MIURA_CONFIDENTIAL

No. S836-583-8110

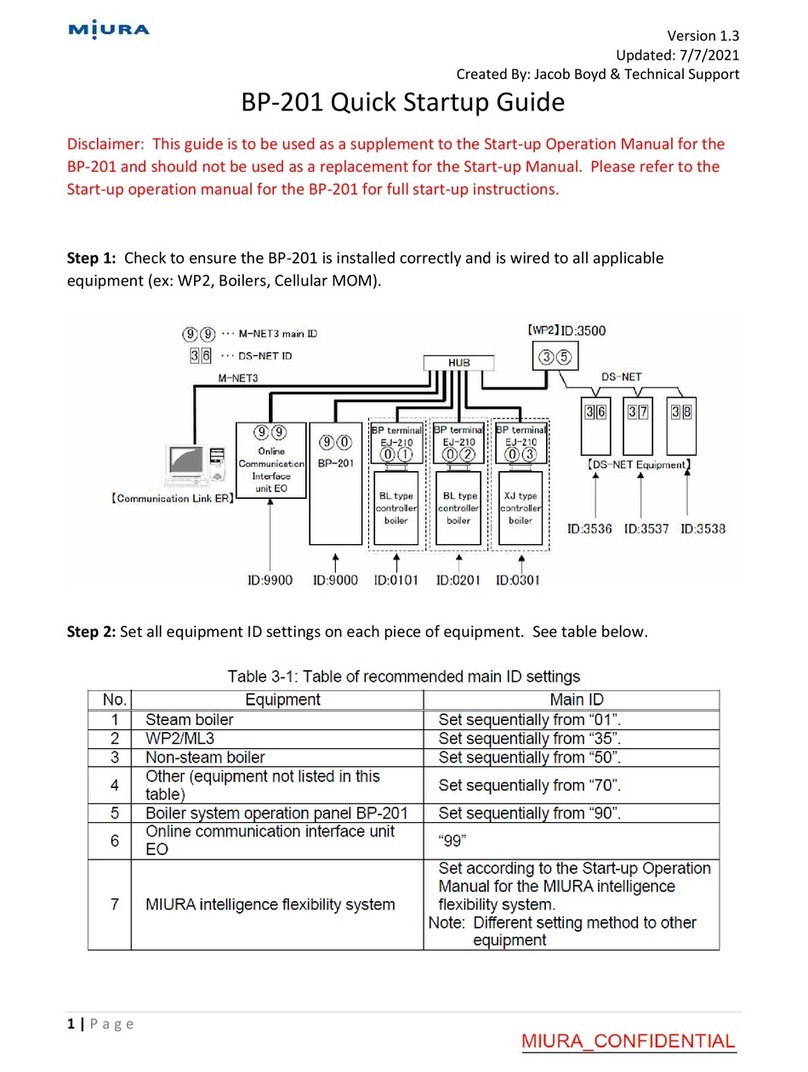

5.1.1 Communication ID Settings for the Control Board......................... 21

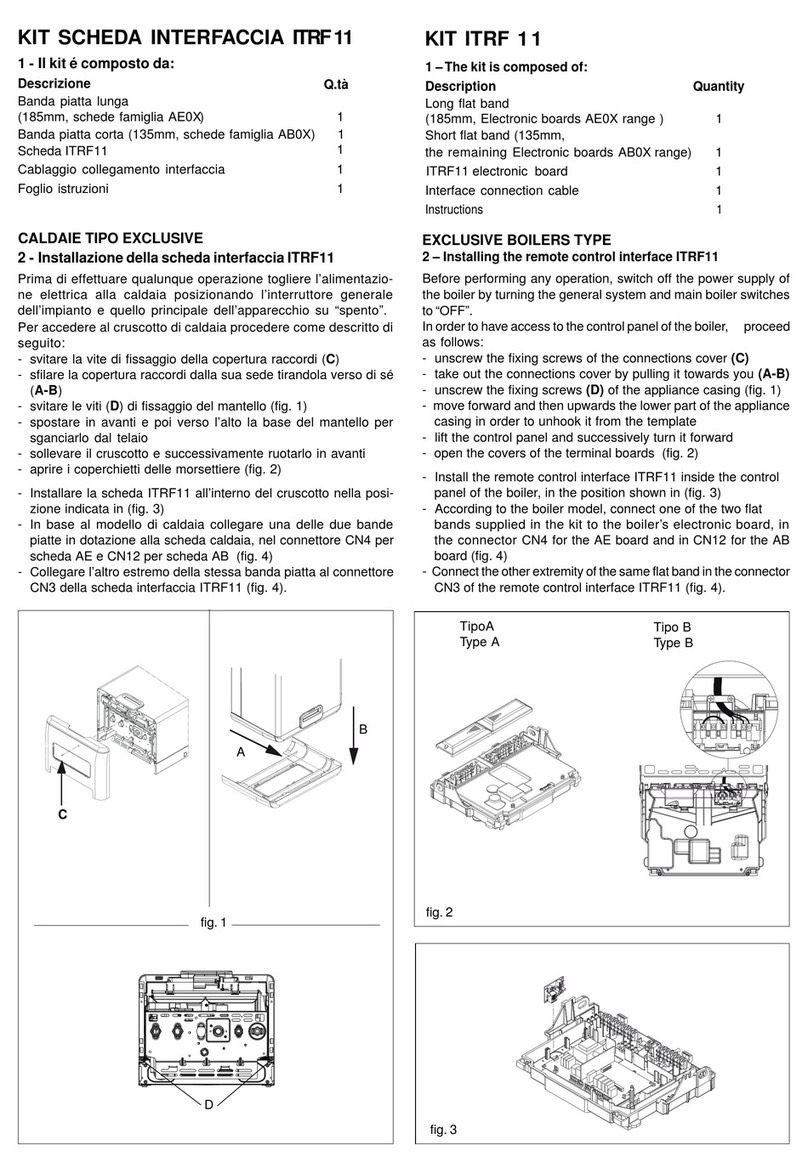

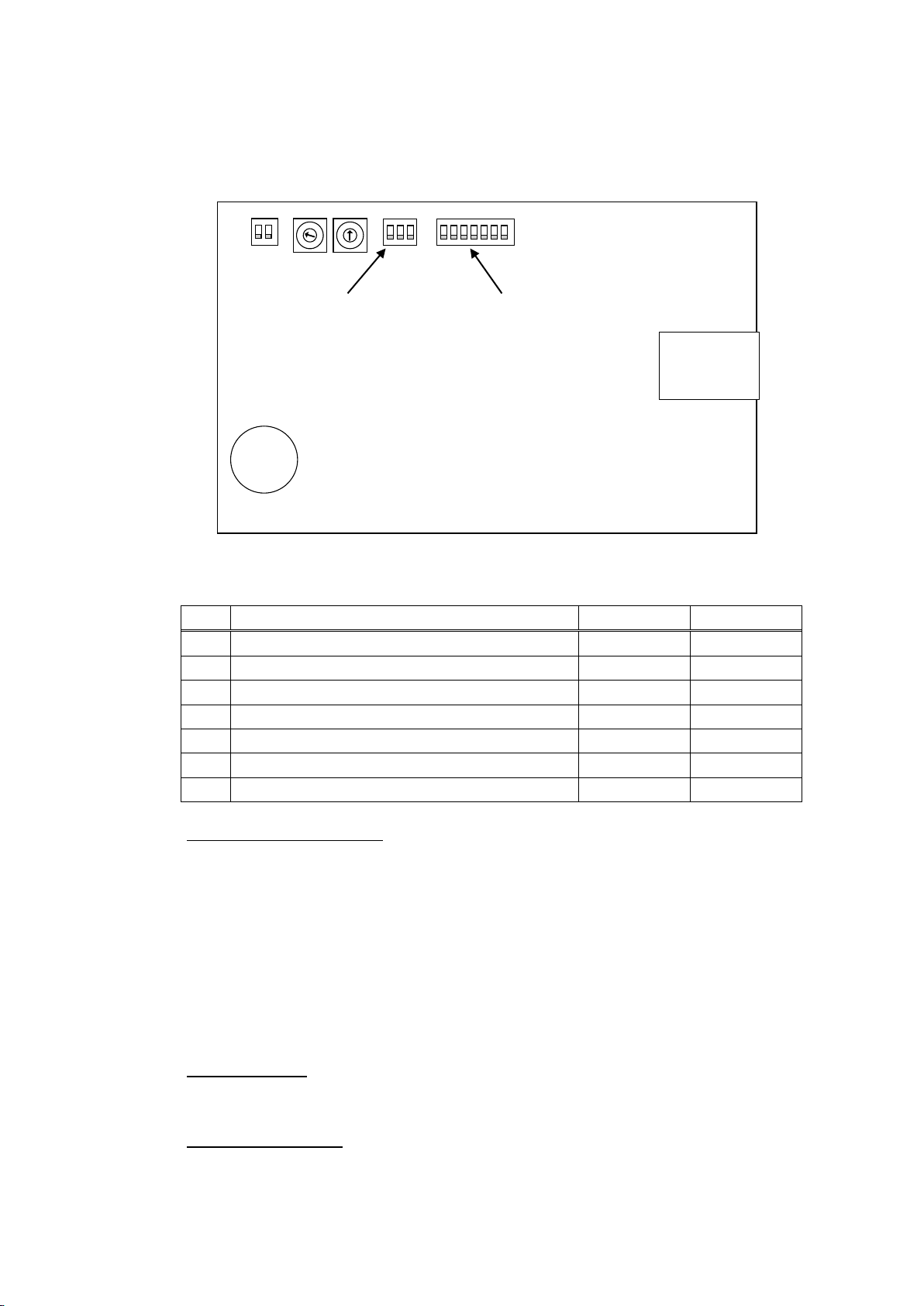

5.1.2 DIP Switch Settings .................................................... 21

5.2 SOFTWARE SETTINGS ...........................................................22

5.2.1 Chemical Feeder Settings (1 to 4) ...................................... 22

5.2.2 Feed Water Control Settings ............................................ 25

5.2.3 Condensate Recovery Settings ........................................... 29

5.2.4 ID Settings for M-NET3 Equipment ....................................... 30

5.2.5 ID Settings for DS-NET Equipment ....................................... 31

5.2.6 MSR Regeneration Control Settings ...................................... 32

5.2.7 Other Settings ......................................................... 33

5.3 ID SETTINGS AND ROM VERSION OF DS-NET EQUIPMENT ................................. 35

5.3.1 ID Settings for DS-NET Equipment ....................................... 35

5.4 SYSTEM EQUIPMENT SETTINGS .....................................................36

5.4.1 Colormetry Settings .................................................... 36

5.5 SETTINGS USING THE PC INSPECTION TOOL ..........................................37

5.5.1 Settings Using the PC Inspection Tool .................................. 37

5.5.2 External Input Contact Settings ........................................ 37

5.5.3 Alarm Notification/Report Settings ..................................... 38

5.5.4 Other Settings ......................................................... 38

6. START-UP OPERATION .................................................... 39

6.1 TURNING ON THE POWER SUPPLY ................................................... 39

6.2 CHECKING THE COMMUNICATION STATUS AND SETTINGS....................................39

6.2.1 Checking Communications with Central Management System and MIURA Office . 39

6.2.2 Checking Sensors ....................................................... 39

6.3 SUPPLYING WATER TO THE FEED WATER TANK .......................................... 40

6.3.1 Feed Water Control by Motor Valve Operation According to Feed Water Control

Signal Outputs................................................................. 40

6.3.2 Raw Water Pressure Pump Control ........................................ 40

6.3.3 Flowmeter (Instantaneous Flow Rate Display) ............................ 40

6.3.4 Low Water Level Bypass Feed Water Control .............................. 40

6.4 MI CHEMICAL FEED ............................................................41

6.4.1 Boiler Feed Water Chemical Feed ........................................ 41

6.4.2 Header Chemical Feed ................................................... 41

6.5 CONDENSATE .................................................................42

6.5.1 Initial Condensate Discharge Control ................................... 42

6.5.2 Condensate Recovery Rate ............................................... 42

7. SUPPORT DOCUMENTATION ................................................. 43

7.1 SETTING ITEMS............................................................... 43

7.1.1 Chemical Feeder Settings (1 to 4) ...................................... 43

7.1.2 Feed Water Control Settings ............................................ 44

7.1.3 Condensate Recovery Settings ........................................... 45

7.1.4 MSR Regeneration Control Settings ...................................... 46

7.1.5 Other Settings ......................................................... 46