3Operator´s Manual Park Ranger 2150 Tipping shovel Operator´s Manual Park Ranger 2150 Tipping shovel

General information

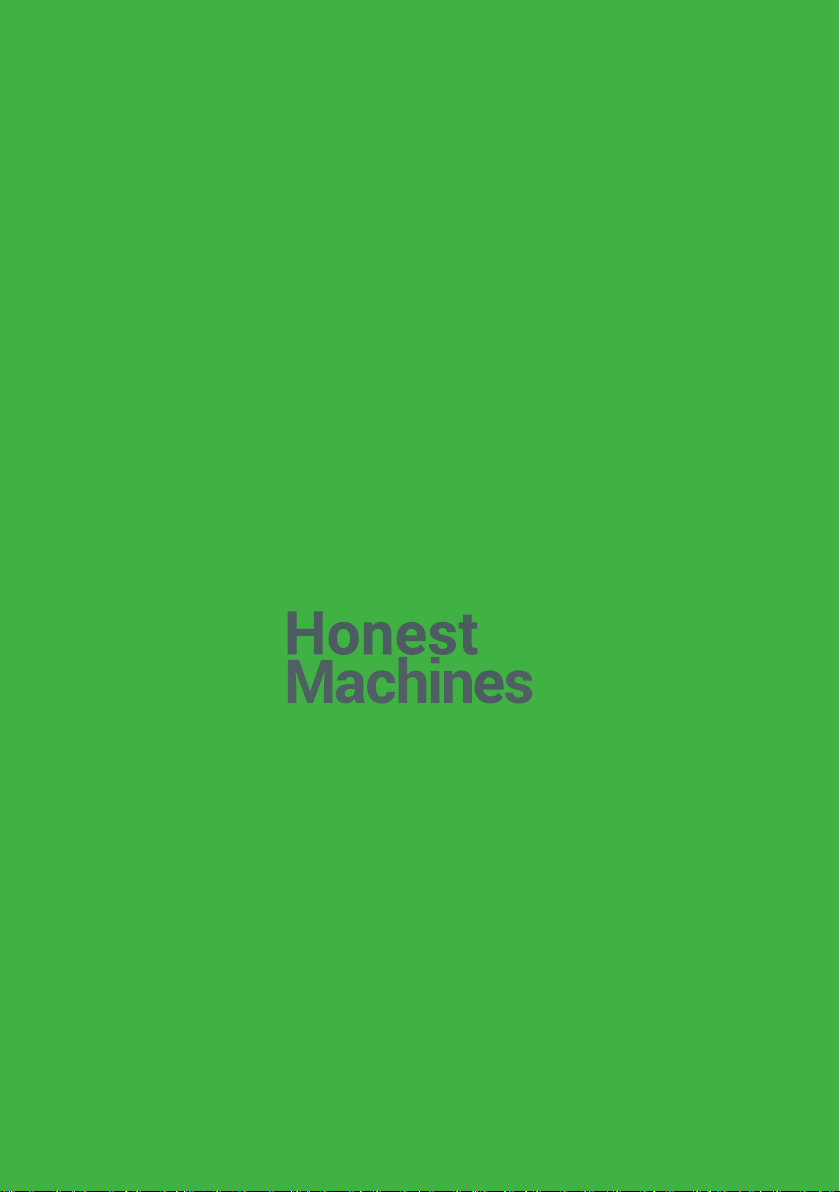

The tipping shovel makes light work of

transporting

gravel, sand or mould and saves the operator

many lifts during the working day. 100 kg is

easily transported from one place to another -

even on the narrowest paths.

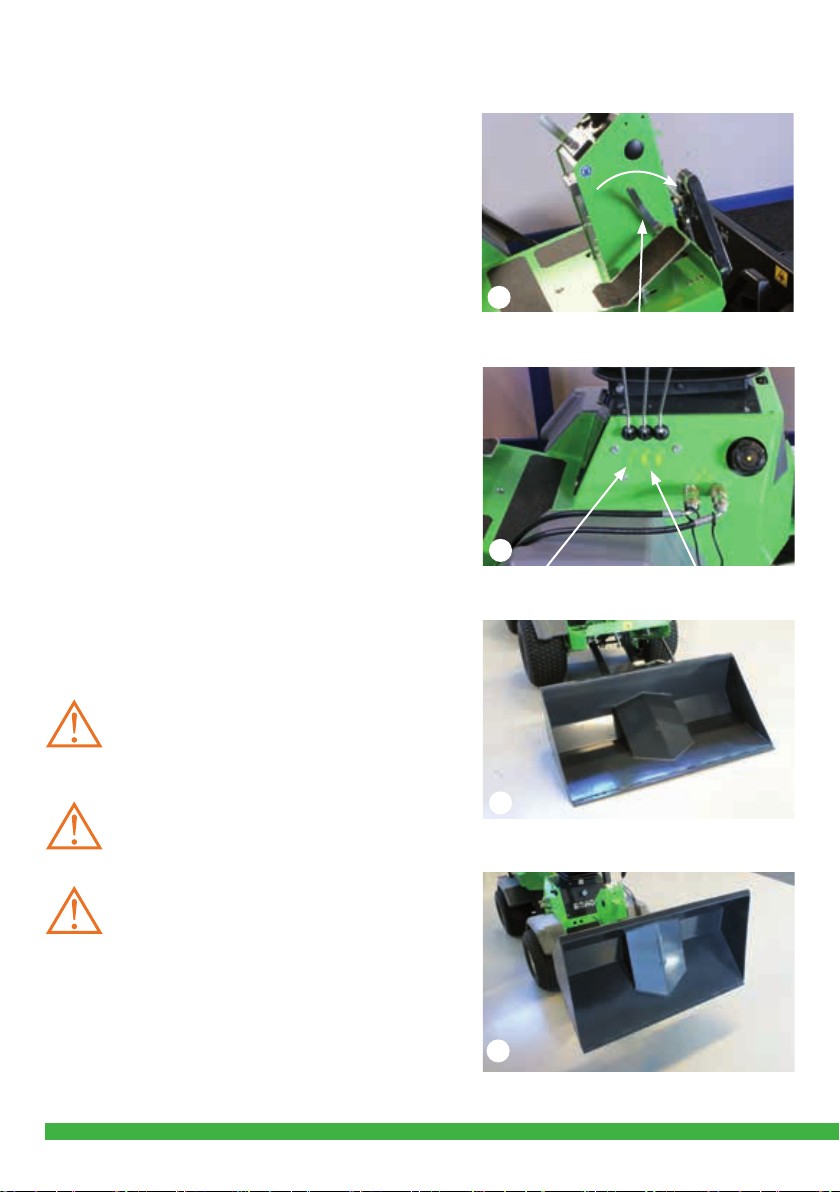

The hydraulic tipping function is easy to work

with and perfect when, for example, the load has

to be tipped over an obstacle such as sandpit

edges or low hedges.

And the load can be spread even while tipping.

The layer is levelled with the shovel edge, giving

a nished result.

The tipping shovel is a robust steel construction

which can perform many tasks other than

shovelling,

such as scraping grass edges of paths with rm

surfaces.

Contents

General information ..........................................................................5

1.1 Safety .................................................................................5

1.2 EC Declaration of Conformity for Machinery...............................................6

1.3 Technical data .........................................................................7

Operator’s manual ...........................................................................9

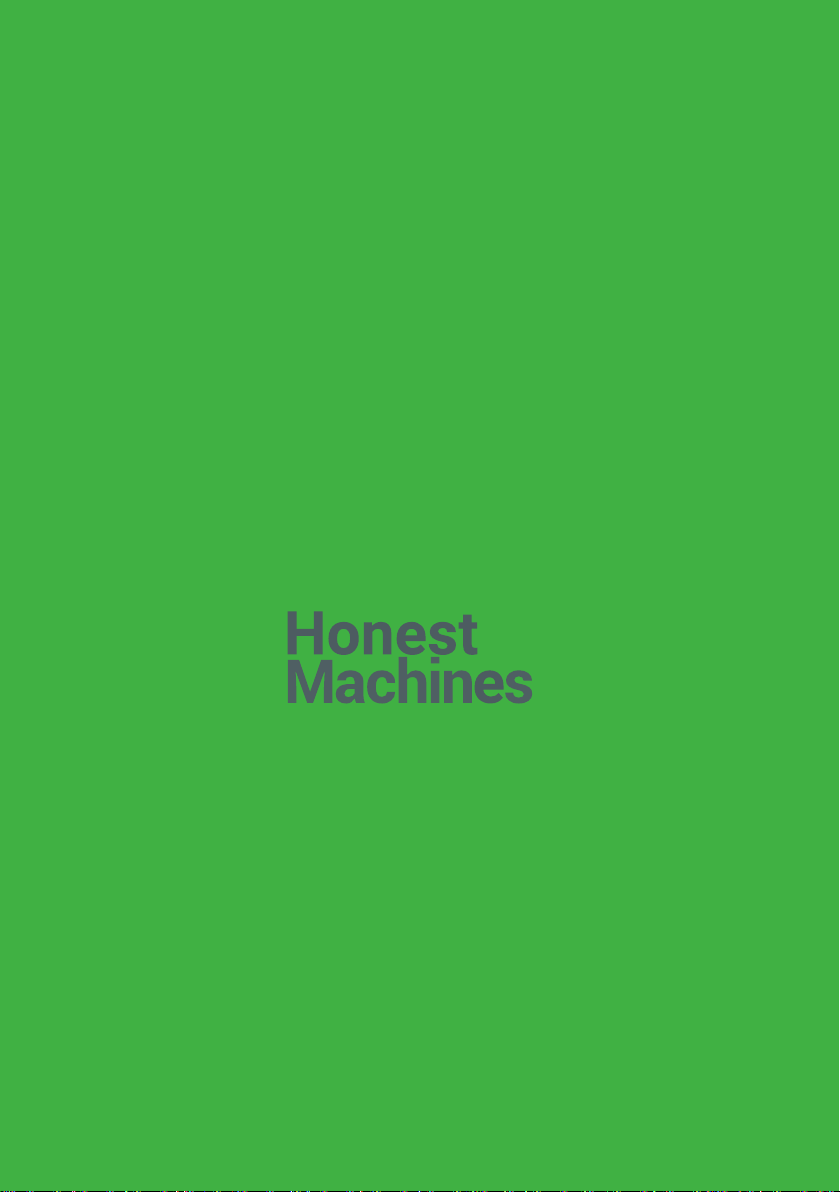

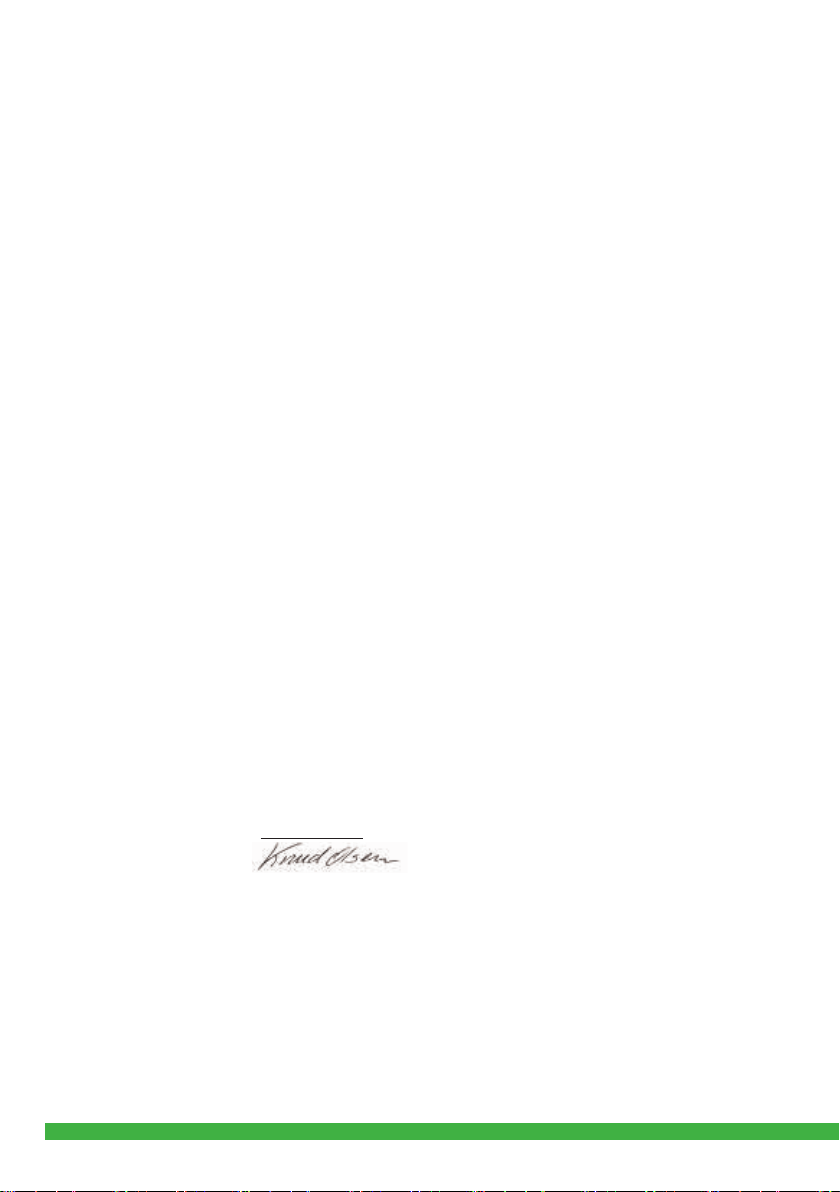

2.1 Assembly / Disassembly ................................................................9

2.2 Before start-up ........................................................................10

2.3 Start-up ..............................................................................10

Service and Maintenance ....................................................................12

3.1 Cleaning ..............................................................................12

3.2 Maintenance ..........................................................................12

Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.1 Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2 Complaints ...........................................................................15

4.3 Disposal ..............................................................................15

Notes .....................................................................................16