EFFIKAL RVGP-KS-BKF Series User manual

1

EFFIKAL INTERNATIONAL INC.

143 NORTHPOINTE DRIVE

ORION, MICHIGAN 48359

(248) 370-9554

DO NOT TURN DAMPER MANUALLY WITH OR WITHOUT ELECTRICAL

POWER OR MOTOR DAMAGE WILL OCCUR, USE THE SERVICE SWITCH.

LIMITED 5 YEAR WARRANTY ON MOTORIZED CONTROLLER

LIMITED 25 YEAR WARRANTY AVAILABLE TO HOMEOWNER

SPECIFICATIONS, INSTALLATION INSTRUCTIONS, AND TROUBLESHOOTING GUIDE FOR EFFIKAL AUTOMATIC

VENT DAMPER RVGP-KS-BKF SERIES FOR USE ON LISTED GAS FIRED BOILERS WITH A DRAFT HOOD.

TO THE USER

For continued safe operation, the appliance-device combination should be inspected annually by a qualified service agency. It is

recommended that the homeowner examine all flue product carry areas of the appliance, its vent system, and the damper device,

with particular attention given to deterioration from corrosion or other sources. This examination should be performed prior to and

during each heating season. Also use Exhibit A, page 2 and Final Inspection, page 7.

CAUTION

Install this plug in hole in damper blade on all boilers

equipped with intermittent ignition systems only. DO

NOT install this plug on standing pilot systems. Failure

to follow these instructions can cause nuisance odor

problems and minor property damage due to moisture if

ignored.

RVGP-KS 3/00 ©

•The Effikal RVGP Series Automatic Damper must be

installed by a qualified installing agency in accordance

with the manufacturer’s installation instructions. The

definition of a Qualified Installation Agency is: any indi-

vidual, firm, corporation or company which either in

person or through a representative is engaged in, and

is responsible for, the installation and operation of gas

appliances and automatic vent damper devices, who

is experienced in such work, familiar with all the pre-

cautions required, and has complied with all the

requirements of the authority having jurisdiction. The

qualified installer shall fill in the installer’s name,

address and installation date on the label attached to

the vent damper device.

•Do not negate the action of any existing safety or

operational controls.

•When servicing controls, all wires must be LABELED

prior to disconnection. Wiring errors can cause

improper and dangerous operation.

•Device must be installed by a qualified installer, in

compliance with local codes or the National Fuel Gas

Code (ANSI Z223.1 NFPA 54) and the National

Electric Code (ANSI C1-NFPA 70).

•Device conforms to ANSI Z21.66 and ADDENDA.

CGA and AGA design certified.

•Use only with a listed gas fired boiler equipped with a

draft hood, the outlet area of which is not greater than

the inlet area of the device.

•Install after the boiler draft hood, as close to the draft

hood as practicable, and without modification to the

draft hood or the vent damper.

•Locate in a venting system or section of a venting sys-

tem so that it services only the single boiler for which it

is intended.

•Aminimum clearance of 6 inches (153mm) between

the damper device and combustible construction must

be maintained and that there be provisions for access

and service of the damper device.

•Position indicator and service switch must be accessi-

ble to the user.

•The installer must fill in the label on the side of the

controller cover.

•This device must be installed only on a boiler connect-

ed to a factory built chimney or vent complying with a

recognized standard, or a masonry or concrete chim-

ney lined with a lining material acceptable to the

authority having jurisdiction.

•This vent damper device shall not be installed on an

appliance with an automatic valve having a manual

opener unless the manual opener has been rendered

in-operative or the automatic valve has been replaced

with a redundant automatic valve not equipped with a

manual opener.

WARNING

READ INSTRUCTION BOOKLET CAREFULLY AND COMPLETELY BEFORE PROCEEDING WITH THE INSTALLATION.

NOT FOR

RETROFIT

IN CANADA

2

IMPORTANT

THE STEP-BY-STEP INSPECTION AND INSTALLATION PROCEDURES

AS SPECIFIED IN EXHIBITS A AND B MUST BE FOLLOWED.

THE QUALIFIED INSTALLER MUST FILL IN LABEL ON THE SIDE OF THE CONTROLLER.

EXHIBIT A

PROCEDURE FOR SAFETY INSPECTION OF AN EXISTING APPLIANCE INSTALLATION

The following procedure is intended as a guide to aid in determining that an appliance is properly installed and is in a safe condition for continuing use.

This procedure is predicated on a central furnace, boiler and water heater installations, and it should be recognized that generalized procedures cannot anticipate

all situations. Accordingly, in some cases deviation from this procedure may be necessary to determine safe operation of the equipment.

a. This procedure shall be performed prior to installation of the automatic vent damper device.

b. If it is determined there is a condition which could result in unsafe operation, the appliance should be shut off and the owner advised of the unsafe condi-

tion. Do not install the automatic vent damper device until the unsafe condition has been corrected.

The following steps are to be followed in making the safety inspection:

1. Conduct a gas leakage test of the appliance piping and control system downstream of the valve in the supply line to the appliance.

2. Visually inspect the venting system for proper size, horizontal pitch and vent termination, and determine there is no blockage or restriction, leakage, corro-

sion and other deficiencies which could cause an unsafe condition.

3. Determine that the chimney or vent is acceptable to the authority having jurisdiction.

4. Shut off all gas to the appliance and shut off any other fuel-gas burning appliance within the same room. Use shutoff valve in the supply line to each appli-

ance.

5. Inspect burners and crossovers for blockage and corrosion.

6. Applicable only to furnaces — inspect heat exchanger for cracks, openings or excessive corrosion.

7. Applicable only to boilers — inspect for evidence of water or combustion product leaks.

8. Insofar as is practical, close all building doors and windows and all doors between the space in which the appliance is located and other spaces of the build-

ing. Turn on clothes dryers. Turn on any exhaust fans, such as range hoods and bathroom exhausts, so they will operate at maximum speed. Do not operate

a summer exhaust fan. Close fireplace dampers, If, after completing Steps 9 through 14, it is believed sufficient combustion air is not available, refer to local

codes, or in the absence of local codes, to the NATIONAL FUEL GAS CODE, ANSI Z223.1—1996 (NFPA 54), for guidance.

9. Place in operation the appliance being inspected. Follow the lighting instructions. Adjust thermostat so appliance will operate continuously.

10. Determine that the pilot(s), when provided, is burning properly and that main burner ignition is satisfactory by interrupting and reestablishing the electrical

supply to the appliance in any convenient manner.

If the appliance is equipped with a continuous pilot(s), test the pilot safety device(s) to determine if it is operating properly by extinguishing the pilot(s)

when the main burner(s) is off and determining, after 3 minutes, that the main burner gas does not flow upon a call for heat.

If the appliance is not provided with a pilot(s), test for proper operation of the ignition system in accordance with the appliance manufacturer’s lighting and

operating instructions.

11. (a) Visually determine that main burner gas is burning properly: i.e., no floating, lifting or flashback. Adjust the primary air shutter(s) as required.

(b) If the appliance is equipped with high and low flame controlling or flame modulation, check for proper main burner operation at low flame.

12. Test for spillage at the draft hood relief opening after 5 minutes of main burner operation. Use the flame of a match or candle, or smoke from a cigarette,

cigar or pipe.

13. Turn on all other fuel-burning appliances within the same room so they will operate at their full inputs. Follow lighting instructions for each appliance.

14. Repeat Steps 11 and 12 on the appliance being inspected.

15. Return doors, windows, exhaust fans, fireplace dampers and any other fuel-gas burning appliances to their previous conditions of use.

16. Applicable only to furnaces — Check both the limit control and the fan control for proper operation. Limit control operation can be checked by blocking the

circulating air inlet or temporarily disconnecting the electrical supply to the blower motor and determining that the limit control acts to shut off the main

burner gas.

17. Applicable only to boilers —

(a) Determine that the water pumps are in operating condition.

(b) Test low water cutoffs, automatic feed controls, pressure, and temperature limit controls, and relief valves in accordance with the manufacturer’s rec-

ommendations to determine they are in operating condition.

EXHIBIT B

PROCEDURE FOR INSTALLING ELECTRICALLY OPERATED AUTOMATIC VENT DAMPER DEVICES ON EXISTING APPLIANCES

This procedure is intended as a guide to aid in safely installing an electrically operated automatic vent damper device on an existing appliance.

This procedure is based on the assumption that the history of the specific appliance has been one of safe and satisfactory operation.

This procedure is predicated on central furnace, boiler and water heater installations, and it should be recognized that generalized procedures cannot

anticipate all situations. Accordingly, in some cases deviation from this procedure may be necessary to determine safe operation of the equipment.

The following steps are to be followed in making the modifications:

1. Perform a safety inspection of the existing appliance installation. See Exhibit A for the recommended procedure for such a safety inspection.

2. Shut off all gas and electricity to appliance. To shut off gas use the shutoff valve in the supply line to the appliance.

3. Install the automatic vent damper device in strict accordance with the manufacturer’s installation instructions. Make certain the device is not located

in that portion of the venting system which serves any appliance other than the one for which the damper is installed.

4. Make certain wiring connections are tight and wires are positioned and secured so they will not be able to contact high temperature locations.

5. When an additional automatic valve has been incorporated or an existing gas control replaced, conduct a gas leakage test of the appliance piping

and control system downstream of the shut off valve in the supply line to the appliance.

6. Visually inspect the modified venting system for proper horizontal pitch.

7. (a) The damper must be in full open position before the gas valve(s) opens.

(b) The damper must remain in the full open position while the gas valve(s) is open.

(c) The gas valve(s) must be closed before the damper begins its return to the closed position.

(d) The damper shall remain in the closed position during the off cycle of the appliance.

8. Determine the amperage draw of the gas control circuit and damper device.

(a) Check appliance transformer for adequate capacity.

(b) Check heat anticipator in comfort thermostat to determine it is properly adjusted.

9. Sequence the appliance through at least three normal operating cycles.

10. Insofar as is practical, close all building doors and windows and all doors between the space in which the appliance is located and other spaces of

the building. Turn on clothes dryers. Turn on any exhaust fans, such as range hoods and bathroom exhausts, so they will operate at maximum

speed. Do not operate a summer exhaust fan. Close fireplace dampers.

11. Place appliance in operation. Follow the lighting instructions. Adjust thermostat so appliance will operate continuously.

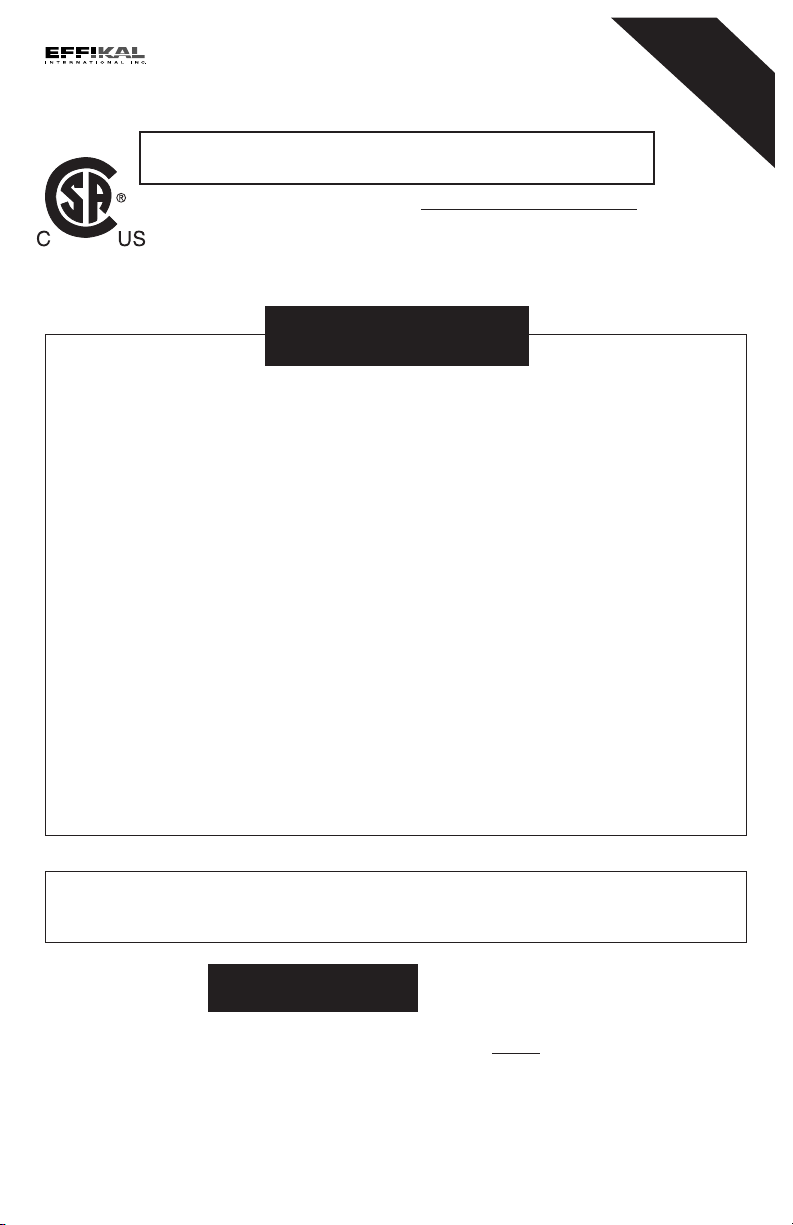

TO INSTALL AN ADDITIONAL GAS VALVE:

a. Shut off the gas and electricity to the gas burner (use the manual

shut off valve in the supply line to the appliance).

b. Locate a position in the supply line between the appliance auto-

matic gas valve and the burner.

c. Both gas valves must terminate the main gas supply to the burn-

er(s). Both gas valves must be piped in series and wired in paral-

lel. See Connection Diagram below.

d. Install an approved appropriately sized single function automatic

gas valve in this location downstream of the existing automatic

gas valve. (Follow the valve manufacturers instructions for flow

directions and position).

e. Restore gas line supply, conduct a leak test on the gas piping and

control system downstream of the appliance shut off valve.

I. INTRODUCTION The Effikal RVGP Series automatic vent damper

was developed to increase the efficiency of boilers by reducing stand-

by losses from the boiler and the conditioned air space. The damper

closes the chimney vent when the burner is off and fully opens it

before the burner is on. The concept is similar to the opening and

closing of a fireplace damper, except the operation is completely auto-

matic. Interlocks have been added, which prevents burner operation

unless the damper is in an open position. A closed damper substan-

tially reduces standby losses on boilers.

II. DESCRIPTION A closed damper prevents residual heat in the boiler

from being drawn up the chimney vent by the chimney’s natural draft.

A closed damper will also prevent conditioned air from being pulled

through the draft hood and up the chimney by the same stack effect, if

it is located within the conditioned space.

When heat is required, the damper rotates to the open position before

the burner circuit is energized. If the damper does not rotate to the

open position, the burner circuit will not be energized. When properly

installed, the electrical circuits in this product are designed not to

override the existing limit and safety controls of the boiler.

III. GENERAL INFORMATION Damper vane and sectional material is

made of stainless steel. Shipping Weight w/Metal Shield Harness.

IV. ELECTRICAL

(MINIMUM WIRING REQUIREMENTS) .........24 VAC, 18 Gauge, 105 C

(THERMOSTAT HEAT ANTICIPATION) ................0.1A PLUS CURRENT

DRAW FOR CONTROL CIRCUIT

(POWER DRAW REQUIREMENT) .......3W AT 24 VAC WHEN OPENING

OR CLOSING

(TIMING) ..........................................................OPENS IN 15 SECONDS

CLOSES IN 15 SECONDS

(CHARACTERISTICS) ......................................................POWER OPEN

POWER CLOSE

V. FEATURES

•SERVICE SWITCH — ELIMINATES NUISANCE CALL BACKS

•FIVE YEAR LIMITED WARRANTY ON MOTORIZED CONTROLLER

FROM DATE OF INSTALLATION.

•25 YEAR LIMITED WARRANTY ON MOTORIZED CONTROLLER

AVAILABLE.

•REDUNDANT INTERLOCK SWITCHES.

•POWER OPEN, POWER CLOSE; EXTENDS PRODUCT LIFE. SELF

CLEANING ACTION.

•24V OPERATION FOR EASY, LOW-COST WIRING.

•SUPPLIED WIRING HARNESS IS COMPATIBLE WITH MANUFAC-

TURERS RECEPTACLE CONFIGURATION.

3

Vent Size RVGP-KS-BKF

43lbs. 6.4 oz.

53lbs. 8.4 oz.

63lbs. 14.4 oz.

74lbs. 6.7 oz.

85lbs. 3.8 oz.

98lbs. 1.5 oz.

10 8 lbs. 12.4 oz.

12 9 lbs. 9.1 oz.

248-370-9554

NOTE: TERMINALS 1, 2 and 3 must be the same polarity

*Add point .1 to Heat Anticipator for vent damper, plus what

is in the circuit.

12. Test for spillage at the draft hood relief opening after 5 minutes of main burner operation. Use the flame of a match or candle, or smoke from a ciga-

rette, cigar or pipe.

13. (a) Visually determine that main burner gas is burning properly: i.e., no floating, lifting or flashback. Adjust the primary air shutter(s) as required.

(b) If the appliance is equipped with high and low flame controlling or flame modulation, check for proper main burner operation at low flame.

14. Determine that the pilot(s), when provided, is burning properly and that main burner ignition is satisfactorily by interrupting and reestablishing the

electrical supply to the appliance in any convenient manner.

If the appliance is equipped with a continuous pilot(s), test the pilot safety device(s) to determine if it is operating properly by extinguishing the pilot(s)

when the main burner(s) is off and determining, after 3 minutes, that the main burner gas does not flow upon or call for heat.

If the appliance is not provided with a pilot(s), test for proper operation of the ignition system in accordance with the appliance manufacturer’s lighting

and operating instructions.

15. Applicable only to furnaces — Check both the limit control and the fan control for proper operation. Limit control operation can be checked by

blocking the circulating air inlet or temporarily disconnecting the electrical supply to the blower motor and determining that the limit control acts to

shut off the main burner gas.

16. Applicable only to boilers —

(a) Determine that the water pumps are in operating condition.

(b) Test low water cutoffs, automatic feed controls, pressure and temperature limit controls, and relief valves in accordance with the manufacturer’s

recommendations to determine they are in operating condition.

17. Label the damper device with information as to:

(a) Name of qualified agency responsible for damper installation.

(b) Date of installation.

For continued safe operation, the homeowner should check all flue product carrying areas of the appliance, its vent system, and the damper device at

least once a year.

Particular attention should be given to the replacement of parts deteriorated by corrosion or other sources. Such replacement must be done by a

qualified installing agency, who shall carry out an annual inspection of the appliance-device combination.

Determine if the appliance has a redundant gas

valve. If it has a redundant gas valve proceed

to install the damper assembly.

WARNING: If the appliance does not have a

redundant gas valve install an additional gas

valve or a redundant gas valve.

4

THE DAMPER MUST BE IN THE OPEN POSITION

BEFORE COMBUSTION TAKES PLACE.

THE DAMPER MUST BE IN THE OPEN POSITION WHEN

THE APPLIANCE MAIN BURNER(S) IS OPERATING.

THE GAS VALVE(S) MUST BE CLOSED BEFORE THE

DAMPER BEGINS ITS RETURN TO THE CLOSED POSI-

TION.

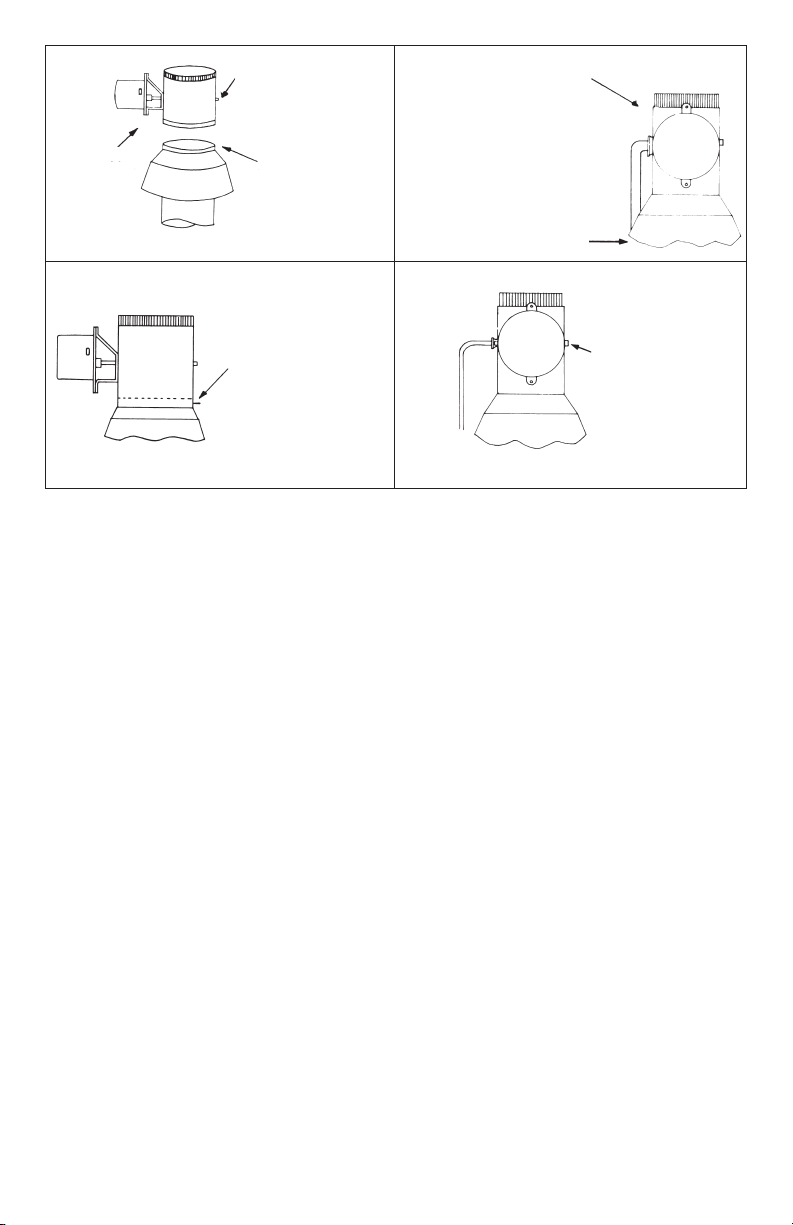

FIGURE 1

INSTALL THE VENT DAMPER TO SERVICE ONLY THE SINGLE

BOILER FOR WHICH IT IS INTENDED. IF IMPROPERLY INSTALLED,

A HAZARDOUS CONDITION, SUCH AS AN EXPLOSION OR CARBON

MONOXIDE POISONING COULD RESULT.

CAUTION: DO NOT INSTALL THE VENT DAMPERS WITHIN 6 IN.

(153mm) OF COMBUSTIBLE MATERIAL.

UNPACKING INSTRUCTIONS

The Effikal RVGP-Series Automatic Gas Vent Damper is

packaged in a single carton containing a stainless steel pipe

assembly, a knock out plug, a motorized controller and

instruction booklet. Inspect for damage prior to the installation.

A wiring harness is required for the installation.

A. The harness may already be attached to the motorized controller per

the boiler manufacturer’s request.

B. The harness may already be attached to the boiler.

C. The harness may be packaged with the vent damper but not attached to

the motorized controller per the boiler manufacturer’s request.

D. A harness may need to be purchased.

EXPLANATION OF MODEL NUMBERS

R=REDUNDANT

V=VALVE

G=GAS

P=PLUG IN AT DAMPER

A=ADAPTER PLATE WITH COUPLING

NUMBER = VENT PIPE SIZE

B=BRUSH THAT PROVIDES A TIGHT SEAL

K=KNOCKOUT FOR STANDING PILOT

F=FLAT ROD IN PIPE ASSEMBLY

KS = CIRCUIT BOARD MODEL

CAUTION

HOW TO INSTALL KNOCKOUT PLUG IN DAMPER BLADE ON GAS FIRED BOILERS

(INTERMITTENT IGNITION SYSTEMS ONLY.)

DO NOT INSTALL KNOCKOUT ON STANDING PILOT SYSTEMS

DO NOT TURN DAMPER MANUALLY – MOTOR DAM-

AGE WILL OCCUR. USE THE SERVICE SWITCH

(SEE FIGURE 6).

The hole in the damper blade provides the minimum vent area required by code for continuous pilot systems. Failure to follow these

instructions can cause nuisance odor problems and minor property damage due to moisture if ignored.

BOILER

*STANDOFF

BRACKET

YES NO

WATER

HEATER

CHIMNEY

ADD .1 TO THE HEAT ANTICIPATOR OF THE ROOM

THERMOSTAT PLUS CURRENT DRAW FOR CONTROL

MODULE.

TYPE A

(CUT-OUT VIEW)

TYPE B

DAMPER BLADE PLACE THE KNOCKOUT

TABS IN THE HOLE

OF THE DAMPER BLADE

HOLD THE KNOCKOUT

AND FOLD THE

FOUR TABS OVER

AB C

1. Remove 2 washers, 1 roundhead slotted

machine screw, and 1 8-32 kep nut from

plastic bag.

2. Place the machine screw through 1 washer.

3. Place damper assembly horizontally.

4. With one hand take the washer and machine

screw and come in from one side of the pipe

assembly UNDER the damper blade.

5. Push the machine screw up through the knock-

out opening.

6. With the other hand take the washer and kep

nut and enter from the opposite side of the

pipe assembly.

7. Place the washer over the machine screw.

8. Put kep nut onto machine screw and hand

tighten.

9. Make sure the knockout opening is totally

covered.

10. Tighten with pliers, adjustable wrench, or

11/32 wrench.

5

HOW TO AVOID NUISANCE NO HEAT CALLS

A. Do not turn damper manually or motor damage will occur. Use the service switch. (See fig. 6)

B. Do not pull on the motorized controller or twist to locate the damper assembly.

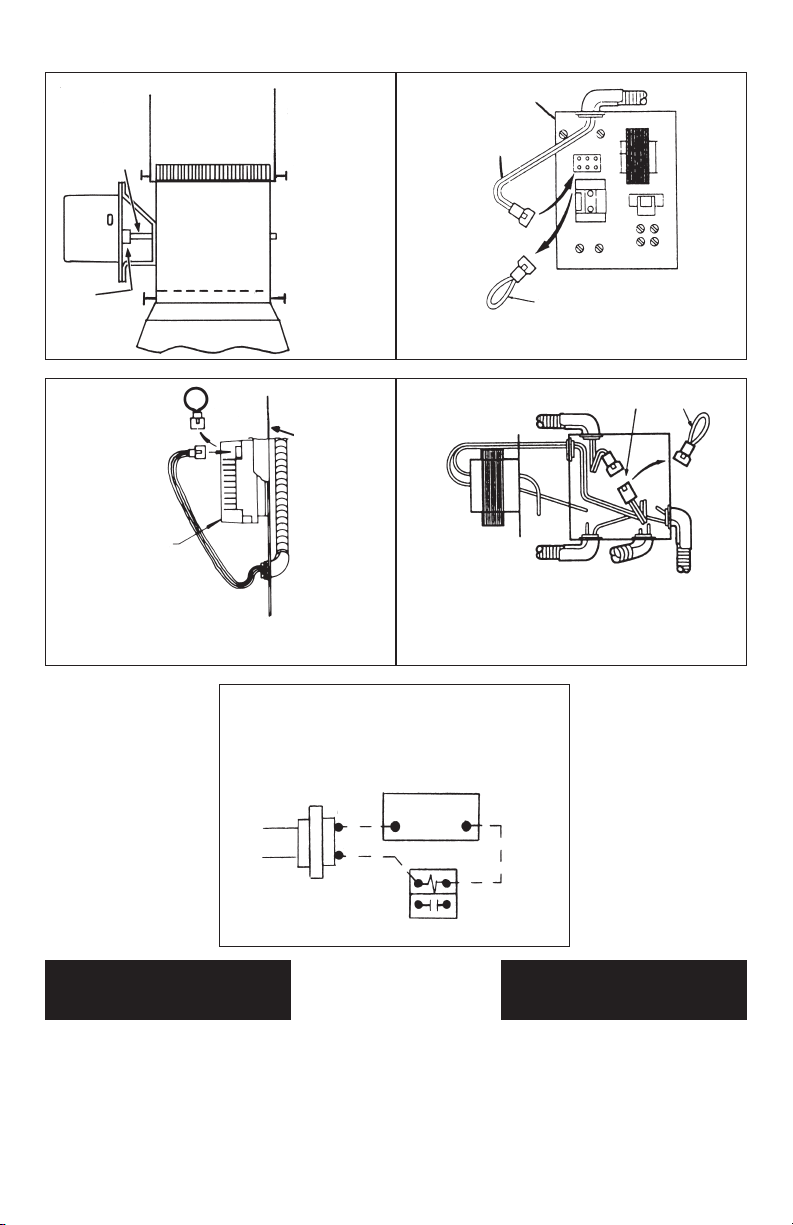

C. If self tapping screws are not sharp enough to penetrate the stainless steel pipe assembly, it may be necessary to drill 3 holes

120 degrees apart at the inlet and outlet of the pipe assembly. This should avoid egg shaping the pipe assembly. (See Fig. 3 & 7)

TO INSTALL THE DAMPER ASSEMBLY

DISCONNECT POWER SUPPLY TO PREVENT ELECTRICAL SHOCK OR EQUIPMENT DAMAGE.

Installer, do not egg shape the pipe during this installation or the shafts from the con-

troller to the pipe will not line up properly. A pipe forced out of round is not covered

under our 5 year warranty program. See figure 3.

Install the damper device after the appliance drafthood, as close to the draft hood as practical, and without modification of either the

draft hood or the vent damper device.

Locate a position in the vent pipe between the drafthood and the chimney for the damper assembly. The vent damper device must

be located in a venting system so that it serves only the single appliance for which it is installed (see Figure 1).

To be used only with an appliance bearing a marking showing the make and

model of the device. Canadian Requirement.

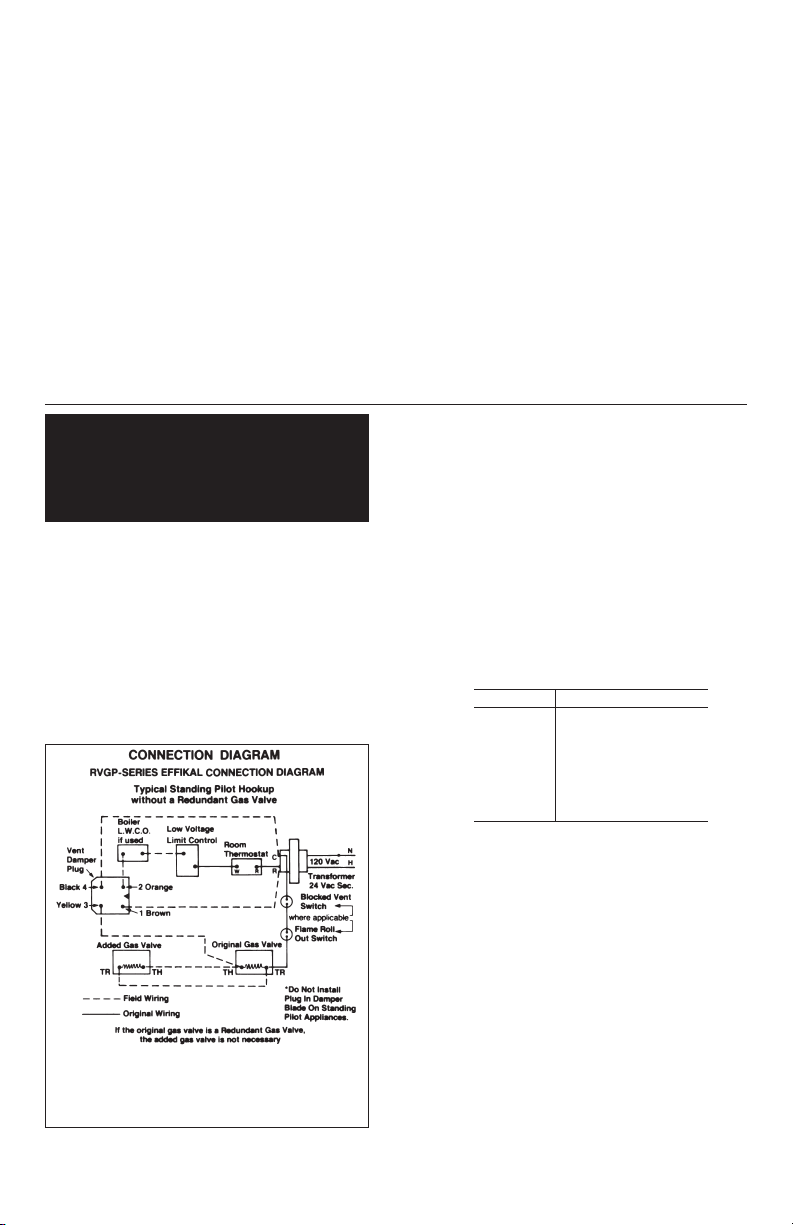

INSTALLING THE VENT DAMPER IN HORIZONTAL AND VERTICAL VENTS:

For vertical vent damper installation, mount the vent damper in any position.

For horizontal vent damper installation, mount the vent damper motorized controller to either side of the vent. See Figure 2.

The vent damper device shall be connected to a chimney or vent complying with a recognized standard, or a masonry or concrete

chimney lined with a lining material acceptable to the enforcing authority.

A minimum clearance of 6 inches (153 mm) between the device and combustible construction must be maintained and that there be

provisions for access and service of the damper device.

To avoid nuisance odor problems, obtain the most radical pitch to the chimney as possible. Remove any appropriate section from

the female end of the vent pipe and reinstall vent pipe and damper assembly. For dimensional data, see Figure 4.

The damper device must be installed in the vent pipe with the

crimped end and directional arrow pointed toward the

chimney, the damper position indicator visible and the

controller unit accessible for wiring. See Figure 5.

The motorized controller is premounted to the stainless steel

pipe assembly. Make sure the controller is secured to the

pipe assembly. The flat rod must be engaged into the slot of

the CAM. This slot protrudes through the base plate of the

controller. See Figures 3 & 7.

The vent damper position indicator is located on the stainless

steel pipe assembly. This is opposite the motorized

controller. The device is equipped with a service switch for

placing the damper in the open position. The service switch is

recessed into the cap of the motorized controller. See Figure

6. It has been appropriately marked hold “open” or

“automatic.” The position indicator and service switch must

be accessible to the user.

Secure the damper assembly at each end to the vent pipe

with three 1/2” sheet metal screws or pop rivets spaced

around the circumference of the vent pipe. If necessary,

provide a suitable hanger to support the damper assembly

independent of the venting system. See Figure 7.

FIGURE 3

BINDING MAY OCCUR

IF THE PIPE BECOMES

EGG-SHAPED.

NUISANCE NO HEAT

CALL MAY OCCUR.

FIGURE 2

CONTROLLER MOUNTING POSITIONS

WHEN INSTALLED IN HORIZONTAL VENT

RVGP-KS-BKF

Top View

CAUTION!

CAUTION

WARNING!

DON NOT PULL ON CONTROLLER

TO POSITION DAMPER OR

‘BINDING MAY OCCUR

DISENGAUGEMENT

MAY OCCUR IF

THE PIPE ASSEMBLY

BECOMES EGG-SHAPED.

1:00 O’clock

Mountng

Range

5:00 O’clock

11:00 O’clock

Avoids excessive heat

Mountng

Range

Avoids condensation

7:00 O’clock

6

PLUG IN APPLICATIONS:

For plug in applications, locate the vent damper receptacle

on the appliance per the manufacturers instructions and

follow accordingly. For additional plug in connections see

Figure 8, 9, & 10.

When the harness is not attached to the motorized

controller. The harness must be routed through the conduit

bracket. Place the harness receptacle into the damper

plug. Then securely fasten the harness to the conduit

bracket. See Figure 6.

The RVGP-KS series damper must be electrically

connected with all automatic gas valves in the system.

Ensure all connections are tight and that wires cannot

touch hot surfaces. If necessary, use standoff brackets.

See Figure 1.

When the harness is used the jumper must be removed

from the receptacle before the harness plug can be

connected to the appliance.

Once the vent damper is plugged into the control system

and operated through one complete cycle, the control

circuit will operate only when the vent damper is in the

control circuit. Plug in type controls with internal fuses.

All electrical work and material used in the installation shall

be in accordance with local electrical codes in absence of

codes consult the National Electrical Code.

To protect the thermostat heat anticipator turn off the

appliance power supply before proceeding with the wiring.

MICROPROCESSOR THERMOSTATS:

An isolation relay is required when a microprocessor based

thermostat is connected electrically to the vent damper.

This primarily occurs with steam boilers and forced air

furnaces. When the vent damper is energized to open a

voltage drop occurs for 15 seconds which does not allow

the thermostat to rob power to maintain the program.

Thermostat battery life is reduced. When the battery runs

down, erratic cycling may occur. For typical hook up of an

isolation relay, see Figure 11.

The vent damper operates on 24 VAC Systems only. Do

not install if the system operates off 120 VAC or

millivoltage to avoid possible damage to the system and

system shut down.

Do not use the Effikal Dampers with Honeywell L8148 or

L8124 with man/auto switch because the switch can

override the safety interlocks in the system wiring, causing

a hazardous condition.

All wiring from the EFFIKAL RVGP-Series gas vent

damper controller shall be routed clear of mechanical injury

and high temperature locations as directly as possible

along building construction or the gas fuel line to the gas

burner controls. Secure with insulated staples, wire ties,

stand off brackets or tape as required. Make sure all the

wiring connections are neat and tight, and done in a

workmanlike manner.

FIGURE 5

FIGURE 6

FIGURE 4 CAUTION

WIRING

CAUTION

WARNING

EFFIKAL

RVGP-KS

Controller

Pipe

Assembly

D

A

C

E

B

DIM. A

TUBE SIZE

DIM. B

LENGTH

DIM. C

TOTAL HEIGHT

DIM. D DIM. E

4” 6” 95⁄8”15/16” 43⁄4”

5” 6” 105⁄8”15/16” 43⁄4”

6” 61⁄2”11

5⁄8”1

1⁄8”5

1⁄4”

7” 7-1/16” 125⁄8”1

3⁄8”5

3⁄4”

8” 8-1/16” 135⁄8”1

7⁄8”6-13/16”

9” 101⁄8”14

5⁄8”2

7⁄8”8

7⁄8”

10” 121⁄8”15

5⁄8”3

7⁄8”10

7⁄8”

12” 121⁄8”17

5⁄8”3

7⁄8”10

7⁄8”

FLUE GAS

FLOW DIRECTION

ARROW POINTS UP

MOUNT VENT

DAMPER OVER

DRAFTHOOD

MAKE SURE

MOTOR IS

LOCATED SO

THAT WIRE

HARNESS WILL

REACH APPLIANCE

RECEPTACLE

SERVICE SWITCH

MUST BE TO THE

CORRECT POSITION

FOR AUTOMATIC

OPERATION

AUTOMATIC

OPERATION

OR

HOLD

OPEN

RVGP-KS-BKF

ATTACH

HARNESS TO

CONDUIT

BRACKET

7

FIGURE 7

SECURE WITH

POP RIVETS

OR SCREWS

3 IN EACH

JOINT 120°

APART

FIGURE 8

INTERMITTENT CIRCULATION VENT

DAMPER CONNECTIONS

FIGURE 11

FIGURE 9

OUTSIDE

BOILER

JACKET

PANEL

ELECTRONIC

IGNITION VENT DAMPER CONNECTIONS

FIGURE 10

JUNCTION BOX CONNECTION -

CONTINUOUS OR GRAVITY

CIRCULATION WITH VENT DAMPER

FINAL INSPECTION

The service switch must be in the automatic position. See Figure 6.

Check the operation of the automatic damper 3 times with the boiler operating controls for proper sequence.

The damper must be in the open position before combustion takes place.

The damper must be in the open position when the appliance main burner(s) is operating.

The gas valve(s) must be closed before the damper begins its return to the closed position.

PERFORM TEST PROCEDURE OF EXHIBITS A & B.

WARNING WARNING

FLAT ROD

CAM JUMPER

(REMOVE AND DISCARD WHEN

CONNECTING VENT DAMPER)

L8148E OR L8124E

CONTROL

WIRING

HARNESS

IGNITION

MODULE

CONNECT

HARNESS

REMOVE

PLUG

TO CIRCULATOR

(IF USED)

TO CONTROL

TO GAS

VALVE

REMOVE

PLUG

CONNECT

HARNESS

TO DAMPER

DRY CONTACTS ACTS AS THERMOSTAT

ISOLATION

RELAY

MICROPROCESSOR THERMOSTAT

Typical Hookup

Isolation Relay

24 VAC

TRANSFORMER

W

R

R

C

8

NOTICE TO CONTRACTOR

UPON COMPLETION OF THE EFFIKAL DAMPER INSTALLATION, FILL IN THE

INFORMATION INDICATED BELOW AND LEAVE THIS INSTRUCTION BOOKLET

WITH THE HOMEOWNER.

INSTALLER: ____________________________________________________________

ADDRESS: _____________________________________________________________

PHONE NUMBER: _______________________________________________________

DATE INSTALLED:_______________________________________________________

DAMPER SERIAL NO.:____________________________________________________

122222222223

4 5

4 5

4 5

4 5

4 5

4 5

4 5

4 5

4 5

4 5

4 5

677777777778

• SEE AVAILABLE 25 YEAR WARRANTY ON FOLLOWING PAGE •

LIMITED WARRANTY

EFFIKAL

Effikal International Inc. will repair or replace, free of charge, any of its

motorized controllers which fail within five (5) years from date of original

installation due to a result of faulty design, workmanship or materials. Effikal

International Inc. will not be responsible for labor or service charges inciden-

tal to the removal and replacement of a defective part. Replacements for

material claimed defective are subject to adjustment after material claimed

defective has been returned to Effikal International Inc. by prepaid trans-

portation for inspection. This warranty does not extend to failures occurring

because of damage incurred in or resulting from shipment or accident in

transit, improper installation, alteration, abnormal use, defective repair, or

exposure to abnormal environment. There are no warranties of either mer-

chantability or fitness for a particular purpose, Effikal International Inc

assumes no liability for consequential damages, loss of goodwill, production,

income or labor in replacing defective products, which result from use or

misuse of its products.

This warranty gives you specific legal rights, and you may also have other

rights which vary from state to state. Some states do not allow limitations on

how long an implied warranty lasts, and some states do not allow the exclu-

sion or limitation of incidental or consequential damages, so the above limi-

tations or exclusions may not apply to you.

Inquiries to the manufacturer concerning this warranty should be directed to:

EFFIKAL INTERNATIONAL INC.

143 NORTHPOINTE DRIVE, ORION, MICHIGAN 48359

ATTN: RETURN GOODS/WARRANTY DEPARTMENT

For prompt and efficient response, the Effikal owner should apply for war-

ranty claims via written notice, to the representative or dealer selling the

product.

9

Registration #____________

Name ___________________________________________________________

Street ___________________________________________________________

City ________________________________ State _________ ZIP _________

Phone __(_____) _____________________

Type of heating appliance: (Check one)

■■Hot Water Boiler ■■Steam Boiler ■■Furnace

Effikal Information

Number of Effikals Series No.(s)

Installed at this address _____________ (outside cap)_______________

Installed by _______________________________________________________

Address__________________________________________________________

Phone __(_____) _____________________

I am interested in the “25 YEAR-LIMITED-LIFETIME WARRANTY.”

I understand that the $100.00 registration fee is per installed Effikal unit.

This is good only for original homeowner (purchaser) at the original address of

installation.

a $100.00 registration fee per Effikal unit installed is enclosed:

■■YES ■■NO

Signature ______________________________________ Date ____________

NOTE: Only the HOMEOWNER may apply for this guarantee.

LIMITED WARRANTY

Effikal International Inc. will replace, free of charge, any of its controllers which fail within twenty-five (25) years from date of original installation due to a result of faulty design, workmanship or materials. Effikal

International Inc. will not be responsible for labor or service charges incidental to the removal and replacement of a defective part. Replacements for material claimed defective are subject to adjustment after

material claimed defective has been returned to Effikal by prepaid transportation for inspection. This warranty does not extend to failures occurring because of damage incurred in or resulting from shipment or

accident in transit, improper installation, alteration, abnormal use, defective repair, or exposure to abnormal environment. There are no warranties of either merchantability or fitness for a particular purpose,

Effikal International Inc. assumes no liability for consequential damages, loss of goodwill, production, income or labor in replacing defective products, which result from use or misuse of its products.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state. Some states do not allow limitations on how long an implied warranty lasts, and some states do not

allow the exclusion or limitation of incidental or consequential damages, so the above limitations or exclusions may not apply to you.

Inquiries to the manufacturer concerning this warranty should be directed to:

EFFIKAL INTERNATIONAL INC., 143 Northpointe Drive, Orion, Michigan 48359, Attn: Return Goods/Warranty Department

For prompt and efficient response, the Effikal owner should apply for warranty claims via written notice to the representative or dealer selling the product.

DEAR EFFIKAL CUSTOMER,

Your Installer has already made you aware that Effikal International Inc., the manufacturer of the Effikal

Automatic Damper System, offers a “25 year Limited Lifetime Warranty” on all Effikal parts.

The Effikal Damper already comes with a 5 year warranty on parts, which no other electric damper offers. This

new offer is supplemental to the original automatic 5 year warranty. This does not mean that 25 years will be

added to the original 5 year warranty, but instead, the customer is purchasing a total package of 25 years from

date of purchase. We feel our damper will maintain its quality under normal conditions, and that it will last the

life of your furnace or boiler.

This warranty applies only to residential gas users, sizes four (4) through eight (8) inch of the RVGP series

dampers.

The administration of this kind of program is very costly. That is the reason we ask for a $100.00 registration

fee per installed Effikal unit. This fee entitles you to a registration number, which will create an efficient

system, that should be easy for you to use, in case of a claim.

In order to participate in this program, the following conditions must be met:

1. The form must be filled out and returned to Effikal International Inc., 143 Northpointe Drive, Orion, Michigan

48359

2. A $100.00 registration fee (money order or personal check made payable to EFFIKAL INTERNATIONAL

INC.) has to accompany the forms.

3. Registration must be submitted to Factory within 90 days from the date of installation.

After this has been completed, Effikal International Inc. will return the original form with a registration number.

This registration number entitles you to repair or replacement of the unit. Only controllers are included in this

warranty. Any service call must be paid by the homeowner. The manufacturer reserves the right to either repair

or replace the unit, depending on the condition and age of the unit.

Any unit sent to the factory will be sent back to the homeowner in the same “condition” it was received. This

means that the unit may not be updated if changes had been made since the original purchase.

This warranty is extended to only one homeowner, and at the original address of installation. If the original

owner sells his/her home the warranty cannot be extended to the new owner.

CLIP HERE AND MAIL

10

FIGURE A

S´ASSURER QUE

LE MOTEUR EST

EN POSITION

TELLE QUE LE

CABLAGE POURRA

ATTEINDRE

LE COFFRET

ELECTRIQUE DE

L´APPAREIL.

MONTER LE

VOLET DE

VENTILATION

SUR LA PARTIE

SUPÉRIEURE DU

COUPE TIRAGE.

LA FLÊCHE INDIQUE

LA DIRECTION DE

CIRCULATION

DES GAZ

FIGURE C

SI NON PRE-CABLE, BRANCHER LA BOITE

MOLEX DU CABLAGE DANS LA PRISE SITUÉE

A L´INTERIEUR DU CARTER MOTEUR.

MODELE RVGP-KS-BKF

PRISE MOLEX MONTEE EXTERIEUREMENT.

CABLAGE DU VOLET DE VENTILATION.

L´INTERRUPTEUR

DE COMMANDE

DOIT ÊTRE DANS LA

BONNE POSITION

POUR OBTENIR

UNE MARCHE

AUTOMATIQUE.

FIGURE D

RVGP-KS-BKF

FIXER LA PARTIE

INFÉRIEURE DU

CORPS DU VOLET DE

VENTILATION AVEC

DES VIS DE 12MM OU

MOINS OÙ BIEN AVEC

DES RIVETS POP.

FIGURE B

TOUS MODELES

A. Monter le volet de ventilation sur le coupe-tirage de

l´appareil aussi près que possible du coupe-tirage et sans

modifier ni le coupe-tirage ni le volet de ventilation.

B. Ce volet de ventilation doit étre positionné dans un

système de mise à l´air libre de manière a ce qu´il ne serve

seulement l´appareil pour lequel il a été prévu.

C. Monter le corps du volet de ventilation sur la chaudière

en suivant les instructions du fabricant.

D.

L´indicateur de position du volet est a l´opposé du contrôleur

motorisé. Ce dispositif est equipé avec un interrupteur

de commande pour mettre le volet en position ouverte.

Cet interrupteur dépasse du couvercle du contrôleur

motorisé. Les indications « OUVERT » ou « FERME »

sont clairement marquées. L’indicateur de position ainsi

que l’interrupteur dovient être facilement accessibles

par l’utilisateur.

E. Il devar être prévu une distance minimum de 153mm entre

loute construction inflammable et le volet de ventilation

ainsi que des possibilitiés d’accès pour l’entretien.

F. ATTENTION! A ètre utilisé uniquement avec un appareil

indiquant la marque et le modèle de ce dispositif.

L’appareil sera relié à une cheminée ou une mise à l’air

libre conforme à une norme reconnue où à une cheminée

en ciment où en maçonnerie avec un recouvrement

intérieur acceptable par les autorités responsables.

ATTENTION ! Ce dispositif doit être installé par un

installateur qualifié se conformant aux instructions

d’installation préconisées par le fabricant. Une installation

incorrecte pourrait présenter des danger tels que

explosion où d’empoisonnement par l’oxyde de carbone.

AVERTISSEMENT ! Installeur, ne pas déformer le

tuyau pendant l’installlation, les axes du contrôleur au

tuyau risqeuraient de ne pas être alignés. Un tuyau

déformé n’est pas couvert par notre garantie de 5 ans.

G. Ajouter 0-1 a l’anticipateur de température de la piéce

plus le courant nécessaire au module de contrôle.

H. Le volet doit étre en position ouverte lorsque le brûleur de

l’appareil est en marche.

I. Pour mettre le volet en position pleine ouverture. Mettre

l’interrupteur de commande en position maintien ouverte.

L’interrupteur de commande dépasse du bouchon du

contrôleur motorisé du volet de ventilation. Vérifier la

position du volet en regardant l’indicateur de position

situe à l’opposé du contrôleur motorisé.

LE VOLET DE VENTILATION DOIT ETRE OUVERT POUR QUE LA COMBUSTION SE PRODUISE.

11

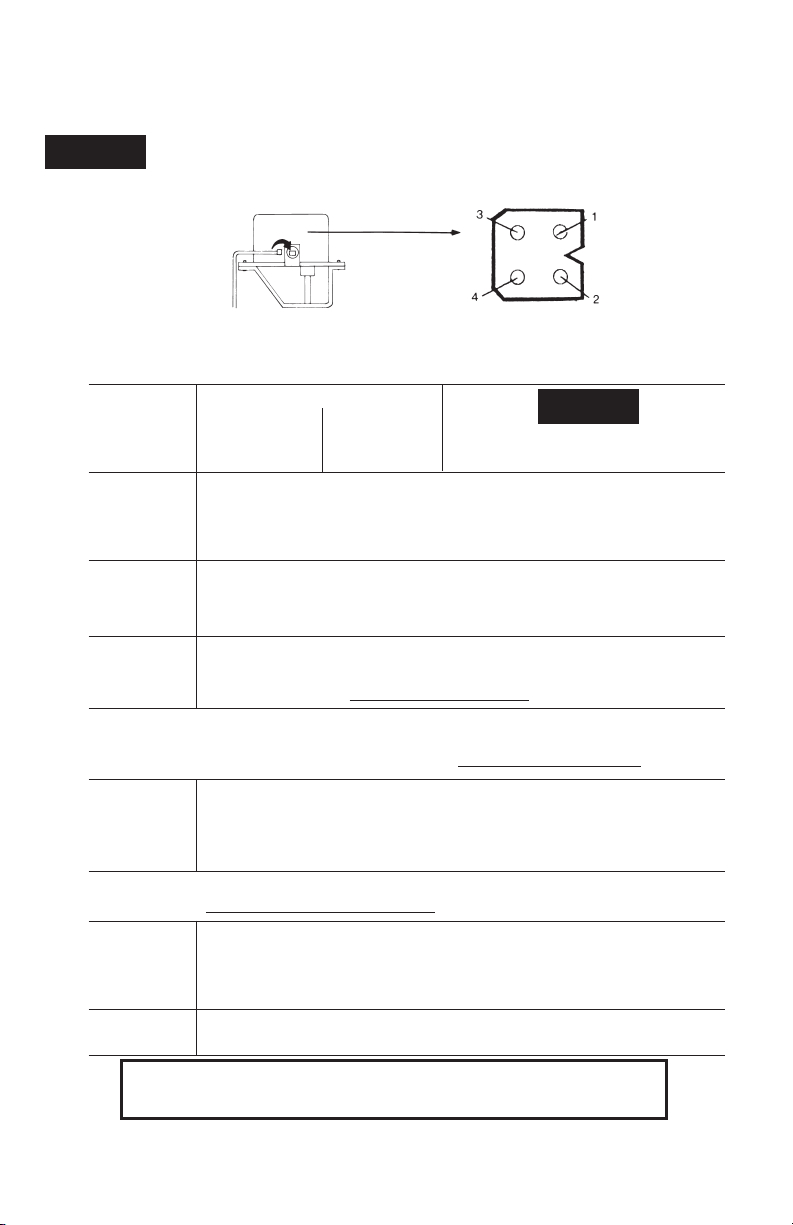

BOUCHON DU

VOLET EXTERIEUR

(VUE EXTRA MITE BROCHE)

ARRIVEE CABLAGE SUR VOLET

24 volts alt

COMMUN

SORTIE

SIGNAL

ENTREE SIGNAL

ARRIVEE 24 volts alt

1

2

3

4

RVGP-KS-BKF

TOUTES LES LECTURES SONT PRISES DE LA BOITE DE CABLAGE. NE PAS POUSSER

LES CONDUCTEURS DANS LA BOITE DE CABLAGE. CELA OUVRE LES FICHES ET FOSERA DES PROBLEMES DE CONTACT!

24 volts alt

COURANT

4 & 1

4 & 2

4 & 3

TOUT LE TEMPS

LORS DE DEMANDE DE CHALEUR

PENDANT COMBUSTION

OUVERT OU FERME

OUVERT OU EN COURS D´OUVERTURE

VOLET OUVERT

SEQUENCE DE L´OPERATION

NE PAS ANNULER L´ACTION DE TOUTE

COMMANDE DE SECURITE OU DE

FONCTIONNEMENT PRESENTE.

AVERTISSEMENT

PAS DE COURANT

4 & 1

LA POSITION 4 EST COMMUNE LA POSITION

1. MAUVAIS REGLAGE

2..TRANFORMATEUR DEFECTUEUX

3. FIL CASSE OU DESSERRE

1 EST ALIMENTEE 24 VOLTS ALT

4. FUSIBLE SAUTE OU DISJONCTEUR DISJONCTE

5. INTERRUPTEUR PRINCIPAL POSITION ARRET

6. CABLAGE NON BRANCHE DANS COFFRET DE L´APPAREIL

PAS DE COURANT

4 & 2

COURANT

4 & 1

1. LE THERMOSTAT N’A PAS DEMANDE DE CHALEUR

2. ANTICIPATEUR DE CHALEUR GRILLE

3. FIL CASSE OU DESSERRE

4. MAUVAIS REGLAGE, NIVEAU OU PRESSION

CONTROLE EAU INTERROMPU

5. INTERRUPTEUR MARCHE ARRET OBSTRUCTION

ORIFICE AERATION, OU RETOUR DE FLAMME

COURANT EN

4 & 1

4 & 2 SUR

VOLET OUVERT

ATTENTION POUR DIAGNOSTIC SEULEMENT. S´ASSURER QUE LE VOLET EST EN POSITION OUVERTE. UTILISER

L´INTERRUPTEUR DE COMMANDE POUR MAINTENIR LE VOLET EN POSITION OUVERTE. RELIER 2 & 3, SI L´APPAREIL

DEMARRE SEPARER 2 & 3 AINSI QUE LA PRISE A L´ARRIERE DU VOLET. SI L´APPAREIL NE DEMARRE PAS, REM-

PLACER LE CONTROLEUR DU VOLET. NE PAS REMPLACER L´ENSEMBLE DU TUBE.

SI UN CONTROLLER DE VOLET N´EST PAS DISPONIBLE, METTRE L´INTERRUPTEUR DE COMMANDE EN POSITION MAINTIEN OUVER-

TURE. CECI DEVRAIT MAINTENIR LE VOLET EN POSITION OUVERTE ET PERMETTRE A L´UTILISATEUR D´OBTENIR DE LA CHALEUR EN

AUTOMATIQUE. RENVOYER OU REMPLACER LE CONTROLEUR CELUI CI EST COUVERT PAR UNE GARANTIE DE 5 ANS A PARTIR DE LA

DATE D´INSTALLATION ORIGINALE. L´ENSEMBLE DU TUBE NE SERA PAS PRIS EN GARANTIE.

COURANT EN

4 & 1

4 & 2

4 & 3

VOLET OUVERT

PAS DE

COMBUSTION

1. VERIFIER QUE L´ARRIVEE DE GAZ EST OUVERTE

2. INTERRUPTEUR DE NIVEAU D’EAU,

INTERRUPTEUR DE SECURITE DE RETOUR D’AIR

CHAUD, INTERRUPTEUR DE RETOUR DE FLAMME

3. FIL CASSE OU DESSERRE

4. PIECE DEFECTUEUSE DANS L´APPAREIL EN AVAL

DU VOLET

LE VOLET TOURNE

CONTINUELLEMENT

REMPLACER LE CONTROLLEUR DU VOLET

NE PAS REMPLACER L´ENSEMBLE COMPLET

VOLET

GRIPPE

1. VERIFIER QUE DES VIS N´EMPECHENT PAS LE FONCTIONNEMENT

2. S´ASSURER QUE L´ENSEMBLE TUBE N´EST PAS DEFORME PAR L´ORIFICE D´AERATION OU PAR LA CHEMINEE

3. S´ASSURER QUE L´EXTREMITE RESSERREE DE L´ORIFICE D´AERATION N´EST PAS TROP ENFONCEE ET

EMPECHE LE MOUVEMENT DU VOLET

NOTA IMPORTANT LE VOLET DOIT ETRE EN POSITION OUVERTE AVANT LE COMMENCEMENT DE LA COMBUSTION

MODELE BRANCHABLE VOLET DE VENTILATION EFFIKAL RVGP DIAGNOSTIC DES PANNES

AVANT DE FAIRE L´ENTRETIEN DES COMMANDES, ETIQUETER TOUS LES FILS AVANT DE LES DEBRANCHER.

DES ERRBURS DE CABLAGE PEUVENT CAUSER UN FONCTIONNEMENT INEFFICACE ET DANGEREUX.

ATTENTION!

NE PAS OUVRIR LE VOLET MANUELLEMENT CAR LE MOTEUR SERA ENDOMMAGE. UTILISER L´INTERRUPTEUR DE

COMMANDE POUR BY-PASSER DISPOSITIF.

12

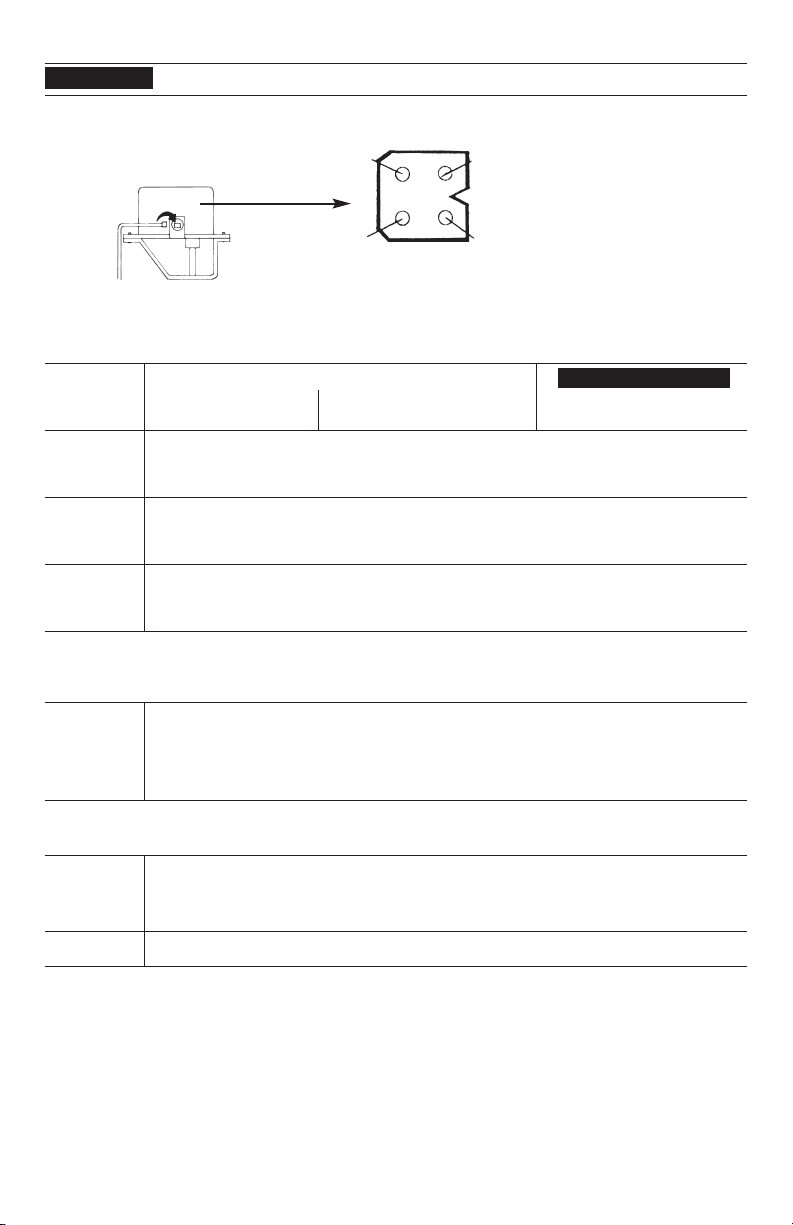

THIS IS NOT A WIRING DIAGRAM.

REFER TO PAGE 3 FOR WIRING DIAGRAM

PLUG-IN MODEL EFFIKAL RVGP SERIES TROUBLE SHOOTING GUIDE

VERIFY SAFE AND PROPER OPERATION

BEFORE LEAVING THE JOB SITE.

DO NOT CUT

PLUG OFF

OF DAMPER

CONTROLLER

OR WARRANTY

WILL BE VOID. PIN END VIEW

HARNESS RECEPTACLE

SIGNAL

OUT

External Damper Plug

All readings are taken from harness receptacle.

Do not push meter leads into harness receptacle. This opens the pins and will create connection problems!

RVGP-KS-BKF

CAUTION

WARNING

WHEN SERVICING CONTROLS ALL WIRES MUST BE LABELED PRIOR TO DISCONNECTION.

WIRING ERRORS CAN CAUSE IMPROPER AND DANGEROUS OPERATION.

Do not turn damper open manually or motor damage will result, use the service switch.

24VAC

COMMON

SIGNAL

IN

24VAC

HOT

IMPORTANT DAMPER MUST BE OPEN BEFORE COMBUSTION TAKES PLACE

If all steps have been tried and vent damper problems persist, call 248-370-9554

24 V.A.C.

POWER

4 & 1 All Times Open or Closed

4 & 2 Calling for Heat Open or Opening Do not negate the action of any

4 & 3 During Combustion Damper Open existing safety or operational controls

POSITION 4 IS COMMON POSITION 1 IS HOT 24VAC

NO POWER 1. Off on limit (120 VAC) 5. Disconnect switch off

4 & 1 2. Bad Transformer 6. Harness not plugged into appliance

3. Loose or broken connections Receptacle

4. Blown fuse or circuit breaker

NO POWER 1. Thermostat not calling for heat 4. Off On Operating limit, pressure

4 & 2 2. Burned out heat anticipator control or low water cut off.

POWER ON 3. Loose or broken connections 5. Off On blocked vent switch or flame

4 & 1 Roll out

POWER ON 1. Check to make sure gas is on 3. Loose or broken connections

4 & 1 2. Off on low water cut off, blocked vent 4. Defective component in appliance after

4 & 2 switch or flame roll out switch the vent damper

4 & 3 WHEN JUMPER IS IN PLACE — FOR TROUBLE SHOOTING ONLY

1. Make sure no screws are obstructing damper blade 4. For additional information see page 5.

2. Make sure damper pipe assembly is not egg shaped

caused by the vent pipe or chimney opening

3. Make sure the crimped end of the vent pipe is not

shoved in so far to obstruct the damper blade

POWER ON

4 & 1

4 & 2

DAMPER OPEN

DAMPER OPEN

NO COMBUSTION

If a damper controller is not available place the service switch in the hold open position. This should keep the damper in

the open position and allow the customer to have automatic heat. Return or replace the controller at your convenience. The

controller carries a 5 year warranty from the original date of installation. Pipe assembly will not be warranted.

WARNING for trouble shooting only. Make sure damper is in the open position. Use the service

switch to keep the damper in the open position. Place a jumper between 2 & 3 if the appliance

fires remove jumper & plug receptacle back into damper controller plug. If appliance does not fire

replace damper controller. Do not replace the pipe assembly.

NORMAL SEQUENCE OF OPERATION

DAMPER ROTATES

CONTINUOUSLY

DAMPER

STICKS

Change the damper controller

Do not change the entire damper assembly

DO NOT REPLACE THE ENTIRE DAMPER ASSEMBLY –

REPLACE ONLY THE MOTORIZED CONTROLLER.

Table of contents