EHRET Voletronic io User manual

VOLETRONIC io

Motorisation for window shutters

Installation and

operating instructions

INSTALLATION

SPECIALIST PERSONNEL

Valid from 03.2021

E 641.4

2

Notes

The present Installation and operating instruc-

tions describe the commissioning of the EHRET

VOLETRONIC io window shutter drive with

wireless remote control.

Carefully read through these operating instruc-

tions prior to commissioning. Observe the

specified process steps and take into account

the notes and recommendations given. Knowl-

edge of and technically impeccable implemen-

tation of the given safety notes and warnings

are prerequisite for the safe and proper opera-

tion of the VOLETRONIC io window shutter

drive. Insufficient knowledge at the time of

commissioning and utilisation leads to the loss

of any liability claims against EHRET GmbH.

Any installation or operation in deviation from

our installation and operating instructions – ei-

ther in full or in part – will result in the warranty

becoming void.

Installation of the shutters in accordance with

the EHRET window shutter installation instruc-

tions is a prerequisite for the commissioning of

the EHRET VOLETRONIC io window shutter

drive.

Remove the labels stuck to the shutters after

installation!

These Installation and operating instructions

are addressed to qualified specialist personnel.

Qualified specialist personnel are persons who

are familiar with the transport, setup, installa-

tion, commissioning and operation of the prod-

uct and who have appropriate qualifications for

their work. Specialist personnel must know and

observe the relevant standards and/or guide-

lines.

These Installation and operating instructions

are a component part of the product and are

therefore always to be retained until the prod-

uct is disposed of.

These Installation and operating instructions

are to be passed along in the event of the sale

of this product. This product is in accordance

with general rules of technology. Safety-con-

scious behaviour is necessary for undertaking

safe commissioning. For this reason, observe

the following notes.

Should you not understand something in these

Installation and operating instructions unam-

biguously, do not fail to contact the specialist

personnel at EHRET GmbH, 77972 Mahlberg

(Germany).

3

Contents

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Explanation of signs and symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

EC Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation FAQs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Electrical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1 Product description

Product properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2 Installation instructions

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Mounting the installation profile and fastening the drive modules . . . . . . . . . . . . . . 13

Cable routing and wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Attaching the cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Attaching sash arms with guide rails on the drive . . . . . . . . . . . . . . . . . . . . . . 18

Attaching guide rails to the sash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Cutting the coupling rod to size and mounting it . . . . . . . . . . . . . . . . . . . . . . . 24

Crimped metal ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3 Operation

Opening and closing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Preferred position “my” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Detecting obstacles and freeze protection . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Activate the new setting mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Reverse sash priority / direction of rotation . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Setting the closing force . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Buzzer function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Reset to factory settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Radio transmitter “io Pure” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4 Maintenance

Installing the emergency battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Restore factory settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Restore the initial configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Operator interface of the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

List of setting parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Error codes on the user interface of the drive . . . . . . . . . . . . . . . . . . . . . . . . 39

4

Important notes

Explanation of signs and symbols

Warning notes

DANGER

Designates an immediately pending dan-

ger that could lead to death or severe in-

juries if the respective precautionary

measures are not implemented.

WARNING

Means that death, severe bodily injury or

major property damage could occur if the

respective precautionary measures are

not implemented.

CAUTION

Means a possibly pending danger that

could lead to minor injuries or property

damage if it is not avoided.

Directives for action

Safety notes

Only qualified specialist personnel may

carry out installation and commission-

ing!

WARNING

Incorrect installation could lead to se-

vere injuries and/or damage to prop-

erty.

Follow all installation instructions.

WARNING

Take into account the following notes

and warnings in order to avoid dangers

and to protect the product.

Observe the accident prevention regula-

tions of the Accident Prevention & Insur-

ance Association.

Observe the rules of the road during trans-

port.

Make sure that the load is well-secured on

the means of transport.

Take care to ensure that the drives are

stored under dry conditions prior to final in-

stallation and commissioning.

Cordon off a generously large area around

the installation site.

Observe without limitation the regulations

of the manufacturers of dowel and attach-

ment materials.

The mounting bases of the installation site

are to be checked for load-bearing capacity

prior to installation.

In the event of uncertainties about the

mounting bases, contact your responsible

building experts.

Electrical work may be carried out only by

authorised electricians.

5

Important notes

The specified connection diagrams are to

be observed, as otherwise damage to the

motor could occur. EHRET GmbH assumes

no liability for damage resulting from incor-

rect installation.

Check the product for damage prior to in-

stallation. Products requiring repair may not

be used.

Do not touch any internal parts of the prod-

uct that become exposed as the result of

damage (e.g. electrical cables/lines).

Discontinue operation of your electrical

drive at once in the event of smoke or

fumes.

Do not allow children to play with the oper-

ating apparatus of the drives.

Electrical/electronic devices are not secure

against failure. Make sure that no hazard-

ous situations for personnel or product

could arise in the event of a power failure.

Devices with electrical controls could go

into motion at any time and without warn-

ing. Prevent situations hazardous to person-

nel and product that arise from this fact.

No personnel or obstacles are permitted to

be within the range of pivoting and/or trav-

elling shutters while they are moving. Keep

personnel and objects away until the shut-

ters have reached their final position.

Do not reach into moving parts or closing

areas while shutters are opening or closing.

Make sure that no articles of clothing or

body parts are able to be caught by moving

parts in the system.

Disconnect the drives from the power sup-

ply during maintenance work.

Ice could form on the product in the event

of snowfall, sleet or icy rain. Do not operate

equipment until the ice formation is no

longer present, and switch automatic con-

trols to manual.

Make sure that the shutters are locked be-

fore any wind load occurs.

The shutters may not be operated at wind

speeds from 62 km/h (stormy wind).

No additional loads such as persons or ob-

jects are permitted to have an effect on the

shutters.

Shutters are not intended to protect indi-

viduals from falls.

WARNING

Danger of injury from the weight of

the product!

Due to the weight of the products,

perform transport and installation by at

least two individuals.

Transport the product carefully in order to

avoid damage.

Take care to ensure that the product is not

damaged when the packaging material is

removed.

WARNING

Danger of suffocation from packaging

foil.

The packaging foil must be kept out of

reach of children.

Store the foil carefully until you turn it

in for recycling.

Turn the packaging materials in for recy-

cling.

6

Important notes

EC Declaration of Conformity

The manufacturer: EHRET GmbH

Aluminium Shutters

Bahnhofstrasse 14 - 18

D-77972 Mahlberg

declares that the product: EHRET window shutter drive

VOLETRONIC io

to which this guideline refers, is in conformance with the stipulations of

2006/42/EC Machinery Directive

2014/53/EC Radio Equipment / R&TTE

2011/65/EU + 2015/863 RoHS Directive

+ 2017/2102

as well as with the following standards:

EN 60335-1:2012 + A1:2019 + A11:2014 + A13:2017 + A14:2019 + A2:2019

EN 60335-2-97: 2006 + A11:2008 +A12:2015 + A2:2010

EN 62233: 2008 ; EN 62479:2010

EN 301489-1 V2.2.3:2019 ; EN 301489-3 V2.1.1: 2019; EN 55014-1:2017 ; EN 55014-2:2015;

EN 61000-3-3:2013 + A1:2019 ; EN IEC 61000-3-2:2019

EN 300220-1 V3.1.1: 2017 ; EN 300220-2 V3.1.1: 2017 ; EN 300220-2 V3.2.1: 2018

EN IEC 63000:2018

—

Name and address of the individual who is authorised to assemble the technical documentation:

Ralf Gielen Location: D-77972 Mahlberg

Head of Technology Date: 01/ 03/ 2015

EHRET GmbH

Eberhard Schopferer

Management

7

Important notes

Installation FAQs

Which parts have been delivered?

• VOLETRONIC io window shutter drive

• Depending on the diagram, 1× or 2× guide

rail and carriage arm

• 1× adhesive buffer, 1× stop buffer, 2× sup-

port for stop buffer per sash

• Coupling set with coupled window shutters

• Optional support for end piece of window

shutter drive, pair

Which means of attachment are being used?

• The means of attachment are not included in

the scope of delivery!

• The selection of the attachment materials

is oriented towards the mounting bases on

hand, the load-bearing capacities of which

are to be checked before the installation.

Observe without limitation the regulations

of the manufacturers of dowel and attach-

ment materials.

WARNING

Danger of injury/property damage caused

by unsuitable fastening materials

The means of attachment are to be select-

ed in accordance with the load-bearing ca-

pacity of the mounting bases.

How is the VOLETRONIC io window shutter

drive mounted?

• First, the installation prole is aligned and

mounted and the drive modules are hooked

into place and attached.

• Then the carriage arms, guide rails and the

stop buffer are mounted, during which the

drive is connected and put into operation

and the priority of the sashes is checked at

the same time that the carriage arms are in-

stalled.

• Afterwards, the coupling rod is cut to size

and mounted in the case of multiple-section

sashes, and, if express hinges are used, then

these are secured.

Electrical installation

WARNING

Electrical shock (230 V)

NOTES

• The connection (Phase L) must be equipped

with a line safety switch with a maximum

nominal current of 6 A.

• The line safety switch must have a switch-off

capacity of at least 6 kA.

• The prescribed tripping characteristic is B.

• The line switch should be equipped with a

thermal tripping device for overload protec-

tion, furthermore it should have an electro-

magnetic trigger as a protection against short

circuits.

• Other requirements may apply to the instal-

lation of the line safety switch, depending

on the location. For example, it could be

necessary to use a line safety switch with

additional separation of Phase N in order to

switch off all poles. It might possibly also be

necessary to have a residual current circuit

breaker in the system. The standards and the

laws of the respective country with respect

to permanent electrical installations are to be

complied with (e.g. VDE 0100).

• It is recommended that no more than ve

drives are secured simultaneously by a single

line safety switch.

• Pursuant to VDE 0100 and/or the statutory

regulations and standards of the respective

country, the permanent electrical installation

must be carried out by a certified electrician.

• According to VDE 0022, the operator and the

installer are responsible for compliance with

the VDE regulations and/or regulations of the

energy supplier.

8

Important notes

Disposal

IMPORTANT

Disposal

• The following information must be strictly

adhered to in order to prevent any environ-

mental damage. Even if the machine is dis-

posed of by certified experts, the operator

must ensure proper execution!

Some materials of the machine are reusable.

By recycling some parts or raw materials from

used products, you make an important contri-

bution to protecting the environment.

Please contact your local authorities if you

require information about collection points

near you.

Recyclable materials of the machine

Reusable

material

Components

Aluminium • Shutters

• Drive housing

• Coupling

• Guide rail

• Fittings

Copper • Cables

• Motor

Plastic,

rubber, PVC

• Guides

• Accessories

• Sealing sleeves

• Cables

Steel • Motor and components

• Coupling

• Carriage arm

• Fittings

• Accessories

IMPORTANT

Disposal

Dispose of all machine parts in accordance

with the applicable legal conditions in or-

der to prevent the possibility of any harm

to human health or the environment.

Hazardous waste

Reusable

material

Components

Electronic

waste

• Electrical supplies

• Control units

• Circuit boards with

electronic components

9

1 Product description

1 Product description

Product properties

Technical data

Power supply 230V – 50 Hz

Emergency 9.6 V/1600 mAh;

rechargeable battery in the event of a

(optional) power failure

Drive housing according to diagram:

(1L/1R, 2) 92 × 66 mm (w × h)

(2L/2R, 3L/3R, 4) 106 × 66 mm (w × h)

Connection cable 3 m, 2-wire, 0,75 mm2

cable exit on the right

or left window side

Nominal torque 4 Nm per motor,

peak torque 50 Nm

Speed 1,5 rpm.

Power consumption max. 50W

Disconnection Load switch-off

Protection class II

Degree of protection IP 24

Operating –20° C to +60° C

temperature

• VOLETRONIC io is a drive system for a max.

of 2 sashes per side for the electronic actuati-

on of window shutters.

• The drive is equipped with tri-band bidirec-

tional (io-homecontrol®) and is suitable for all

types of window shutters.

• Operation takes place via the supplied

wall transmitter Smoove 1 O/C RTS, radio

frequency 868-870 MHz or optionally via

1-channel or 5-channel hand-held transmit-

ter (Situo io Pure II) or Handheld transmitter

Nina io (bidirectional touch display control).

• The VOLETRONIC io folding shutter drives

are checked and delivered fully charged.

• The drives are pre-programmed for mounting

type, stop scheme, side of the cable exit, di-

rection of rotation and priority of the sashes,

closing force as well as time delay for spe-

cial construction situations (e.g. 90° opening,

overlapping of the sashes).

1× 2×

1× 2×

2× Ø 4,8 S3

10

1 Product description

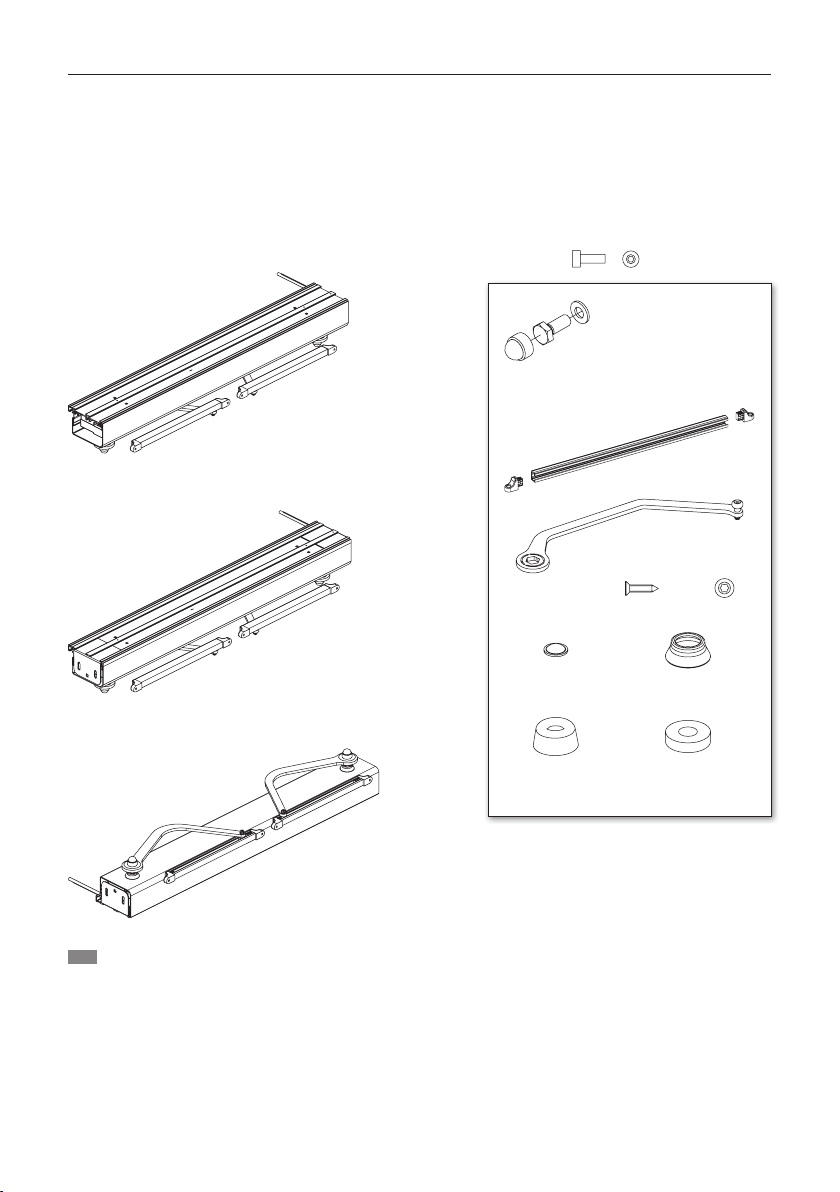

VOLETRONIC io

Scope of delivery

Motorisation for window shutters

Variante A

Header installation

Accessories per sash

M3 × 6 mm S1

1× (1L/1R, 2L/2R); 2× (2, 3L/3R, 4)

Adhesive buffer Shaft seal ring

Stop buffer Support for

stop buffer

Guide rail

Carriage arm

Variant B

Reveal installation

(on the side)

Variant C

At the bottom above

the windowsill

INFO Fastening material at the installation site

(for all variants)

Washer Ø10.5 mm A2

S2 Hexagon screw M10 × 20

Cover cap, hexagon, WAF17

1× (1L/1R, 2L/2R); 2× (2, 3L/3R, 4):

2× Ø 4,8 × 32 mm S4

11

1 Product description

Torx

TX 20+25

Gr. 10

Masonry drill

Drill Ø 4.2 mm

Coupling with multiple-section sashes

2L/2R, 3L/3R, 4

Operation

6440 wall transmit-

ter Smoove 1O/C io

Pure Shine, wireless

Situo io Pure II

hand-held transmit-

ter (optional)

6441 1-channel

6642 5-channel

6643 Nina io hand-

held transmitter (bidi-

rectional touch display

control)

6220 Support for end piece of window

shutter drive, pair

To be used with window shutter models with

protruding slats

6360 Cover remover

for simplified subsequent

dismantling of the cover

6406 Emergency battery, 9.6 V / 1600 mAh,

(optional)

6631 Extension cable

3m

Optionen

Guide lug

Guide rod

Pivot bearing

2× rivets N1

WAF4

WAF17

WAF2.5

Tools required*

*not included in the scope of delivery

12

2 Installation instructions

2 Installation instructions

Preparation

NOTES

Before mounting the drive, make sure that each sash of the folding shutter can be moved freely

over the entire swivel range. The folding shutter must not jam or rub against its immediate sur-

roundings (frame, masonry, etc.). The resistance of the folding shutter must not exceed a torque of

4 Nm during movement.

Remove any pre-existing locking elements (e.g. shutter bolt, espagnolette, etc.).

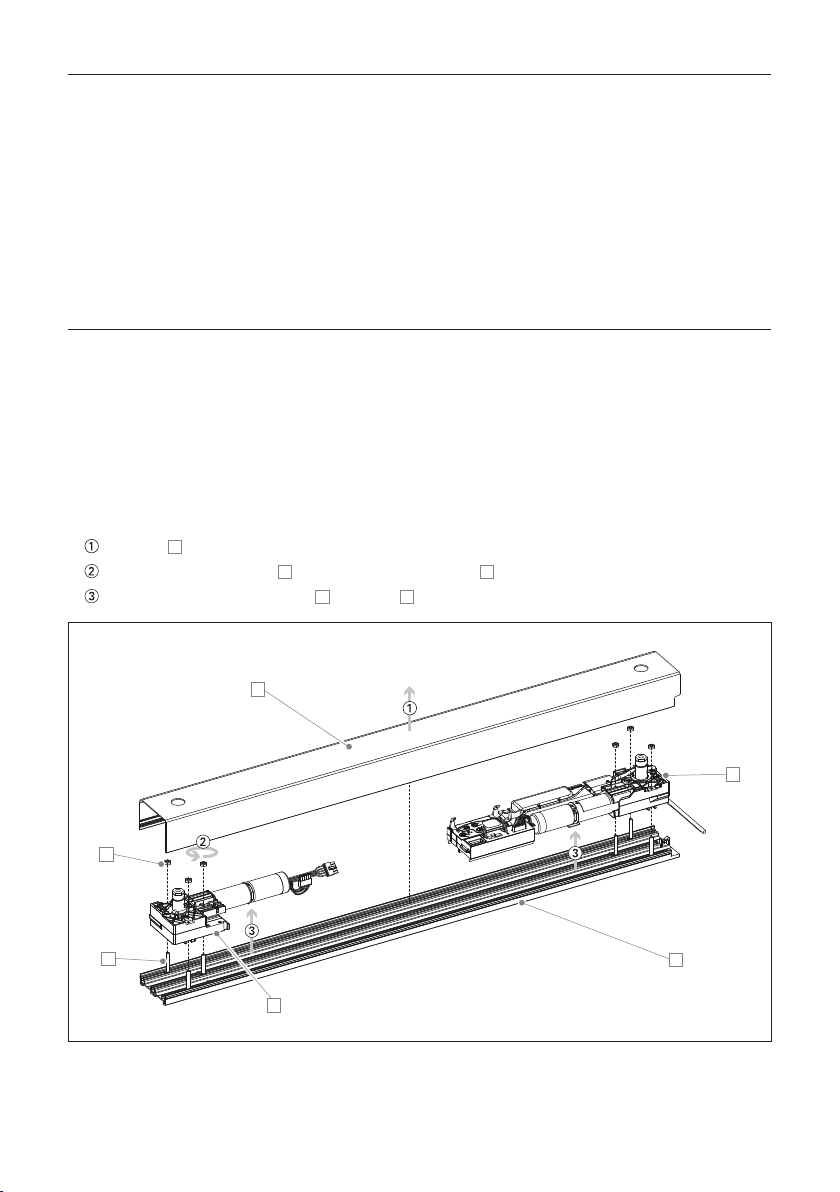

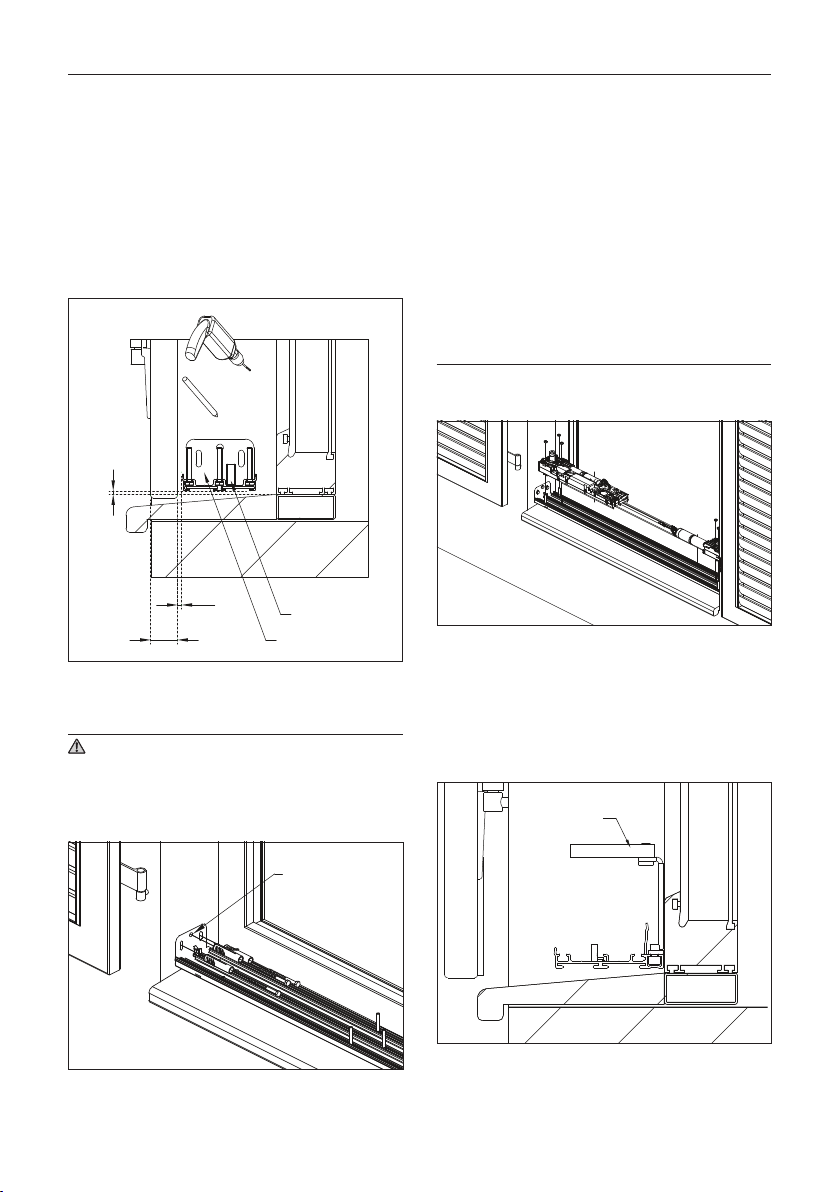

Dismantle cover and drive modules

Remove Athe cover

Loosen the 6 drive nuts B, leave the 6 drive screws Cin the installation profile

Remove the 2 drive modules Dfrom the Einstallation profile

A

B

CE

D

D

13

2 Installation instructions

Mounting the installation profile

and fastening the drive modules

WARNING

Danger of injury/property damage caused by

unsuitable fastening materials

Select the fastening material in accordance

with the load capacity of the installation sub-

strates!

NOTES

• The selection of the fastening method is de-

pendent on the substrate and is therefore

exclusively your own responsibility.

• Note that the lintel must be horizontal in both

width and depth.

• The dowels used must be able to withstand a

force of at least 40 kg. The brackets must be

fastened at at least two points.

• EHRET recommends the use of screws with

a diameter of at least 6mm.

14

2 Installation instructions

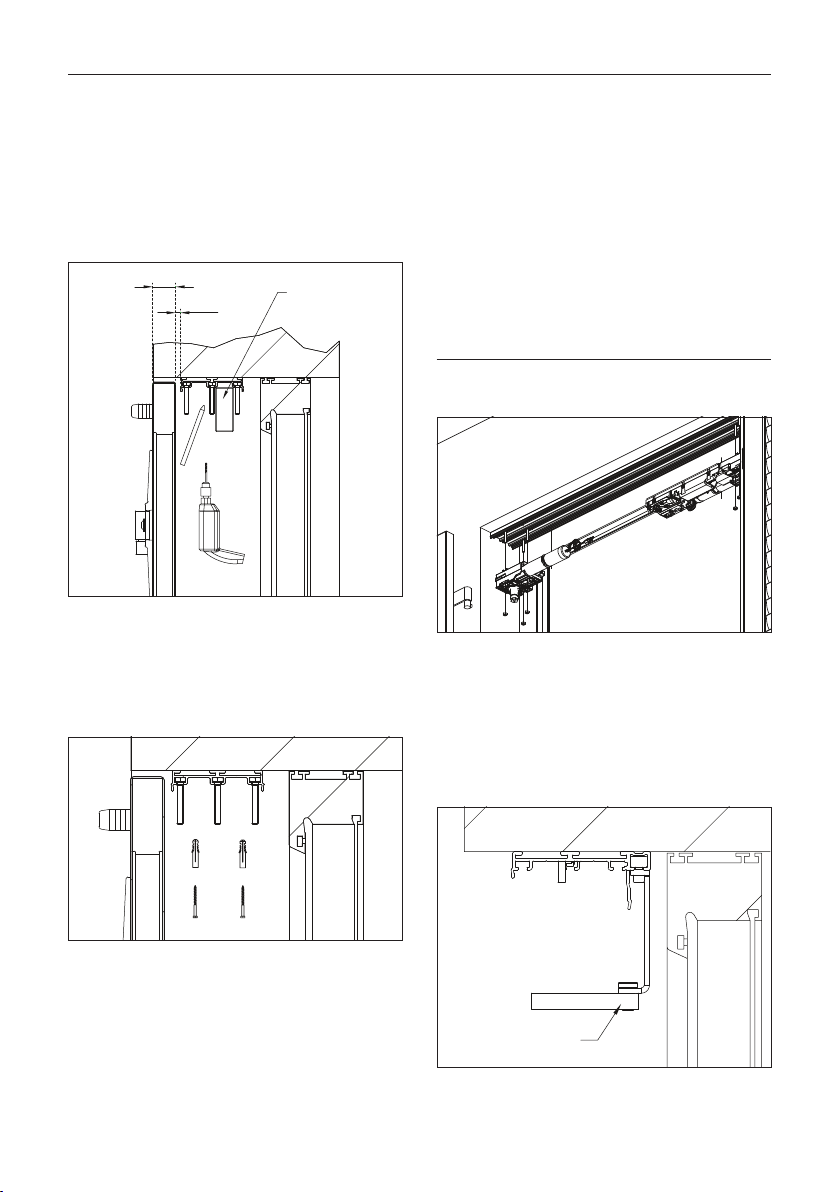

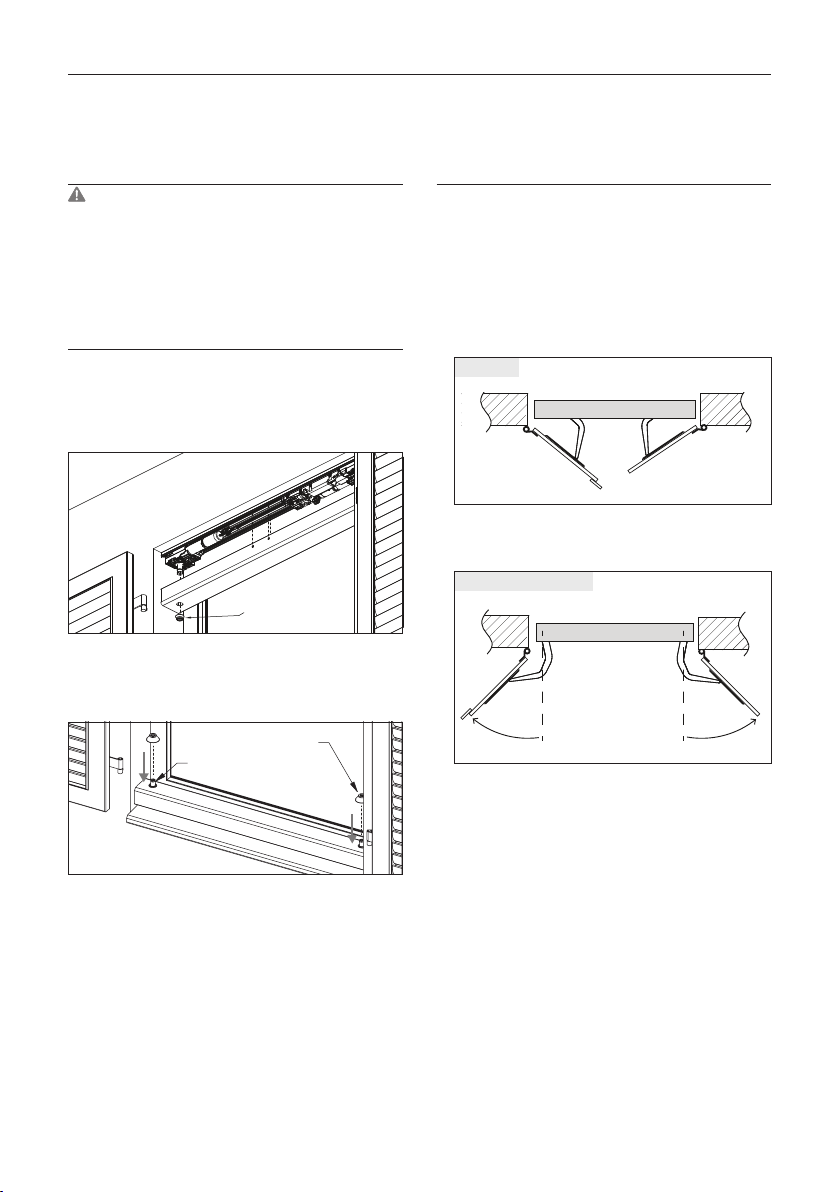

Variant A

Header installation

Position the installation profile with shutters

closed (dimension X + 5 mm) and align it

horizontally.

X

5Spirit level

X = sash thickness in the reveal

Mark and drill the fastening holes.

Fasten installation profile at at least four

points.

Insert the electromechanical module into the

frame on the side where the power supply

enters.

Insert the drive modules into the installation

profile, move them as far as they will go (limit

screw S1) and fasten them with the drive

nuts.

NOTE

Do not screw the drive nuts too tightly!

For multiple-section sashes

Diagram 2L/2R, 3L/3R, 4

Insert pivot bearings into the installation pro-

file when coupling multi-section sashes!

Pivot bearing

15

2 Installation instructions

Variant B

Reveal installation

Position the installation profile with lateral

fastening brackets (dimension X + 5 mm) and

align it vertically and horizontally with a spirit

level; drill and attach.

X

5

Spirit level

Fastening bracket

X = sash thickness in the reveal

CAUTION

Property damage caused by sliding of the

drive due to insufficient fastening

Use security bore hole!

2.3_B

Security

bore hole

Insert the electromechanical module into the

frame on the side where the power supply

enters.

Insert the drive modules into the installation

profile, move them as far as they will go (limit

screw S1) and fasten them with the drive

screws.

NOTE

Do not screw the drive nuts too tightly!

For multiple-section sashes

Diagram 2L/2R, 3L/3R, 4

Insert pivot bearings into the installation pro-

file when coupling multi-section sashes!

Pivot bearing

16

2 Installation instructions

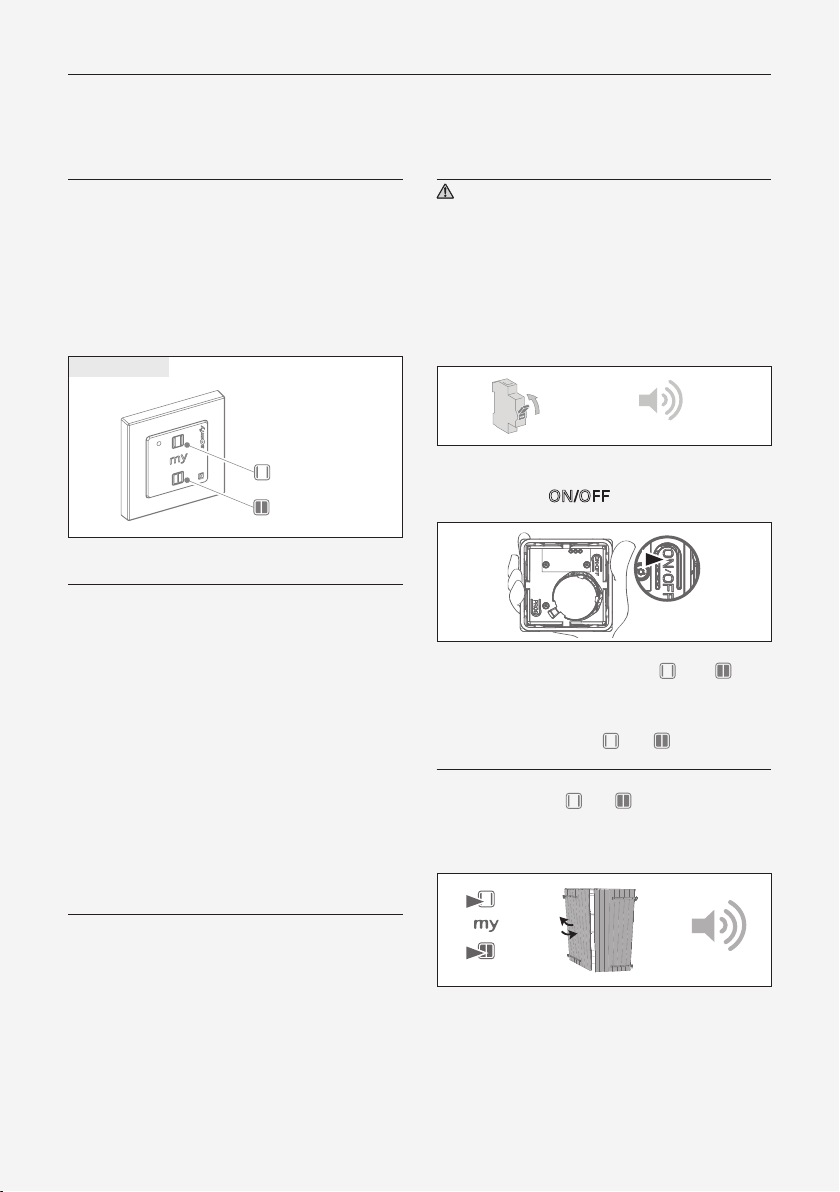

Variant C

At the bottom above the windowsill

Position the installation profile with lateral

fastening brackets at the bottom above the

windowsill (dimension X + 5 mm) and align

it vertically and horizontally with a spirit level;

drill and attach.

X

5

Y = min. 5 mm

Spirit level

Fastening bracket

X = sash thickness in the reveal

Y = air (upper edge of windowsill to lower edge of installation

profile), min. 5 mm

CAUTION

Property damage caused by sliding of the

drive due to insufficient fastening

Use security bore hole!

Security

bore hole

Insert the electromechanical module into the

frame on the side where the power supply

enters.

Insert the drive modules into the installation

profile, move them as far as they will go (limit

screw S1) and fasten them with the drive

screws.

NOTE

Do not screw the drive nuts too tightly!

For multiple-section sashes

Diagram 2L/2R, 3L/3R, 4

Insert pivot bearings into the installation pro-

file when coupling multi-section sashes!

Pivot bearing

17

2 Installation instructions

Cable routing

WARNING

Electrical shock (230 V) resulting from dam-

age to cable

Pass the cable through the cable holder to

guarantee electrical safety and the integrity

of the cable.

CAUTION

Danger of crushing/property damage from

incorrect cable placement

Install the electromechanical module next to

the voltage supply inlet. Note while doing so

that the mains cable proceeds outward from

the product on the window side!

Do not disconnect the mains cable in the

area between the drive and the red cable

marking!

Cable holder

Wiring

WARNING

Electrical shock (230 V) resulting from dam-

age to cable

Protect mains cable against contact with the

activated window shutter!

CAUTION

Impairment of the antenna and the radio

range

Do not alter the placement of the cables in

the interior of the product!

Do not cut off the cable in the interior of the

product!

Always switch off the power supply via the

mains cable before each operation.

OFF

Connect the drive as follows:

230 V 50 Hz

VOLETRONIC io

Switch on the voltage supply.

ON

The VOLETRONIC io folding shutter drive con-

firms by means of an audible signal. If this is not

the case, check the electrical connection again.

Switch off the power supply again after

checking the electrical connection.

OFF

18

2 Installation instructions

Attaching the cover

WARNING

Electrical shock (230 V) resulting from dam-

age to cable

Position the recess of the cover on the side

with the mains cable!

Protect the mains cable against crushing by

the cover of the drive housing!

Hold the cover parallel and clip it firmly in

place.

Attach adhesive buffers.

Sealing

sleeve

Place the left and right sealing sleeves on

the drive axle and press them onto the trim

cover.

Drive axle

Sealing sleeve

Sample drawing – variant C

Attaching sash arms with guide

rails on the drive

NOTES

• The swivel arms must be fitted in accord-

ance with one of these two recommenda-

tions:

a) half open, outside the end positions, ob-

serving the sequence of the covered sash

and the sash with cover strip

Half open

VOLETRONIC io

b) at an angle of more than 90°outside the

open end position.

VOLETRONIC io

90° 90°

Angle of more than 90°

• Note whether a left-hand or right-hand sash

arm is required.

• The castor of the sash arm must be posi-

tioned at the middle of the guide rail at the

time of installation.

• The joints of the guide rails must face down-

wards at the time of installation.

• Remove all objects that could obstruct the

movement of the folding shutter.

• Do not use a hammer during assembly.

19

2 Installation instructions

Thread the sash arm into the guide rail and

plug the end pieces into the guide rail

Sash arm

End piece

Guide rail

Set the sash arm on the drive hex nut and

fasten with the self-locking S2 screws pro-

vided

Use the washers provided.

Set covers on S2 screw.

Guide rail

with end pieces

Drive hex nut

Sash arm with

castor

S2

Cover cap WAF17

Washer

Attaching guide rails to the sash

NOTES

Observe the edge clearance of the guide rails

with rabbet or surface-mounted installation.

For models with protruding slats, use the 6220

supports for end pieces of window shutter drive

with the corresponding S4 screws.

When selecting screws for window shutters

made of wood (a decision that is the exclusive

responsibility of the installer), care must be

taken to ensure that the sliding guides cannot

be torn off.

Centre the guide rail in the sash width and

use a spirit level to align it horizontally.

Mark fastening holes, drill them with a

Ø 4.2 mm drill bit and fasten them with the

S3 screws supplied.

94.5

86

ca. 3 mm

111

S3

Adhesive buffer

Stop buffer

with support

Anschlagpuffer als Flügelanschlag montieren.

INFO

The stop buffers can be installed as stops either

on the exterior side of the sash at the top-outer

corner or on the façade.

20

2 Installation instructions

COMMISSIONING

NOTE

In order to carry out commissioning success-

fully, the following commissioning work steps

must be carried out consecutively and coher-

ently.

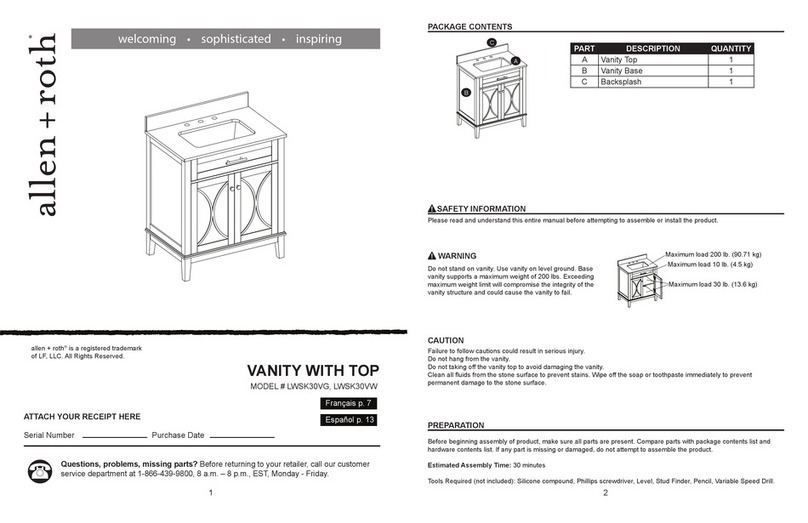

Wireless Radio wall transmitter

Smoove 1 O/C io

open

close

ACTIVATE RADIO WALL TRANSMITTER

(P. 20)

CHECK DIRECTION OF ROTATION AND

PRIORITY OF THE SASHES (P. 21)

SELF-LEARNING PROCESS (P. 21)

CONNECTING THE RADIO WALL

TRANSMITTER TO THE DRIVE (P. 23)

VERIFICATION OF PROPER FUNCTION-

ING (P. 23)

ACTIVATE RADIO WALL TRANSMITTER

CAUTION

Do not press against the sensitive side of the

wireless wall transmitter with the flat of the

hand because otherwise unintended com-

mands could be triggered.

Switch on the voltage supply.

The drive emits a beep.

beep

ON

Check that the radio wall transmitter is

switched on (ON/OFF).

Press and hold the buttons and only

until the product confirms the activation with

a short up/down movement and a signal tone.

Release the buttons and immediately!

ATTENTION!

If the and buttons and continue to be held

down after the drive has confirmed activation,

the drive blocks.

beep

Table of contents

Other EHRET Indoor Furnishing manuals

Popular Indoor Furnishing manuals by other brands

Courtyard Creations

Courtyard Creations XTM015W Assembly instructions

SEI

SEI BE6621 instruction manual

Salamander Designs

Salamander Designs SYNERGY SYSTEM SLC20 Assembly instructions

Emmezeta

Emmezeta AVA DD8018-4R Assembly instructions

Allen + Roth

Allen + Roth LWSK30VG manual

HULALA HOME

HULALA HOME SCBSD0590 manual

pottery barn kids

pottery barn kids EVERETT MODULAR DESK CUBBY BASE manual

Home affaire

Home affaire 23345327 Assembly instructions

Zedbed

Zedbed CUSTOM Z manual

Safavieh Furniture

Safavieh Furniture DSK9000 quick start guide

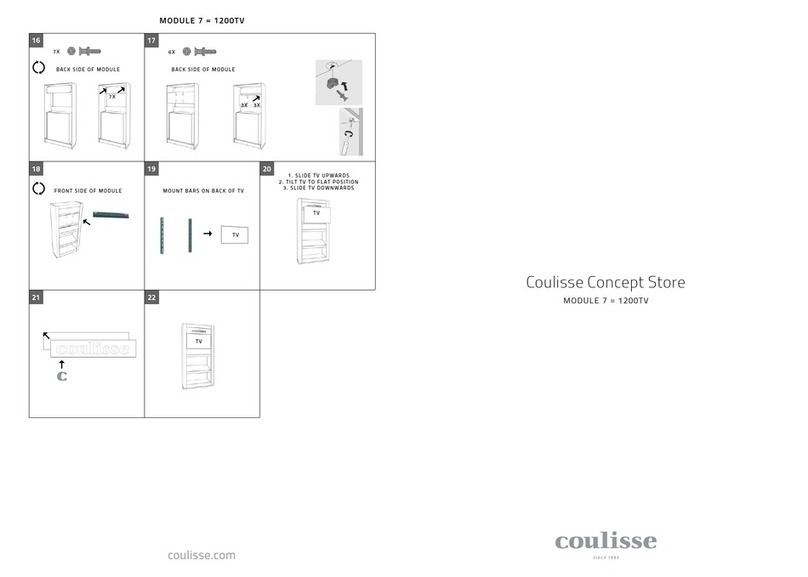

Coulisse

Coulisse Module 7 Installation instructions manual

Martin Svensson

Martin Svensson Space Saver 899922 Assembly instructions