Egger JUSTclic! User manual

Installation instructions

Egger Laminate Flooring

with JUSTclic! installation system

2

. Obligatory testing and exercise of due care

EGGER laminate flooring is manufactured in precise stages in highly-advanced and modern production facilities. Both finished and

ongoing products are subjected to regular stringent checks. Yet, despite quality controls, damage to individual boards, for example

during transport, cannot always be completely prevented. Therefore, it is a requirement to visually double-check each flooring

element before and during the installation job. Damaged or otherwise unsuitable flooring elements (products) must not be installed

and should be returned to the retailer and exchanged.

. Sub-floors

2.1

All sub-floors must be prepared for installation in accordance with regular sub-floor preparation procedures and accepted

tolerances within the flooring industry. Please consider the following points before beginning installation of laminate flooring

manufactured by EGGER. In case of failure to comply, all guarantee and warranty claims will become void.

Check the moisture level in the sub-floor:

Use a CM device to make sure the following levels are not exceeded:

For cement-based screed ≤ 2CM % – heated screed ≤ 1.8 CM %

For calcium sulphate screed /calcium sulphate floating screed ≤ 0.5CM% – heated screed ≤0.3 CM%

These values apply to screeds without additives. With the use of additives and in case of fast-setting screed, the measurements

and limitis specified by the respective manufacturer shall apply.

The test material must be obtained from the lower one-third of the screed. During this process, the thickness of the screed must

be measured and documented.

Check if the sub-floor is level:

The evenness test is based on common standards and takes place by placing a yardstick/straight-edge on the high points of the

surface and determining the gauge at the deepest location in relation to the bearing surfaces (measuring point intervals).

Use a max. 2mm gauge (vertical deviation) at 100 cm intervals. Larger deviations should be addressed by suitable measures (e.g.,

with self-levelling compounds).

Check the load-bearing capacity of the sub-floor:

The sub-floor must be a sealed, self-supporting layer.

Check if the sub-floor is clean:

The sub-floor must be vacuum cleaned.

Check atmospheric conditions:

The following conditions should be met before, during and after installation:

an air temperature of at least 18° C

a floor surface temperature of at least 15° C

a relative air humidity of between 40% and 70%

2.2

Laminate flooring from EGGER installed as a floating flooring configuration can be installed on all sub-floors which meet the above

described requirements. This includes in particular:

all types of screed including hot water-heated screed

chipboard constructions

fibreboards

existing floor coatings such as PVC, linoleum, natural stone slabs and ceramic tiles

Obligatory testing and exercise of due care/Sub-floors

3

Unsuitable sub-floors:

EGGER laminate flooring may never be installed on textile floor coverings (e.g., carpeting) or sub-floors that are not properly

prepared for installation. In case of failure to comply, all guarantee and warranty claims will become void.

Sub-floors of limited suitability include:

electrically operated underfloor heating (controlling the surface temperature)

Electrical underfloor heating systems are classified as sub-floors with limited suitability given that a range of film-based,

electrical heating systems are able to generate surface temperatures that significantly exceed 28°C. EGGER approves use of an

electrically operated underfloor heating system if it can be controlled digitally and the surface temperature can never exceed 28°C.

Furthermore, the heating system manufacturer must approve the use of the system in combination with laminate flooring.

Screed

If the laminate flooring system is installed floating on screed, you have to consider that possible residual moisture in the sub-floor

will seep to its surface. Consequently, all types of screed (with the exception of mastic asphalt) require, prior to the installation of

a system-specific insulating layer (see section: Attention! Underlay materials), a moisture protection film with an SD value ≥ 75m to

be installed as vapour barrier over the entire surface & extend up the wall. When properly and professionally installed, the strips of

the moisture protection film must overlap 5-20cm in the joining areas depending on the design.

Screeds with hot water floor heating

When building a heated flooring structure, all participants (builder, architect, heating specialist, heating technician, installer and

flooring manufacturer) must work together in a coordinated manner. All surface-heated flooring requires appropriate planning

and co-ordination for the heating system and screed in order to ensure maximum long-term performance without causing any

damage. The standard checks of the installation sub-floor must include inspecting the function of the floor heating/cooling system

(functional heating/cooling). Proof of the proper raising and lowering of the temperature of the heated screed structure in any

season must be provided and documented according to a protocol.

When heating the load and heat distribution layer, a distinction is made between functional heating and floor curing heating.

Functional heating is the proof of the heating installer that a proper structure has been built and is used to verify the functionality

of heated flooring structures.

Floor curing heating is the expelling of the residual moisture in the screed until installation suitability is reached.

Attention: Functional heating does not guarantee that the screed has reached the residual moisture required for installation

suitability. Therefore, installation curing is generally necessary.

Attention! The surface temperature of a heated floor structure may not exceed 28°C (83°F). EGGER laminate flooring is generally

installed floating. When installing on mineral sub-floors, it is absolutely necessary to install a moisture protection film with an

SD value ≥ 75 m as vapour barrier prior to the insulation underlay, on the entire surface and extending up the wall. During floating

installation, the heat conductivity of the laminate flooring and of the insulation underlay must be taken into account. The sum of the

heat conductivity values of all components must be ≤0.15m² K/W in line with EC requirements. When using insulating layers which

are not part of the EGGER accessories range, floating installation on heated screed voids all warranties in regards to compliance

with the effective, maximum allowable thermal transfer resistance of the overall structure.

Natural stone and ceramic tiles

Possible residual moisture in the sub-floor may rise to the surface (see section: Attention! Underlay materials), a moisture

protection film with an SD value ≥ 75m must be installed as vapour barrier over the entire surface & extending up the wall.

Woodchip and fibreboard

A specially designed insulating underlay is recommended (see section: Attention! Underlay materials) should be installed. A

moisture protection film (vapour barrier) is not necessary.

Sub-floors

4

Wooden boards

Any loose boards should be properly screwed down. A specially designed insulating underlay is recommended to improve

soundproofing (see section Attention! Underlay materials). A moisture protection film (vapour barrier) is not necessary. The

laminate flooring boards must be laid at right angles to existing floorboards.

Elastic flooring surfaces (PVC, linoleum, vinyl)

The use of flexible floor coverings meets the damp-proofing requirements and thus eradicates the need for a moisture protection

film. A specially designed insulating underlay is used to improve soundproofing (see section: Attention! Underlay materials).

Wet rooms/wet areas

Attention! Laminate flooring from EGGER is not suitable for installations in wet rooms and wet areas such as bathrooms, saunas or

in similar rooms. In case of failure to comply, all guarantee and warranty claims will become void.

Attention! Underlay materials

On mineral sub-surfaces, however, a moisture protection film with an SD value ≥ 75m must always be installed first, over

the entire surface and extend up the walls. Exceptions are the use of EGGER Silenzio Duo (2 in 1 insulation underlay with

integrated moisture protection) or a comparable 2 in 1 underlayer board. In these cases, a separate moisture protection

film is not necessary.

A system-specific EGGER Silenzio underlay must be used under EGGER laminate flooring. Alternative underlayer boards are

available at www.egger.com. The exception is the EGGER laminate flooring with laminated Silenzio underlayer board on the

reverse. An additional insulation underlay is not permitted in this case.

. Before the installation

Acclimatisation of the floor boards

The packages of laminate flooring have to be stored in the room where they will be installed or in a room with the same climate

condition before starting the installation. Acclimatisation takes place within the following guidelines:

packed

for a period of at least 48 hours

laid flat with a minimum of 50cm from all walls

at a room temperature of at least 18° C

at a flooring surface temperature of at least 15° C

at a relative atmospheric humidity of between 40% and 70%

Direction of installation

Laminate flooring looks best when the floor boards are installed parallel to the light direction. However, in the case of sub-floors

made of floorboards or strip parquet/wooden floors, the floorboards must be installed at right angles or in the same direction of

the strip parquet/wooden floor.

Planning the first row

First, the room must be measured to determine whether the width of the first row should be reduced. This will be necessary if the

last row to be laid is calculated to be less than 5cm wide.

Planning expansion gaps

Laminate flooring, like all organic materials, is subject to certain types of movement (shrinkage/expansion) due to changes in

climate conditions. If expansion joints are used, the installed floor will not be affected as they provide spaces for these changes

to take place. Expansion gaps 8 to 10 mm wide to all fixed objects such as walls, door frames, pipes, pillars, stairs etc. should be

observed.

Installation sub-floors/Prior to installation

5

Planning movement profiles

Transition mouldings must be installed in the following areas and flooring sizes because of the natural movement behaviour of

laminate flooring:

door thresholds

passageways

angled areas

room lengths and/or widths of more than 10m

. Installation

Check the floor panels in the first row for any damage/fault. Ensure you understand the difference between the tongue and the

groove on the panel (Fig. 1).

Start laying the first row of boards in a left-hand corner of the room with both tongue sides of the panel facing the wall (Figure 2).

In order to fit the panels insert the new panel to be laid at an angle from above into the connection system of the already laid

panel and lower it until it lies flat on the sub-floor (Figure 3). The last panel in the first row can be marked and cut to the required

length. In order to allow subsequent rows to be added to the long edge without gaps, make sure the long edges of the panels are

lined up precisely in the first row. It is recommended to insert a piece of the flooring as a stop / spacer between the wall and the

flooring being installed in the first row, respectively in the area of the end joints. After installing the first 2-3 rows, remove these

positioning elements and correctly align the installed laminate flooring with the walls, observing the required gaps (placing the

spacers). (Figure 3 to 10)

Start installing the 2nd row with the remaining panel of the 1st row, if the latter is at least 200 mm long. In the following rows, the

new row can be started with the remaining panel, while observing the minimum offset of the short ends.

Attention! Make sure that the short ends are staggered at least 200mm (8”). In case of products supplied with the bevel and/or

with a special decor (e.g., tiles decor), ensure the offset is even according to the bevel and/or pattern.

Place the tongue on the protruding lower lip of the first panel of the first row (Figure 5). Connect all other panels for this row on

their narrow sides as described above, until the entire row is installed. Afterwards, all short sides of the panels in this row should

be adjusted and connected with each other (Figure 6).

Slightly raise the first panel or panel section and connect its long edge with the first row. Continue to do so until you have

connected the whole row with the previously laid row (Figure 7). Pay attention that the panels are not displaced along the short

sides.

You can now install panel after panel, row after row.

In order to prepare the last row of panels for installation, take the panel and place it exactly on top of the row before last. By means

of a residual panel (panel width), it is possible to transfer the wall structures to the element within a pre-chosen distance.

A

B

2

8-10 mm

3

ba

4

ba

5

6

ba

7

b ca

8 9

ba

10

A B

1

Prior to installation/Installation

6

Removal/Dismantling of Elements

In order to replace installed panels without destroying them, you first have to unlock the entire row by tilting it and then offset the

panels at the short ends while tilted. Proceed with due care in order to avoid damaging the tongue and groove.

a b c

a b a b

Class , and Commercial Applications

PVAC glue (D3)PVAC glue (D3)

In industrial areas you have to anticipate extraordinary exposure to moisture. As a result, additional sealing with PVAC glue (D3) is

mandatory for such applications. Apply the sealing glue to the top of the tongue on the short and long edge. The glue should ooze

out along the complete long and short edge after the panels have been connected together. Excess sealing glue is easy to remove

from the surface immediately or after a short drying period.

Attention! Ensure that the elements below the sealing glue are installed without a gap.

Built-in kitchens/built-in cabinets

Built-in kitchens and built-in cabinets should be assembled prior to installation and the laminate floor should be laid under the

plinth panel.

Pipes

Measure the position of the pipes and mark it on the panel (allow for edge joint).

Drill at least 16 mm more than the diameter of the pipe.

Saw to the holes at a 45° angle.

Fit and glue the sawn piece.

Installation

7

Door frames

Remove this

part

PVAC glue (D3)

For wooden door frames, we recommend undercutting them – with the approval of the customer – according to the thickness of

the flooring and the underlay.

Install the flooring underneath the door frame – leave the necessary expansion gaps. In the event that your installation job will

end underneath a door frame, we recommend that the locking part is removed from the protruding groove of the pre-installed

panel with a chisel. The newly installed panel can then be pushed horizontally over the groove of the previously installed panel.

This connection area has to be glued with a PVAC glue.

If you have a door frame that cannot be shortened, e.g., one made of metal, we recommend that you close or cover the expansion

gaps with sealant or suitable end profiles.

= + 16 mm

a

b

c

Floor profiles

Install the required flooring profiles and the skirtings after the laminate flooring has been installed in the correct way as described

above. Simple assembly instructions are enclosed with all the accessories.

Attention! With most types of profile, the base (sub-profile) taking the cover profile must be installed prior to installing the laminate

floor.

Installation

8

. Cleaning and maintenance

Entrance areas must be fitted with a properly sized clean-off zone/doormat.

In commercial applications where the laminate flooring area leads directly outside, an appropriately sized clean-off zone must be

built into the floor structure.

Attach felt pads to the feet of furniture, including chairs and tables. Clean these regularly, check for proper functionality, and

replace if required.

Lift furniture when moving, rather than pushing or dragging.

Use soft furniture castors (type W) in the case of office chairs and all other objects on castors. Clean office chair and furniture

castors regularly, check for proper functionality and replace if required.

Wipe any stagnant moisture/liquids from the laminate flooring immediately.

Steam cleaners should not be used, with the exception of Aqua+Laminate Flooring.

Only clean the laminate floor with a damp cloth.

Never use abrasives or scouring agents on the laminate floor.

Do not use cleaning products that may leave a residue. We recommend our system-related flooring cleaner Clean-it from EGGER.

Waxing and/or polishing is neither necessary nor permitted.

Subsequent surface sealing of EGGER Laminate Flooring is not necessary and not permitted.

Use the hard floor nozzle (brush accessory) when vacuum cleaning.

No matter how hard-wearing your floor is, a laminate floor board may still get damaged. If the damage is slight, the problem can be

easily solved with EGGER’s system-related repair paste Decor Mix & Fill. If the damage is more serious, a professional installer will

be able to replace an entire panel. Separate instructions are available upon request.

For special installation instructions, for example how to deal with stairs, or other questions, please contact your retailer for expert

advice.

Cleaning and maintenance

www.egger.com

EGGER Holzwerkstoffe Wismar

GmbH & Co. KG

Am Haffeld 1

23970 Wismar

Germany

T +49 3841 301-0

F+49 3841 301-20222

flooring@egger.com

EGGER Drevprodukt Gagarin

Ezhvinsky proezd, 1

215010 Gagarin

Oblast Smolensk

Russia

T +7 48135 79-300

F+7 48135 79-311

info-ru@egger.com

BR_flo_EGGER_installation_instruction_JUST clic!_en_03/2018_SCG

Subject to technical modifications and printing errors.

Advice, service and more:

Table of contents

Other Egger Other manuals

Popular Other manuals by other brands

Raptor Series

Raptor Series 1501-0581 Installation instruction

Mitsubishi

Mitsubishi City multi PCFY-P installation manual

Universal Electronics

Universal Electronics REMOTE EXTENDER Safety precautions

Schweitzer Engineering

Schweitzer Engineering SEL-300G quick start guide

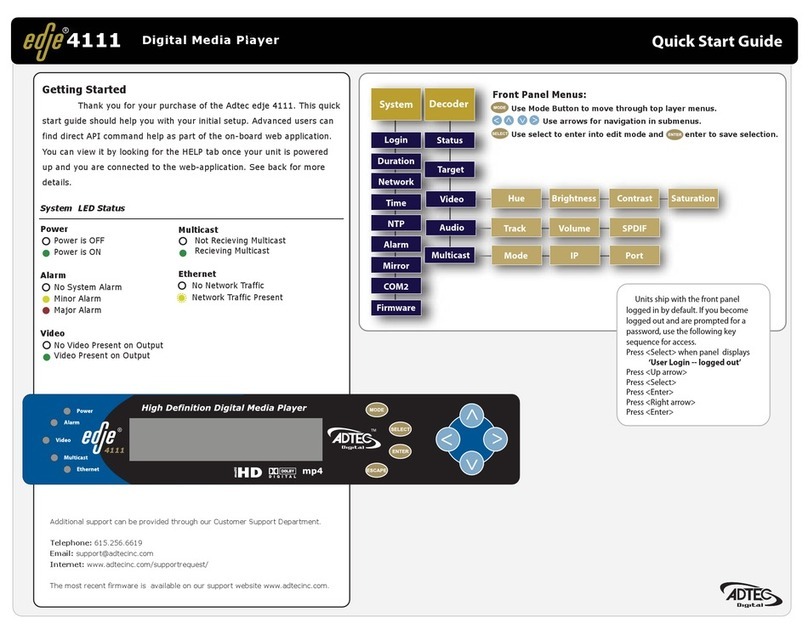

Adtec

Adtec edje 4111 quick start guide

Juniper

Juniper NETWORK CHANGE PLAN REVIEW - SERVICE DESCRIPTION DOCUMENT... manual