Efcon omy Instruction Manual

Installation & User Manual - Sampling Systems

Version 140618 UK

Page 1

Efcon® Water

Installation & User Manual

Sampling systems

Installation & User Manual - Sampling Systems

Version 140618 UK

Page 2

Table of content ` Page

1.1 General 4

1.2 pplication area 4,5

1.3 Transportation 5

1.4 System set-up 5, 6

2 Enclosure 6 12

2.1 Technical specifications 6, 7

2.2 Dimensions and parts 7, 8

2.3 Installation 8 10

2.3.1 Mechanical installation 8

2.3.2 Electric installation 9, 10

2.4 Maintenance 11

2.5 Trouble shooting 11

3 Sampler Settings 12 17

3.1 Technical specifications 12

3.2 Operation explanation 13, 14

3.2.1 Sampling 13

3.2.2 Container distributor system 13

3.2.3 Cycle data 13

3.2.4 larm function 13, 14

3.2.5 Sampling on programmed periods 14

3.2.6 Stop sampling after xx containers 14

3.3 Manual operation 14

3.4 Display & cycle data read out 14

3.5 Change sampler settings 15 17

3.5.1 Changing Date/Time 15

3.5.2 Changing Settings 15

3.5.3 Changing Sampling Settings 16

3.5.4 Changing Distributor settings 16

3.5.5 Changing Program Settings 17

3.5.6 Changing Input . Output Settings 17

3.5.7 Changing Cool Unit Settings 17

4 Vacuum sampler 18 21

4.1 Technical specifications 18

4.2 Parts 18

4.3 Principle of operation 19

4.4 Installation instructions 19, 20

4.5 Changing sample volume 20

4.6 Maintenance 20, 21

4.7 Trouble shooting 21

5 ILS Guillotine G05 sampler 22 25

5.1 Technical specifications 22

5.2 Measurements and parts 22

5.3 Principle of operation 23

5.4 Installation instructions 24

5.5 Changing sample volume 24

5.6 Maintenance 24

5.7 Trouble shooting 25

Installation & User Manual - Sampling Systems

Version 140618 UK

Page 3

Table of content (continued) ` Page

6 ILS 2-way sampler 25 27

6.1 Technical specifications 25

6.2 Measurements and parts 26

6.3 Principle of operation 26

6.4 Changing sample volume 27

6.5 Maintenance 28

6.6 Trouble shooting 29

7 ILS 3-way SS sampler 29 33

7.1 Technical specifications 29

7.2 Measurements and parts 30

7.3 Principle of operation 30

7.4 Installation instructions 31

7.5 Changing sample volume 31

7.6 Maintenance 32

7.7 Trouble shooting 33

8 ILS 3-way PVC sampler 34 36

8.1 Technical specifications 34

8.2 Measurements and parts 34

8.3 Principle of operation 34

8.4 Installation instructions 34, 35

8.5 Changing sample volume 36

8.6 Maintenance 36

8.7 Trouble shooting 36

9 Peristaltic Sampler 37 40

9.1 Technical specifications 37

9.2 Measurements and parts 37

9.3 Principle of operation 38

9.4 Installation instructions 38

9.5 Changing 39

9.6 Maintenance 39

9.7 Trouble shooting 40

10 Spare parts 41

11 CE Declaration 42

12 Menu Navigation Jazz Controller 43

Installation & User Manual - Sampling Systems

Version 140618 UK

Page 4

1.1 General

Efcon

is developed by .V.M. (Netherlands) as a complete package for

Effluent Control Systems. Efcon

products are designed for measuring and

controlling wastewater flows.

Efcon

products meet the tough Dutch regulations (NEN 6600-1) and the

international standards according ISO 5667-2/3&10.

Products from the Efcon

program

Samplers (several types), level controllers, pump controllers, registration

equipment, sample distributor systems, flowmeters (industrial and

sewers), measurement pits, cool units, mobile systems, etc.

BEFORE YOU START

Read the manual before you connect the unit to a power supply or

install.

In case of illegal use or use in non-defined areas, any form of warranty will

be denied. The user needs to be informed about the user manual and

application dangers.

Installing and adjusting parameters of the sampling system should be

done by qualified personnel.

Check transported equipment for any transport damage. In case of

damage, directly contact your supplier and do not install the equipment.

The equipment is tested (different quality tests) in the VM factory (Hei-

en Boeicop, Netherlands) before it is transported. Required maintenance

or repair, which will not influence the warranty period, will have to be

carried out by trained Efcon

specialists. ll equipment returned to VM

needs to be cleaned, sterilised and transported in a safe enclosure to avoid

health-threatening situations. In case of service or repair, the equipment

will not be accepted by VM if there is no declaration of origin and safety

added to the equipment. Extra cleaning can be refused or will be charged!

Warranty will be denied if there are mechanical, electronic or software

changes in the unit which are not performed by VM.

BASIC WARRANTY PERIODS

When used and installed according specifications, not used for more than

150 samples and 24 distributor turns a day in a non-aggressive well

ventilated environment.

•

••

•48 months for thermoplastic enclosures for stationary use

•

••

•24 months for electronic components

•

••

•12 months for moving parts, such as pumps, pinchers & actuators.

•

••

•3 months under courtesy for wearing Parts such as Seals, Rotor & discs of

the vacuum pump.

Installation & User Manual - Sampling Systems

Version 140618 UK

Page 5

1.2 Application area Efcon

equipment

Be aware! Wrong application or misuse can damage the equipment or

the surrounding of the unit and is not covered by any form of warranty.

Surrounding conditions

•Temperature: 0°C / +40°C (-25°C / + 55°C optional).

•Well ventilated place.

•Efcon

advises not to place the enclosure into direct sunlight, for

an optimal cooler output. Systems in direct sunlight cool less

efficient due to a higher surrounding temperature!

Use in explosion hazardous environment is prohibited

unless mentioned on product and manual!

Sample Medium

•Free of solid parts (guillotine excluded).

•Free of air inclusion.

•Temperature: +0,1°C / +50°C. (higher optional).

•Minimal conductivity: 50µS (only for vacuum systems).

1.3 Transportation

• Transport all systems, equipped with a cool unit, straight up.

• For warranty claims, send the system packed in the original

package and on the supplied pallet.

1.4 System set up

Efcon

sampling systems are available in different thermoplastic

enclosures and are standard equipped with a Unitronics Jazz controller.

Efcon

sampling systems can be supplied in various operation principles,

for different circumstances, according NEN 6600-1 & ISO 5667-2&10.

Standard enclosures

•Efcon

omy Monoblock: on request in mobile version available

(with wheels and carry brackets).

•Efcon

Industrial: industrial model with Plug-In-Cool unit. Bigger

compartment for electronic components like recorders /

measurement electronics etc.

•Efcon

CarryBox: portable enclosure for vacuum samplers without

cooler.

•Efcon

omy SystemBox: enclosure for built-in flowmeters,

samplers, air compressors etc. To combine with Efcon

omy

Monoblock enclosure.

•Efcon

Industrial SystemBox: enclosure for built-in flowmeters,

samplers, air compressors, CIP installations, switch boxes etc. To

combine with Efcon

Industrial enclosure.

CPU’s

•Jazz controller: with basic functionality.

•Vision controller: custom made controllers on request.

Installation & User Manual - Sampling Systems

Version 140618 UK

Page 6

Sampling principles

•Vacuum principle: suction system from open channels

•In-line principle: In-Line-Sampler (ILS) are suited for wastewater

sampling from 100% filled pipes and available in different types:

•ILS Guillotine: pneumatic driven SS 316 sampler, for raw

wastewater.

•ILS 3WP *22: pneumatic driven, SS 316 flush system for

raw wastewater, available in multiple diameters and

pressure classes.

•ILS 3WE *12: electric driven, cost-effective PVC flush

system, with SS 316 sample bullet, available in multiple

diameters and pressure classes.

•ILS 2WE 412: electric, cost-effective PVC-sampler with SS

316 sample bullet.

2 Efcon

omy enclosure

2.1 Technical specifications

Efcon

omy

Electric

• Power supply / current

• Power

230V C ±5% / 2,5 / 50 Hz

± 400 W

Enclosure

• Height

• Width

• Depth

• Material enclosure

• Material window

• Material plates

• Isolation

Thermoplastic Green (different colours optional)

• 1100 mm ± 2%

• 600 mm ± 2%

• 600 mm ± 2%

• LLDPE double wall according VM patent

• Polycarbonate

• SS 316 / PE

• 40 tot 60 mm PUR foam

Surrounding conditions

• Protection class

• mbient temperature

• Direct sunlight

• Zone

• IP 54/ Cool shaft IP23

• (option -25°C) 0 / +40°C (optional +55°C)

• llowed, if possible avoid

• Not in explosion hazardous environments.

Cooling characteristics

• Principle

• Coolant

• Evaporator spiral

• Compressor

• Condenser

• Cool temperature

• Defrost cycle

• Heater

• Forced 24VDC ventilator moist protected

• R134

• Efcon

SS 316 / V4

• Electrolux coated

• Coated

• +3°C tot +5°C according NEN6600-ISO 5667

• utomatic (adjustable on controller)

• 24VDC-25W SS spiral (option)

Sample container

• without distributor

• with direct distributor

Material Polyethylene - White (optional glass)

• from 2L till 50L

• 2x25L / 4x13,5L / 12x2L / 24x1L

• CE-Declaration • Yes

Installation & User Manual - Sampling Systems

Version 140618 UK

Page 7

Efcon

®

Carrybox (vacuüm monsternemer)

Elektrisch :

•Voedingsspanning / stroom

•Vermogen

230V AC ±5% / 1 A / 50 Hz

±100 W

Behuizing

•Hoogte

•Breedte

•Diepte

•Gewicht

•Materiaal

•Afsluitplaat

Thermoplastisch Groen draagbaar model

•412 mm± 2%

•340 mm ± 2%

•302 mm ±2%

•± 9 kg

•LLDPE

•Aluminium met ophang sparing

Omgevingscondities

•Protectie klasse

•Omgevingstemperatuur

•Zon instraling

•Zone

•IP 41

•0°C tot +40°C

•Mogelijk, bij voorkeur voorkomen

•Niet in explosiegevaarlijke ruimtes.

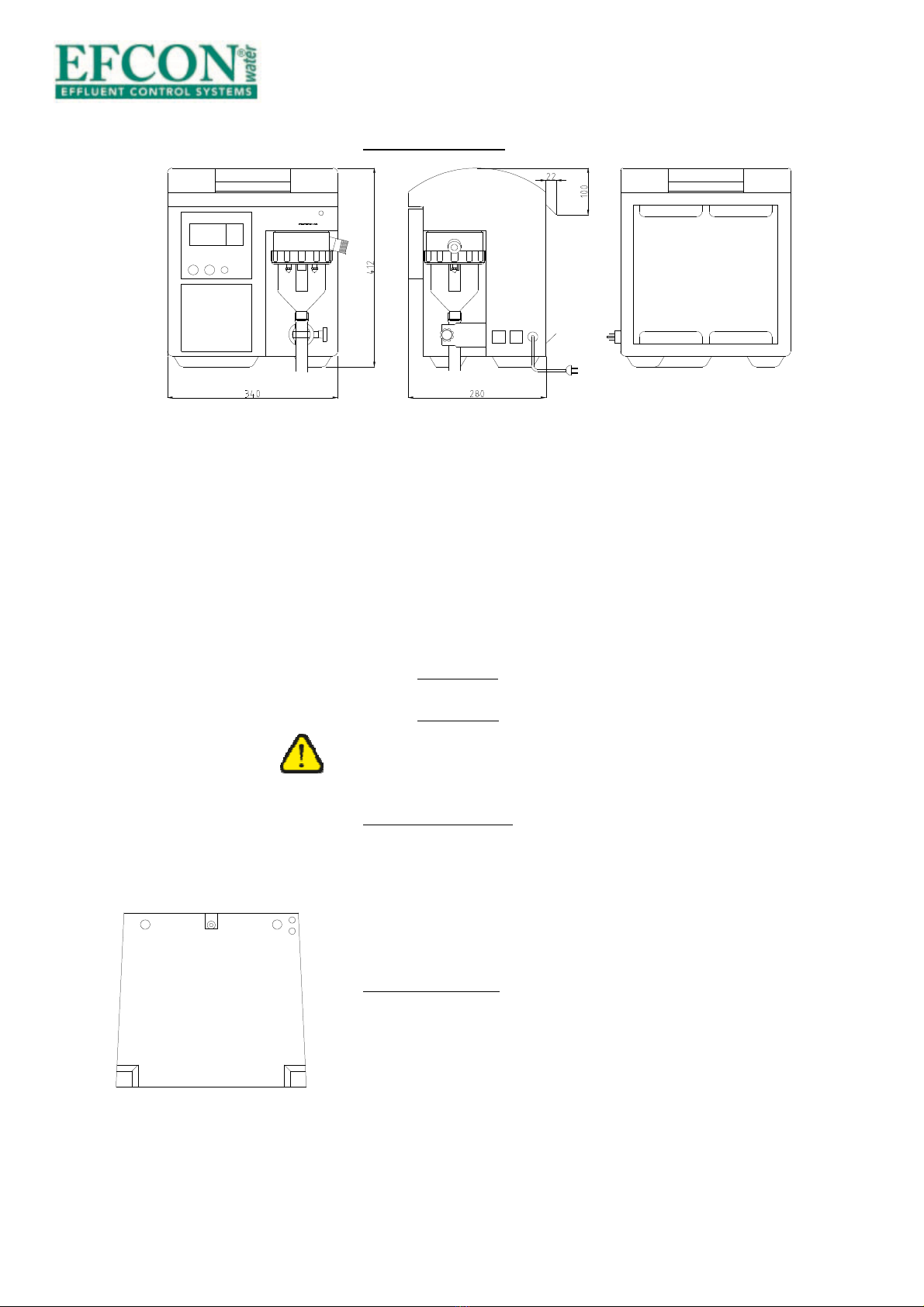

2.2 Measurements and parts

Efcon

omy enclosure

) Main switch (left side standard)

B) Sample / suction hose inlet

C) Protect cover of the cool shaft

D) Power supply

E) Mounting brackets

F) Electrics front plate with buttons and display

G) Sample garniture (only for vacuum systems)

H) Distributor engine with bracket

I) Sample container

J) Cooled sample storage compartment

A

B

C

B

D

E

E

F

G

H

I

J

Fig. 2.2a

Installation & User Manual - Sampling Systems

Version 140618 UK

Page 8

R

Efcon

Carry-Box Enclosure

) Handle

B) Operating panel

C) Vacuum chamber

D) Pincher

E) Splash board

F) Connectors

G) Power supply

H) Suspension bracket

2.3 Installation

2.3.1 Mechanical

First determine where the sampler must be placed (in case of an ILS

system) before installing the enclosure. This way you can check if the

sample hose (from sampler to enclosure) has a gradual slope.

Efcon

omy enclosure

Place the enclosure on a firm horizontal (water-levelled) ground and fix

the enclosure with the two supplied SS mounting brackets, bolts and

plugs. BE CAREFULL! Don’t turn the M6 bolt too tight in the enclosure.

Beneath the enclosure a condensate drain outlet is fitted. The outlet has a

push-in fitting for 8 mm tubing. See fig. 2.3a.

Carrybox enclosure

This enclosure is only available for vacuum and peristaltic samplers.

Mount ±300 mm DIN-rail horizontal to the wall on which the enclosure is

placed. Make sure there is sufficient height for an gradual, siphons free

and nod free sample drain to the container.

A

D

D

A

B

C

E

F

F

H

Fig. 2.3a

Fig. 2.2b

G

Installation & User Manual - Sampling Systems

Version 140618 UK

Page 9

2.3.2 Electric:

Work as followed when installing the enclosure:

•Remove the protection cover (B in fig.2.3b) from the cool shaft by

loosening the four bolts which hold the cover. If necessary remove

the connector and earth cable from the fan on the cover to create

more working space. Loosen the two grip nuts from the electro

front plate ( in fig.2.3b). Unplug the connectors to remove the

plate from the enclosure

•Pull the connection cable through the cable tubes which run

through the enclosure ( in fig.2.3c).

•Pull the cable through the cable glands (B in fig.2.3c) on the

separation plate between the cool shaft and electronic

compartment. Strip the cables long enough to reach the terminal.

Terminal connections

Power supply

Connect the power supply cable (230V C/50Hz) to contacts 1 (live), 2

(null) and 3 (ground) of the terminal (see sticker in fig.2.3d).

Pulse Input

Connect the potential free pulse / batch contact to contacts 4 and 5.

(pulse input) for pulse registration and pulse proportional sampling. Be

aware: keep the pulse input frequency <1 Hz. Use a pulse length of ±100

msec.

When using the pulse input for batch control sampling, the pulse counter

in the display counts every batch contact.

Digital Input 1 & Digital Input 2

Connect a potential free contact to contact 4 & 6 (DI1) and/or

4 & 7 (DI2), check §3.5.6 to configure the inputs.

Analogue Input (current)

Connect the 4—20m flow signal cable to terminals 8 (+) & 9 (-). Check

§3.5.5 to configure the analogue input.

Digital output 1 (2= optional)

Terminals 10 and 11 are used for the programmable digital output 1,

The relay output is normally open. Terminals 10 & 12 are used for digital

output 2. Check §3.5.6 to configure the digital output.

A

B

A

Fig. 2.3b

Fig. 2.3c

Fig. 2.3d

Installation & User Manual - Sampling Systems

Version 140618 UK

Page 10

In-/output Connectors (optional)

Optional for

Efcon

systems are connectors on the side. Connect the pins

of the connectors according fig. 2.3e. Place the cable inlet downwards to

prevent moisture inside the connector.

230V C Power supply in (male connector)

•Pin 1 = L 230V C 50Hz

•Pin 2 = N 230V C 50Hz

•Pin PE = GND

24VDC Power supply in (female connector)

•Pin 1 = +24V DC

•Pin 2 = 0V DC (gnd)

Flow Input (female connector)

•Pin 1 = + 4-20m

•Pin 2 = - 4-20m

•Pin 3 = potential free contact

•PE = potential free contact

Distributor Output (female connector)

•Pin 1= + 24V DC

•Pin 2 0 V (Gnd)

Sampler Output (female connector)

•Pin 1 = +24VDC sampler

•Pin 2 = -24VDC sampler

•Pin 3 = sampler response signal (24VDC pulse) optional

Digital Outputs (optional), (male connector)

•Pin 1 = Digital output 1 (potential free contact)

•Pin 2 = Digital output 2 (potential free contact)

•Pin 3 = Common digital output1&2

230V C Power supply out (female connector)

•Pin 1 = L 230V C 50Hz

•Pin 2 = N 230V C 50Hz

•Pin PE = GND

Fig.2.3e

Fig. 2.3e

Installation & User Manual - Sampling Systems

Version 140618 UK

Page 11

2.4 Maintenance

Be aware! Switch off power supply before maintenance or revision.

Remove compressed air couplings and remove pressure and medium

from wastewater piping.

Maintenance and reparations should be done by qualified personnel.

Avoid direct contact with wastewater. Wear protective gloves during use,

maintenance and reparations.

The maintenance frequency depends on wastewater characteristics. Clean

(or replace if necessary) all parts which come in contact with the sampled

medium regular.

Check if the cool shaft of the cooler is clean / not clogged by dust.

Cleaning the enclosure can be done with a moist cloth, but avoid all

electrical parts.

Check annually if the screws of all the electronic connection are tightened.

2.5 Trouble shooting

Problem Diagnose Solution

Cooler freezes the

containers

Wrong settings controller

Door not closed

Door “leaks” air

24VDC circuit out of

range

Check setting (§3.5.7)

Close door, check rubber

seal of the door with a

flash light.

djust the pot. meter on

the power supply to

24,00 VDC ±0,10 VDC.

Cooler doesn’t cool Wrong settings controller

Fan inside the protection

cover doesn’t work

Check settings (§3.5.7)

Check / replace fan

Distributor does not turn

(properly)

Wrong distributor

settings

Check settings (§3.5.7)

Hex. bolt on the

distributor engine is loose

Fasten bolt

Silicon hose doesn’t turn

free in rotation

Shorten silicone hose

Installation & User Manual - Sampling Systems

Version 140618 UK

Page 12

3 Program settings

Be aware! Incorrect settings may lead to defect hardware.

Adjusting parameter settings should be done by qualified personnel.

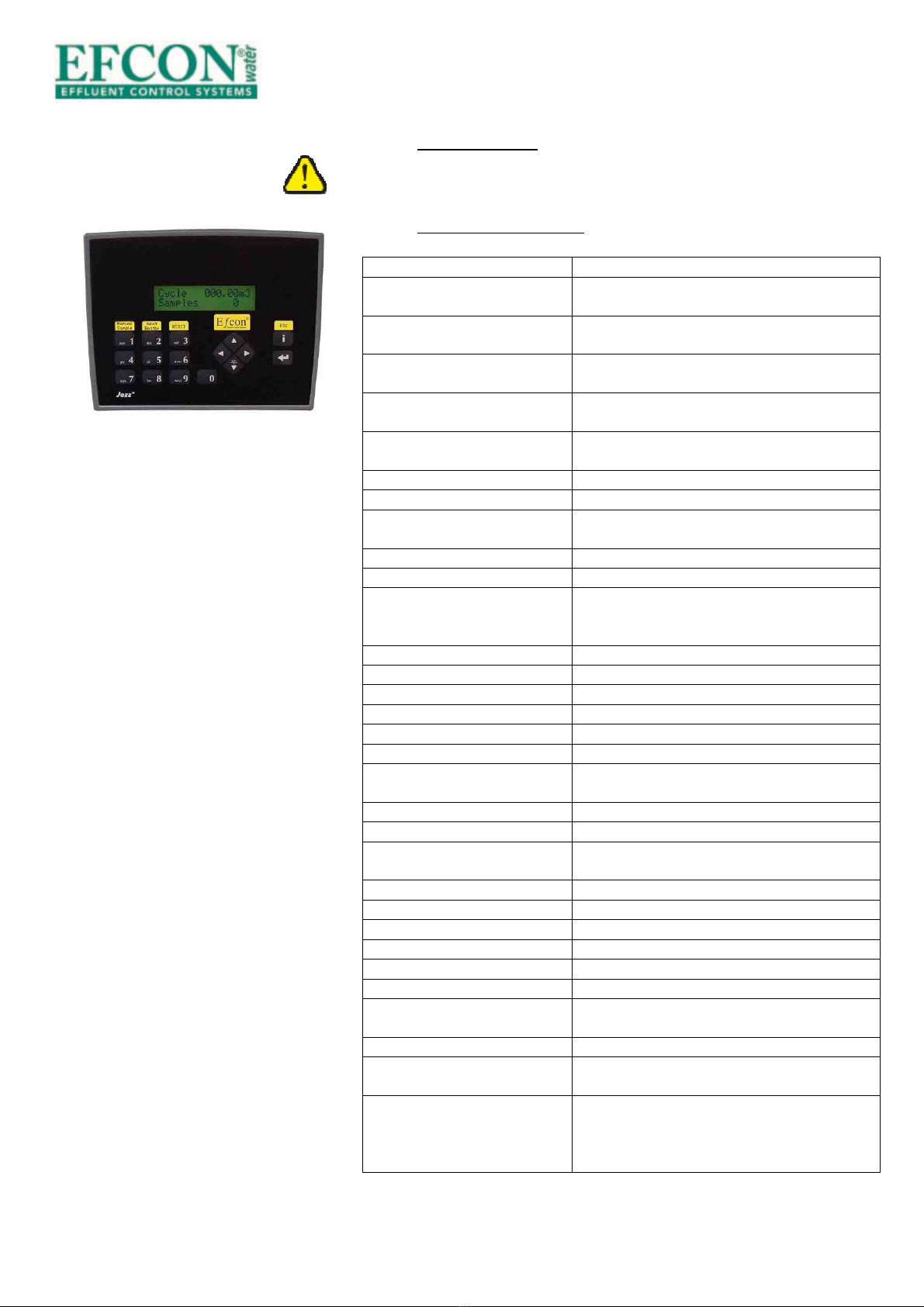

3.1 Technical specifications

Setting Range

Display 2 lines 16 characters, 16 keys, Totalizer

3000000,0 m

3

max (autom. resets)

I/O hardware 8 digital inputs, 4 analogue inputs, 11 relay

outputs

Basic operation Manual sample button, Next container button,

Reset button

Inputs Pulse input, Current flow input (4-20m ),

2x digital inputs (free config.)

Outputs 1x 24VDC relay output (free config.)

(2x optional)

Sample principle ILS / Vacuum / Peristaltic

Sample program Volume / Time / Batch

Sample interval 0,1- 2500,0 m

3

/ sample

2- 250 minutes / sample

Max error samples 0-999

Sample Volume 1-9999 ml

Vacuum settings

Peristaltic

Purge time 1-99 sec

Max suction time 1-99 sec

Dose time 1-99 sec

ILS settings ctivation time 1-99 sec

Turn time 00:00 - 23:59

Select day (MTWTFSS)

Turn Interval 00:00:00 - 99:59:59 (HH:MM:SS)

Container config. 1-24 containers, volume 0,01-99,99 l

Overflow protection Off, move next container, stop sampling

Program settings Start program according date & time (0=Off)

Stop program according date & time (0=Off)

Stop after xx containers 0-99 (0= Off)

Password Yes, (1-9999)

Date & time Changeable (no automatic summer / winter

time)

Cool unit set points On = 1-99°C, Off = 1-99°C

Defrost cycle Interval 1-99 hours, duration 1-99 minutes

Offset -99 - 99 °C

Defrost time 0-99 hours (0= continue cooling)

Eco cool On/Off

Flow signal Pulse / current / pulse + current

Pulse input

0,1 – 1000,0 m

3

Pulse unit: m3 / l / p

Current 20m = 1,0 – 360,0 m

3

/h

Input Options

(2 inputs)

Program on/off, Start program, Stop program,

take sample, next container, start cool unit.

Output Options (1 output)

(2

nd

output optional)

General alarm, sample alarm, sampling active,

sample ok, high temperature, sample error,

1m3 Pulse, 0,1 m3 pulse, 0,01 m3 pulse,

Containers full

Installation & User Manual - Sampling Systems

Version 140618 UK

Page 13

3.2 Operation explanation

3.2.1 Sampling

Sampling system can take samples on three different principles:

•Manual sample, by pushing a button on the operation panel.

•utomatic sample, as programmed:

-Time proportional sampling

-Volume proportional sampling(by pulse input or current input)

-Batch sampling (start time prop.sampling when the pulse

input is active).

•utomatic sample on programmed start- and stop date.

3.2.2 Container distributor system (optional)

The distributor ensures a proper sample distribution across different

sample containers.

Systems with multiple sample containers are equipped with a direct

distributor. The distributor positions the sample hose from the sampler

(clockwise) above the container. This operates automatically (by program)

of manually (by push button). The distributor is programmable to turn on:

•Fixed time (example: set on 10:00) & selected days.

•Time interval (example every 2 hours), time interval starts after

programmed fixed time.

•fter a number of taken samples, dependable on sample and

container volume (overflow protection).*

* When the distributor turns the cycle totalizer & sample counter

are reset. These values are stored in the jazz controller.

3.2.3 Cycle data (optional)

The display totalizes the cycle’s m

3

and taken samples. These values reset

when a new cycle is started (the distributor rotates to the next container).

The values are stored with the average temperature and date & time. The

controller stores up to 24 cycles.

3.2.4 Alarm function (optional for In Line Samplers)

fter multiple sample failures or power failure the alarm output relay of

the sampling system closes.

When a sample cycle is not completed the CPU registers an error sample.

fter a set number of error samples (default = 3) the sampler stops taking

automatic samples and switches to alarm condition. The alarm is

perceptible on 2 ways:

• programmed output relays switches.

•Display describes current alarm status.

Installation & User Manual - Sampling Systems

Version 140618 UK

Page 14

Push the Reset button on the controller to reset the alarm. fter

resetting, the system will sample according program. lso when power

failure occurs, the alarm contact closes.

3.2.5 Sampling on programmed periods

By activating this setting it is possible to start and stop automatic sampling

on a programmed date and time. This way the system can be

programmed (§3.5.11) to take samples only.

3.2.6 Stop sampling after xx containers

When activated the sampler stops sampling after a programmed number

of containers. By pushing Reset, the system samples further until the

same number of samples are taken §3.5.12.

3.3 Manual operation

The sampling system can be manually operated by 3 numeric keys on the

sampler controller. But only when the menu is not entered.

•(1) Manual Sample, push to take an manual sample.

•(2) Next Bottle, push to sample in the next container

(The distributor will wait 3 seconds).

•(3) Reset alarm, if the alarm is activated (too many error

samples), push this button to reset an alarm.

3.4 Display & cycle data read out

The display changes every 5 seconds between:

1

st

row: Totalizer in m

3

, this totalizer doesn’t reset.

2

nd

row: Program status, this shows the status of the program.

1

st

row: Cycle totalizer in m

3

, resets when turning to next container.

2

nd

row: Samples taken this cycle, also resets when turning.

1

st

row: Time & current flow (in m

3

/h).

2

nd

row: Date & current temperature (in °C).

Access stored cycle data:

When one of the above displays is active, press ▼to read the previous

cycle data, press ▼ again to read the cycle before that, press ▼ again

etc..

1

st

row: Data cycle number, end date & end time of the cycle

2

nd

row: Total m3 counted this cycle

Press ►to check the number of taken samples & average temperature

1

st

row: Data cycle number, number of taken samples this cycle

2

nd

row: verage temperature during this cycle

Total 00000,00m3

Program stopped

Cycle 00000,00m3

Samples 236

16:55 0,0m3/h

10/07 3°C

#1 31.12 08:00h

> 1000,00m3

#1 100 S

< 4°C

Installation & User Manual - Sampling Systems

Version 140618 UK

Page 15

3.5 Changing Sampler settings

To change settings it is necessary to enter the program of the Jazz

controller. The controller is password protected (default 5555), this

password can be changed or canceled.

3.5.1 Changing date/time

•Press Enter to enter the password

•Enter 5555 and press Enter

•Select Program settings with 2x ►

•Press Enter to select

•Press 3x▼and press Enter

•Enter the date with numeric keys and press enter

•Enter the time with numeric keys and press enter

•Press 2x ESC to go back to the total display

3.5.2 Changing Settings

See the attached menu diagram ( ppendix I) for a quick view of all the

parameters.

To change settings:

•Press Enter to enter the menu,

•Enter password (default 5555) & press Enter

•Select the submenu with ► or ◄ and press Enter

•Scroll with ▼and ▲ trough the parameters

•Press Enter (◄ or ► with parameters with ← or → signs) to

change the parameter value.

•Use numeric keys to enter a value & press Enter to store

Submenu

Parameters

Sample settings

Sample by, Sample Interval, Error Sample Max,

Sample Volume, Purge time (VS/PS), Max.

suction time (VS/PS), Dose (VS/PS), activation

time (ILS)

Distributor settings

Turn Time, Turn Day, Turn Interval, Containe

r

Config., Overflow protection

Program settings

Start date/t

ime, Stop date/time, Stop fter xx full

containers, Change date/time, Change password

Input

/output settings

Flowsignal, Pulse Value, Current 20m value,

Input 1&2 config, Output 1&2 config, Com.

settings(optional)

Cool Unit Settings

Set

points Cool unit, Defrost cycle, Temperature

offset, Defrost Time, Eco Cool settings.

Installation & User Manual - Sampling Systems

Version 140618 UK

Page 16

3.5.3 Changing Sample Settings

Select submenu Sample Settings and press Enter.

Select from the following parameters. Press Enter to change its value.

Parameter

Description

Sample by

Select with

◄

or

►

the following:

Volume Interval: sample every xxx,xx m

3

by flow

signal (pulse or current).

Time Interval: sample every xx minutes.

Batch: sample every xx minutes when the pulse

input is activated.

Sample interval

Enter the value of the desired interval

.

Error sample max

Enter the

max

.

number

of consecutive error

samples to trip the sample alarm.

Sample volume

Enter the sample volume

.

Purge

-

, Max suction

-

,

Dose- (VS only) &

ctivation Time (ILS

only)

Purge time:

time to clean

the suction tube

.

Max suction time: maximum time to reach the

level pins. Dose time: time to dose the sample.

ctivation time: time to activate the ILS sampler.

3.5.4 Changing Distributor Settings

Select submenu Distributor Settings and press Enter.

Select from the following parameters. Press Enter to change its value.

Parameter

Description

Turn Tim

e

Enter the

clock

time the distributor needs to

change the sample outlet to the next container.

Turn Da

il

y

Select the days the distributor needs to turn,

Everyday, Skip Sunday, or Off(don’t turn on the

Turn time)

Turn Interval

Enter the desired time int

er

val for the distributor

to turn (0=off).

Container c

onfig.

Enter the number of containers & container

volume.

Overflow protect.

Select

what action to take when the container

starts to overflow: Off (continue program), Next

container, Stop sampling (& restart when the

turn time is reached).

Installation & User Manual - Sampling Systems

Version 140618 UK

Page 17

3.5.5 Changing Program Settings

Select submenu Program Settings and press Enter.

Select from the following parameters. Press Enter to change its value.

Parameter

Description

Start Date-time Enter date & time to start sampling (00-00 = off).

Stop Date-time Enter date & time to stop sampling (00-00 = off).

Stop after full containers Enter desired number of container to be filled, the

sampler then stop sampling & restarts when reset is

pushed.

Date time. Enter time & date. Change it when needed.

Password Enter a number from 1-9999 to change the password.

3.5.6 Changing Input / Output Settings

Select submenu Input / Output Settings and press Enter.

Select from the following parameters. Press Enter to change its value.

Parameter

Description

Flow signal Select with ◄ or ► to totalize the desired flow signal.

Pulse = totalize contact (>50 ms) on the pulse input.

Current = totalize a 4-20m flow signal.

Pulse + Current = totalize contact on the pulse input,

current is only to display.

Pulse input value Select the pulse unit= 0=none, 1=m3, 2= l, 3=p

lso assign a value to the pulse contact, 0,1 -1000,0

(0,1 for current flow signal).

Current Value Enter the 20m value of the current signal

2600,0m

3

/h max.

Input 1 config.

Input 2 config.

Select with ◄ or ► to configure the inputs.

Choose from the following functions:

Start/Stop PRG, Start Program, Stop program

Take Sample, Next container, Start Cool unit,

Not in Use.

Output 1 config.

Output 2 config.

Select with ◄ or ► to config. the outputs.

Choose from the following functions:

General larm, Sample larm, Temperature High,

Sampling ctive, Sample OK, Error sample, 1 m

3

pulse,

0,1 m

3

pulse, containers full.

Communication settings ID# = Unit ID number, sign a unique network ID

number, Pari= Parity (0=even, 1=odd, 2=none),

Baudrate (legal baudrates=300, 600, 1200,2400, 4800,

9600)

3.5.7 Changing Cool unit Settings

Select submenu Cool Unit Settings and press Enter.

Select from the following parameters. Press Enter to change its value.

Parameter

De

scription

Cool Unit On/Off On and off set points cool unit.

Defrost cycle Fill in the desired interval (F) in hours and how many

minutes the Cool Unit needs to defrost (t).

Temperature. offset Temperature offset, to correct the temperature

measured inside the cabinet.

Defrost Time Fill in the desired time (in hours) to stop the cool unit.

Set to 0 hours to activate the Cool Unit again.

ECO cool Not available.

Installation & User Manual - Sampling Systems

Version 140618 UK

Page 18

4 Vacuum sampler

4.1 Technical Specifications

Vacuum

sampler conform ISO 5667

-

2&10

and

NEN 6600

-

1

Sample principle

• Max. suction height

• Minimal suction speed

• ir pump

• Pincher

• Sample volume

• Repeatability

• Dose accuracy

• Medium temperature

• Max. sample frequency

• Diameter suction hose

• Coupling suction hose

• Material vacuum chamber

• Sample settings

Principle Vacuum suction

• 4 meter (optional 6)

• 0,5 m/sec

• 24 VDC bi - directional ± 2800 rpm

• 24 VDC bi - directional ± 30 Nm with Current

Limiter.

• 20 ml tot 250 ml adjustable, 50 ml prefab

• 2% (at 50 ml and more)

• 4% (at 50 ml and more)

• max 50°C (higher on request)

• 1 sample / 2 minutes (software blocked)

• 16 mm (minimal 12 mm) inside

• 3/4”

• Polycarbonate

• djustable purge, suction time out, dose

time

4.2 Parts

Hardware of the vacuum sampler is located in the sample storage

compartment, with exception of the air pump.

) Coupling suction hose

B) Vacuum head

C) PP glass holder

D) Vacuum glass

E) Contact pins

F) Sample volume hose

G) Pincher

H) Pincher nut / bolt

I) Sample drain hose

A

A

B

C

F

E

D

G

G

H

I

Fig. 4.2a

Installation & User Manual - Sampling Systems

Version 140618 UK

Page 19

4.3 Operation principle

The sampling cycle from a vacuum sampler:

•CLOSING PINCHER: the pincher squeezes the silicone hose air

tight.

•PURGE: the air pump starts and generates pressure in the sample

chamber. From the end (inlet) of the suction hose air bubbles will

escape. Which is a sign the ‘old wastewater’ has left the suction

hose.

•SUCTION: the air pump changes rotation and a vacuum is created

inside the sample chamber. Wastewater will be sucked up

through the suction hose until it reaches the level pins. If the pins

aren’t reached within a programmed time (default 30 sec.) the

sampling system will count an error sample and will wait until the

next sample must be taken. fter (default setting 3) error samples

the sampling system will switch in alarm.

•DOSE: The level switch changes the rotation direction of the

pump. This creates pressure in the sample chamber and will blow

the excess volume back through the suction hose. fter a short

period (default 10 sec.) air bubbles escape from the end (inlet) of

the suction hose.

•PINCHER OPEN: the pincher opens and the sample will drop to the

container. fter several seconds the air pump stops and the cycle

is complete. The sampler waits a minimum of 1 minute* (due to

cooling period air pump) till the next automatic sample is taken.

* ll vacuum samplers have a 1 minute pause time between two

taken samples to give the air pump time to rest / cool.

4.4 Installation instructions

Follow the following procedures during installation

•Connect the suction hose to the supplied suction hose coupling.

Feed the hose through the inlet and fasten the gland air tight.

•Mount the end (inlet) of the suction hose on a fixed

representative turbulent point to sample homogeneous

wastewater. Ensure the suction hose is always emerged in the

wastewater / medium.

Fig. 4.4a

Fig. 4.3a

Installation & User Manual - Sampling Systems

Version 140618 UK

Page 20

Keep in mind

•Maximum suction height: 4 meter.

•Maximum suction length: 20 meter.

•void siphons in the suction hose.

•Mount the end (inlet) from the suction hose always downward

and on a lower point than the sample chamber.

4.5 Changing sample volume

With vacuum systems the sample volume is adjustable by the length of

the silicon hose (3 in Fig. 4.5a) inside the vacuum chamber (4). The longer

the hose the smaller the sample volume. Standard sample volume is ± 50

cc. Follow the following procedures to change the sample volume.

• Disconnect power supply.

• Carefully loosen the PP glass holder (2) counter clockwise until the

glass (4) is loose from the vacuum head.

• If necessary remove the white bolt from the pincher to create

more working space.

• Determine the length of the silicon hose (3) (lengthen or shorten).

• Reassemble the parts and connect power supply.

4.6 Maintenance Vacuum samplers

Be aware! Remove power supply, compressed air supply and medium

pressure before maintenance or reparations.

Maintenance and reparations should be done by qualified personnel.

Avoid direct contact with wastewater / medium. Wear protective gloves

during use, maintenance and reparations of the sampler.

Be aware! When removing the sample drain hose from the pincher, the

danger of fingers entering the pincher occurs. This can cause serious

injuries.

Points of attention Vacuum samplers

-Clean the inside of the vacuum chamber.

-Check if the silicone sample hose is intact, replace if necessary.

-Check regularly if the suction hose is clean and intact, replace if

necessary.

-Regularly check the air pump capacity.

-Check if the power supply is 24 ± 0,1VDC.

Afb. 2.5 “Correcte installatie”

Fig. 4.5a

Fig. 4.4b

Table of contents