4!

INTRODUCTION 5!

Introduction 5!

Purpose of this document 5!

Requirements 5!

CONNECTION 7!

Modbus RTU 7!

Modbus TCP 7!

Preliminary operations 7!

MODBUS LINES 11!

Introduction 11!

New Modbus line 11!

MODBUS REGISTERS 15!

Creation of registers 15!

Multiple reads and writes 20!

Register details 21!

Events and connections 21!

REVISIONS 22!

OPEN SOURCE 22!

Eelectron Spa

IN00B02WEBFI00060134_MODBUS_MANUAL_IT

4/22

INTRODUCTION

Safety Information

This manual contains the information necessary to safely operate the device. Anyone interacting

with the device must first have read this documentation, especially this safety information. This

document supplements and does not replace any safety laws or directives.

The device has been developed using state-of-the-art technologies and following current safety

regulations; it is, however, not possible to totally exclude all possible damage or interaction with other

devices during its operation. The device complies with EMC guidelines and harmonised European

standards; any changes to the device may affect EMC compatibility.

The supply voltage must be strictly within the range indicated in this manual and on the device;

danger of fire or explosion if power is supplied outside this range. The equipment shall be powered

by a limited power supply circuit whose isolation from the mains shall be not less than that between

the primary and secondary circuits of a safety transformer according to IEC 61558-2-6 or equivalent.

The CE declaration of conformity of the device can be requested from Eelectron SpA, at the contacts

on the website www.eelectron.com

In accordance with Directive 2002/96/EC, electronic devices must be disposed of in

dedicated facilities and not in the collection of municipal solid waste.

Copyright

HORIZONE SERVER technical instructions, manuals and software are subject to copyright; all rights

are reserved. Copying, reproduction, translation and/or modification, even partial, are expressly

prohibited unless approved in writing by Eelectron SpA.

Eelectron Spa

IN00B02WEBFI00060134_MODBUS_MANUAL_IT

5/22

INTRODUCTION

Introduction

HORIZONE can use the Modbus RTU and Modbus TCP/IP protocol to supervise one or more slave

devices, connected via both RS485 and network connection.

Once communication logs are configured with a Modbus slave device, they can be managed as

objects on the supervision pages or associated with other objects using logic.

Purpose of this document

This manual contains all the information you need to install, configure and use the specific features

of Modbus technology in the HORIZONE SERVER. It is aimed primarily at installers, but can also

be a useful guide for end users who are interested in customising the supervision features of their

building automation system.

It assumes a good knowledge of the Modbus protocol, the related devices to be supervised and

controlled on the system and HORIZONE; many sections of this document refer to general concepts

of supervision that can be explored in the general product INSTALLATION MANUAL.

For more information on the Modbus protocol, please consult the following page:

http://www.modbus.org/tech.php

Requirements

You must have the following in order to manage an integration of Modbus devices with HORIZONE:

● A HORIZONE SERVER

● MODBUS module activation license

To enter the activation license:

● Log on to HORIZONE SERVER administration

● Select “SETUP” from the side menu, then “MANAGE MODULES AND LICENSES”

● Identify “ACCESS CONTROL” and enter the activation code

Eelectron Spa

IN00B02WEBFI00060134_MODBUS_MANUAL_IT

6/22

● Press the “SAVE” button and wait for the page to reload

Refer to the INSTALLATION MANUAL for further details.

Eelectron Spa

IN00B02WEBFI00060134_MODBUS_MANUAL_IT

7/22

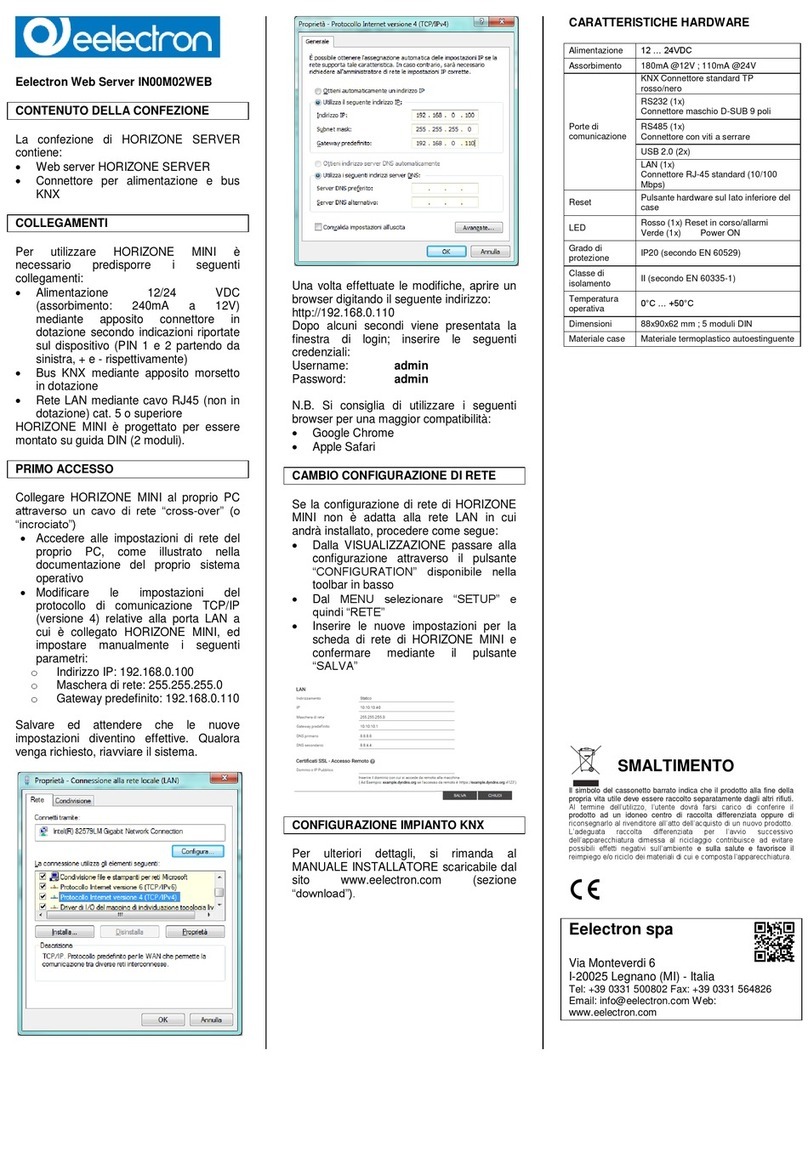

CONNECTION

Modbus RTU

To manage a device operating with MODBUS RTU protocol, simply connect it to the RS485 port

integrated into HORIZONE SERVER, respecting the polarity indicated on both the webserver and

the device.

Alternatively, you can use the RS232 port or one of the USB ports, using an RS485 adapter.

Modbus TCP

Interfacing with a device operating on MODBUS TCP protocol requires it be connected to the same

LAN as the webserver and for the two to be able to dialogue on the communication port of the

protocol, typically port 502.

Preliminary operations

Before starting the configuration of a Modbus device in HORIZONE SERVER, it is necessary to

obtain the table (or “mapping”) of the read and/or write logs. You will be able to identify the useful

information in it to make the HORIZONE communicate with the device, including the fundamental

information you need to know before proceeding with the integration:

Eelectron Spa

IN00B02WEBFI00060134_MODBUS_MANUAL_IT

8/22

COMMUNICATION

PARAMETERS

They vary depending on the type of protocol used by the Modbus

device.

In the case of Modbus RTU, the entries are as follows:

- Baud rate

- Parity

- Data bit

- Stop bit

- Communication mode (RS232 or RS485)

With the Modbus TCP, you need to know:

- IP Address

- Port

SLAVE ADDRESS

Each Modbus peripheral, whether communicating via RTU or

TCP, has a unique address on the network.

Unless the manufacturer specifies it, you can change it. The

procedure to follow is specified in the manual and is usually

performed through pre-configuration software of the device or

via hardware with dedicated switches. Eligible addresses on a

Modbus network range from 1 to 247. The Master device of the

line, which in our case will always be HORIZONE, does not need

an address for communication while address 0 is reserved for

“broadcast” messages

Eelectron Spa

IN00B02WEBFI00060134_MODBUS_MANUAL_IT

9/22

FUNCTIONS

In the Modbus, the “Function” entry indicates the second byte of

a message. It is sent by the Master and indicates which table of

Slave logs must be entered to access the data and whether a

read or a write operation should be performed.

Read functions:

FC 01: Read coil status

FC 02: Read input status

FC 03: Read holding register

FC 04: Read input registers

Write functions:

FC 05: Force single coil

FC 06: Preset single register

FC 15: Force multiple coils

FC 16: Preset multiple registers

It is essential to know each device registry on the network with

which Modbus function must be written and read in order to

access the correct data; as with other information, this is also

contained in the device manuals.

REGISTERS

A register contains the data to be read and/or written with

HORIZONE. Each device has a mapping that identifies each

register and declares its contents: a register, for example, may

contain a temperature value, an on/off command or an alarm

signal.

As you can see below, the logs will be the “objects” available to

the user on the supervision page in order to interact with the

device through the Modbus, whether they are read, write or both.

Since they are HORIZONE objects, they can be used for each

of the server functions: schedules, logics, conditions, composite

objects, etc.

For more information, consult the HORIZONE configuration

manual.

Eelectron Spa

IN00B02WEBFI00060134_MODBUS_MANUAL_IT

10/22

DATA TYPES

Indicates the set of values for each register that the variable can

assume and the operations that can be performed on it. For

example, you can only perform simple arithmetic operations on

integers on an integer log (INT).

The device logs table also mainly shows the type of encoding

needed to interpret the value.

Once you have obtained all of the above information about the Modbus device, it is recommended

that you test write and read with Modbus software from your PC. This step allows you to get in-depth

information about the device function by performing a test bench before proceeding with integration

with HORIZONE.

All you need to do is install the Modbus Master software on your PC and connect it with a serial

cable or network cable to the device, depending on whether the protocol is Modbus RTU or TCP, in

order to access the device and its registers. This will allow you to test all the key aspects that will

allow integration: communication parameters, addresses, functions, registers and data types. Once

you have succeeded in interacting with the Modbus device, resolving any problems encountered,

integration on HORIZONE will be easier and faster.

Obviously, this procedure must be followed for each device that you want to insert into a HORIZONE

line.

You can find lots of free Modbus Master programs on the internet; we recommend the following:

http://www.modbustools.com/modbus_poll.html (30 days free trial)

https://oceancontrols.com.au/OCS-011.html

http://www.qmodbus.sourceforge.net/

After obtaining all the information required to integrate one or more Modbus devices with the

HORIZONE and performing the communication, write and read tests, you can proceed to create the

HORIZONE registers.

Eelectron Spa

IN00B02WEBFI00060134_MODBUS_MANUAL_IT

11/22

MODBUS LINES

Introduction

HORIZONE potentially supports more than one Modbus interface, through the creation of the same

number of Modbus lines on different communication channels; these lines can operate

simultaneously, provided they are properly configured on the communication interfaces available in

HORIZONE:

● RS485

● RS232

● USB

● Network

For each line, it is possible to create a number of objects (similar to Modbus registers), belonging to

the different devices connected to it, which can then be entered in the supervision graphics pages.

It is also possible to manage more than one slave device if connected in a “cascade” to the same

RS485 line, thus creating only one line in HORIZONE and differentiating devices through the slave

address, as further detailed below. In this case, all devices must operate with the same

communication parameters (BAUD rate, parity, etc.)

It is essential to create only one bus line for each HORIZONE communication port; otherwise,

communication conflicts will occur.

New Modbus line

Proceed as follows to create a new Modbus line:

● Log on to HORIZONE administration

● Open the “TECHNOLOGIES” section of the side menu

● Select “Modbus” and expand the “Modbus Lines” entry

● Press the “ADD” button in the toolbar below (“+” symbol)

A new bus line is created and added to the list; at this point, by clicking on it and selecting the “three

dots” on the right (or, alternatively, after selecting it, pressing the “EDIT” button in the toolbar), you

access then its configuration page.

In the “GENERAL SETTINGS” section, the following parameters are available, varying depending

on whether the “Communication” entry is set as Serial/USB or Network:

Eelectron Spa

IN00B02WEBFI00060134_MODBUS_MANUAL_IT

12/22

NAME

Modbus Line identifier label

COMMUNICATIONS

Allows the Modbus communication protocol, choosing from:

● Serial/USB

● Network

DEBUG

There are two entries in the Debug field:

● None

● Log File

By selecting “Log file”, all the events that affect the Modbus line, both

in transmission and in reception, with related errors, line settings and

other information will be written to a file, which can be downloaded with

the “Download Log” button.

This tool can be useful during the commissioning of Modbus devices

with HORIZONE but, once the system is operational, it is

recommended to activate it only if strictly necessary (e.g.

maintenance or software modifications).

The “Clear Log” button clears all content written to the log file by

deleting all previously logged messages and reducing their size.

ENABLE MONITOR

BUS

Selecting this option stores all modbus traffic in a temporary file, which

can be accessed via the MONITOR BUS button (only available if this

option is enabled).

Eelectron Spa

IN00B02WEBFI00060134_MODBUS_MANUAL_IT

13/22

The following parameters must be entered for serial communication:

SERIAL PORT

Determines which communication channel HORIZONE will use to

connect to the Modbus devices connected.

You can use any of the serial ports of the HORIZONE:

● External RS232 port

● USB port 1

● USB port 2

When connecting to HORIZONE USB ports, a USB-serial adapter must

be provided.

BAUD RATE

Sets the Modbus channel communication rate in bits/s.

The speed must be the same as the speed of the devices connected to

the HORIZONE server:

● 1200

● 2400

● 4800

● 9600

● 19200

● 38400

● 57600

● 115200

PARITY

Modbus line communication parameter to be selected based on the one

set on the devices with which communication is to take place:

● EVEN

● ODD

● NONE

STATUS BIT

Modbus line communication parameter to be selected based on the one

set on the devices with which communication is to take place

Eelectron Spa

IN00B02WEBFI00060134_MODBUS_MANUAL_IT

14/22

STOP BIT

Modbus line communication parameter to be selected based on the one

set on the devices with which communication is to take place

COMMUNICATION

METHOD

Set RS485 for natively devices operating in RTU mode, vice versa use

RS232 mode for converters or other similar types of serial

communication interfaces

Conversely, in the case of network communication:

IP ADDRESS

IP address of the Modbus device.

PORT

Communication port used by the Modbus device.

The “Execution status” entry tells the user the status of the Modbus line: “running (continuous) if

there is communication, “Stopped” if there is no packet transmission and reception.

There are two buttons to intervene on line communication: “START” and “STOP” that respectively

allow you to start or stop communication with the Modbus line.

There are also three other buttons available: “CLOSE”, which simply closes the open Modbus line

page, “DOWNLOAD LOG” and “CLEAR LOG”.

The “DOWNLOAD LOG” and “CLEAR LOG” buttons appear only if the Debug entry has been

enabled in the properties. By pressing the “DOWNLOAD LOG" button, the browser will start

downloading the file containing all the events that will affect the Modbus line, both in transmission

and reception, with related errors, line settings and other useful information.

The “CLEAR LOG” button clears the contents of the Log file by deleting all previously logged

messages and reducing the size.

The “Enable Communication” flag, if not selected, allows you to maintain the configuration of a bus

line within the project, but make communication inert.

Eelectron Spa

IN00B02WEBFI00060134_MODBUS_MANUAL_IT

15/22

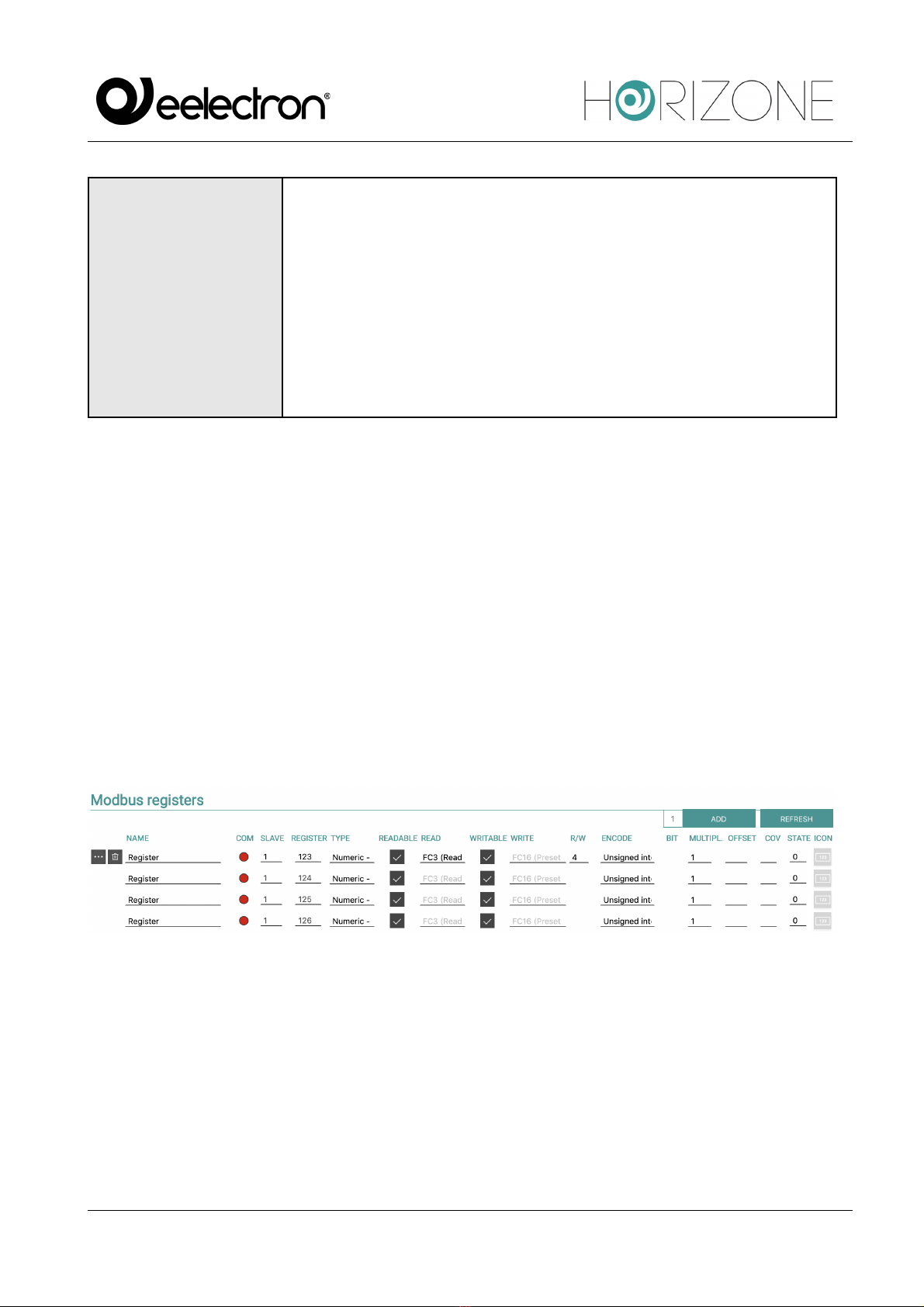

MODBUS REGISTERS

Creation of registers

To create one or more registers for each slave connected to the HORIZONE Modbus line:

● Access the Modbus Line

● Type the number of registers to create in the text field next to the “ADD” button under the

section title “MODBUS REGISTERS”

● Press the ADD button

As many new registers as required are automatically created.

Once created, the registers can be renamed simply by typing the new name in the appropriate text

box; You can also access the register detail tab, through the corresponding edit button; the

“DELETE” button vice versa removes (permanently) the register from the project.

For each register, you can set the following properties:

NAME

Label used within the supervision to identify the Modbus Slave register.

E.g. “outdoor temperature”, “living room light” etc.

SLAVE

Address of the Slave device to which the register belongs.

REGISTER

Register address.

TYPE

Determines the type of data contained in the register:

● Boolean (ON/OFF)

● Numeric - rational (with comma)

● Numeric - integer (no comma values)

Note: we recommend using integer encoding if you do not expect

comma values to be handled.

READABLE

Flag to enable if the register can be read.

Eelectron Spa

IN00B02WEBFI00060134_MODBUS_MANUAL_IT

16/22

READ

If the register is readable, determine which Function to query with:

● Read Coil Status (FC1)

● Read Input Register (FC2)

● Read Holding Registers (FC3)

● Read Input Registers (FC4)

WRITABLE

Flags to enable if the log is writable.

WRITE

If the register is in write, choose the appropriate Function to run it:

● FC05 (Force Single Coil)

● Preset Single Register (FC06)

● Force Multiple Coils (FC15)

● Preset Multiple Registers (FC16)

R/W

Allows you to determine the number of registers to be read and/or

written simultaneously. For further details, please refer to the

appropriate section below

Eelectron Spa

IN00B02WEBFI00060134_MODBUS_MANUAL_IT

17/22

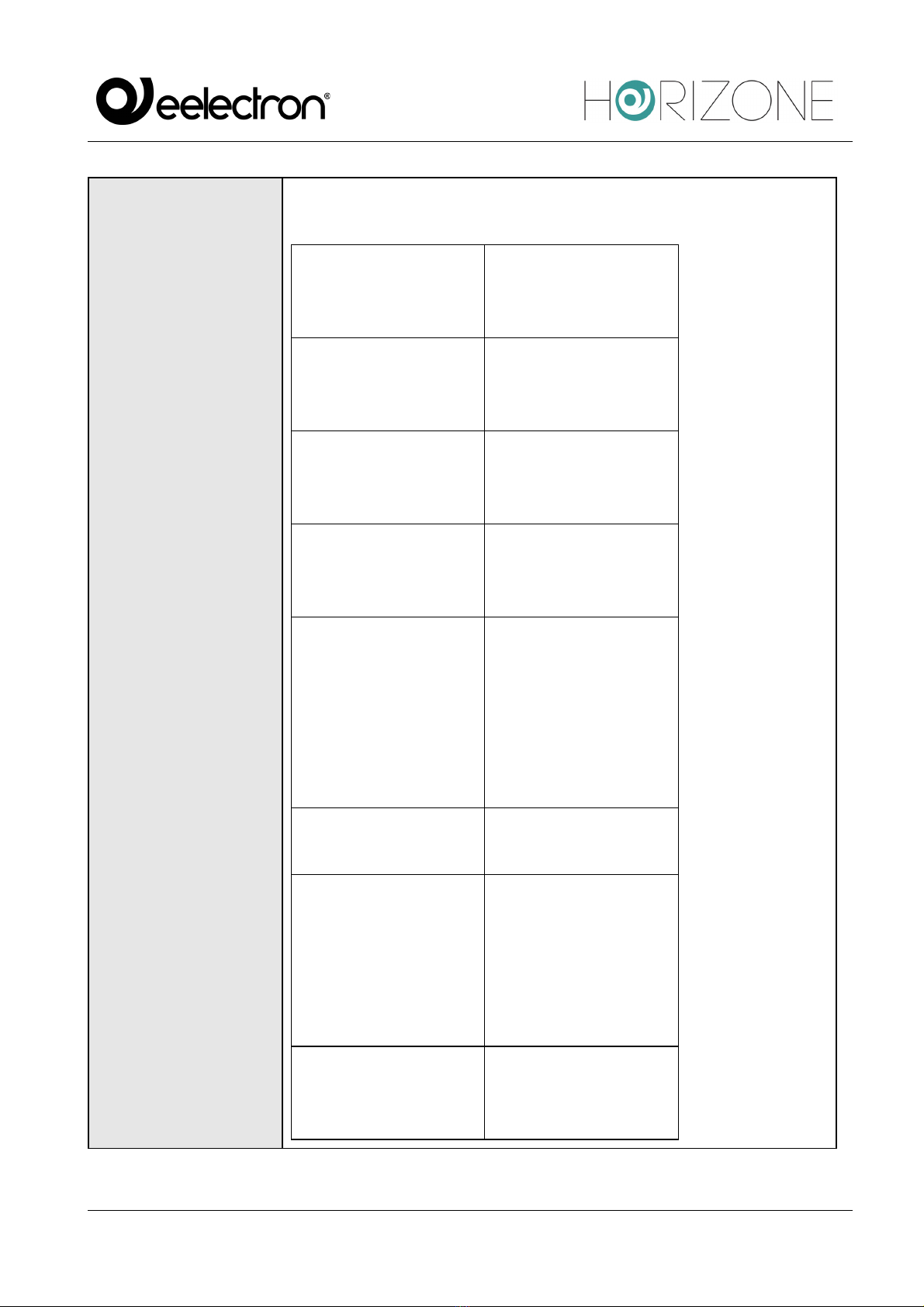

ENCODING

Determines the type of encoding to be used for interpreting the data

within the register. The following encodings are supported:

Unsigned Integer

Unsigned integer

1 register (2 bytes)

Signed Integer

Signed integer

1 register (2 bytes)

Unsigned long

Unsigned Long

2 registers (2 bytes) *

Signed Long

Signed long

2 registers (4 bytes) *

Signed long inverted

Signed long inverted

Note: the order of the

two registers is

reversed with respect to

the “long” encoding

2 registers (4 bytes) *

Floating point

2 registers (4 bytes) *

Inverted floating point

Note: the order of the

two registers is

reversed with respect

to the "floating point"

encoding

2 registers (4 bytes) *

Bit mask

Bit mask

1 register (2 bytes)

Eelectron Spa

IN00B02WEBFI00060134_MODBUS_MANUAL_IT

18/22

Signed double

Signed double

4 registers (8 bytes)

Unsigned double

Unsigned double

4 registers (8 bytes)

(*) in order to be selected, 4-byte encodings require the R/W field be

set to “2” beforehand, since two registers must be read/written

together. Similarly, the field must be set to 4 for 8-byte encodings.

Eelectron Spa

IN00B02WEBFI00060134_MODBUS_MANUAL_IT

19/22

BIT

This entry is available only if the register on which you write and read is

encoded as Bit Mask.

This encoding is used where each individual bit has a precise meaning

(e.g. a one-byte register where each individual bit is an on/off output of

an 8-channel actuator).

The Bit entry then determines on which bit within the mask the read

and/or write operation will be performed.

MULTIPLIER

The contents of the register are multiplied by the value set in this field.

E.g. register (temperature): 235;

multiplier: 10;

value on HORIZON: 235x10 = 23.5

OFFSET

Allows you to add a fixed value to the value read by the device.

E.g. register (temperature): 235;

multiplier: 10;

offset: 10;

value on HORIZON: 235x10 - 20 = 3.5

COV

In the case of numerical encodings, it allows you to set a threshold,

below which variations in value are ignored and not “propagated” within

the supervision.

Note: for decimal values, use the period as the separator

STATUS

Current register value.

Eelectron Spa

IN00B02WEBFI00060134_MODBUS_MANUAL_IT

20/22

ICON

Choice of graphic set to display in the Frontend register.

Lets you choose which icon to use in HORIZONE's “FRONTEND” to

graphically represent the register.

The library of available icons depends on the selection of the register

type (Boolean or Numerical).

Press the “UPDATE" button to the left of the Modbus Registers bar to confirm the creation or changes

of the logs and make them active. Once the communication has started, the coloured indicator in the

COM column indicates whether the register is reachable or not.

Multiple reads and writes

It is possible to read and/or write simultaneously to more than one register; this option is necessary

(setting the value “2”) for registers that adopt 4-byte encoding, but more generally it can be used (if

the slave device supports it) to operate on contiguous registers with a single read/write operation,

thus speeding up communication.

To activate a multiple read/write, enter a value other than “1” in the R/W field; the same number of

“sub-objects” are automatically created (with respect to the main register) as the number of

read/write set, automatically configured with the registers adjacent to the first:

Sub-objects must share some attributes with the former, such as read/write flags and encoding.

Conversely, it is possible to enter the multiplication factor, COV and icon set independently, since

they represent independent values in the graphic supervision (which could also represent quantities

of different types).

Other manuals for HORIZONE

1

This manual suits for next models

1

Table of contents

Other Eelectron Server manuals