Eicor 230 User manual

PrroTotrACT* FolJ.* ffitcoR,

dnoDEr 230

st

o

g

EI

:l

lr|

o

o

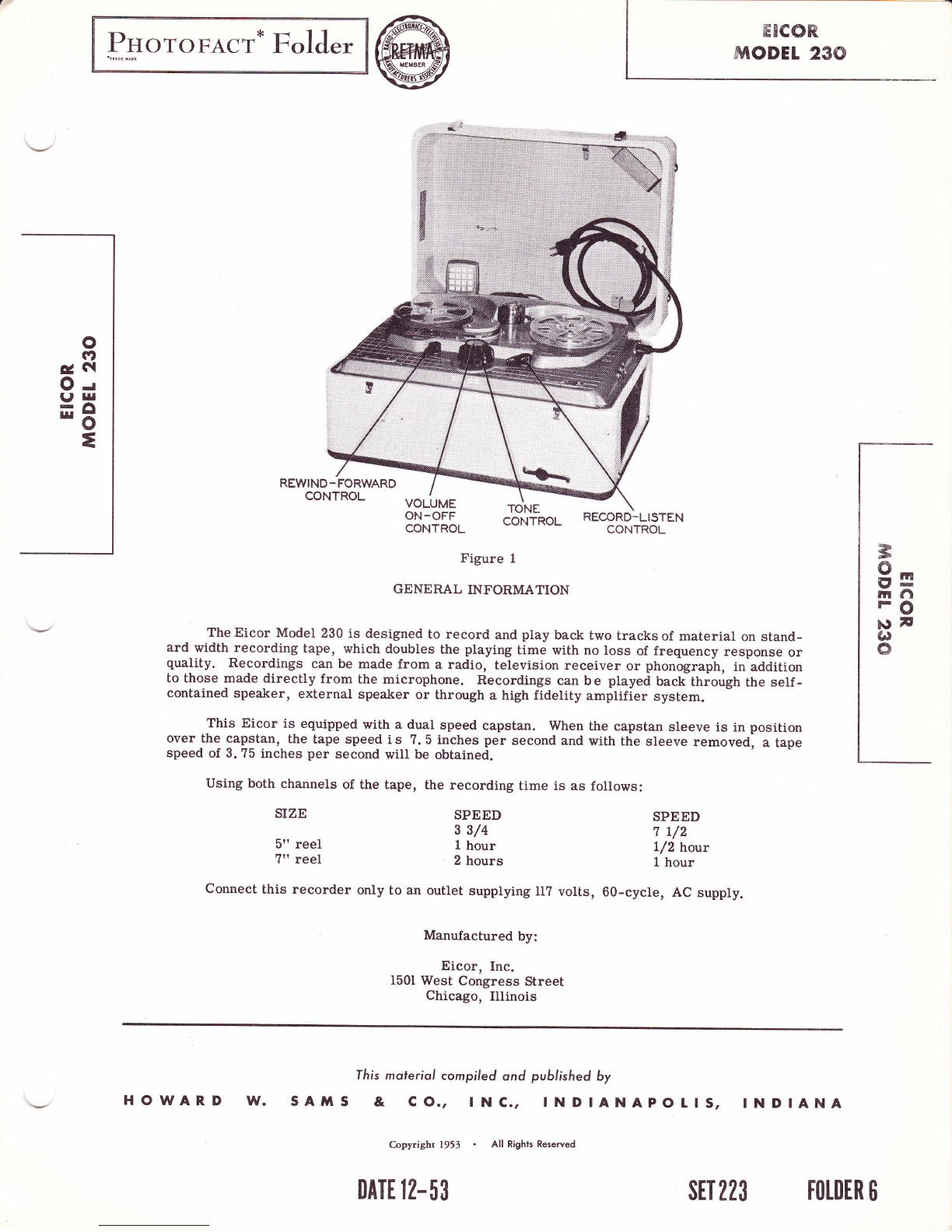

=REWIND.FORWARD

CONTROL VOLUME

ON-OFF

CONTROL TONE

CONTROL RECORD-LISTEN

CONTROL

Figure 1

GENERAL INFORMATION

The Eicor Model 230 is designed to record and play back two tracks of material on stand-

ard width recording tape, which doubles the playing time with no loss of frequency response or

quality. Recordings can be made from a radio, television receiver or phonograph, in addition

to those made directly from the microphone. Recordings can b e played back thiough the self -

contained speaker, external speaker or through a high fidelity amplifier system.

This Eicor is equipped with a dual speed capstan. When the capstan sleeve is in position

over the- capstan, the tape speed i s ?. 5 inches per second and with the sleeve removed, a tape

speed of 3.75 inches per second wiII be obtained.

using both channels of the tape, the recording time is as follows:

3

8s

rnl"i

FO

t9F

(.)

o

SIZE

5" reel

?tt reel

SPEED

3 3/4

t hour

2 hours

SPEED

7 L/2

L/2 hour

L hour

Connect this recorder only to an outlet supplying Il? volts, 60-cycle, AC supply.

Manufactured by:

Eicor, Inc.

1501 West Congress Street

Chieago, Illinois

fhis molerial compiled ond published by

sAxrS & co., tNc., INDIANAPOLtS,

C.opyright 1953 . All Rights Reserved

INDIANA

DATE 12-53 srT 223 FOTDER 6

HOWARD l^f.

Figure 2

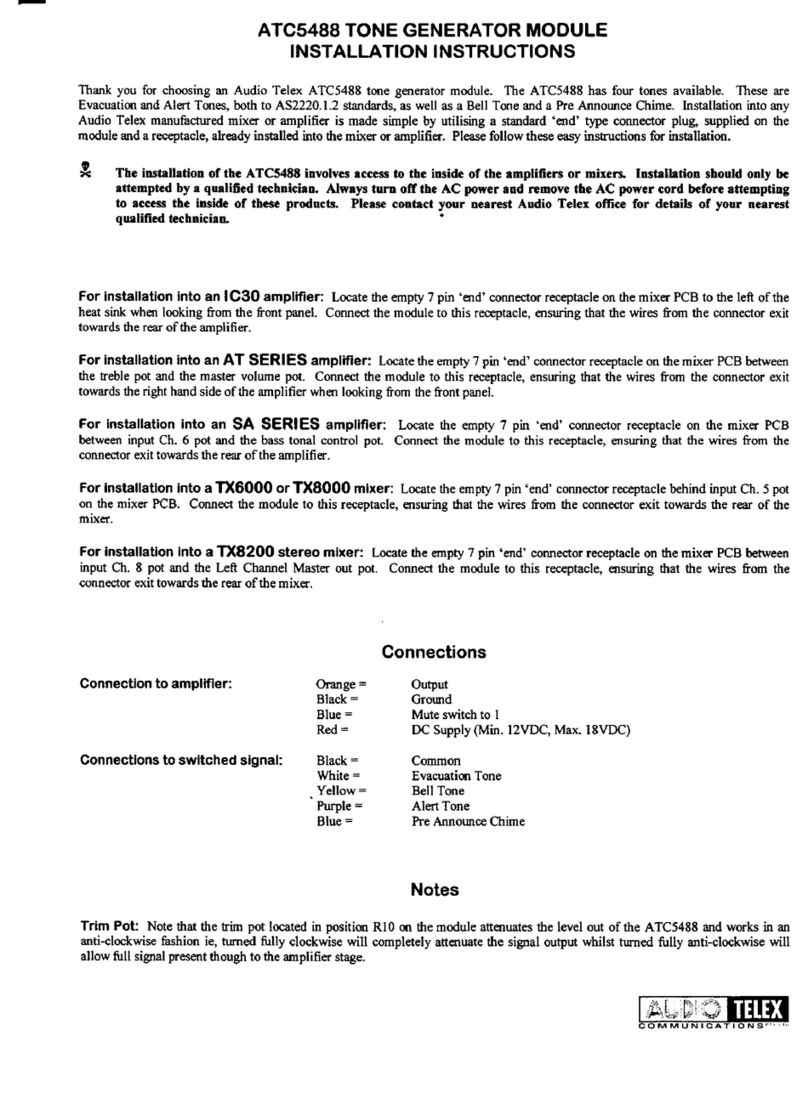

To Start-

Turn

Volume-

OPERATING CONTROLS

volume control knob (9) clockwise.

Degree of rotation of volume control knob

determines volume of recording and play back.

Tone-

Tone control knob (I0) controls tone and operates

only for play back.

Tape Travel-

Rewing-Stop-Forward control knob (I) controls

direction of tape tlavel. Always return this knob to

"Stop" position before turning unit off.

Record-Listen-

Record-Listed control knob (ll) controls amp-

Iifierand record playback head. To prevent acciden-

tal erasur€, place in "Listen" position immediately

after recording is completed.

OPERATING INSTRUCTIONS

1. Insert the AC power cord into the receptacle

on the right side of the top plate.

Page 2

2. PIug the AC cord into a convenient wall re-

ceptacle of the proper rating.

@1. Place a reel of tape (either 5" or ?") on the

left spindle (23) and an empty reel on the right spindle

(43) making sure the reel slots engage the reel pin on

the spindles.

2. Thread the tape by following the solid printed

line on the top panel (Fig. 1).

NOTE: This recorder uses Type "A" wound tape ,

i. e. the d u I I magnetic coated side faces

inwardonthe reel. If thetapeused is

Type "8" (coated side facing outward) the

recordingwill bemade at avery lowsound

level and the playback will be almost in-

audible.

3. Insert the free end of the tape through to the

hub of the right reel and place a pencil firmly over

the tape, fbrcing it into one of the three radial slots.

Turn the reel several turns (counterclockwise) with

the pencil in this position until the tape i s secured to

the reel and all slack is taken up between reels.

Setting Tape Speed-

The Eicor i s equipped with a quick change dual

speedcapstan. When thecapstansleeve (8)is in

(e)

11

Figure 3=

9s

rnfi

FO

pF

ot

o

position over the capstan, the tape speed will be T. b

inches per se cond and with the sleeve removed, a

tape speed of 3.75 inches per second will be obtained.

Because the tone fidetity will vary with the speed

of the tape, a compensating cireuit activated by the

slide switch located next to the green indicator light

has been provided. For operation with the capstan

sleer/e in position, the switch button should be in a

fuII left position and when operating with the sleeve

removed, the switch button should b e placed in a full

right position.

NOTE: For recording speech, the slower speed

is excellent and allows the maximurn r€:

cording and playing time. For higher

quality recording as is desired for music

reproduction, the faster speed is best.

To Record From Microphone-

1. Turn the volume control knob (9) to the right

until a click is heard and allow about thirty seconds

for the amplifier to warm up.

2. Insert microphone plug into input socket

labeled "Micro".

3. Turn record-listen knob (1I) to "Record" po-

sition. When in record position the red Iight on the

right side of the top plate will come on.

4. While talking into the microphone, adjust the

volume control until the neon indicator light flashes

slightly.

NOTE: Correct recording volume is very impor-

tant. T o o weak a signal, which does not

cause the neon indicator to flash, will re-

sult inweak playback and high background

noise. Too strong a signal, causing the

indicator to flash constantly, will result

in distortion during playback.

To Record From Radio-

Recordings can be made from a radio by placing

the microphone near the loudspeaker of the radio;

however, this type of recording may not be satisfactory

as other sounds m a y be picked up by the microphone

which as a result will be recorded on the tape. A su-

perior quality recording can be made by use of the

radio-phono attachment cord which is supplied with

the recorder. Connect attachment cord as follows:

1. Connect the cord clips across the voice coil

terminals on the radio speaker.

2. Insert the attachment cord plug into the socket

labeled "Radio".

3. Proceed as described

Microphone".

NOTE:

in "To Record From

cord after recording

Remove attachment

is completed.

To Record From Phonograph-

1. Connect the cord clips of the attachment cord

to the pickup Ieads on the phonograph.

Page 3

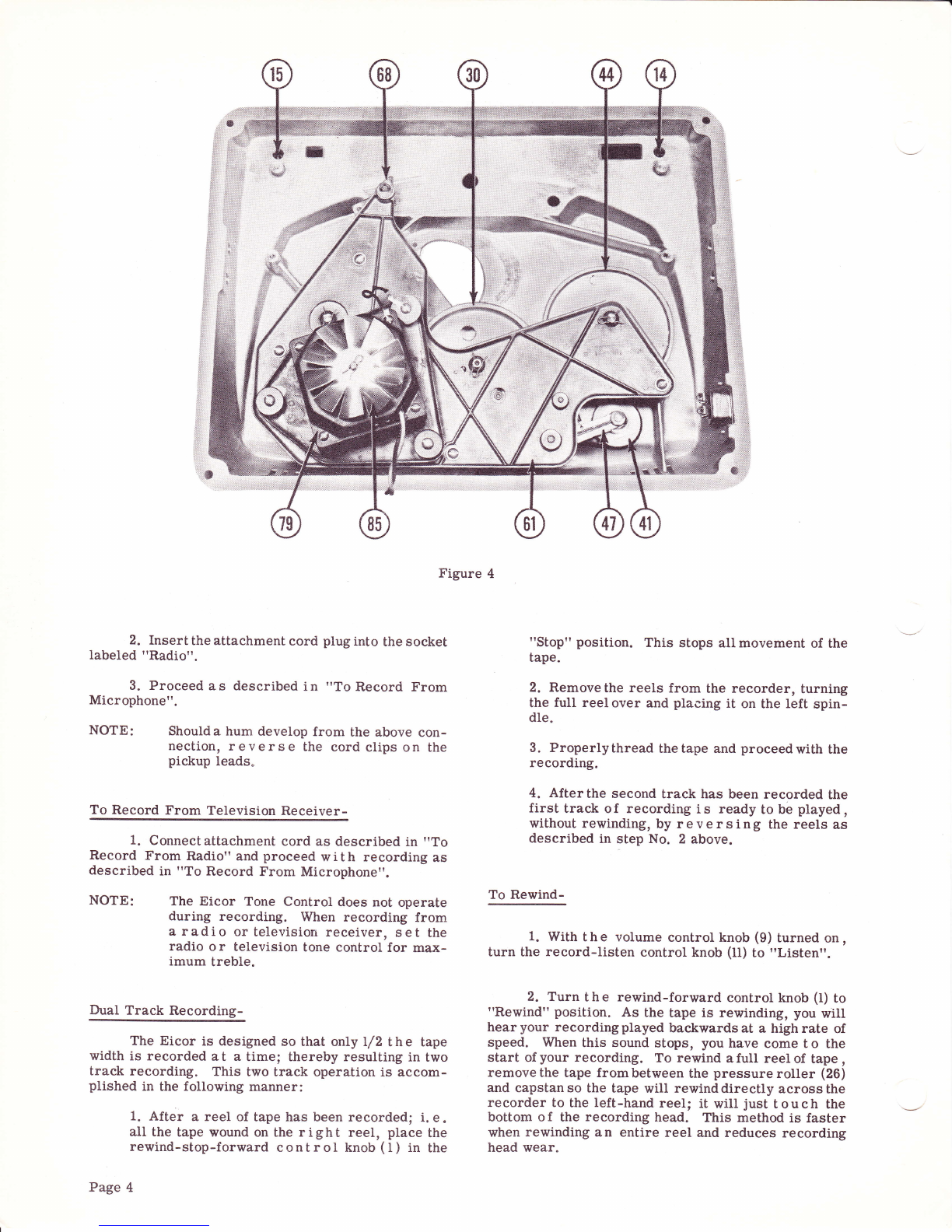

Figure 4

2. Insert the attachment cord plug into the socket

Iabeled "Radio".

3. Proceed as described in "To Record From

Microphone".

NOTE: Should a hum develop from the above con-

nection, reverse the cord clips on the

pickup leads.

To Record From Television Receiver-

1. Connect attachment cord as described in "To

Record From Radio" and proceed with recording as

described in "To Record From Microphone".

NOTE: The Eicor Tone Control does not operate

during recording. When recording from

a radio or television receiver, set the

radio o r television tone control for max-

imum treble.

Dual Track Recording-

The Eicor is designed so that only l/2 t h e tape

width is recorded at a timel thereby resulting in two

track recording. This two track operation is accom-

plished in the following manner:

1. After a reel of tape has been recordedl i. e.

aII the tape wound on the right reel, place the

rewind-stop-forward control knob (l) in the

Page 4

"Stop" position. This stops all movement of the

tape.

2. Remove the reels from the recorder, turning

the full reel over and placing it on the left spin-

dle.

3. Properlythread thetape and proceedwith the

recording.

4. After the second track has been recorded the

first track of recording i s ready to be played,

without rewinding, by reversing the reels as

described in step No. 2 above.

To Rewind-

1. With the volume control knob (9) turned on,

turn the record-Iisten control knob (It) to "Listen".

2. Turn t h e rewind-forward control knob (I) to

"Rewind" position. As the tape is rewinding, you will

hearyour recordingplayed backwardsat a highrate of

speed. When this sound stops, you have come t o the

start of your recording. To rewind a full reel of tape ,

remove the tape from between the pressure roller (26)

and capstanso the tape will rewinddirectly acrossthe

recorder to the left-hand reel; it will just touch the

bottom o f the recording head. This method is faster

when rewinding an entire reel and reduces recording

head wear.

Figure 5=

9=

tnfl

FC)

trl F

G'

o

To Play a Recording-

1. Thread thetape as described under "Thread-

ing the Tape".

2. Turn the On-Off Volume control knob (9) on

and allow approximately thirty seconds f o r the tubes

to warm up.

3. Place the record-Iisten control knob (ll) in

the "Listen" position.

4. Place the rewind-stop-forward control knob

(l) in the "Forward" positiori and ad just the Volume

and Tone control to the desired level.

To Use an External Speaker-

Anysize speaker of the permanentmagnet typ€,

having a 3.2 O voice coil, may b e used by connecting

the attachment cord across the v o i c e coil terminals

of the speaker and then inserting the plug of the attach-

ment cord into the socket labeled "3. 2 Q Speak".

To Edit and Splice Tape-

NOTE: Since it is impossible to edit and splice

one track without affecting the other, re-

cordings which are to be edited should be

' limited to one track only.

1. The tape maybe editedby cutting outunwanted

portions, or by joining selections into another se-

quence. Announcements may be inserted between

selections, etc. Unusedsections of tape canbe spliced

together for re-use.

2. For best results, cut tape at a slightdiagonal ,

join ends together with splicing tape on the glossy side

and trim off any excessive width.

Erasing Recorded Material-

Itis notnecessary tofirst erasea recorded tape

if the same tape is to be used f or a new recording.

Erasing of recorded material takes place automatically

when new material i s recorded. If it is desired only

to erase a tape, set the machine for recording without

having the microphone or attachment cord connected

to input jacks.

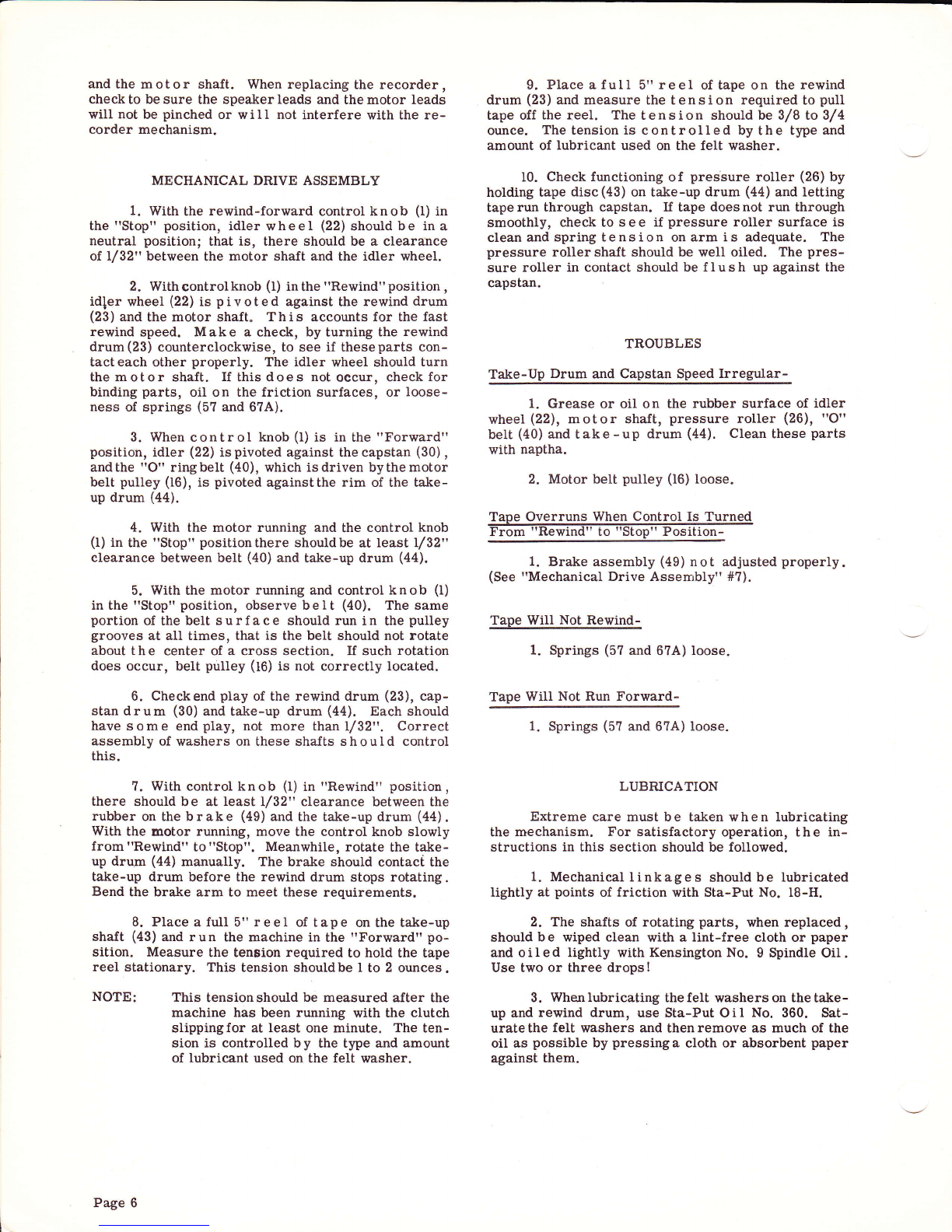

DISASSEMBLY INSTRUCTIONS

To remove the recorder from its cabinet, dis-

connect the line cord and remove the f our No. I0

Phillips head wood screws (I3) at the corners of the

top panel (12). Insert a thin-blade screwdriver between

the panel and the cabinet and pry upwards enough to

slip the f ingers under the panel. Lift up enough to

permit the speaker plug to be disconnected from the

amplifier. The recorder can now be removed com-

plete.

In handling the recorder out of its cabinet, care

must be taken to avoid damage to the motor fan (85)

Page 5

and the m o t o r shaft. When replacing the recorder ,

check to be sure the speaker leads and the motor leads

will not be pinched or will not interfere with the re-

corder mechanism.

MECHAMCAL DRIVE ASSEMBLY

1. With the rewind-forward control knob (l) in

the "Stop" position, idler wheel (22) should be in a

neutral positionl that is, there should be a clearance

of. l/32" between the motor shaft and the idler wheel.

2. Withcontrolknob (I) inthe "Rewind"position,

idler wheel (22) is pivoted against the rewind drum

(23) and the motor shaft" This accounts for the fast

rewind speed. Make a check, by turning the rewind

drum(23) counterclockwise, to see if theseparts con-

tacteach other properly. The idler wheel should turn

the motor shaft. If this does not oecur, check for

binding parts, oil on the friction surfaces, or loose-

ness of springs (57 and 6?.A).

3. When control knob (l) is in the "Forward"

position, idler (22) is pivoted against the capstan (30) ,

andthe "O" ringbelt (40), which isdriven bythemotor

belt pulley (16), is pivoted againstthe rim of the take-

up drum (44).

4. With the motor running and the control knob

(l) in the "Stop" positionthere shouldbe at least lrl32"

clearance between belt (40) and take-up drum (44).

5. With the motor running and control knob (f)

in the "Stop" position, observe belt (40). The same

portion of the belt surface should run in the pulley

grooves at all times, that is the belt should not rotate

about the center of a cross section. If such rotation

does occur, belt pulley (t6) is not correctly located.

6. Checkend play of the rewind drum (23), cap-

stan drum (30) and take-up drum (44). Each should

have some end play, not more than /32". Correct

assembly of washers on these shalts should control

this.

7. With control knob (I) in "Rewind" position,

there should be at least /32" clearance between the

rubber on the brake (49) and the take-up drum (44) .

With the motor running, move the control knob slowly

from"Rewind" to"Stop". Meanwhile, rolate the take-

up drum (44) manually. The brake should contact the

take-up drum before the rewind drum stops rotating.

Bend the brake arm to meet these requirements.

8. Place a full 5" reel of tape on the take-up

shaJt (43) and run the machine in the "Forward" po-

sition. Measure the tension required to hold the tape

reel stationary. This tension shouldbe I to 2 ounces.

NOTE: This tensionshould be measured after the

machine has been running with the clutch

slippingfor at least one minute. The ten-

sion is controlled b y the type and amount

of lubricant used on the felt washer.

9. Place a f ull 5" reel of tape on the rewind

drum (23) and measure the tension required to pull

tape off the reel. The tension should be 3/8 to 3/4

ounce. The tension is eontrolled by the type and

amount of Iubricant used on the felt washer.

I0. Check functioning of pressure roller (26) by

holding tape disc(43) on take-up drum (44) and letting

tape run through capstan. If tape does not run through

smoothly, check to s e e if pressure roller surface is

clean and spring tension on arm is adequate. The

pressure roller shaJt should be well oiled. The pres-

sure roller in contact should be flush up against the

capstan.

TROUBLES

Take-Up Drum and Capstan Speed lrregular-

1. Grease or oil on the rubber surface of idler

wheel (22), motor shaft, pressure roller (26), "O"

belt (40) and take -up drum (44). Clean these parts

with naptha.

2. Motor belt pulley (16) Ioose.

Taoe Overruns When Control Is Turned

From "Rewind" to "Stop" Position-

@justedproperly.

(See "Mechanical Drive Assembly" #?).

Tape Will Not Rewind-

1. Springs (57 and 6?.A) loose.

Tape WiIl Not Run Forward-

1. Springs (57 and 6?A) Ioose.

LUBRICATION

Extreme care must be taken when lubricating

the mechanism. For satisfactory operation, the in-

structions in this section should be followed.

1. Mechanical Iinkages should be Iubricated

lightly at points of friction with Sta-Put No. 18-H.

2. The shafts of rotating parts, when replaced,

should be wiped clean with a lint-free cloth or paper

and oiled lightly with Kensington No. 9 Spindle Oil .

Use two or three dropsl

3. Whenlubricating thefelt washers on thetake-

up and rewind drum, use Sta-Put Oil No. 360. Sat-

urate the felt washers and then remove as much of the

oil as possible by pressinga cloth or absorbent paper

against them.

Page 6

=

gtr

mfl

FO

)9v

G}

o

e.---@

H"--o

e

e..iq f*g

ffl @'-*@

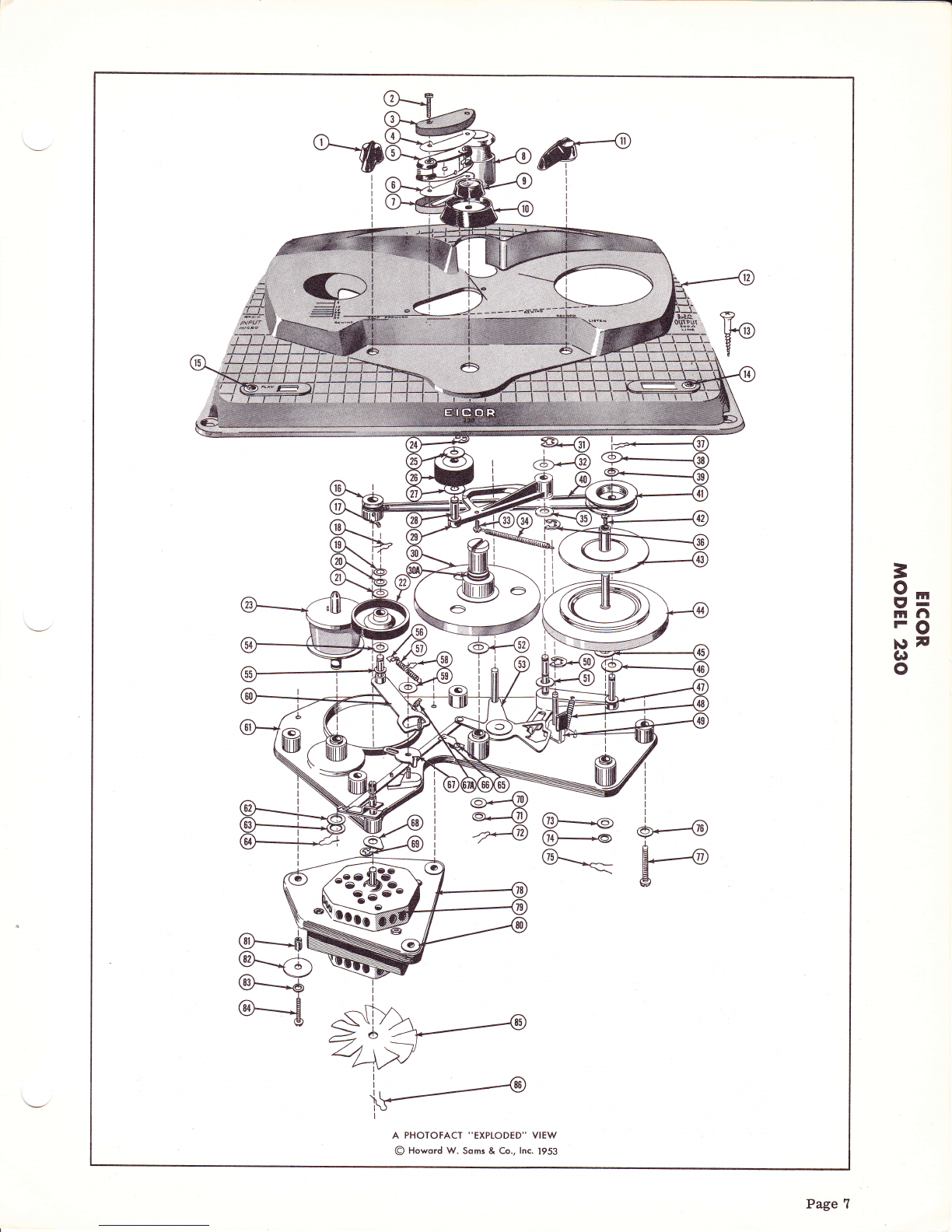

A PHOTOFACT "EXPLODED'' VIEW

@ Howord W. Soms & Co., lnc. 1953

6--_d

@-*rt

.^. \-

ar__*6

*€

3\ASb

?50'

4:@-

Page 7

(0

o

F{

t

b0

.t{

Fr{

Page 8

=

gtr

lrrfl

FO

leF

GI

o

@

.=

o- t4

o

C\

gr':t

M

o

E-

ul

.t- o

F

{l

M

t-

\tl

hI

o

.s

o- 6t c\I C\t 6t €\t

€

.E

o-

b0

o

"?

AT

{-

bo

o

cr:)

6,i

{- fr{

aM

c\t

€o fr{

a

to

.s

o- M

l.t: M

ro M

o

(o

rf)

M

c\l

oo

o

N

r{

.s

o- bD

o

Fa

X

o

o

rl.)

o

t(?

\ir

{- o

u?

$

{-. k

a

(r)

.s

o- 14

r() M

ro M

{- o

rt)

$

+- o

6T

6l

(\t

.s

a- oo o o o

c

o- oo o oo

o

lttt-

F"

a

CO

t-

l-

(n

(o (o

M

@l(:

l-

CO

F{

(,

II:

X

(0

E

lt)

=c1 tro

o

rq

F.{

z

g

a

frl

a

a

ts

A

frl

o

X

lz1 17

20

9F

HB

OA

AO"i

Xtr>

OO.--

f;H6

s.E€

<zz

}f*ii

*z'-

EH B

a*F

(5 Fr Fr

Fe a

1,4 E

HE H

'.1 B d

"1lt 5

<r;

I

tr

=

u

I

Hr

z-.

o:

h

$e

z4

OE

e,o

<.n

2>

3-

.no)

oo

<i

be

F

o

-

e

.n

o

z

6

llJ

e,

ur

U

z

L

o

llJ

e,

Ellil

l-l

e,

il

o

t

T

J

o'

I

o

tr

o

o

lrj

d.

/4,

:-

f0UOr

I-J

Rg

@

Eg

I

o

F

It

o

!d.

Q8

dl lrl

la

JZ

c-

67

i."-

Pa9

ot

3-3

to,o-

@

ltl

@

-@

9

()

c

I t-il''

@

U

(:

Hil

@

aN

E-

< Itt

.6

P-us

O-

a{!

<

-@

1

o

N

o

5F

*o

=€

:Y

=€

=@

Uffi

Page 9

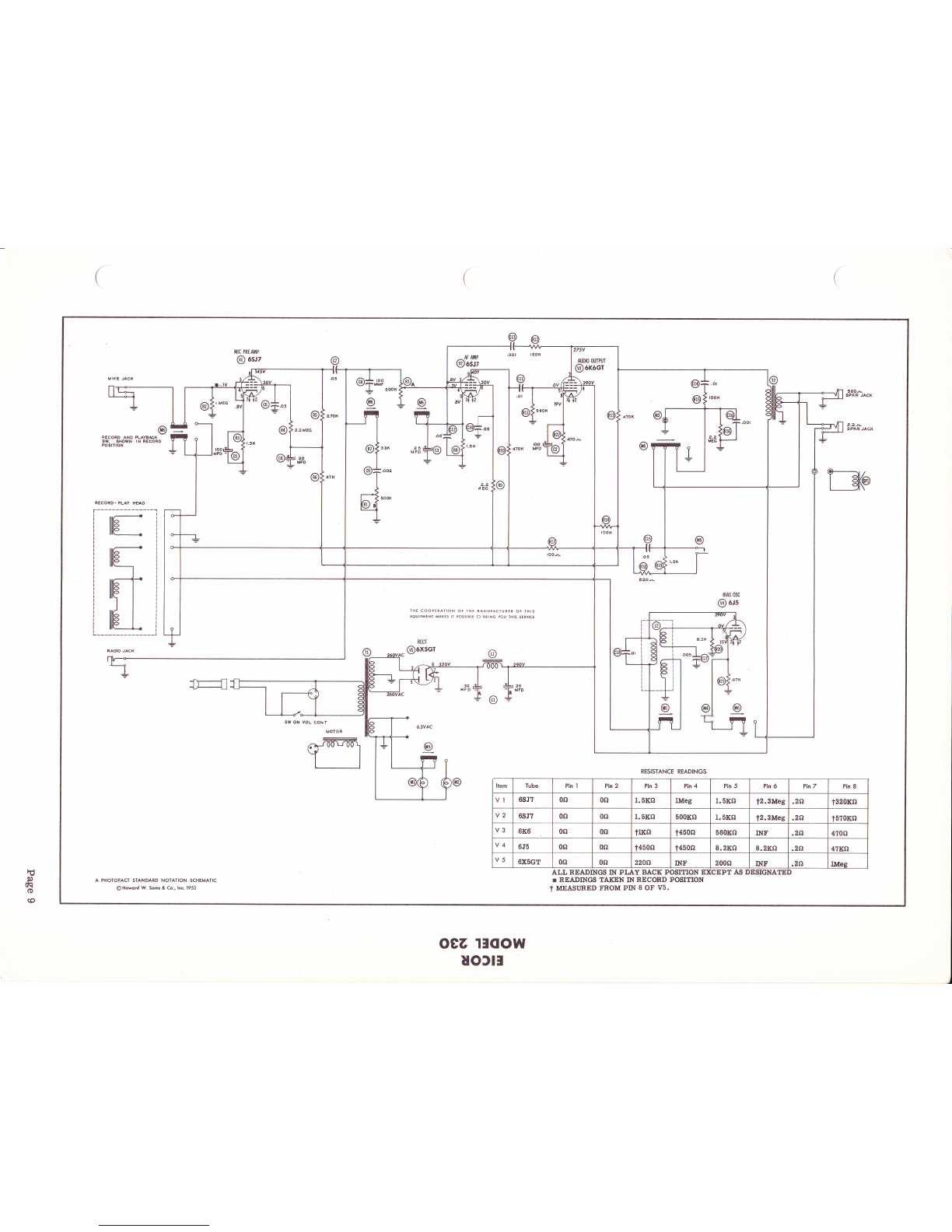

6SJ 76SJ7 6K6

GT

Figure ?

6J5 6X5GT

MECHANICAL PARTS LIST

Ref .

No. Part

No. Description Ref.

No. Part

No. Description

1

2

3

4

5

6

7

8

I

10

11

t2

13

L4

15

16

t7

18

19

20

2L

22

23

24

25

26

27

28

29

30

30A

TR-101-4119

TR- 101-7031

TR-101-1016A

TR-101-102?

TR-301-1062

TR- 101-102?

TR-301-1065A

TR-301-2199

TR-301-4280

TR-301-4195A

TR-101-4119

TR-301-41964

TR- 101-7010

TR-301-4202

TR-301-4201

TR-101-2033

TR-101-?004

TR- 101-20?3

TR-101-2044

TR-101-2030

TR-101-2065

TR-101-2003

TR-301-2195

TR-301-21?0

TR-301-2184

TR-301-216?A

TR-301-2L84

TR-301-21?9

TR-301-2177A

TR-301-2163

TR-301-21?3

Rewind-Stop - Forward Control

Knob

Phillips Round Head Screw,6-32

Upper Head Shield

. 010" Shield

Head Assembly (cartridge only)

.010" Shield

Lower Head Shield

Capstan Head & Button Assy.

Volume Control Knob

Tone Control Knob

Record-Listen C ontrol Knob

Top Plate

Phillips Head Wood Screw,

r0xLl/4

Indicator Plug Button (red)

Indicator Plug Button (green)

Motor Belt Pulley

Allen Set Screw, 6-32

Spring Retainer

Bakelite Washer

Felt Washer

Fishpaper Washer

Idler Wheel

Rewind Drum Assembly

'!C" Washer

Bakelite Washer

Pressure Roller Assembly

Bakelite Washer

Pressure Roller Shaft

Pressure RoIIer Arm

Capstan Drum Assembly

#9 rro'r Ring

31

32

33

34

35

36

37

38

39

4A

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

TR-301-21?0

TR-301-2184

TR-301-2180

TR-101-4092

TR-301-2184

TR-301-21?0

TR- 101-2072

TR-301-2184

TR-101-2012

TR-101-2002

TR- 101-2081

TR-101-7005

TR-101-20?9

TR-301-2194

TR-301-2185

TR-301-2184

TR-101-2080

TR-101-2101

TR-101-2094

TR-301-21?0

TR- 101-2012

TR-301-2185

TR-301-2168

TR-101-2065

TR-101-2044

TR-101-2042

TR-101-2038

TR-101-20?r

TR-101-203r

TR-101-2089

TR-301-2182

t'Ct'Washer

Bakelite Washer

No. 6 Self Tapping Screw

Pressure Roller Arm Spring

Bakelite Washer

"Ct'Washer

Spring Retainer

Bakelite Washer

Felt Washer

"O" Ring Belt

BeIt Pulley & Bushing Assy.

Binder Head Machine Screw,

4-40 x 3/16

Tape Disc Assembly

Take-Up Drum Assembly

Bakelite Washer

Bakelite Washer

BeIt PuIIey Lever & Bushing

Assembly

Brake Drive Spring

Brake Assembly

"C" Washer

FeIt Washer

Bakelite Washer

Control Link Assembly

Fishpaper Washer

Bakelite Washer

Idler Lever Spring Clip

Idler Lever Spring

Spring Retainer

Retaining Washer

Idler Lever & Pin Assembly

Base & Bushing Assembl.y

Page I0

t'

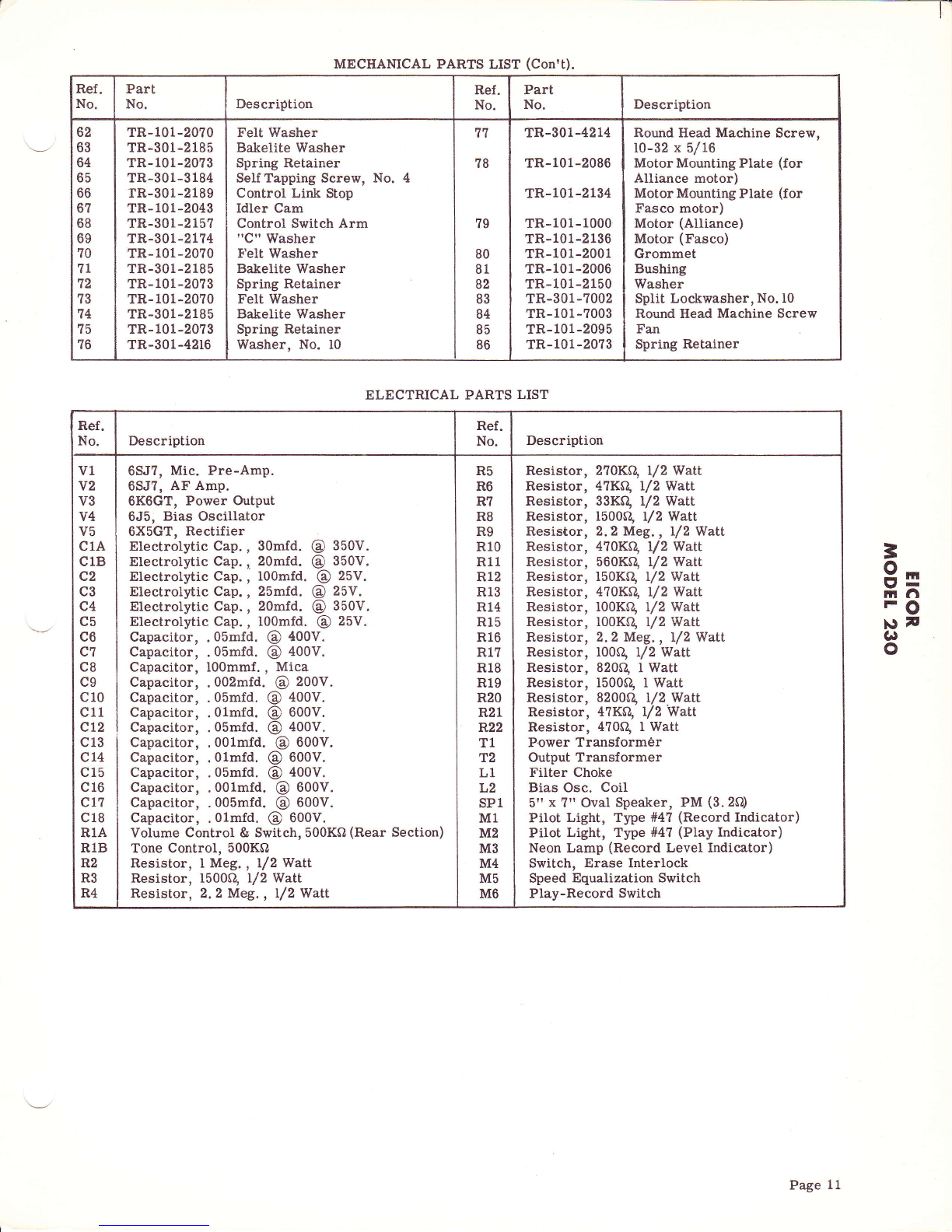

MECHANICAL PARTS LIST (Con't).

Ref .

No. Part

No. Description Ref.

No. Part

No. Description

62

63

64

65

66

6?

68

69

?0

7t

12

?3

14

?5

?6

TR-101-2070

TR-301-2185

TR-101-20?3

TR-301-3184

rR-301-2189

TR-101-2043

TR-301-215?

TR-301-2174

TR-101-2070

TR-301-2185

TR-101-20?3

TR-101-2070

TR-301-2185

TR-101-20?3

TR-301-4216

FeIt Washer

Bakelite Washer

Spring Retainer

SeI{ Tapping Screw, No.

Control Link Stop

Idler Cam

Control Switch Arm

"C" Washer

tr'elt Washer

Bakelite Washer

Spring Retainer

Felt Washer

Bakelite Washer

Spring Retainer

Washer, No. l0

77

?8

?9

80

81

82

83

84

85

86

TR-301-4214

TR-101-2086

TR-101-2134

TR-101-1000

TR-101-2136

TR-101-2001

TR-101-2006

TR-101-2150

TR-301-7002

TR-101-7003

TR-101-2095

TR-101-20?3

Round Ilead Machine Screw,

l0-32 x 5/16

Motor Mounting Plate (for

Alliance motor)

Motor Mounting Plate (for

Fasco motor)

Motor (Alliance)

Motor (Fasco)

Grommet

Bushing

Washer

Split Lockwasher, No. l0

Round Head Machine Screw

Fan

Spring Retainer

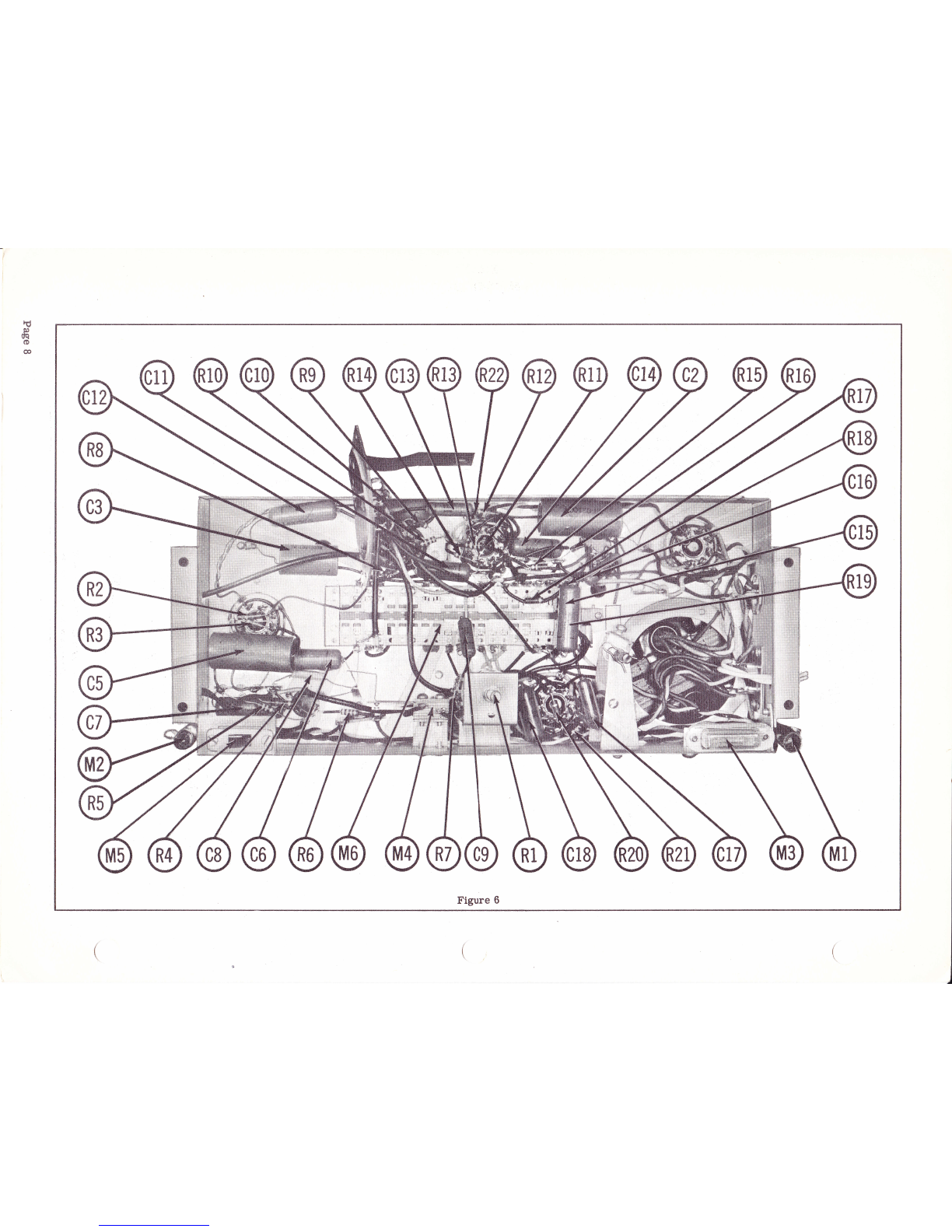

ELECTRICAL PARTS LIST

Ref .

No. Description Ref.

No. Description

v1

v2

v3

v4

v5

c1A

c1B

c2

c3

c4

c5

c6

c7

c8

c9

c10

c11

c12

c13

cL4

c15

c16

c1?

c18

R1.A

R18

R2

R3

R4

6SJ?, Mic. Pre-Amp.

6SJ?, AF Amp.

6KOGT, Power Output

6J5, Bias Oscillator

6X5GT, Rectifier

Electrolytic Cap., 30mfd. @ 350V.

Electrolytic Cap., 20mfd. @ 350V.

Electrolytic Cap., lOOmfd. @ 25V.

Electrolytic Cap., 25mfd. @ 25V.

Electrolytic Cap., 20mfd. @ 350V.

Electrolytic Cap., I0Omfd. @ 25V.

Capacitor, .05mfd. @ 400V.

Capacitor, .05mfd. @ 400V.

Capacitor, I00mmf., Mica

Capacitor, .002mfd. @ 200V.

Capacitor, .05mfd. @ 400V.

Capacitor, .01mfd. @ 600V.

Capacitor, .05mfd. @ 400V.

Capacitor, .001mfd. @ 600V.

Capacitor, .01mfd. @ 600V.

Capacitor, .05mfd. @ 400V.

Capacitor, .001mfd. @ 600V.

Capacitor, .005mfd. @ 600V.

Capacitor, .01mfd. @ 600V.

Volume Control & Switch, 500Kfl (Rear Section)

Tone Control, 500KQ

Resistor, I Meg. , l/2 Watt

Resistor, 1500Q l/2 Watt

Resistor, 2.2 Meg. , l/2 Watt

R5

R6

R?

R8

R9

R10

R11

R12

R13

R14

R15

R16

R1?

R18

R19

R20

821

F.22

T1

T2

L1

L2

sP1

M1

M2

M3

M4

M5

M6

Resistor, 2?0Kg I/2 Watt

Resistor, 41KO, I/2 Watt

Resistor, 33KQ t/2 Watt

Resistor, 1500Q /2 Watt

Resistor, 2.2 Meg. , l/2Watt

Resistor, 4?0Kg l/2 Watl

Resistor, 560Kq 12 Watt

Resistor, 150K0, l/2 Watt

Resistor, 4?0Kq 12 Watt

Resistor, l00KA, I/2 Watt

Resistor, l00Kq 12 Walt

Resistor, 2. 2 Meg. , l/2 Watt

Resistor, t00Q /2 Watt

Resistor, 820Q I Watt

Resistor, 1500Q f Watt

Resistor, 8200S1, l/2 V'latt

Resistor, 4?KQ /2 Watt

Resistor, 4?0Q I Watt

Power Transform6r

Output Transformer

Filter Choke

Bias Osc. Coil

5rt x ?ri OvaI Speaker, PM (3. 2f,l)

Pilot Light, Type #4? (Record Indicator)

Pilot Light, Type #4? (Play Indicator)

Neon Lamp (Record Level Indicator)

Switch, Erase Interlock

Speed Equalization Switch

Play-Record Switch

=

9=

rrl.t

FO

\)t

(.)

o

Page 11

Popular Recording Equipment manuals by other brands

Toshiba

Toshiba W602C Service manual

Rami

Rami PRT 666 user manual

Sound Devices

Sound Devices Kashmir MIXPRE-3 II quick start guide

Miditech

Miditech i2 Control-37 black edition user manual

Scanlab

Scanlab RTC 4 Installation and operation

Bulldog Security

Bulldog Security 718 (FPB Installation and owner's guide