Table of contents

ii M1890721_en | Installation and operating instructions Pellet suction system RS 4 / RS 8

1 General ......................................................................................................................................................... 4

2 Safety............................................................................................................................................................ 5

2.1 Hazard levels of warnings..................................................................................................................... 5

2.2 Permitted uses...................................................................................................................................... 6

2.2.1 Permitted fuels........................................................................................................................... 6

2.3 Qualification of assembly staff .............................................................................................................. 7

2.4 Personal protective equipment for assembly staff ................................................................................ 7

2.5 Qualification of operating staff .............................................................................................................. 7

2.6 Protective equipment for operating staff ............................................................................................... 8

2.7 Design information................................................................................................................................ 8

2.7.1 Standards................................................................................................................................... 8

2.7.2 Requirements at the installation site.......................................................................................... 9

3 Technical information ................................................................................................................................. 10

3.1 Dimensions and recommended distances............................................................................................ 10

4 Store layout and construction.................................................................................................................... 12

4.1 Size of store space ............................................................................................................................... 13

4.2 Buffer mat ............................................................................................................................................. 13

4.3 Planking on the store door.................................................................................................................... 14

4.4 Sloping floor.......................................................................................................................................... 14

4.5 Filling couplings .................................................................................................................................... 15

4.5.1 Position within the store............................................................................................................. 15

4.5.2 Installing the filling couplings ..................................................................................................... 16

4.6 Probe distribution with four suction probes........................................................................................... 17

4.6.1 Store size up to 4m²................................................................................................................... 17

4.6.2 Store size from 4 m²................................................................................................................... 18

4.7 Probe distribution with eight suction probes ......................................................................................... 19

4.7.1 Store size up to 8 m².................................................................................................................. 19

4.7.2 Store size from 8 m²................................................................................................................... 19

4.8 Store pyramids (optional)...................................................................................................................... 20

5 Assembly...................................................................................................................................................... 21

5.1 Materials supplied - RS 4...................................................................................................................... 21

5.2 Materials supplied – RS8...................................................................................................................... 22

5.3 Transport .............................................................................................................................................. 23

5.4 Temporary storage ............................................................................................................................... 23

5.5 Correct assembly position .................................................................................................................... 23

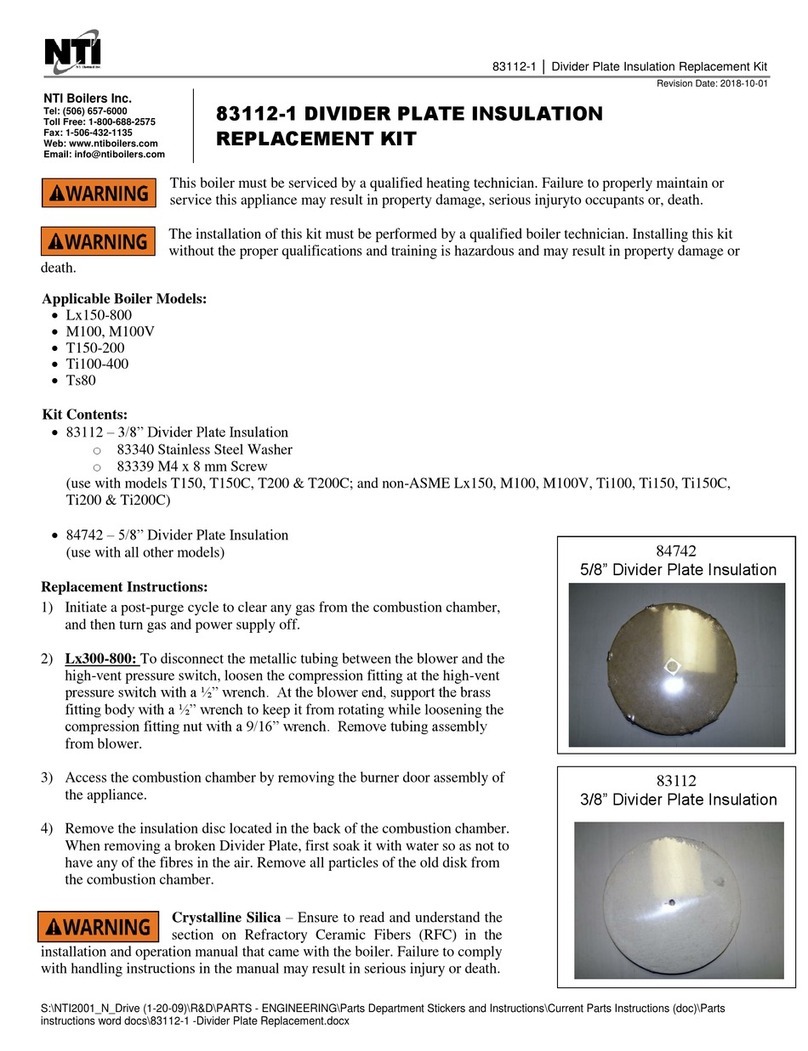

5.6 Fitting the fire protection package......................................................................................................... 24

5.7 Installing the RS 4 pellet suction system .............................................................................................. 27

5.8 Installing the RS 8 pellet suction system .............................................................................................. 28

5.9 Installing the suction probes and lines.................................................................................................. 29

5.10 Sealing the fire protection panels (for fire protection package) ............................................................ 30

5.11 Hose feed-through to boiler room (depending on model)..................................................................... 31

5.11.1 Installing the fire protection collar in the boiler room.................................................................. 31

5.12 Installing fuel store pyramid(s) (optional).............................................................................................. 31

5.13 Assembly information for hose lines..................................................................................................... 32

5.13.1 Potential equalisation................................................................................................................. 33

5.14 Installation information for hose clips (optional).................................................................................... 34

5.15 Electrical connection............................................................................................................................. 34