EHRET VOLETRONIC User manual

Operating instructions

INSTALLATION

SPECIALIST PERSONNEL

Valid from 09.2011

E 917.2

VOLETRONIC

Motorisation for sliding shutters

2

Notes

The present operating instructions describe

the commissioning & programming of EHRET

sliding shutter drive VOLETRONIC.

It is essential to install the sliding shutter sys-

tem in accordance with the specifications laid

out in the E915 Installation instructions

EHRET sliding shutters before commissioning

the sliding shutter control.

Carefully read through these instructions prior

to commissioning. Observe the specified pro-

cess steps and take into account the notes and

recommendations given. Knowledge of and

technically impeccable implementation of the

given safety notes and warnings are prerequi-

sites for safe and proper operation of the

EHRET sliding shutter control. Insufficient

knowledge at the time of commissioning and

utilisation lead to the loss of any liability claims

against EHRET GmbH. Installation and/or oper-

ation in full or partial deviation from our installa-

tion and operating instructions will lead to the

warranty for defects becoming void.

Installation instructions

INSTALLATION BY

SPECIALIST P ERSONNEL

Valid from 09.2011

E 915.5

Sliding shutters

Aluminium shutters

E 915 Installation instructions | EHRET Sliding shutters

These operating and maintenance instructions

are a component part of the product and are

therefore always to be retained until the prod-

uct is disposed of. These operating and main-

tenance instructions are to be passed along in

the event of the sale of this product.

These instructions are addressed to qualifi ed

specialist personnel. Qualified specialist per-

sonnel are persons who are familiar with the

transport, setup, installation, commissioning

and operation of the product and who have ap-

propriate qualifications for their work. Specia-

list personnel must know and observe the rele-

vant standards and/or guidelines.

This product is in accordance with general ru-

les of technology. Safety-conscious behaviour

is necessary for undertaking safe commissio-

ning. Observe for that reason the following no-

tes. Should you not understand something in

these Installation & operating instructions un-

ambiguously, do not fail to contact the specia-

list personnel at EHRET GmbH, 77972 Mahl-

berg (Germany).

Bore hole sizes and fastening material are re-

commendations; these could vary because of

the substrate!

3

Contents

Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Explanation of signs and symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Safety notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Electrical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Incorrect operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Behavior at power breakdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

EC Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

A VOLETRONIC 230 V | serial push-button operation

Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Setting the running direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Executing a learning run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Setting the speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Impulse/dead man mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

B VOLETRONIC 230 V | wireless remote control

Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Teaching master transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Checking/Changing the running direction . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Performing a learning run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Setting the speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Teaching an additional transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Clearing of an additionally taught transmitter . . . . . . . . . . . . . . . . . . . . . . . . . 26

Global clearing of all additionally taught transmitters . . . . . . . . . . . . . . . . . . . . . 27

Group control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

C VOLETRONIC Solar 12 V | wireless remote control

Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Attach solar panel on the cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Attaching the rechargeable battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Teaching master transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Monitoring/modification of the direction of travel. . . . . . . . . . . . . . . . . . . . . . . 37

Further settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4

Important notes

Explanation of signs and symbols

Warning notes

DANGER

Designates an imminent danger that

could lead to death or severe injuries if

the respective precautionary measures

are not implemented.

WARNING

Means that death, severe bodily injury or

major property damage could occur if the

respective precautionary measures are

not implemented.

CAUTION

Means a possible danger that could lead

to minor injuries or property damage if it

is not avoided.

Directives for action

Safety notes

Only qualified specialist personnel may

carry out installation and commission-

ing!

WARNING

Incorrect installation could lead to se-

vere injuries and/or damage to prop-

erty.

Follow all installation instructions.

WARNING

Take into account the following notes

and warnings in order to avoid dangers

and to protect the product.

Observe the accident prevention regula-

tions of the Accident Prevention & Insur-

ance Association.

Observe the rules of the road during trans-

port.

Make sure that the load is well-secured on

the means of transport.

Take care to ensure that the drives are

stored under dry conditions prior to final in-

stallation and commissioning.

Cordon off a generously large area around

the installation site.

Observe without limitation the regulations

of the manufacturers of dowel and attach-

ment materials.

The mounting bases of the installation site

are to be checked for load-bearing capacity

prior to installation.

In the event of uncertainties about the

mounting bases, contact your responsible

building experts.

Electrical work may be carried out only by

authorised electricians.

5

Important notes

The specified connection diagrams are to

be observed, as otherwise damage to the

motor could occur. EHRET GmbH assumes

no liability for damage resulting from incor-

rect installation.

Check the product for damage prior to in-

stallation. Products requiring repair may not

be used.

Do not touch any internal parts of the prod-

uct that become exposed as the result of

damage (e.g. electrical cables/lines).

Discontinue operation of your electrical

drive at once in the event of smoke or

fumes.

Do not allow children to play with the oper-

ating apparatus of the drives.

Electrical/electronic devices are not secure

against failure. Make sure that no hazard-

ous situations for personnel or product

could arise in the event of a power failure.

Devices with electrical controls could go

into motion at any time and without warn-

ing. Prevent situations hazardous to person-

nel and product that arise from this fact.

No personnel or obstacles are permitted to

be within the range of pivoting and/or trav-

elling shutters while they are moving. Keep

personnel and objects away until the shut-

ters have reached their final position.

Do not reach into moving parts or closing

areas while shutters are opening or closing.

Make sure that no articles of clothing or

body parts are able to be caught by moving

parts in the system.

Disconnect the drives from the power sup-

ply during maintenance work.

Ice could form on the product in the event

of snowfall, sleet or icy rain. Do not operate

equipment until the ice formation is no

longer present, and switch automatic con-

trols to manual.

Make sure that the shutters are locked be-

fore any wind load occurs.

The shutters may not be operated at wind

speeds from 62 km/h (stormy wind).

No additional loads such as persons or ob-

jects are permitted to have an effect on the

shutters.

Shutters are not intended to protect indi-

viduals from falls.

WARNING

Danger of injury from the weight of

the product!

Due to the weight of the products,

perform transport and installation by at

least two individuals.

Transport the product carefully in order to

avoid damage.

Take care to ensure that the product is not

damaged when the packaging material is

removed.

WARNING

Danger of suffocation from packaging

foil.

The packaging foil must be kept out of

reach of children.

Store the foil carefully until you turn it

in for recycling.

Turn the packaging materials in for recy-

cling.

6

Important notes

Electrical installation

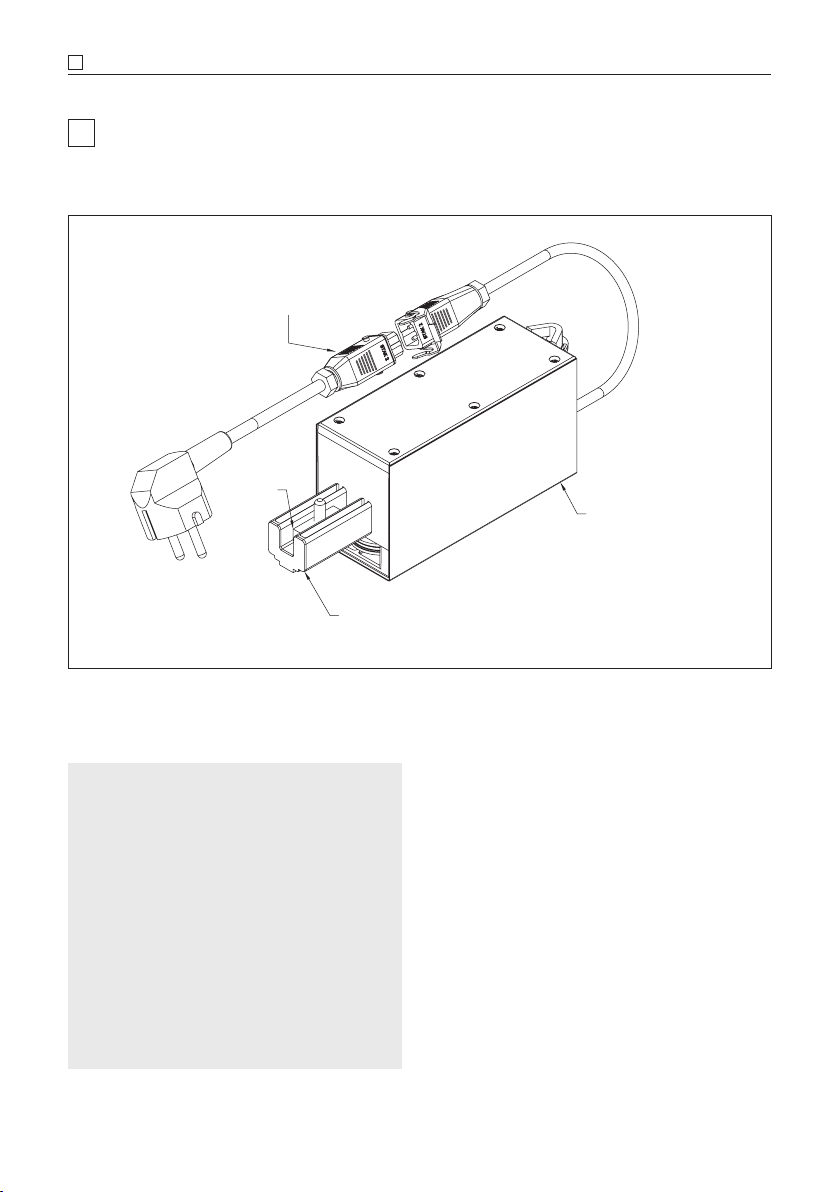

DANGER

Electrical shock (230 V)

The correct installation of the sliding shut-

ter drive may be carried out only by autho-

rised specialist personnel!

At the time of installation, all connections,

as shown schematically in the illustration,

are to be connected. The guarantee ex-

pires if the Hirschmann plug is removed.

The connection (Phase L) must be equip-

ped with a line safety switch with a maxi-

mum nominal current of 6 A.

The line safety switch must have a switch-

off capacity of at least 6 kA.

The prescribed tripping characteristic is B.

The line switch should be equipped with a

thermal tripping device for overload protec-

tion, furthermore it should have an electro-

magnetic trigger as a protection against

short circuits.

Other requirements may apply to the instal-

lation of the line safety switch, depending

on the location. For example, it could be

necessary to use a line safety switch with

additional separation of Phase N in order to

switch off all poles. It might possibly also be

necessary to have a residual current circuit

breaker in the system. The standards and

the laws of the respective country with res-

pect to permanent electrical installations

are to be complied with (e.g. VDE 0100).

It is recommended that no more than fi ve

drives are secured simultaneously by a sin-

gle line safety switch.

Pursuant to VDE 0100 and/or the statutory

regulations and standards of the respective

country, the permanent electrical installati-

on must be carried out by a certified electri-

cian.

According to VDE 0022, the operator and

the installer are responsible for compliance

with the VDE regulations and/or regulations

of the energy supplier.

7

Important notes

Incorrect operation

Correct operation can no longer be ensured if

the sliding shutter is moved by hand quickly

and with great force in its position, and not by

means of operation with the OPEN- or

CLOSE-button.

A force may be applied to the sliding shutter in

such cases in such a way that the current me-

chanical position of the sliding shutter no lon-

ger matches the position present in the con-

trol.

This leads to incorrect information within the

control, as a result of which the control will no

longer function correctly.

This condition usually is rectified by an as-

cent and descent run.

Behavior at power breakdown

IMPORTANT

Deletion of reference position due to po-

wer failure

Power failure can lead to deletion of the re-

ference position.

Move the sliding shutter with push-but-

ton OPEN- or CLOSE in direction

of motor to until the end position. In

this position the control system recog-

nize the reference of the normal wor-

king.

If the sliding shutter has been in position

of reference, at power breakdown, it is

necessary to have to move the shutter

for and backward with push-button

OPEN- or CLOSE.

After that the function is again guaran-

teed.

8

Important notes

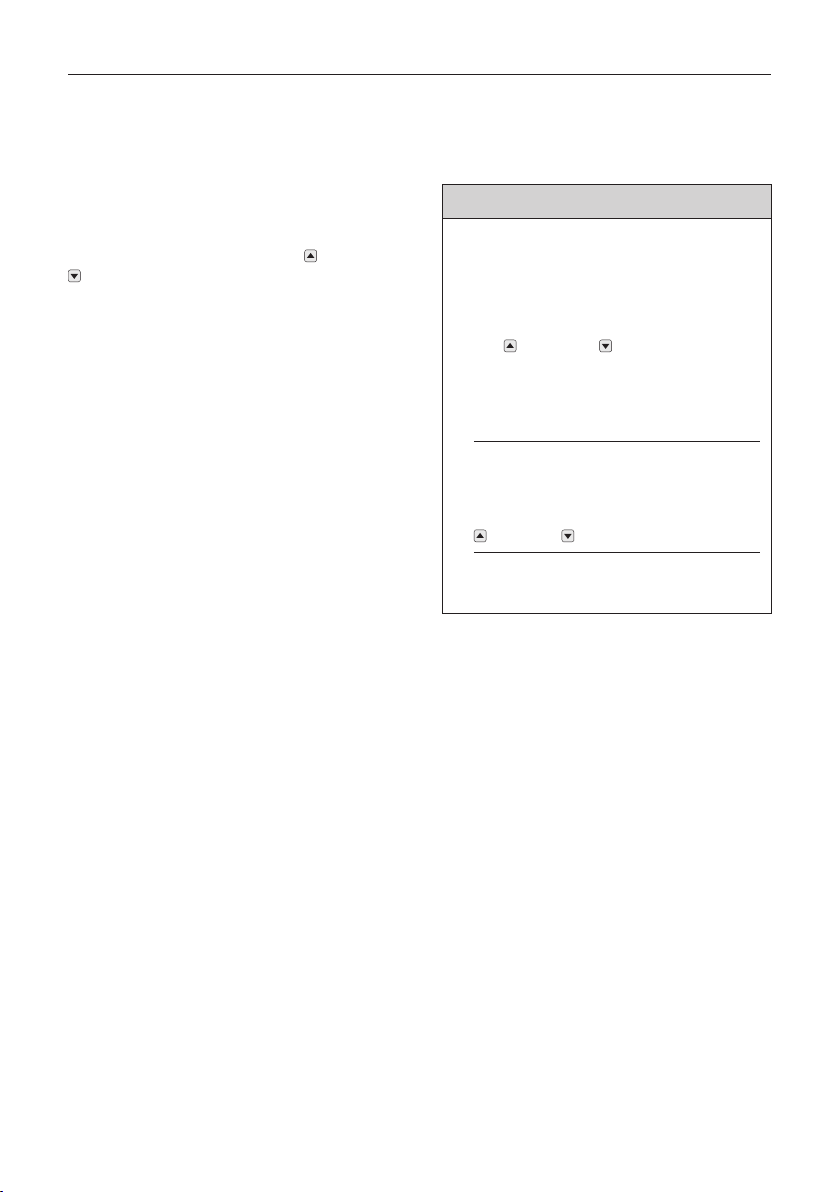

Disposal

IMPORTANT

Disposal

• The following information must be strictly

adhered to in order to prevent any environ-

mental damage. Even if the machine is dis-

posed of by certified experts, the operator

must ensure proper execution!

Some materials of the machine are reusable.

By recycling some parts or raw materials from

used products, you make an important contri-

bution to protecting the environment.

Please contact your local authorities if you

require information about collection points

near you.

Recyclable materials of the machine

Reusable

material

Components

Aluminium • Sliding shutters

• Suspensions

• Guide brackets

• Window sill cover

• Fittings

Copper • Cables

• Motor

Plastic,

rubber, PVC

• Guides

• Accessories

• Seals

• Cables

Steel • Motor and components

• Fittings

• Accessories

IMPORTANT

Disposal

Dispose of any machine parts in such a

way that damage to human health and the

environment can be excluded.

Hazardous waste

Reusable

material

Components

Electronic

waste

• Electrical supplies

• Control units

• Circuit boards with

electronic components

9

Important notes

EC Declaration of Conformity

The manufacturer: EHRET GmbH

Aluminium Shutters

Bahnhofstrasse 14 - 18

D - 77972 Mahlberg

erklärt für das Produkt: VOLETRONIC 230 V sliding shutter drive

VOLETRONIC Solar 12 V sliding shutter drive

to which this guideline refers, is in conformance with the stipulations of

Guideline 1999/05/EC Radio equipment and telecommunications terminal equipment

as well as with the following standards:

EN 301 489-3:2000 Electromagnetic compatibility and Radio spectrum Matters

(ERM), Electromagnetic Compatibility (EMC) standard for radio

equipment and services – Part 3: Specific conditions for Short-

Range Devices (SRD) operating on frequencies between 9 kHz

and 40 GHz

EN 300 220-3:2000 Electromagnetic compatibility and Radio spectrum Matters

(ERM); Short Range Devices (SRD) radio equipment to be used

in the 25 MHz to 1000 MHz frequency range with power levels

ranging up to 500 mW – Part 3: Harmonized EN covering essen-

tial requirements under Article 3.2 of the R&TTE Directive

98/37/EC Machinery Directive

EN 73/23/EEC Low Voltage Directive

EN 60730 +A1 +A2 +A11 Safety requirements for automatic electric regulators and

+A12+A13+A14+A15 controllers

—

Name and address of the individual who is authorised to assemble the technical documentation:

Ralf Gielen Location: 77972 Mahlberg, Germany

Head of Technology Date: 01/01/2015

EHRET GmbH

Andreas Schnaase

Head of Sales

EHRET GmbH

Eberhard Schopferer

Management

10

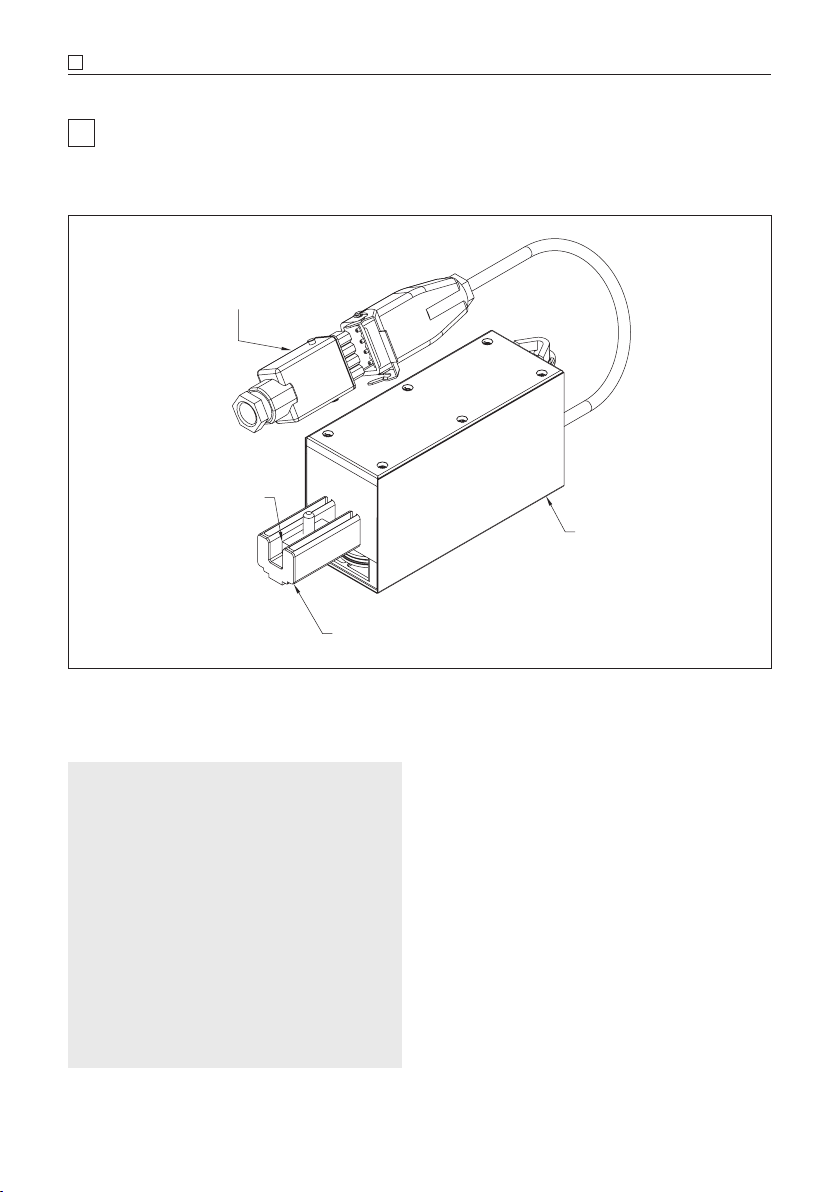

AVOLETRONIC 230 V | serial push-button operation

A VOLETRONIC 230 V | serial push-button operation

Product description

Rail connection

Motor cover

Rail clamp

Connection cable

with 5-pin Hirschmann plug

Technical data

Power supply 85 VAC–265 VAC,

50/60Hz, 30 W

Standby < 1 W

Protection class I

IP type of protection IP 43

Temperature range – 20° C to + 60° C

in operation

Speed max. 120 mm/s

Propulsion max. 150 N

Connection cable 5-pin Hirschmann

plug

Power input of the < 5 mA (1 W)

Close/Open entrance

The EHRET VOLETRONIC 230 V sliding shutter

drive is a drive with integrated control for the

actuation of sliding shutters.

• Congurable running speed

• Electronic locking in end position

• Programming of the pick-up position of dou-

ble bars and acceleration or delay of the run-

ning speed at the beginning, the end and in

the pick-up range.

• Creep travel upon reaching the start and end

position

11

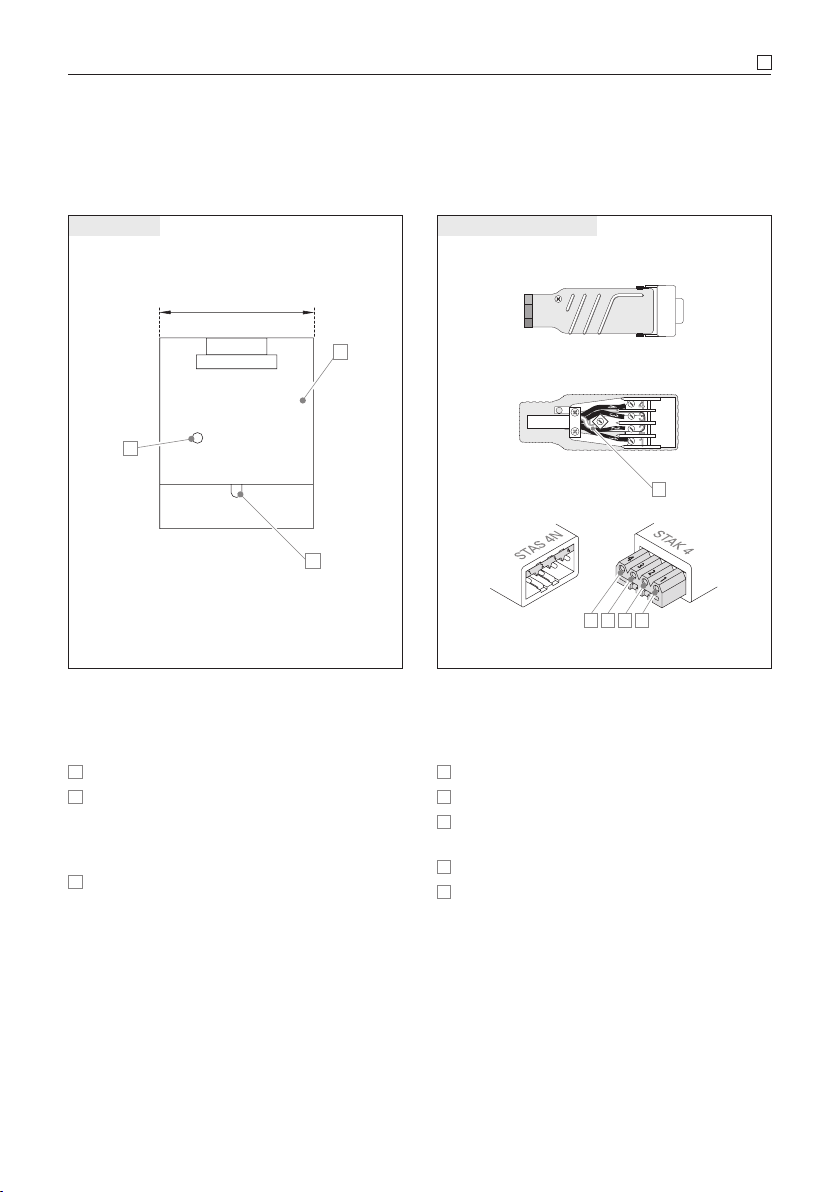

VOLETRONIC 230 V | serial push-button operation A

Connection

B

C

A

ca. 55

Motor housing

Motor

AMotor cover

BMains connection 230 V with Hirschmann

coupling, 5-pin. The motor is equipped with

a 5-pin connection cable with Hirschmann

coupling approx. 0.5 m.

CMonitoring LED on the side of the motor

housing (green | yellow | red) used for exam-

ple for checking the running direction.

4

3

2

1

4

3

2

1

0

4321

Connection cable with plug

5-pin Hirschmann plug

0Earth – protective conductor (green/yellow)

1Mains connection, L-Phase (230V)

2Mains connection N-neutral conductor

(230V)

3OFF-button signal (230V)

4ON-button signal (230V)

12

AVOLETRONIC 230 V | serial push-button operation

Commissioning

NOTE

• The correct installation of the sliding shutter

drive may be carried out only by authorised

specialist personnel; it is only then that the

entire functionality can be guaranteed.

Initial commissioning can be carried out once

the motor has been correctly installed in the

sliding shutter system.

Connect the 5-wire Hirschmann coupling to

your serial push-button and your electrical cir-

cuit!

Check the running direction

If the running direction is correctly set, then the

LED display on the motor will light up green

during ascent and red during descent.

If this is not the case, then the running direction

must be changed (see chapter “Setting the

running direction”, page 13).

SERIAL PUSH-BUTTON

• In order to avoid an unwanted change of pa-

rameters, the time (max. 2 sec.) between the

individual programming steps must be ob-

served.

• The signal tones must have gone out before

the next programming step.

• Always check the running direction after a

change of parameters. It is displayed accord-

ingly through the LED on the drive housing

with green for ascent, red for descent

and yellow during the learning run.

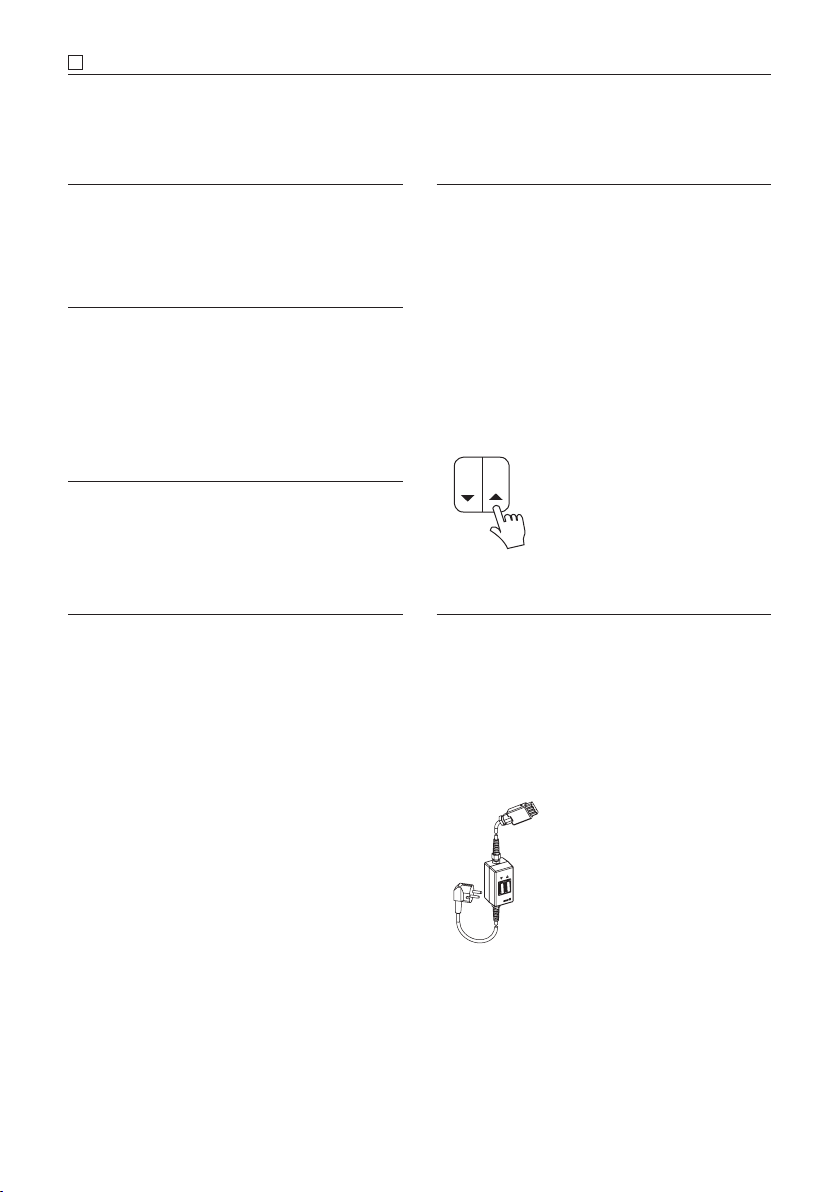

MOTOR SETTING & INSPECTION UNIT

• As an optional alternative to the serial push-

button, the motor can also be tuned through

the “motor setting & inspection unit V3,

5-wire”, art. no. 881057.

• If no connector is available at the time of the

installation, then the motor setting & inspec-

tion unit must be used.

13

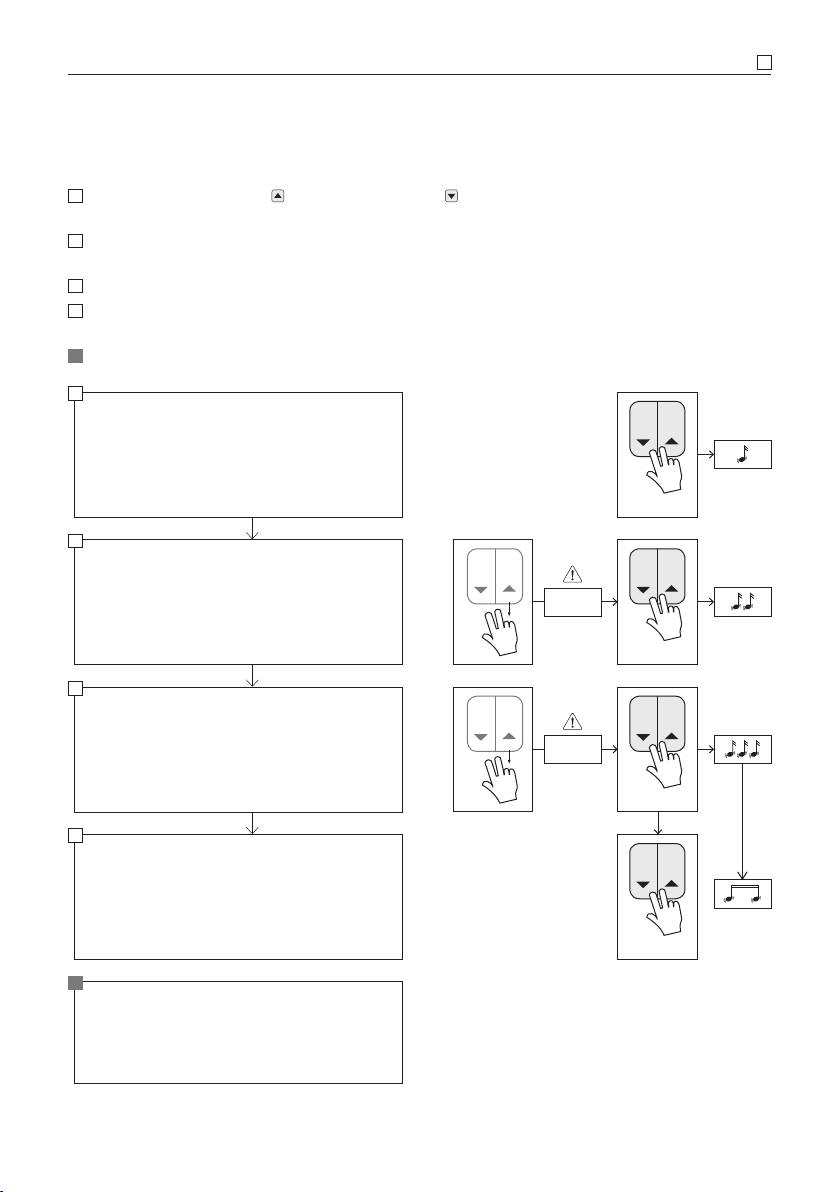

VOLETRONIC 230 V | serial push-button operation A

Setting the running direction

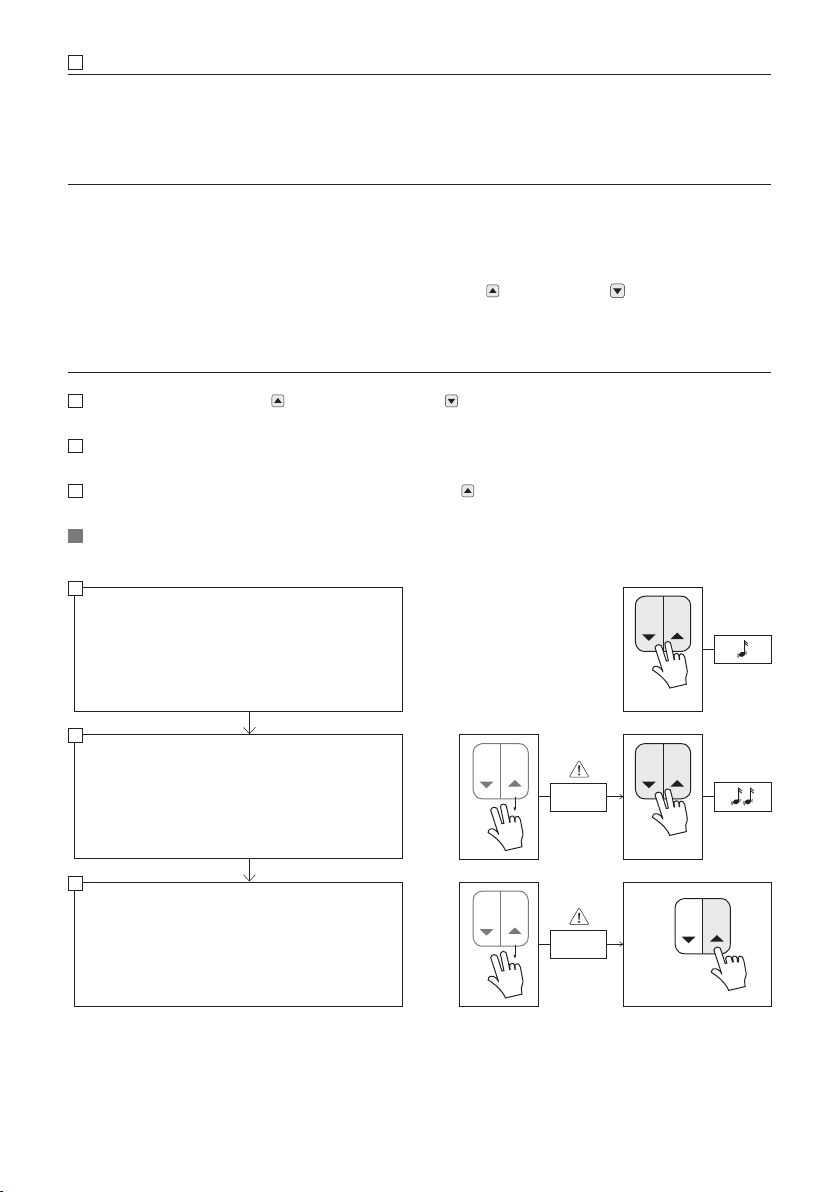

1Press and hold down the OPEN button and the CLOSE button together and simultaneously

(approx. 3 sec.), until a brief signal tone is heard and then goes out.

2Release the buttons only briefly, then, within a maximum of 2 seconds, press and hold them

down simultaneously again until the following 2 signal tones go out.

3Release the buttons briefly again and then repeat the procedure once more.

4However, after the sounding of the 3 signal tones, do not release the buttons until a longer sig-

nal tone is heard and goes out. The running direction is thus changed.

Check the running direction through LED check.

Hold OPEN + CLOSE button pressed down for

approximately 3 sec.

1 signal tone

Release OPEN + CLOSE button

Press and hold OPEN + CLOSE button down once

more within 2 sec. for approx. 3 sec.

2 signal tone

2

Release OPEN + CLOSE button

Press and hold OPEN + CLOSE button down once

more within 2 sec. for approx. 3 sec.

3 signal tone

3

Continue to hold OPEN + CLOSE button pressed

down until

Long signal tone

the running direction is changed

4

≤ 2 sec.

≤ 2 sec.

1

Check the running direction

If the running direction is correct, the LED will show:

green at ASCENT

red at DESCENT

14

AVOLETRONIC 230 V | serial push-button operation

Executing a learning run

NOTES

Systems with double bars (a sash that is not connected with the drive cable)

The double bars must be manually taught during the learning run:

Move sashes into the Open end position

As soon as the powered sash moves the double bar, the OPEN and the CLOSE button must

be actuated briefly and simultaneously. A signal tone confirms the programming.

This procedure must be repeated in the case of systems with several double bars (max. 4). Each

manual actuation of an additional double bar is acknowledged with an additional signal tone.

1Press and hold down the OPEN button and the CLOSE button together and simultaneously

(approx. 3 sec.), until a brief signal tone is heard and then goes out.

2Release the buttons only briefly, then press and hold them down together again once more until

the following 2 signal tones go out.

3After the second signal tone, immediately press the OPEN button 3× in quick succession. The

learning run starts automatically.

LED monitoring: When the learning run is correct, the LED on the drive lights up yellow and ends

with a twotime signal tone.

≤ 2 sec.

3×

≤ 2 sec.

Hold OPEN + CLOSE button pressed down for

approximately 3 sec.

1 signal tone

Release OPEN + CLOSE button

Press and hold OPEN + CLOSE button down once

more within 2 sec. for approx. 3 sec.

2 signal tone

Release OPEN + CLOSE button

Press the OPEN button within 2 sec. 3× in quick

succession

Learning run starts automatically

1

2

3

15

VOLETRONIC 230 V | serial push-button operation A

Setting the speed

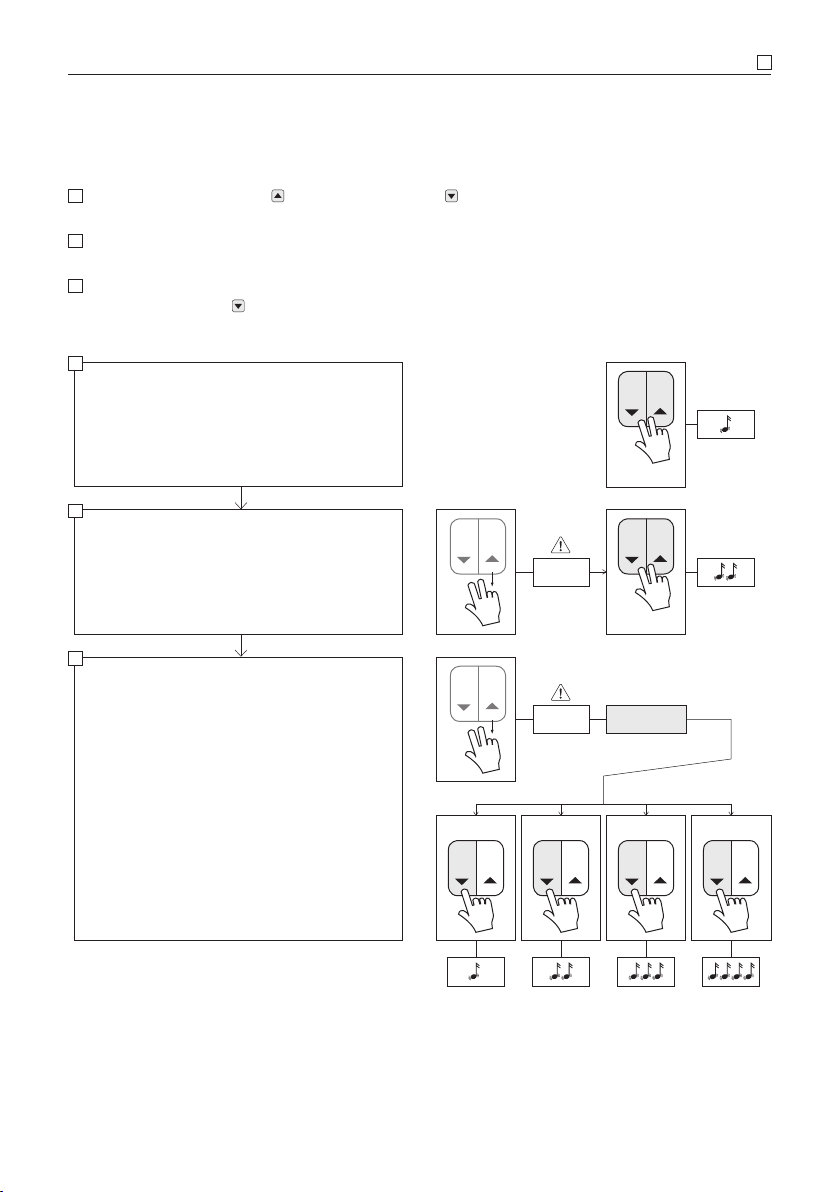

1Press and hold down the OPEN button and the CLOSE button together and simultaneously

(approx. 3 sec.), until a brief signal tone is heard and then goes out.

2Release the buttons only briefly, then press and hold them down together again once more until

the following 2 signal tones go out.

3Release the buttons and then select the desired speed level (max. 4 levels) by repeatedly and

briefly pressing the CLOSE button. The respective speed level is displayed accordingly by the

number of signal tones.

1×

≤ 2 sec.

≤ 2 sec. Levels 1–4

2× 3× 4×

Hold OPEN + CLOSE button pressed down for

approximately 3 sec.

1 signal tone

Release OPEN + CLOSE button

Press and hold OPEN + CLOSE button down once

more within 2 sec. for approx. 3 sec.

2 signal tone

Release OPEN + CLOSE button

select the speed level within 2 sec.

1× pressing CLOSE button = speed level 1

2× pressing CLOSE button = speed level 2

3× pressing CLOSE button = speed level 3

4× pressing CLOSE button = speed level 4

1

2

3

16

AVOLETRONIC 230 V | serial push-button operation

Impulse/dead man mode

1Press and hold down the OPEN button and the CLOSE button together and simultaneously

(approx. 3 sec.), until a brief signal tone is heard and then goes out.

2Release the buttons only briefly, then press and hold them down together again once more until

the following 2 signal tones go out.

3Repeat this procedure until 3 signal tones are heard and go out.

Repeat this procedure until 4 signal tones are heard and go out. However, after the fourth signal

tone sounds, continue to hold the OPEN button and the CLOSE button pressed down until

a brief signal tone confirms impulse mode, or a long signal tone confirms dead man mode.

Hold OPEN + CLOSE button pressed down for

approximately 3 sec.

1 signal tone

Release OPEN + CLOSE button

Press and hold OPEN + CLOSE button down once

more within 2 sec. for approx. 3 sec.

2 signal tones

Release OPEN + CLOSE button

Press and hold OPEN + CLOSE button down once

more within 2 sec. for approx. 3 sec.

3 signal tones

Release OPEN + CLOSE button

Press and hold OPEN + CLOSE button down once

more within 2 sec. for approx. 3 sec.

4 signal tones

Continue to hold OPEN + CLOSE button pressed

down until:

Long signal tone = dead man mode

Short signal tone = impulse mode

≤ 2 sec.

≤ 2 sec.

≤ 2 sec.

1

2

3

17

18

BVOLETRONIC 230 V | wireless remote control

B VOLETRONIC 230 V | wireless remote control

Product description

Rail connection

Motor cover

Rail

clamp

Connection cable

with 3-pin Hirschmann plug

Technical data

Power supply 85 VAC–265 VAC,

50/60Hz, 30 W

Standby < 1 W

Protection class I

IP type of protection IP 43

Temperature range – 20° C to + 60° C

in operation

Speed max. 120 mm/s

Propulsion max. 150 N

Connection cable 3-pin Hirschmann

plug

Power input of the < 5 mA (1 W)

Close/Open entrance

The VOLETRONIC sliding shutter drive with

wireless remote control is a drive with integrat-

ed control for the actuation of sliding shutters.

• Congurable running speed

• Electronic locking in end position

• Programming of the pick-up position of dou-

ble bars and acceleration or delay of the run-

ning speed at the beginning, the end and in

the pick-up range.

• Creep travel upon reaching the start and end

position

19

VOLETRONIC 230 V | wireless remote control B

Connection

B

C

A

ca. 55

D

Motor housing

Motor

AMotor cover

B230 V mains connection with Hirschmann

coupling. The motor is equipped with a 3-pin

connection cable with Hirschmann coupling

approx. 0.5 m.

CMonitoring LED on the side of the motor

housing (green | yellow | red) used for exam-

ple for checking the running direction

DAntenne 868 MHz

• Connected shock-proof plug for setup and

programming of the system by the installer.

• Hirschmann plug (must be connected to the

electrical circuit by an electrician)

2

1

0

1

2

1

2

Connection cable with plug

3-pin Hirschmann-plug

0Earth – protective conductor (green/yellow)

1Mains connection L – Phase (230 V)

2Mains connection N – Neutral conductor

(230 V)

20

BVOLETRONIC 230 V | wireless remote control

Commissioning

NOTES

• The correct installation of the sliding shutter

drive may be carried out only by authorised

specialist personnel; it is only then that the

entire functionality can be guaranteed.

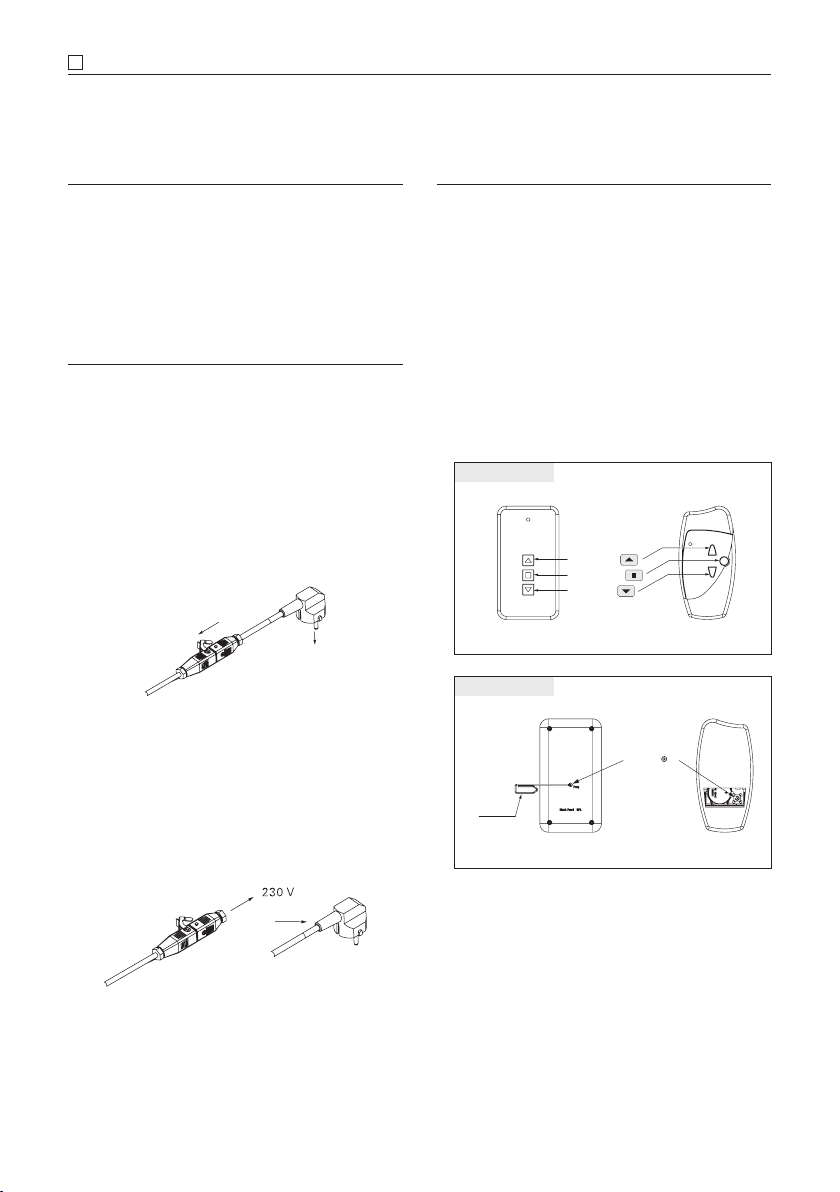

INITIAL COMMISSIONING

A) Installer (optional)

The shock-proof plug is used to supply current

to the drive for optional first-time commission-

ing by the installer or in the absence of an elec-

trical supply line at the building site.

If necessary, connect it to the Hirschmann

coupling and to an electrical outlet.

B) Electrical permanent installation

Remove the shock-proof plug and connect

the 3-wire Hirschmann coupling to your elec-

trical circuit. Do not remove the Hirschmann

coupling while doing so!

WIRELESS REMOTE CONTROL

In order to avoid an unwanted change of pa-

rameters, the time (max. 2 sec.) between the

individual programming steps must be ob-

served.

The signal tones must have gone out before

the next programming step.

Always check the running direction after a

change of parameters! It is displayed accord-

ingly through the LED on the drive housing

with green for ascent, red for descent

and yellow during the learning run.

Black Pearl HSN

OPEN

STOP

CLOSE

transmitter front

Black Pearl HSN

PROG

Paper

clip

transmitter back

Table of contents

Other EHRET Indoor Furnishing manuals

Popular Indoor Furnishing manuals by other brands

Costway

Costway JV10651 Instruction booklet

Next

Next 227884 Assembly instructions

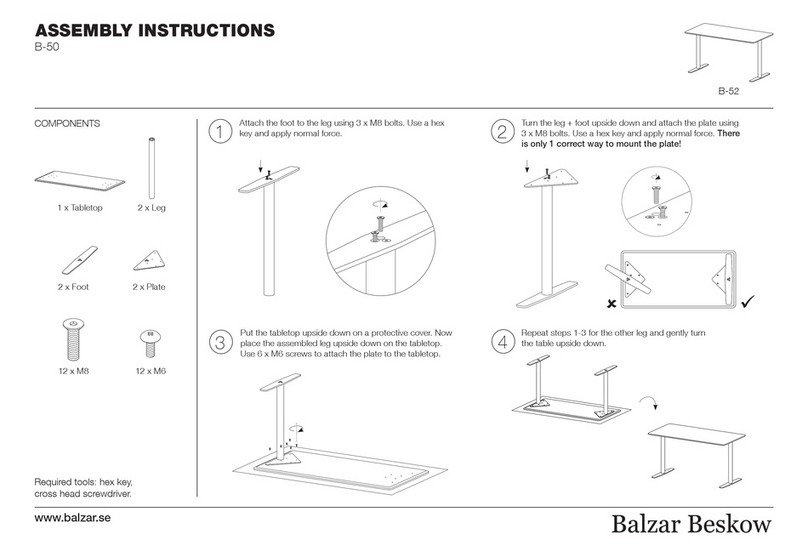

Balzar Beskow

Balzar Beskow B-50 Assembly instructions

VERTBAUDET

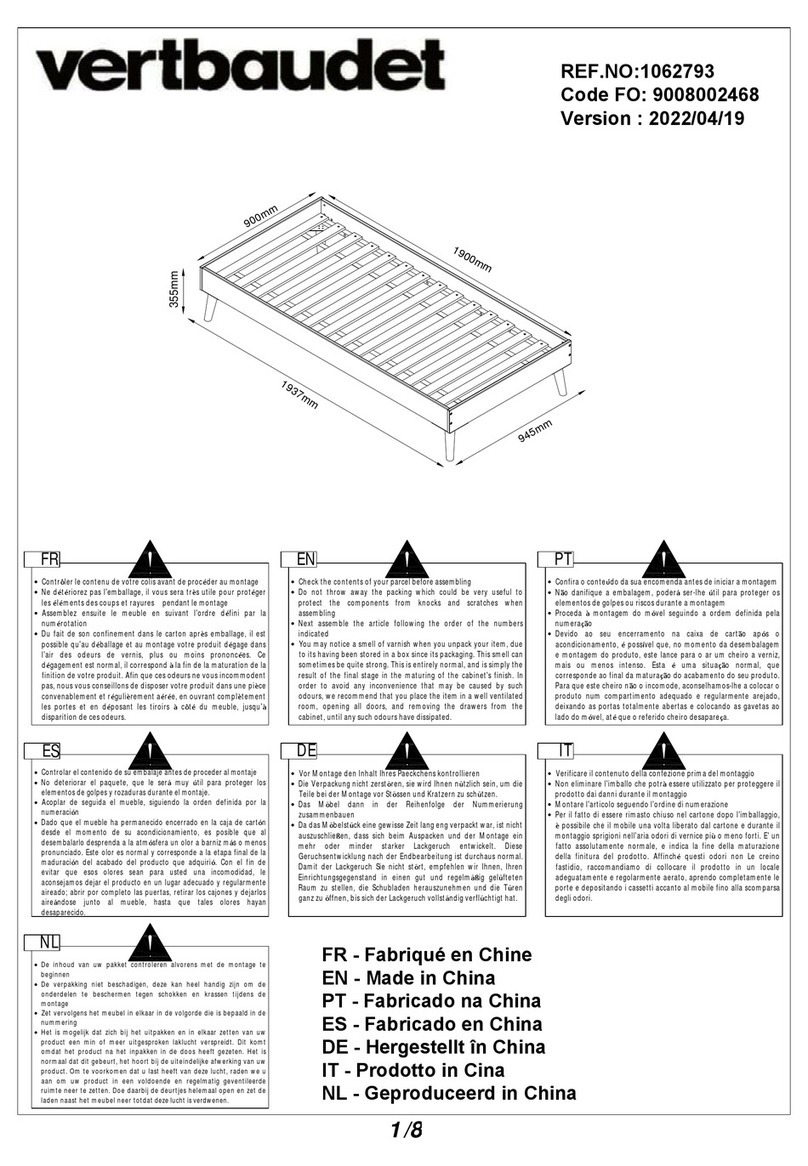

VERTBAUDET 1062793 manual

Furniture of America

Furniture of America Kristie CM3314T-5PK Assembly instructions

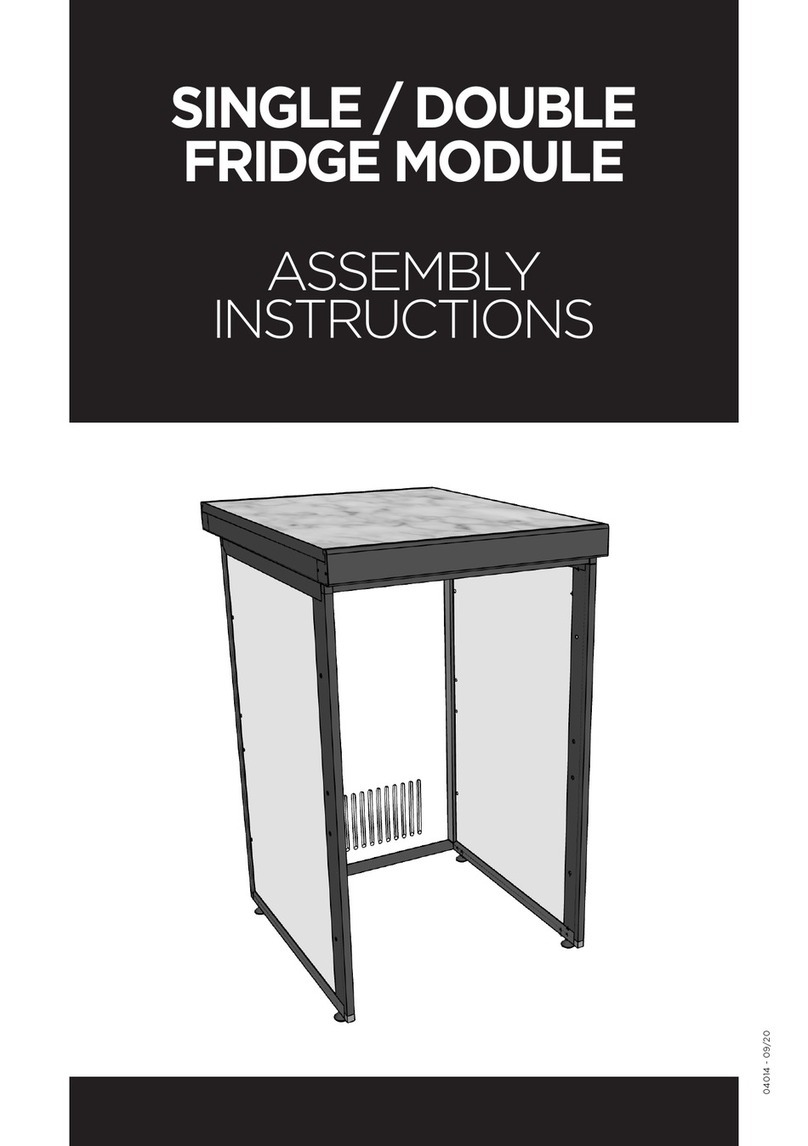

AlfrescoPlus

AlfrescoPlus APSFM Assembly instructions