EHP KGW Series User manual

Warranty ............................................................................................................................................. 8

Digital- crane scale KGW | KGW-Y | KGY .......................................................................................... 10

Eyelet & braket.................................................................................................................................. 12

Load hook.......................................................................................................................................... 12

Heat protection ................................................................................................................................. 12

LED-Display........................................................................................................................................ 13

Control panel..................................................................................................................................... 15

Infrared remote control .................................................................................................................... 17

Setting the channel of the infrared remote control.......................................................................... 21

Charger & Accumulator..................................................................................................................... 24

Automatic switch-off......................................................................................................................... 27

Master - Slave scale function ............................................................................................................ 32

Set weight limits................................................................................................................................ 34

Set signal time for weight limits........................................................................................................ 35

Automatic taring for weight values................................................................................................... 36

Manufacturer: EHP-Wägetechnik GmbH

Address: Dieselstrasse 8

D-77815 Bühl (Baden)

Germany

hereby declares that the product: digital crane scale type KGW / KGW-Y / KGY

Plant number:

Year of manufacture:

complies with the following harmonized standards with all options:

Machinery Directive 2006/42/EC

EN 61000-4-2, EN 61000-4-3, EN 61000-4-4, EN 61000-4-5, EN 61000-4-6, EN 61000-4-11 according

to the directive 2014/30/EU (electromagnetic compatibility)

EN 61010-031:2017-04 Part 1/ Safety requirements for electrical equipment for measurement,

control and laboratory use

EN 60950-1:2006 according to Directive 2014/35/EU (Low Voltage Directive)

EN 62368-1:2016-05 Equipment for communication technology - Part 1: Safety requirements

according to Directive 2014/35/EU (LVD)

For use as a non-automatic weighing instrument with EC type-approval, the requirements of

Directive DIN EN 45501:2015 are met.

The crane scale complies with the requirements of the standard EN 13155:2009-08 "Crane-safety-

less load handling attachments".

The optional radio equipment complies with Directive 2014/53/EU.

The following national standards and technical specifications were also applied: DGUV regulation

100 - 500 chapter 2.08.

The product is marked with the CE mark.

Bühl, April 2023 Markus Ebel / Technical Managing Director

This declaration is in accordance with DIN EN ISO/IEC 17050-1.

In this technical manual you will find the necessary information for operating the digital crane scale

KGW | KGW-Y | KGY.

►Please read the operating instructions before you put your crane scale into operation. This will

protect you and prevent damage to your equipment.

►Always keep this manual in a place where employees, service personnel etc. can read it. Present this

manual to the inspector or the appointed specialist company at each periodic inspection.

Design features of this manual

Various elements of this manual have fixed design features. This allows you to easily distinguish the

following elements:

Normal text

● Enumerations

►Action steps

Table titles and illustrations are printed in bold.

Tips contain additional information.

Design features of illustrations

If reference is made to elements of an illustration in a legend or in the running text, they are given a

number (1). The numbers in the running text always refer to the figure shown.

Figure 1 - Explanation of design features

Table 1 - Technical data

●The unit should only ever be opened by a qualified specialist technician!

● The device must be protected from heat and moisture!

Before installation

● The crane scale is suitable for weighing and transportating accordance with EN 13155:2009-08

„Crane safety - section 5.1.1.1 Mechanical load-bearing parts“.

● The crane scale is attached to the hook of a crane in accordance with the regulations.

● The operator is responsible for the safety of the device. Crane scales are load suspension devices

according to DIN EN 13155, including accessories such as hooks, shackles and eyes. These parts must

be inspected for safety at regular intervals, but after one year at the latest. Visual inspections for

damage to tensile stressed parts such as hooks, eyes, connecting links etc. should be carried out

continuously.

Especially in 3-shift operation, this inspection cycle must be carried out in accordance with the

Industrial Safety Regulation §11.

We recommend a safety inspection every 4 months, and after 12 months at the latest an additional

crack detection with the electrical crack detection method or the red-white process must be carried

out during this monitoring.

We would be pleased to take over these safety checks for you by sending your device to our head

office (EHP Wägetechnik GmbH | Dieselstraße 8 | 77815 Bühl).

● Check that the safety flaps of the hooks are in perfect condition. These prevent hanging loads

(ropes, chains, etc.) from unhooking.

● Check that the eyelets, shackles, lower load hooks, bolts and safety pins are in perfect condition.

In case of heavy wear (≥10% of the original dimensions) of these parts, please contact the EHP

customer service.

● Safety and protective devices must never be removed or modified.

● Make sure that the scale is securely suspended.

● Observe the regulations for prevention of accidents.

● Keep this technical manual in a safe place close to your working area.

When moving loads, avoid at all costs:

●Lifting unevenly.

●Trailing the goods on the floor.

●Sudden lifting or setting down or abrupt stopping.

During use:

● Staying under lifted loads is strictly prohibited!

● Always ensure that the scale and load are securely hung up.

● Lifting or transporting persons and live animals with the crane scale is prohibited!

● Loads that are heavier than indicated on the load plate mounted on the side of the crane scale

are not allowed to be lifted.

●When lifting the load, move away a few meters and check that the load is correctly balanced by

lifting the load a few centimeters from the ground. On the display of the crane scale you can read if

the load is exceeded..

● If the display starts flashing or the display shows OL, the maximum load has been exceeded. The

load must be lowered again immediately.

● Never allow the load to swing.

● Lift at minimum speed.

For CE-M approved scales (model KGY):

● CE-M approved scales are only approved for use in a weatherproof environment.

● Do not operate the scale at risk of frost (below -10°C) or in a very hot environment (above +40°C).

In this temperature range.

● The verification marks and seals on CE-M approved scales must be handled with care. If they are

damaged, please notify your regional weight and measures authorities.

In case of malfunctions:

●Repairs may only be carried out by qualified personnel!

●Read the chapter "Troubleshooting“ and „Error detection“.

●Contact the EHP customer service.

Special applications:

A standard crane scale cannot be used in pickling or galvanizing baths within production, as this can

lead to irreversible damage to the load-bearing parts and electronics due to liquid metal

embrittlement. If you still wish to use the crane scale in these areas, it must be specially equipped

by EHP. Even if the crane scale is well-protected, damage can still occur from this application.

Technical defects caused by use in these baths are not covered by warranty or liability.

The warranty is void in case of:

•Improper use of the manufacturer's instructions in this technical manual.

•Operating the device in an unintended use.

•Mechanical damage, damage by humidity and liquids.

•Mechanical modification of the crane scale.

•Wear and tear.

•Use of non original EHP batteries, chargers and power supplies.

•Manipulation of the loading device.

•Overloading the crane scale.

•Modification or replacement of the load-bearing parts.

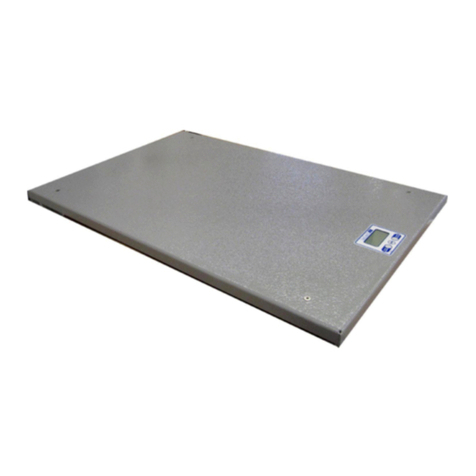

● Digital crane scale KGW | KGW-Y | KGY

For extreme foundry applications, shock and

heat protected

For permanent industrial use

(KGW-Y=calibrated; KGY=CE-M approved)

Figure 2 - Digital crane scale KGW and KGW-Y/KGY

The following accessories are included in the scope of delivery:

● Bracket (KGW) or Mounting eyelet (KGW-Y & KGY)

●Heat protection (only KGW)

●Load hook

● Infrared remote control

● Rechargeable battery 12V/14,4Ah

● Charger 12V/4Ah with charging current limiter

Depending on the product configuration, the accessories may differ from the standard.

Figure 3 - Front view

The LED-Display (1) is located at the front of the crane scale. The control panel with 6 functional keys

is covered and protected by a protection cover (2).

The bracket or eyelet (3) is located on top of the crane scale and the load hook (4) is located at the

bottom. The KGW model is also protected from extreme temperatures by a surrounding heat shield

(5). Depending on customer configuration, the figure shown above may vary.

At the back of the digital crane scale KGW | KGW-Y | KGY the battery box is located, which can be

opened by releasing the quick release. Inside the housing is the 12V battery.

Figure 4 - 12V battery/14.4Ah (Article-No. 79849)

This is connected via the two round connectors. The round plugs are designed in such a way that it is

not possible to inadvertently swap the + / - poles.

Figure 5 –Round plug for 12V battery connection

The crane scale will be hung up with its eyelet or braket in the crane hook. It

must be ensured that the eyelet can move freely in the hook base of the crane

hook, rests properly in the hook and is not tilted.

The load hook is used to weigh and transport the goods. The load capacity of

the load hook matches the load capacity of the crane scale. It is restricted to

exchange the hook for any other handling equipment.

The safety catch of the load hook prevents the load from accidentally slipping

out. Before lifting the load, make sure that the safety catch is fully closed.

The surrounding heat protection of the KGW scale model protects the

electronics and measuring unit from extreme ambient heat.

Figure 6 - Eyelet

Figure 7 - load hook

Figure 8 - Heat

protection

The LED display shows the weight of the lifted goods and additional parameter.

Figure 9 - LED-Display

1. 5-digit weight display

2. +/- sign

3. Battery empty

4. PT (PreTara)

5. Net weight value (Tare function activated)

6. 1 / 2 range display

7. Standstill indicator

The display consists of a 5-digit, 7-segment LED.

Every weight is displayed combined with its algebraic sign.

If more than 2e (double number unit) above the nominal weight is

added, the display on the scale starts flashing.

If more than 9e above the nominal weight is added the crane scale

shows “OL“ (overload) and switches OFF automatically.

Example:

The scale has a weighing range of 10t; calibration value 5 kg x 2e = 10

kg, i.e. the display flashes at a weight exceeding 10010kg and "OL"

appears from 10045 kg.

Always pay attention that the crane scale is never overloaded due to

safety reasons.

If the battery is discharged (at 10.6 volts), the symbol appears on

the display.

This indicates that the battery is "empty" and needs tob e recharged. If

this is not possible immediately because of the work process, you can

continue working for approx. 30 minutes. If the battery is discharged

(at 10.0 volts), the crane scale switches off automatically to avoid deep

discharge and damage to the battery.

This symbol is shown together with the - symbol when a tare value

is entered manually with the remote control. The weight value

displayed is a net weight.

This symbol is shown when a tare value has been entered. The weight

value displayed is a net weight.

For dual range scales, this symbol indicates the weighing range in which

the crane scale operates. The weighing ranges are printed on the

nameplate of the crane scale.

The illuminated symbol means that the load on the scale is hanging

steady and a valid weight value is shown.

If the symbol flashes, then the peak value display or the casting

speed display has been activated with key 9 on the remote control.

Table 2 - Display indication

The crane scale can be operated via the integrated control panel below the LED display.

Figure 10 - Control panel

•Switch on the crane scale

•Activates the automatic segment control

•Crane scale automatically is set to „0“

Always switch on the crane scale 5 minutes before the first weighing

operation.

If the preload (e.g. slings) is greater than 20%-30% of the nominal

load, only the + sign is shown. The scale then switches itself off.

The normal operating mode is only reached again by reducing the

preload and switching on again.

•Switch off the crane scale

Switch off crane scale eliminates temporary errors (reset function).

By pressing this key, a check of each individual display segment

(segment check) is performed and further information of the scale will

be shown.

For approx. 5 seconds, the display flashes consecutively:

8 8 8 8 8 (Segment control)

L A H (Software version)

1 2.2 1 (Version number, Release)

0 1 (Scale number)

C 0 1 (Channel frequency)

H 0 1 (Canal of IR remote control)

I n I t (Self test of crane scale)

•TARE (subtractive) is activated

•Scale stores the current weight value in the tare memory

•Display shows "0"

•Net- weight symbol is shown

•Pressing the TARE button again resets the tare function, clears

the tare memory and the display shows the gross weight

again, the Net- weight symbol disappears

•Sets weight to "0" (semi-automatic zero setting device).

•Zeroing range: -1 to +3% of nominal load for LDN model;

•max. zeroing range: -99 to +99% of nominal load (LD model)

„Zero" is not possible outside this zeroing ranges or in tare mode.

By default, this key is not assigned any function. On customer request,

this key can be equipped with special functions.

Table 3 - Control Panel

The infrared remote control has a robust housing and is equipped with large control buttons that can

be easily operated even when wearing gloves.

All functions of the crane scale can be controlled via remote control, such as OFF, TARE or zeroing.

Furthermore, the remote control offers further operating possibilities, which are used in connection

with EHP weighing data receiving units, such as the print function.

Up to a distance of 30m the crane scale can be operated with the remote control. If the working

range should shorten (less than 20m), this is an indication that the batteries need to be changed (3

pieces 1.5V Type AAA, Micro LR03, AM4, MN2400).

Figure 11 - Infrared remote control

Some functions like Print, Add or Total can only be used in combination with EHP weighing data

receiver (see Accessories on page 37).

This button has the same function as on the crane scale control panel.

Press this key to transfer the weighing data to optionally available EHP

receiving devices (see Accessories on page 37).

For example, an individual receipt can be printed out on TELEDATA USB

weighing data receiver.

This button has the same function as on the crane scale control panel.

Pressing this key activates the addition function.

This function helps to store individual weights within a batch or to add them.

This function can only be used with additional weighing data receiving

units, e.g. the TELEDATA USB.

Press this key to switch the increment range of your scale (this function is

not included in standard crane scales. For example, from 1 kg increments to

2 kg increments.

Note:

The scale automatically switches to the second range as soon as a

corresponding load value is reached. After the load has been removed (0 kg

display on the scale), you can switch back to the first measuring range. It

may be necessary to press the zeroing button beforehand to record an exact

0 kg value.

Herewith the total weight (plus additional data) is transmitted by radio to

weighing data receiving units, e.g. the TELEDATA USB. At the integrated

printer a sum voucher (addition of the single registrations transmitted by

add function) is printed out.

This button has the same function as on the crane scale panel.

Press this button to switch off the scale via remote control. The display

flashes 10x off during the switch-off phase. During this time you can

interrupt the switch-off process by pressing any key.

This button can be assigned with any special functions like showing the peak

value or displaying the casting speed.

Special functions are not included in the standard scope of delivery. Contact

your EHP contact person for further information.

Press this button to activate the pre-tare function. The display shows now

the last pre-tara value. Use the keys 1 to 0 to enter the tare value and

confirm with the ENTER key. The tare values must lie within a calibration

value. Higher or lower values are rounded up or down.

Pressing this button activates the numeric buttons on the IR remote control.

Additionally the LED above the shift key is flashing. Now any numbers from

0...9 can be entered as a code (maximum 5 digits). Press the ENTER key to

confirm the entry, the Shift LED goes out again.

This code is now transmitted to the weighing data receiver.

Press this key to confirm the numerically entered values.

Flashing of this LED indicates that the IR remote control is transmitting data.

Table 4 - Buttons of IR remote control

This manual suits for next models

12

Other EHP Scale manuals