EIJKELKAMP PlantControl D User manual

PlantControl D

Wireless Data Logger and Soil Moisture Sensors

Operating Instructions Ver. 3.46

P.O. Box 4, 6987 ZG Giesbeek

Nijverheidsstraat 30,

6987 EM Giesbeek,

The Netherlands

T+31 313 880200

F+31 313 880299

Ihttp://www.eijkelkamp.com

M1.19.52.E

Contents

1. Introduction 3

Scope of delivery 3

Optional accessories / Optional Functions 3

Basic aspects 4

General features 4

Technical specifications 4

Quick start guide 5

PlantControl front panel 6

PlantControl menu structure 7

PlantControl electrical power connections 7

Introducing the repeater (range extender) 8

Sensor operation 9

Inserting/replacing the batteries 9

Switching on/switching off/testing reception 9

LED display on the sensor 10

Setting the sensor frequency band 10

Replacing the sensor felt 10

2. Commissioning 11

Step 1. Switching on your PlantControl 11

Step 2. Configuring your PlantControl central unit 11

Step 3. Initializing a repeater 12

Step 4. Repeater settings 16

Step 5. Initializing the sensors 17

Step 6. Sensor settings 18

Step 7. Commissioning the GPRS Modem 18

Further PlantControl menu items description 22

Menu Status 22

Menu Sensors 22

Menu Alarms 22

Erase logbook 23

System reset 23

3. Installation 24

Inserting the sensor into the soil 24

4. Moisture output in hPa suction pressure 28

5. Data readout and firmware update 30

Data analyses with PlantCare DataViewer 30

6. Troubleshooting 31

6. Deactivation / Re-Activation 32

Entire system 32

Individual sensors 32

7. Warranty 32

8. Disclaimer 32

9. Support 32

1. Introduction

Please read through these instructions carefully before configuring your PlantControl D central

unit and the soil moisture sensors.

Scope of delivery

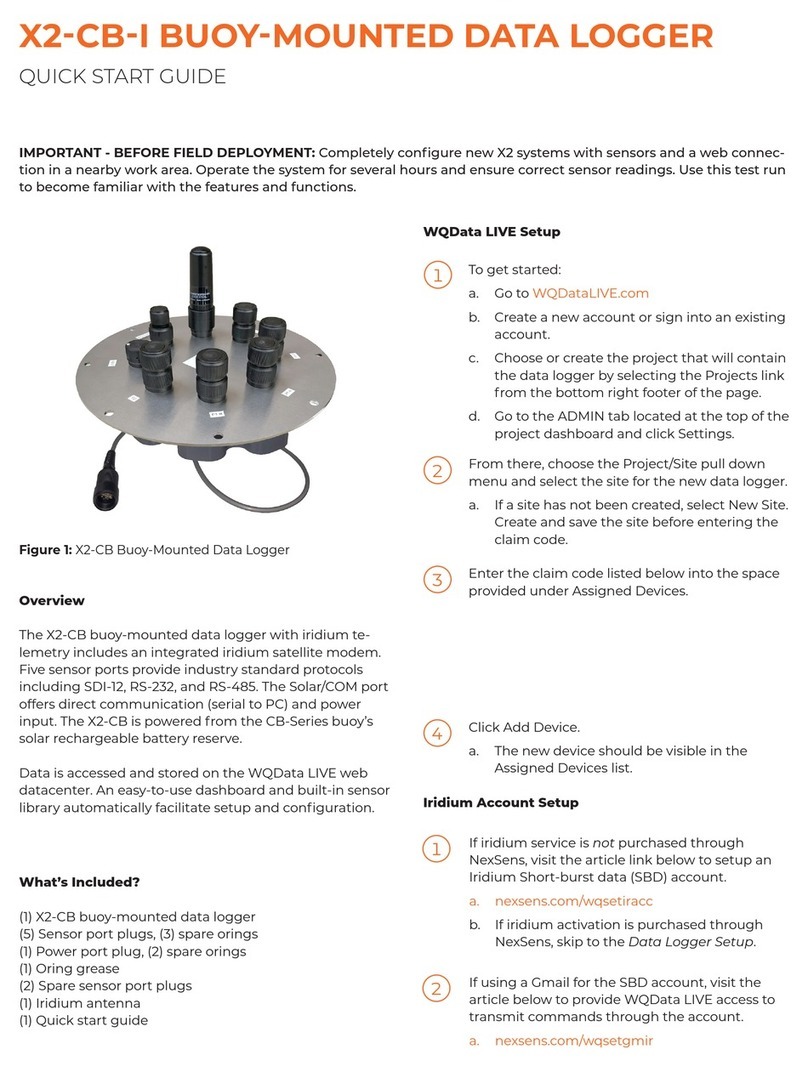

PlantControl D central unit (Data Logger)

Wireless soil moisture sensors (quantity and version acc. to order)

PlantCare DataViewer software for the display and analysis of the measured data

Optional accessories

Solar cell with

cable connection to

the Data Logger

PlantControl D central unit

External antenna for enhanced

signal reception. PlantControl

central unit or GPRS Modem

3

Wireless sensor

stick version Wireless sensor

cable version Sensor with

protection cap

Optional functions

Remote retrieval function

SMS-Alarm function

Repeater

(Range Extender)

Replacement tip with

felt for sensor (depending on

soil type, different felts

are available)

Basic aspects

In combination with PlantCare’s wireless soil moisture sensors, the PlantControl D is used for the wireless

monitoring of soil moisture levels and soil temperature for scientific and agricultural applications. A

specially designed software allows the connection of up to 99 sensors, which are synchronized by the

PlantControl D central unit and coordinated. This means that the sensors transmit the measured data

sorted and in the correct sequence within a short period of time. A USB interface allows to export data

very easily. The optional remote retrieval function incl. a GPRS Modem allows the remote retrieval of data

over the mobile network, i.e. over virtually any distance (either automatically and/or by SMS request). In

addition, all relevant system data and alarm messages are transmitted as an E-Mail attachment. With the

optional SMS-Alarm function, alerts are sent by a SMS. A special software (PlantCare DataViewer) allows

quick analysis of irrigation data. Corrective actions can be carried out from a distance without extensive

analysis on the spot.

The worldwide patented PlantCare sensor technology is based on a micro-thermal method of measuring

soil moisture. A specially designed felt material, which is in moisture equilibrium with the soil serves as a

standardized interface between the soil and the sensor. For the measurement of soil moisture, the sensor

is heated for a short time and the cooling time is then determined, which varies depending on the soil

moisture level. The cooling time of the sensor thus provides a reliable indication of the water content in the

soil. The sensors require no maintenance and have no corrosion-prone parts.

In developing the Plant Control D, performance, the ease of use and reliability were given the greatest

priority.

General Features

Up to 99 wireless sensors can be connected.

Weatherproof IP67 housing (central unit and sensors)

Signal range up to 200 meters line-of-sight, dependent on the type of terrain and visual contact

between sensors and the central unit. With optional range extenders, this range can be extended to

several kilometers.

Licence-free transmission frequency: 868 MHz or 915 MHz, interchangeable

Measurement of soil moisture levels and soil temperature at freely selectable intervals.

Measurement in: relative % or hPa (for hPa 6 standard soils to choose from)

Speedily reaction to changes in moisture levels.

Reliable results even at minimum depths (from 5 cm).

Value measured is unaffected by salt or fertilizer content.

Precise recording of measurements through built-in quartz clock in PlantControl D central unit.

The PlantCare DataViewer Software allows an optimal display and analyses of the data.

Various options such as remote retrieval and SMS-Alarm functions are available.

Frost resistant

Operating temperature: -20°C to +50°C

Language setting German/English

Technical specifications PlantControl D

Up to 100.000 data sets can be recorded

USB interface for data export on USB stick

Power supply: 8 AA rechargeable batteries (inclusive), in combination with mains (110/230V)

or solar cell 12W

Dimensions: 29 x 23 x 15 cm

Technical specifications sensors

Can be used in all soil types

Power supply: 2 AA 1.5 V batteries

Battery life span approx. 1 year depending on measuring cycle

Dimensions: 4 x 4 x 29 cm (shortest version)

Available length:

Stick version: 18/35/60/100 cm

Cable version: 60/250 cm (other length available on request)

4

Technical specifications repeater (range extender)

Weatherproof IP67 housing

Signal range sensor to repeater up to 200 meters and repeater to repeater up to 3km (line-of-

sight and dependent on the type of terrain).

Power supply: 8 AA rechargeable batteries (inclusive), in combination with mains (230V AC)

or solar cell

Dimensions: 5.5 x 13 x 17 cm

Sensor measurement data

Moisture display:

•In relative %-units or

•hPa suction pressure for 6 standard soils

Measuring range soil moisture (at a soil temperature between 2°C to +37°C*):

•Relative %-units: 0 - 100%

•hPa: 0 –400 hPa high sensitivity / > 400 - 800 hPa lower sensitivity

Measuring range soil temperature: -20°C to +50°C

Measuring accuracy:

•Soil moisture: +/- 3%

•Soil temperature: +/- 0.3°C

Reading accuracy:

•Soil moisture in relative %: 1%

•Soil moisture in hPa: 1hPa

•Soil temperature: 0.1 °C

* Sensors for soil moisture measurements at soil temperature range between 2°C to +50°C on request

5

Quick start guide

At the office

1. Connect cable for mains-connection or solar cell to the PlantControl central unit.

2. Outside Switzerland, pull out security film from the PlantControl central unit (already assembled with

batteries). Insert sensor batteries.

3. Define settings for the PlantControl D central unit: Menu Settings > Controller

4. Initialize repeater (if part of delivery scope): Menu Initialize > Repeater OK-button, hold the button

on the repeater for 5 seconds.

5. Initialize sensors: Menu Initialize > Sensors

6. Define sensor settings: Menu Settings > Sensors

7. For settings of optional functions such as remote retrieval and SMS-Alarm function, go to the

appropriate chapter in this manual.

On-Site:

1. Switch on sensors at the insertion place and check reception strength : Menu Status> Sensors. Insert

afterwards the sensor with the protection cap into the soil.

PlantControl: Front Panel

1: ON/OFF key

2: Restore-Settings: not yet activated

3: Main Menu

4: DEL = Deletes last entry

5: BACK = Goes back one menu level

6: OK = Confirm selection or entry

7: Cursor keys

8: Display Alarm: Displays active alarms

9: Reset Alarm: Resets alarms

10: USB Imp/Exp: Button to call the import-export functions via USB interface

11: Alarm-LED

12: GPRS-Terminal-LED: Flashes every 3 seconds when network connection is established

13: Busy-LED: Lights up when the central unit is busy (operating panel is blocked)

14: USB-Interface

15: Service Interface

16: Service Interface

17: Space key: Deletes entries in a text field

Special characters can be found under the key "1" and the "semicolon" key.

Key Lock: By simultaneously pressing the keys "2nd" and "MENU" on or off.

1

2

3

4

5

6

7

8 9 1011 12 13

14 15 16 17

6

Connection

solar cell Mains-Connection

115 or 230V AC

Removable plugs

for cable entry

PlantControl Electrical Power Connections

PlantControl Menu Structure

Go to the required menu item by using the cursor

keys. Selectable menu items as well as data entry

fields are shaded in grey. Enter in selected menu

or data field by pressing the OK key.

Please note that no mains plug is included in the delivery, as every country requires its own special plugs. For

each required cable entry, a cable gland is recommended, in order to protect the electronics. Do not connect to

the power supply, unless you have finished the cabling as described below.

To connect your specific mains plug or any other cable connection, please unscrew the lid at the bottom of the

casing.

Mains 115 or 230 VAC: The picture above shows the connection terminals for the mains. Besides the phase

(P) and the neutral line (N) a ground wire has to be used. The power cable is fed through one of the cable

entries and connected to the screw terminal.

Caution: Check first under the menu Settings> Controllers> AC Input, whether 115 or 230 volt is displayed. If

you would like to change the AC input, please contact your supplier.

Solar Cell: The solar cell is connected to the 16V DC screw terminals. For this, the cable is pulled through one

of the cable entries. Connect the black wire to GND and the red wire to 16 VDC.

After finishing the cabling, the cover has to be placed and screwed again. Please make sure that the rubber

seal on the lid as well as the opposite side is not dirty.

7

Example cable gland

1 Status

2 Sensors

4 Settings

5 Initialize

13 Controller

14 Sensors

29 Identify

41 Controller

42 Sensors

44 GSM/GPRS

45 Repeater

46 Alarms

51 Sensors

54 Repeater

57 Erase logbook

58 System Reset

59 Code Input

Introducing the Repeater (Range Extender)

Since the signal range between a sensor and the PlantControl central unit is limited to a maximum of 200

meters, repeaters with a signal range of up to 3 kilometers have been developed. If several such

repeaters are used, the signal range can be extended up to 30 km. Power is supplied by either an AC

adapter or a solar cell.

Configuration options

Up to 30 repeaters can be connected with a PlantControl.

Up to 10 repeaters can be connected to each other in a row

(max. 30 km).

Up to 5 repeaters can be connected to one repeater.

Up to 60 sensors can be connected with a repeater.

Note:

The first repeater must be positioned within 200 meters from

the PlantControl.

No sensors may be assigned to the first repeater.

A PlantControl system requires a minimum of two repeaters.

Signal range is up to 3 km line-of-sight and dependent on the

type of terrain.

The repeater frequency band is 868 MHz. Therefore the

PlantControl as well as the sensors must be set to 868 MHz.

Control button / Connections

A. Power connection (power supply or solar cell)

B. LED

C. Control button

D. Interface for external antenna (optional)

Switching on/ switching off/ checking power supply

Please note that repeater are usually delivered with built-in

rechargeable batteries (8x AA).

1. Unscrew the 4 screws and remove the front cover.

2. Attach the battery connector to the battery holder (see picture).

By doing so the repeater is switched on.

3. Mount the front cover.

4. Plug now the AC adapter or solar cell to the power connection.

5. To switch off the repeater the battery connector must be

removed from the battery holder. It is not enough to just pull out

the AC adapter or solar cell cable.

6. Check by pressing the control button, whether the repeater is

receiving sufficient power. If the LED flashes, the repeater is

operational. If the LED does not flash then either there is

currently not enough power available (if a solar cell is used, the

repeater enters in a sleep mode if the battery voltage is < 8.2V in

and is only ready for operation again when the battery voltage

rises again) or the repeater is defective.

Operating (check also chapter "Initializing the repeater")

By pressing the control button, the repeater sends a test

message to the Plant Control. The test Telegram can be used to

identify the repeater (see also Plant Control menu Sensors>

Identify.)

To initialize a repeater, hold down the control button for 5

seconds (see also chapter "Initializing the repeater").

A

B

C

D

8

Inserting/replacing the batteries

Switch off the unit if it is still on.

1. Release the retaining screw to remove the sensor cover.

2. Carefully remove the battery holder from the casing.

3. Insert 2 AA batteries. Ensure correct polarity to avoid damaging

the sensor. Dispose of old batteries properly.

4. Reinsert the battery holder carefully into the casing, ensuring

that the wires are positioned between the battery holder and

the partition in the white interior casing.

5. Check if frequency band setting is correct for your country

(Europe generally 868 MHz - see also next page).

6. Replace the cover so that it sits on the white interior casing.

Ensure that the cover seal is located in its groove in the cover

and is free of any dirt. Reattach the cover by tightening the

retaining screw firmly but not too tightly.

7. Switch on the sensor. If the sensor has already been initialized,

all the settings will have been saved and it is ready for use

again immediately.

CAUTION: When you remove

the sensor cover, take care

to put it back on the same

sensor.

Sensor operation

Please note that the sensors are usually supplied without installed batteries.

Switching on/ switching off/ testing reception

Switching on: Briefly press the ON/OFF button. The LED

will flash for a moment.

Switching off: Depress the ON/OFF button until the LED

lights up and goes out. Then release the button.

IMPORTANT: The sensor cannot be switched off if a

measurement is being taken. If so, wait for 2-3 minutes

and try again.

Testing reception

This is only possible if the sensor has been switched on

and already initialized and if moisture measuring is not

taking place:

Briefly press the ON/OFF button. The LED will flash for a

moment and a test telegram sent to the PlantControl.

After a few seconds, the reception strength and other data

can be read off the PlantControl display in Status >

Sensors.

On completion of a successful transmission, the LED will

briefly flash twice. Otherwise the LED will light up for 1

second.

Use this function, for example, when repositioning a

sensor.

9

Cover

Gasket

Antenna

ON/OFF

Button

LED Fixing Screw

Marking

Area

Replacing the sensor felt

LED display on the sensor

Switching on: LED flashes for a moment.

Switching off: LED lights up and goes out.

Successful initialization: LED emits 1 long and 1 short flash.

PlantControl was in initialization mode and the sensor has been initialized successfully.

LED flashes 1x 12 seconds after switching on: Control unit was not in initialization mode and the

sensor has been started successfully.

This is what normally happens if the sensor has previously been initialized successfully and then

switched off and on again.

LED flashes 1x every ½ second after switching on Error:

Sensor has not been initialized yet.

LED stays on continuously Error:

The frequency band switch on the sensor has been changed and no longer matches the frequency

band on the PlantControl unit (switch off the sensor/correct the frequency band on the sensor/switch

on the sensor).

LED flashes continuously 2x in quick succession Error:

Replace batteries.

Setting the sensor frequency band

The frequency band must have the same setting as

defined in the controller. Q.v. also Settings > Controller >

“Frequency band”

The factory setting for the frequency band is 868 MHz.

1. Switch off the sensor and unscrew the retaining

screw to remove the sensor cover.

2. Use the sliding switch to set the frequency band

permitted in your country. The frequencies are

marked on the PCB.

Frequency band 868/915 MHz

sliding switch

10

2. Commissioning

Step 1. Switching on your PlantControl

1. Withdraw the safety film to activate the factory-installed and charged 8 AA batteries.

2. Press the ON button

3. Press the MENU button

4. Check, if the battery status symbol on the display shows at least one bar. Otherwise charge up the

batteries either with a mains plug or, if ordered along with the PlantControl, the solar cell.

Step 2. Configuring your PlantControl central unit

Settings > Controller > OK button:

Press the -cursor keys in a sub-menu to scroll up or down and then select with the OK button. Use

the alphanumeric keypad for your input.

* Device name: The controller can be allocated a specific name or location. The unit name will also

appear in data files exported.

* Measure cycle: Your entry specifies the time between two measurements (minimum: 5

sensor minutes/maximum: 360 minutes).

* Time: Enter hours, minutes and seconds

* Date: Enter day, month, year

Network number: Automatically allocated. The network number is determined by the system with a

random generator and also transmitted to all sensors linked to the PlantControl unit.

This prevents any mutual interference from neighboring networks.

Recommendation: Do not change the network numbers allocated by the system.

Radio channel: The factory setting for the radio channel is 5. Channels 2,3,4 and 5 can be

selected. The channel number should only be changed if there is radio-frequency

interference from a neighboring installation. If you change the channel number, the

corresponding sensors must be initialized again.

Frequency band: The factory setting for the frequency band is 868 MHz. Two frequency bands are

available. The 868 MHz waveband is permitted and standard in Europe. 915 MHz is

permitted in the US and certain other countries. Your national telecommunications

authorities can provide information on which frequency band is allowed in your

country. You can then adjust the factory setting as needed. However, all the

allocated sensors will also need switching to the frequency band selected (q.v.

Operation > Sensors).

If your system has already been initialized at the factory and you change the

frequency band, the sensors will require initializing again.

* Language: Choose between German and English.

* LCD contrast: The contrast of the LCD display can be optimized by entering a higher or lower

number.

* LCD light on: Here, you can select how many seconds the background illumination will stay on.

Recommendation: Set as short a period as possible to conserve battery power.

AC Input: AC Input display

* O NLY THESE ADJUSTM EN TS MAY BE MADE !

11

Step 3. Initializing a repeater (range extender)

Skip this chapter, if you do not use a repeater.

Wireless systems must first “recognize” each other if they are to communicate. Initialization of the

PlantControl unit with the repeater must therefore be carried out first.

Commissioning of already initialized repeaters:

If the PlantControl unit and repeaters have been initialized already at the factory (would be labeled on

PlantControl central unit), no initialization must be performed.

Initializing a repeater

Initialize > Repeater > OK-button

Before you begin initializing the repeater, you should create a simple plan with the position of the

individual components. The plan should show the assignment of repeaters to the PlantControl respectively

how the repeaters are assigned between themselves.

For a better understanding see the following example with a total of 5 repeaters, wherein repeater 1 is

directly assigned to the PlantControl and repeater 2 to 5 are connected with the PlantControl via repeater

number 1.

12

The following display shows the settings (inputs) for the above example of repeater number 1.

PlantControl

Central unit Repeater

1 Repeater

2

Input

0 Input

2

Repeater

5

Repeater

4

Repeater

3

Input

3

Input

4

Input

5

1. Select Initialize > Repeater > OK-button.

2. Before initializing a repeater, you must first make the following settings:

Repeater Number: Here, number 1 is displayed as the first repeater.

in direction of Controller: Enter here over which other repeater, a repeater is connected to the

PlantControl central unit. As in the example above no other repeater is placed in direction to the

PlantControl enter here the number zero (number 0 = Controller). Otherwise press the OK-button

and enter the repeater number, which is between repeater 1 and the Plant Control.

in direction Sensor: You can assign up to five other repeaters to a certain repeater. Therefore, you

have to enter here which other repeaters are connected to the repeater number 1. In this example,

the repeater number 2, 3, 4 and then 5 were entered.

Place the repeater approximately at a distance of 1 meter from the controller and press the control

button on the repeater for 5 seconds. Now release the button. Once the controller has detected a

repeater, you label it with the repeater number assigned by the system. You can then initialize the

next repeater. When the repeater has not been detected, “failed” will be displayed. In such a case,

the procedure from point 1 must be repeated.

The settings for the second repeater are as on the following display:

13

Repeater Number: Here, number 2 is displayed as the first repeater.

in direction of Controller: Enter here over which other repeater, repeater number 2 is connected

to the PlantControl central unit. As in the example above repeater number 1 is placed in direction to

the PlantControl enter here number 1 (see also sketch on previous page).

in direction of Sensor: As no other repeater is placed into the direction of sensors, no input is

required (see also sketch on previous page).

Initialize now the second repeater as described previously.

Further repeaters can be initialized as described with the above examples.

4. After having initialized all repeaters press the BACK-button to return to the main menu.

5. Check under the menu item Settings > Repeater> OK-button if the number of initialized repeaters is

correct.

Further example:

Example repeater number 6: Enter under "in direction of Controller" the number 0. Nothing to enter

under "in direction Sensor" as no further repeater is connected with repeater number 6.

Example repeater number 3: Enter under "in direction of Controller" the number 1, as repeater

number 3 is connected with the PlantControl central unit via repeater number 1. Enter under "in

direction Sensor" the number 7 and then 8.

Example repeater number 9: Enter under "in direction of Controller" the number 2, as repeater

number 9 is connected with the PlantControl central unit via repeater number 2. Enter under "in

direction Sensor" the number 10 and then 11.

Testing the connection in the field

After you have initialized also the sensors, press and release the control button of a sensor. The sensor

LED will blink twice, which means that the sensor is connected with the PlantControl central unit via the

repeater.

Replacing a repeater

1. Disconnect the old Repeater from the power supply (also the battery connector inside the repeater

must be disconnected from the battery holder).

2. Menu Initialize > Repeater > OK-button. Scroll with the cursor-buttons - to the repeater number

which you would like to replace

3. Initialize new repeater (see chapter "Initializing a repeater").

PlantControl

central unit Repeater

1 Repeater

2

Input

0

Repeater

5

Repeater

4

Repeater

3

Input

0

Repeater

6

Repeater

7

Repeater

8

Repeater

9 Repeater

10

Repeater

11

Deactivate a repeater, respectively removing it without replacing

Depending on where a repeater is positioned within the system, deactivating it must be addressed

differently. If it is a repeater, which is positioned as the last in a line (i.e. repeaters 4,5,6,7,8,10,11) the

effort is relatively low. But must a repeater be disabled, which is surrounded by other repeaters (ie,

repeaters 1,2,3,9), it may be more time-consuming. So not only the surrounding repeaters must be re-

initialized, but it must also be ensured that the radio range of the surrounding repeaters are not affected by

the loss of a repeater. The following are some examples.

14

PlantControl

Zentraleinheit Repeater

1 Repeater

2

Input

0

Repeater

5

Repeater

4

Repeater

3

Input

0

Repeater

6

Repeater

7

Repeater

8

Repeater

9 Repeater

10

Repeater

11

Deactivating (removing) repeater number 8:

1. Switch off repeater number 8 by removing the battery connector from the battery holder. It is not

enough to just pull out the AC adapter or solar cell cable.

2. Deactivate all sensors connected with repeater number 8 (see also chapter "Sensor settings").

Deactivating (removing) repeater number 9:

1. Switch off repeater number 9 by removing the battery connector from the battery holder. It is not enough to

just pull out the AC adapter or solar cell cable.

2. Deactivate all sensors connected with repeater number 9 (see also chapter "Sensor settings").

3. Go to PlantControl menu Initializing > Repeater > OK-button and scroll with the cursor-buttons to the repeater

number 2.

Enter under the top line "in direction sensor" repeater number 10.

Enter under the second top line "indirection sensor" repeater number 11.

Initialize again repeater number 2

4. Scroll with the cursor-buttons to the repeater number 10.

Enter under "in direction controller" repeater number 2.

Enter under the top line "in direction sensor" the number 0.

Initialize again repeater number 10

5. Scroll with the cursor-buttons to the repeater number 11.

Enter under "in direction controller" repeater number 2.

Enter under the top line "in direction sensor" the number 0.

Initialize again repeater number 11.

CAUTION: Make sure that the radio range of the surrounding repeater is not affected by

deactivating a certain repeater.

Step 4. Repeater settings

Settings > Repeater > OK-button

Number of repeaters: This is automatically assigned based on the number of initialized repeaters. For

this reason, the figure should not be changed.

Examples of repeater configurations

15

PlantControl

Central unit Repeater

1

Repeater

3

Repeater

2

--------------------------------------------------------------------------------------------------------------------

PlantControl

Central unit Repeater

1

Repeater

2

--------------------------------------------------------------------------------------------------------------------

PlantControl

Central unit Repeater

1

Repeater

3

Repeater

2

Repeater

4

16

Step 4. Repeater settings

Settings > Repeater > OK-button

Number of repeaters: This is automatically assigned based on the number of initialized repeaters. For

this reason, the figure should not be changed.

Step 5. Initializing the sensors

Initialize > Sensors > OK button

Wireless systems must first “recognize” each other if they are to communicate. Initialization of the

PlantControl unit with the sensors must therefore be carried out first.

Commissioning of already initialized sensors:

If the PlantControl unit and sensors have been initialized already at the factory (would be labeled on

PlantControl central unit) , then proceed as follows:

1. Switch on the PlantControl

2. Switch on the sensor(s)

3. For an immediate test of the reception strength, briefly press the ON/OFF button of the sensor.

Otherwise, depending on the number of sensors, check after approx. 60 minutes the reception

strength on the PlantControl display (Status > Sensors).

Commissioning, if frequency band needs to be changed due to legal requirements in your

country:

Proceed as follows, if your system has already been initialized at the factory and you need to change the

frequency band. Otherwise start from point 2.

1. First, deactivate all sensors on the PlantControl unit (Settings > Sensors > OK button > Deactivate).

2. Change the frequency band on the PlantControl unit (Settings > Controller > OK button > Frequency

band).

3. Change the frequency band on all the sensors (q.v. “Sensor operation”).

4. Initialize the sensors as described below.

Initializing the sensors

Initialize > Sensors > OK button:

1. Leave the sensor switched off.

2. Ensure that the controller and sensors are set to the same frequency band.

3. Select Initialize > Sensors > OK button.

4. If you use a repeater (range extender), enter now the repeater number with which the sensor shall be

connected.

5. Hold the sensor about 1 meter away from the controller and switch on the sensor. As soon as the

controller recognizes the sensor, mark it with the sensor number allocated by the system so that clear

allocation is later guaranteed between the sensor and the data record. You can then initialize the next

sensor. If a sensor is not recognized, “fail” will appear in the display. In this case, repeat the process

from step 1.

6. When all the sensors have been initialized, you can return to the menu with the BACK button.

7. Ensure that the number of initialized sensors is correct using Settings > Sensors > OK button.

8. Check reception strength: Using the menu item Status > Sensors, the reception strength will be

shown in % for all sensors (Signal). Use the cursor key to move to the desired sensor as

necessary. Do not stand in the transmission path between sensors and Data Logger when checking

reception strength. If a sensor has a reception strength of below 10%, briefly pressing the ON/OFF

button of the corresponding sensor will trigger radio contact and the reception strength will be

displayed again after approx. 2 seconds. If it is still below 10%, the sensor should be repositioned as

necessary. Briefly pressing the sensor’s ON/OFF button will show reception strength again.

9. Follow-up check: The sensors do not have an accurate clock and must therefore be synchronized by

the PlantControl central unit. This is carried out separately for each sensor in the network and ensures

that transmission of the measuring results is well-regulated and reliable.

When the system is switched on, a certain amount of time elapses between the first and last sensors

being manually switched on. If moisture measurement is triggered during this time, the last sensors

may not yet have been switched on and the PlantControl will miss these sensors. This will then trigger

an alarm (flashing red LED on the PlantControl unit). This alarm can be dismissed since it should not

reoccur after a few measuring cycles. Recommendation: Only carry out a follow-up check as in menu

item Status > Alarms after approx. 3 measuring cycles when system installation has been completed.

17

Step 6. Sensor settings

Settings > Sensors > OK button

This menu item summarizes all the setting parameters for the sensors.

Number of sensors: This is automatically assigned based on the number of initialized sensors. For

this reason, the figure should not be changed.

Highest sensor no.: This states the total number of sensors initialized in the controller. This figure

cannot be overwritten.

* Moisture in:Pressing the OK button allows you to choose between 3 readout units:

rel %: Data readout is in relative moisture percentages (factory setting).

sec: Sensor cool-down time in seconds

hPa: Suction pressure (see also chapter 4)

Note: The stored measurements, for example in rel%, can be read at any time

for the same measurement period in hPa and vice versa.

* Sensor No.: Press the OK button to enter up a supplementary designation for the sensor

after the sensor no.

* Suction pressure: If you have selected hPa under "Moisture in", then push the OK key and select

one of the soil types, which matches best with your soil (see also chapter 4).

Alternatively, if your specific soil has been calibrated by PlantCare, the

corresponding parameters for converting the measurement data into hPa can be

entered here.

Repeater: Indicates to which repeater number the sensor is assigned.

Deactivate: Proceed as follows if you wish to deactivate a previously initialized sensor:

Deactivate > OK button. Use the - cursor keys to move to the next or

previous sensor and to deactivate another sensor.

If you want to initialize again a deactivated sensor, proceed with steps 1 to 8 as

described under "Initializing the sensors.

* O N L Y T H E S E AD J U S T M E N T S M A Y BE M AD E !

Step 7. Commissioning the GPRS Modem

Settings > GSM/GPRS > OK button

Disregard this step, if you have not purchased any of the optional functions such as remote data

retrieval or SMS-Alarm function.

Working principles

The GPRS modem is used for the optional functions such as remote data retrieval and SMS-Alarm

function. When transmission is set to automatic, the data is sent to the e-mail address entered in the

corresponding menu field. In addition, the data required can be sent to any e-mail address by sending an

SMS to the GPRS Modem.

Please note that for proper function of the modem minimum receiving power of 50% should be available.

Check the current GSM receiving power on your PlantControl under the menu "Status> Controller".

SIM-Card

A GPRS-enabled SIM-Card is required for your GPRS Modem to be able to transmit data. We

recommend purchasing a SIM-Card from a local supplier with excellent network coverage. A GPRS-

enabled, prepaid SIM-Card can also be used.

Unlocking the SIM-Card

Insert the SIM-Card in a mobile phone and follow the instructions in your mobile phone operating

instructions. The SIM-Card is correctly unlocked when no PIN code entry is requested after switching off

and switching on your mobile phone.

18

SIM-Card

holder RS232 Interface Antenna socket

Power socket

LED:

- Flashes every second when GPRS is searching the network

- Flashes every 3 seconds when network connection is established

SIM-Card

holder

Audio

Interface

(not needed)

Unscrew the 4 screws on

the front panel. Lift the front panel with the

help of a small screwdriver Tilt the front panel 90°

forward and slide into the

slots

Remove the SIM-Card

holder place the SIM-Card

properly and push the

holder back again (see

details below).

GPRS Modem

Inserting the SIM-Card

SIM -Card

holder

unlocking pin

Unlock the SIM-Card holder by pressing the small button to the right of the SIM -Card holder with the tip of

a ballpoint pen or similar. Put the unlocked SIM-Card into the card holder and push it gently into the

GPRS Modem. Reattach the front panel an tighten the 4 screws.

Switch on your PlantControl D central unit and select

MENU > Settings > GSM/GPRS. Set now the following parameters:

1. Terminal operation

Activating/deactivating the GPRS Modem: select Terminal operation and then the OK-key.

Note: If you have purchased the SMS-Alarm function, the modem will be, if deactivated, activated

automatically for a short time for transmitting alerts.

2. Email Data output

Choose between Data File or Status: select Email Data output and then the OK-key.

3. Email send

To test your settings or to manually initiate a transmission, select Email send followed by the OK key (only

after entering all the parameters). The GPRS Modem will immediately transmit an

e-mail to the e-mail address specified under “Recipient”.

4. Power switch-on

For automatic data transmission or transmission in response to an SMS request, the GPRS Modem can be

left permanently switched on (not recommended when used with a solar cell) or temporarily once a day at

the specified time.

Select Power switch-on followed by the OK key. Now choose between the following options: 0

(permanently switched on) or, for example, 16 (= 4 p.m.), which is recommended when the Terminal is

used with a solar cell –and the GPRS Modem will be switched on every day at 4 p.m. for 30 minutes.

5. Send email every (transmitting interval)

Here, you must specify the interval at which the e-mail address entered under “Recipient” is to receive the

data automatically. If you do not require this option, the data can be also retrieved remotely by SMS

Select Send email every followed by the OK key. Now choose between the following options:

0 (never) or, for example, 5 days (the GPRS Modem will send data every 5 days).

6. Credit query:

In the event of a GPRS-enabled, prepaid SIM-Card being used, the data file transmitted will contain

information on your residual credit. Select Credit query followed by the OK key. Then enter the code given

to you by your SIM-Card provider (not all provider support this function).

19

7. APN (not required, if the modem is only used for sending and receiving SMS)

To enter the APN (Access Point Name), select APN followed by the OK key. Now enter the APN

given to you by your SIM-Card provider.

8. E-mail account settings (not required, if the modem is only used for sending and receiving SMS)

To ensure that your GPRS modem can send email messages, it requires an email account. You can

use the existing Plant Care Account settings (recommended) or create a new account.

8.1 Mail Server (Incoming mail server)

Select Mail Server followed by the OK key. Now enter the name of the incoming mail server.

recommended setting = pop.plant-care.ch

8.2 User Name

Select User Name followed by the OK key. Now enter the user name.

recommended setting = gprs@.plant-care.ch

8.3 Password

Select Password followed by the OK key. Now enter the password.

recommended setting = plantcare

9. Recipient (not required, if the modem is only used for sending and receiving SMS)

Select Recipient followed by the OK key. Now enter the e-mail address to which the data is to be

automatically transmitted in accordance with the interval defined (q.v. “Send e-mail every”).

If you do not require this option, the data can also be remotely retrieved by SMS.

Configuration example

Terminal operation activated

Email Data output Data File

Email send now execute

Power switch-on 14 o‘clock

Send email every 7 days

Credit query *130# (differs depending on the SIM card provider)

APN gprs.swisscom.ch (differs depending on the SIM card provider)

* Mail Server pop.plant-care.ch

* Password plantcare

* For a proper function, it is recommended not to change this PlantCare settings.

Data retrieval by SMS

In addition to automatic data transmission, the data required can also be sent to any e-mail address by

sending an SMS to the GPRS Modem. Use the following procedure to retrieve the data file or a system

status file:

Send an SMS with the following message to the SIM-Card number of your GPRS Modem

(„pc email d“ or „pc email s“ must be written in small letters):

Data File retrieval:

Status File retrieval:

IMPORTANT: Mobile phone settings when using a solar cell and data retrieval by SMS:

To minimize power consumption when powered by a solar cell, the GPRS Modem should only be switched on once

every 24 hours (see also "power switch-on”). As soon as your GPRS Modem is switched on, it will send data or

receive SMS for 30 minutes. After 30 minutes, the GPRS Modem will be switched off to reduce power consumption.

This is why you should also change your mobile phone settings for text messages (used for remote data

retrieval by sending a SMS). We recommend setting message validity to the maximum possible time as 24 hours can

elapse between sending your SMS for data retrieval and the time when your GPRS Modem is switched on. Please

read the section in your mobile phone operating instructions on defining message validity.

With message validity, you specify the length of time that the message centre of your SIM-Card provider will resend

your message if the first attempt fails (network service). If the message cannot be sent within this timeframe, the

message is deleted by the message centre and your GPRS Modem will not receive your SMS for data retrieval.

Generally, you can specify message validity for a single SMS or change the settings in the basic text message

settings in your mobile phone. Werecommend changing message validity in the basic settings.

20

This manual suits for next models

1

Table of contents

Other EIJKELKAMP Data Logger manuals