FIEDLER H40 User manual

Small telemetry station

HYDRO LOGGER H40

user manual version 1.01-E

Hydro Logger H40

User manual

2

electronics for ecology

FIED L E R

Hydro Logger H40

User manual

FIED L E R electronics for ecology

3

1. USE OF H40 4

1.1. AUTOMATIC DATA COLLECTION VIA GPRS NETWORK 5

2. BASIC DESCRIPTION 7

2.1. OVERVIEW OF PROGRAM PROCEDURES AND FUNCTIONS 8

2.1. MECHANICAL DESIGN 9

2.2. COMMUNICATION 10

2.3. POWER SUPPLY SYSTEM 11

3. INSTALLATION 12

3.1. MECHANICAL POSITIONING OF THE TELEMETRY ASSEMBLY 12

3.2. TO INSERT A SIM CARD 13

3.3. GSM MODEM OPERATIONAL STATUS SIGNALLING 14

3.4. ANTENNA AND ITS LOCATION 14

3.5. CONNECTING SENSORS AND TRANSDUCERS 17

3.5.1. CONNECTION CONNECTOR K2 17

3.5.2. POWER SUPPLY FOR CONNECTED SENSORS AND TRANSDUCERS 18

3.5.3. ANALOG INPUT AV1 18

3.5.4. RS485 SERIAL LINE 18

4. PARAMETER SETTINGS 19

4.1. MOST PROGRAMME 19

4.1.1. BASIC RULES FOR WORKING WITH PARAMETERS 19

4.2. BASIC PARAMETERS 20

4.2.1. IDENTIFICATION 20

4.2.2. TIME ZONE 20

4.2.3. ARCHIVING 21

4.2.4. POWER AND DIAGNOSTICS 21

4.2.5. COMMUNICATION SPEEDS AND PROTOCOLS 21

4.3. ANALOG CHANNEL SETTINGS 22

4.3.1. SETUP PROCEDURE AND BASIC PARAMETERS 22

4.3.2. ARCHIVING 25

4.3.3. ADVANCED PARAMETERS 27

4.4. CONTROL CHANNELS 29

4.5. GSM PARAMETERS 30

4.6. SMS COMMUNICATION 31

4.6.1. LIST OF AUTHORISED PERSONS 31

4.7. SMS DISTRIBUTION 31

4.7.1. INFORMATIVE SMS 31

4.7.2. INQUIRY SMS 32

4.7.3. SPECIAL CHARACTERS INSERTED IN SMS TEXT 33

4.7.4. CONTROL SMS INCOMING 34

4.8. WARNING AND CONTROL SMS 35

4.9. PARAMETERS FOR SENDING DATA UNDER TCP/IP PROTOCOL 37

5. SERVICE AND MAINTENANCE 38

5.1. FIRMWARE UPDATES 38

5.2. REPLACING THE BATTERY POWER PACK 39

CONTENT

S:

Hydro Logger H40

User manual

4

electronics for ecology

FIED L E R

1. Use of H40

HydroLoggers H40 are suitable for building monitoring net-

works in the water industry, for monitoring surface and ground-

water levels, in environmental monitoring projects and in many

other similar applications where the small size of the instru-

ment, its robust design and the long life of the power batteries

are advantageous.

Type H40G is equipped with a built-in GSM/GPRS communica-

tion module, which is used for automatic transfer of measured

and archived data to the database on the server and for possible

sending of warning SMS. The communication module can also

be used to remotely make any changes to the control parame-

ters.

The modern electronic circuitry of the Hydro Logger with its very

low current consumption and the controlled power supply of the

connected sensor allows the device to operate without changing

the battery pack for more than 10 years, even with daily auto-

matic data transmission via GSM network to a database server

on the Internet.

In applications where a GSM network is not available or auto-

matic data transfers to the server are not required, the H40D var-

iant, which lacks the GSM/GPRS communication module, can

be used for data acquisition and archiving. In this case, the

measured and archived data must be read out to a connected

PC (laptop) using the MOST program.

TYPICAL APPLICATIONS

▪Measurement of levels and temperatures in boreholes

and open streams

▪Measurement of levels in sewer manholes and water

reservoirs

▪Temperature and humidity measurement

▪Accurate measurement of up to 6 temperatures using

TEP-06 transmitter and Pt100 sensors

If it is necessary to monitor several different physical variables in

one location, it is preferable to use telemetry stations such as

STELA-3, H1 or more sophisticated units such as M4016 or H7,

which have more inputs for connecting external sensors.

1

E m b e d d e d

G S M / G P R S

c o m m u n i c a t i o n

m o d u l e

Ve r y l o w c u r r e n t

c o n s u m p ti o n

Hydro Logger H40

User manual

FIED L E R electronics for ecology

5

1.1. Automatic data collection via GPRS network

The HydroLogger H40G is equipped with a GSM/GPRS data module for automatic trans-

fer of measured data from the instrument to the database on the server.

ACTIVE STATIONS SYSTEM

FIEDLER telemetry stations are characterized by long battery life and very low operating

costs with regular data transmission to the server. This has been achieved by a system

of active stations and a passive server:

▪The server is always on and waiting for data from the individual telemetry sta-

tions, which themselves determine when the data will be transmitted to the

server.

▪The system can receive data from multiple stations simultaneously.

▪The GSM/GPRS modem in the station is switched on only for the time necessary

for data transfer from the station to the server - saving power of the power bat-

tery.

▪If an extraordinary event occurs at the measurement location, the station can

immediately transmit this information to the server - the usual delay of cyclical

calling of stations by the server is eliminated.

▪The system allows the use of operationally cheap types of tariff SIM cards with-

out a fixed IP address in the stations. The fixed IP address is usually charged

for, which increases the overall operating costs of the system.

DATA SERVER SERVICES

The data server is accessible via a standard web browser. After logging in, the user can

use the services of the data server, which include:

▪generation of graphs and tables of measured values

▪exports measured values for the selected period to the user's PC

▪automatic forwarding of received data from the station to another ftp server

▪printing of graphs and monthly reports including statistical summaries

▪creating virtual stations that can contain differently averaged, summed or other-

wise adjusted data from different real stations in one graph

A u t o m a t i c d a t a

c o l l e c t i o n s y s t e m

Hydro Logger H40

User manual

6

electronics for ecology

FIED L E R

▪automatic sending of e-mails to preset addresses after meeting the set condi-

tions (exceeding or dropping of the measured value over the set limits, switching

on/off of the binary channel, error conditions, ...).

PARAMETERIZATION OF THE STATION REMOTELY

A special server service allows you to change the settings of the station parameters

remotely over the Internet and GSM/GPRS network via the MOST program. All previous

and current parameter

files are stored in the

server database, including

the date and time of their

change and the login

name of the specific user

who made the change.

All these services are

available to the station

user for a low annual fee,

which is incomparable to

the investment in the

equipment of your own

server and its regular

maintenance. This makes

the data collection system

accessible to users of one

or two telemetry stations

as well as to operators of a

large monitoring network.

MAP VISUALIZATION

In some applications, it may be advantageous to display the location of the station and

its current status on a map

base. The status can be

both information about the

station's trouble-free op-

eration and the measured

values of the selected

channel.

An example is the freely

accessible server

www.hladiny.cz, which

displays measured data

from hundreds of stations

installed on rivers and

streams across the coun-

try.

Incorporation of the sta-

tion into the system is per-

formed by the server administrator at the request of its owner.

Hydro Logger H40

User manual

FIED L E R electronics for ecology

7

2. Basic description

The Hydro-Logger H40 is

characterized by its robust

mechanical design, small size

and modern electronic circuit

concept with very low self-cur-

rent consumption. It is suitable

for direct use in outdoor envi-

ronments as well as in perma-

nently wet environments in

waterworks.

The H40 station allows you to

set up to 8 recording channels

K1 - K8 for measuring se-

lected physical quantities and 8 binary channels B1 - B8 for recording states on binary

inputs.

In addition to the recording and binary channels, the station contains 7 control channels

K9 - K15 for recording the battery supply voltage, remaining battery capacity expressed

in %, current drawn by the connected sensors during measurement, temperature and

humidity inside the instrument.

The data memory can hold up to 400,000 values including date and time of acquisition.

The capacity of the data memory is sufficient for several years of data recording in nor-

mal operation. When the memory is full, the oldest stored values are gradually overwrit-

ten. The data memory also records extraordinary events - receipt or sending of SMS,

occurrence of an input error, data transfer to the server, etc.

The H40 operates in a power saving mode, in which the instrument is hibernated most

of the time and only wakes up and takes measurements at the set archiving interval.

During the measurement period, power is supplied to the connected sensors and trans-

ducers. The magnitude of the supply voltage is adjustable from 6 to 15 VDC.

The H40G telemetry station transmits the measured values via GSM/GPRS communi-

cation to a database server. In addition, the station can send warning or informative SMS

and receive query or control SMS. Parameter settings can also be changed and FW

upgrades can be performed via GSM/GPRS data communication.

All H40 station parameters are set via the MOST program. Parameters can be changed

from a PC (laptop) via a cable connection or remotely via a web browser and data server.

A 3.6V/19 Ah (H40D) or 3.6V/28 Ah (H40G) lithium battery pack is used to power the

unit, with a connector for easy field replacement. This battery pack allows many years

of operation of the instrument with daily transmission of measured data to the server via

GSM/GPRS network. Unlike the H1, H7 or M4016 stations, the H40 station is not

adapted for external power supply connection.

2

R e c o r d i n g c h a n n e l s

C o n t r o l c h a n n e l s

D a t a m e m o r y

E c o n o m i c a l

o p e r a t i n g m o d e

G S M

c o m m u n i c a t i o n

P a r a m e t e r s e t t i n g s

P o w e r s u p p l y

system

Hydro Logger H40

User manual

8

electronics for ecology

FIED L E R

2.1. Overview of program procedures and functions

The following overview briefly summarizes the programming procedures and functions

contained in the H40 station FW, which are fully available to the station users during its

parameterization and setup. Most of these functions will be described in detail in the

"Setup" chapter.

▪Calculation and storage of the measured quantity in set units of measurement

▪Non-linear signals can be corrected by a 2nd order polynomial separately for

each of the set channels.

▪Calculation of the remaining capacity of the power battery based on continuous

measurement of the current drawn from the battery

▪Separate limit alarm for each recording channel

▪Separate gradient alarm for each recording channel

▪For the duration of an alarm on a channel, you can set a different frequency of

data being written to memory and a different frequency of data being sent to the

server than in the normal state.

▪Data transmissions are performed under the FINET protocol (binary protocol

with fixed frame) or Modbus RTU. Data packet transmissions over the

GSM/GPRS network are performed under the TCP/IP protocol.

▪Regular sending of archived values via GPRS network to the Internet to the set

IP address (to the server with the MOSTNET-SERVER program installed)

▪Phonebook for 10 recipients, up to 3 groups possible

▪Alert system based on 14 user configurable SMS messages

▪Activation of sending SMS or transferring data to the server via GPRS network

periodically in time or after reaching the limit value on the measuring channel,

after activation of limit or gradient alarm, in case of sensor fault, low battery volt-

age, after activation of binary input or on request by SMS

▪Adjustable delay and hysteresis for SMS warning limits

▪25 query and command codes for creating a query or control SMS

▪Automatic insertion of the instantaneous value of the measuring channel into the

SMS text

▪Setting the time for sending daily SMS and the day for weekly SMS

▪Automatic switching between daylight saving time and standard time, automatic

time comparison with the server

▪Automatic archiving of the current parameter file on the server after each pa-

rameter change

▪The event log contained in the data memory records extraordinary events (acti-

vation of selected inputs, incoming and outgoing SMS, occurrence of error sig-

nals at connected sensors, successful and unsuccessful data transmission to

the server, etc.).

C o m m u n i c a t i o n

O p e r a t i o n a l

d i a r y

Hydro Logger H40

User manual

FIED L E R electronics for ecology

9

2.1. Mechanical design

The Hydro-Logger H40 is housed in a cylindrical stainless steel housing with a diameter

of 40 mm, which is terminated on one side with a K2 connector for connecting the sensor

and on the opposite side with a K1 communication connector for connecting a PC (lap-

top). The H40G variant of the instrument equipped with a built-in GSM/GPRS communi-

cation module has a small SMA coaxial connector next to the K1 connector for connect-

ing an external GSM antenna.

The robust mechanical design protects the electronic circuits from external interference as

well as from adverse climatic influences and is highly resistant to intentional and unintentional

mechanical damage.

LEVEL METER WITH TSH22 PROBE

Typically, the Hydro-Logger H40 is used as a level gauge to monitor wa-

ter level and temperature. In this case it is convenient to order the H40

station together with the TSH22 sensor and the DH40 stainless steel

mounting bracket. The bracket includes clamps for mounting the H40

station and a screw hanger for clamping the cable of the submersible

transducer (TSH22). The entire measuring assembly can then be sus-

pended from the bracket, e.g. in a borehole. The small dimensions of the

H40 station itself and the DH40 holder allow the measuring assembly to

be placed in a borehole with an inner diameter of only 50 mm.

Detail of the DH40 bracket mounting holes, the DA284 filter location

on the connector body and the TSH22 level sensor cable attach-

ment.

The special hydrostatic level sensor cable contains a capillary to com-

pensate for the atmospheric air pressure acting on the submerged sen-

sor. A semi-permeable filter located on the body of the level gauge con-

nector prevents air moisture from penetrating the capillary to the sensor

electronics and possible subsequent corrosion inside the level gauge.

M o u n t i n g b r a c k e t

D H 4 0

F i l t e r D A 2 8 4

Hydro Logger H40

User manual

10

electronics for ecology

FIED L E R

2.2. Communication

Parameter setting in the station and transmission of measured data can be done either

by cable from a connected PC (laptop) or remotely via a server and GSM network.

MOST PROGRAMME

All communication between the H40 and the connected PC (laptop) is done via the

MOST program. Using this program, you can, for example, parameterize the station,

transfer measured data from the station to the connected PC or view the current meas-

ured data. The MOST program is described in detail in chapter 4 of this manual.

Parameterization of the station consists in creating the current parameter file for the ap-

plication and then saving this parameter file to the H40 station. The MOST program is

also used to archive the current station parameter file and to modify this file. A special

server function can transfer the parameter file from the server via GSM/GPRS data net-

work to the H40G station even remotely.

After purchasing a license for the MOST program, the user gets an unlimited time option

to upgrade the program.

Download the current version of MOST from the station manufacturer's website:

http://www.fiedler.company/cs/ke-stazeni/stahnout-software-most

GSM/GPRS COMMUNICATION MODULE

The H40G telemetry station contains a GSM/GPRS communication module that usually

mediates all data transmissions between the station and the user. Connecting to the sta-

tion from a PC (laptop) is therefore usually not necessary.

Measured data stored in the station is automatically transferred via GPRS network to the

database on the server at the specified time. Conversely, a parameter file is transferred

from the server to the station if any changes to the station parameters are needed. The

parameter file is transferred at the end of the data session and only if the user has changed

at least one of the parameters and placed the new parameter file on the server. The MOST

program is used to manage the parameter file.

CONNECTING A PC (LAPTOP) TO THE H40 DATA

LOGGER

Transfer of measured data from the H40 station to a con-

nected PC or setting of parameters in the H40 station can

also be done from a PC (laptop) connected to the station

with a 2 m long KP232/M12 communication cable.

On the PC side, the cable is connected via a 9-pin con-

nector to the RS232 port. If the PC or laptop is not

equipped with an RS232 connector, it is necessary to add

a USB/RS232 converter (a suitable type of converter can

be ordered with the station).

On the side of the H40 unit, the K1 connector type M12 is

used for cable communication.

Connecting the pins of communication connector K1

P a r a m e t e r i z a t i o n o f

t h e s t a t i o n

PIN

1

2

3

4

Signal

TxD

NC

GND

RxD

Connection cable KP232/M12

Hydro Logger H40

User manual

FIED L E R electronics for ecology

11

2.3. Power supply system

The Hydro-Logger H40 is powered by a lithium battery block, which guarantees many

years of operation of the device even when the measured data is transmitted to the

server via GSM/GPRS network on a daily basis. The instrument is supplied with an in-

serted battery pack and since the instrument has an extremely long operating time when

the parameters are set correctly, there is no need to replace the battery pack for the first

few years of operation.

A lithium battery pack with a voltage of 3.6 V and a capacity of 26 Ah is used to power

the Hydro-Logger H40G (basic version with built-in GSM module). The block is com-

posed of lithium batteries enclosed in a shrink wrap into a single unit and is equipped

with a short cable ending with a connector for easy connection to the electronic board of

the device.

The Hydro-Logger H40D without GSM communication module contains a smaller power

supply unit with a voltage of 3.6V and a capacity of 19Ah.

The K2 connector contains, in addition to the 485 data signals and the AV1 analog input,

a program-controlled supply voltage for the connected sensor. The magnitude of the

supply voltage is user adjustable from 6 to 15V DC according to the requirements of the

connected sensor or measurement probe. A lower supply voltage saves battery capacity.

The +Unap supply voltage is only present on pin 1 of connector K2 for a short period of

time when the station requests a new measurement. The magnitude of the +Unap supply

voltage, the frequency of the measurement and the supply voltage on time are adjustable

parameters.

USUAL OPERATING TIME

The system of active stations and a passive server allows the GSM module to be perma-

nently switched off and only switched on when the station requests to transfer measured

data to the server or to send a warning SMS. This concept also allows the station to oper-

ate for many years without changing the power supply batteries. In a practical test, the

H40G was tested to be able to perform more than 5,000 data sessions to the server (or

send the same number of SMS alerts) without changing the battery pack.

With a typical archiving interval of 10 - 15 minutes with one sensor connected via RS485

or analogue input, the H40G station can operate for more than 10 years without changing

the battery pack, while transmitting data to the Internet on a daily basis.

In addition to the power required for data transmissions to the server, the power supply

must also cover the power consumption of the measuring probe or sensor connected to

the station. However, this consumption does not consume even 10% of the total capacity

of the power supply batteries during normal use of the instrument and over 90% of their

energy is consumed for GSM data transfers from the station to the server.

The current drawn from the batteries is continuously integrated in the station and the

energy drawn is continuously subtracted from the initial capacity of the power batteries.

The remaining battery capacity is archived on the user-accessible control channel K13.

The time record of the declining battery capacity can in many cases explain the often

mysterious rapid discharge of batteries - for example, inappropriate parameter settings,

a fault in the connected sensor, cable damage, etc.

When the battery pack is depleted, the user can replace it himself in the field. The de-

tailed procedure for replacing the battery pack is given in the chapter "Service".

The Hydro Logger H40 is not designed for external power supply connection.

H 4 0 G

H 4 0 D

I n t e g r a t e d v o l t a g e

c o n v e r t e r

R e p l a c i n g d e a d

b a t t e r i e s

N o t i c e

Hydro Logger H40

User manual

12

electronics for ecology

FIED L E R

3. Installation

The installation of the telemetry assembly

can be divided into its mechanical place-

ment, including the connection of sensors

and transducers, finding the optimal location

of the GSM antenna and inserting the SIM

card, and setting the control parameters.

The detailed description and setting of the

individual parameters is covered in Chapter

4.

3.1. Mechanical positioning

of the telemetry assembly

If possible, then install the assembly in a lo-

cation free of permanently condensing mois-

ture. If this cannot be avoided, then extra

care must be taken when connecting the

connectors - to tighten them (they have a

built-in O-ring). It is also advisable to treat

the GSM antenna connector with silicone

petroleum jelly or insulating self-adhesive or

self-vulcanizing tape to seal any leaks.

The telemetry assembly should not be in-

stalled in locations where the temperature is

consistently above 40 °C, as this increases

the self-discharge of the power supply bat-

teries, resulting in a shorter battery life. Con-

versely, low temperatures below -20 °C re-

duce the usable capacity of the batteries.

The measuring set H40(G) + water level and

temperature sensor TSH22 is usually sup-

plied with a stainless steel bracket DH40,

which also forms a hanger for the connected

sensor cable. This type of bracket is particu-

larly suitable for placing the H40(G)+TSH22

in a borehole or narrow installation pipe with

a diameter of only 50 mm.

3

P r o t e c t i o n a g a i n s t

m o i s t u re

Te m p e r a t u r e

i n f l u e n c e s

M e a s u r i n g

a s s e m b l i e s a n d

H 4 0 G + T S H 2 2

Hydro Logger H40

User manual

FIED L E R electronics for ecology

13

3.2. To insert a SIM card

The station manufacturer has long been lending its own SIM cards to its products for a

low monthly fee, which includes 1 MB of free data/month. The Hydro Logger H40G can

therefore be supplied with an already inserted SIM card. The operating costs of the bor-

rowed SIM card are invoiced to the station user together with the data hosting for data-

base rental and server services.

When inserting or replacing your own SIM card, please note the following:

PIN unblocking

The SIM card must be unblocked before it is inserted into the station and the

PIN code must be requested after switching on. Unblocking can be done on any

mobile phone - security function.

GSM module power off

When inserting and removing the SIM card, the GSM module must be switched

off from the power supply. This can be achieved, for example, by setting the

GSM modem permanently off in the station parameters. It is not recommended

to switch off the modem power supply by disconnecting the power connector of

the battery pack, as this may affect some previously set variables (real time of

the station, total leaked volumes, ...).

To access the SIM card holder

The SIM card is inserted into a flip-up holder located on the PCB next to the

GSM module inside the station. This PCB is mechanically connected to the plas-

tic cap of the cylindrical housing of the station. The cap is fitted with a sealing O-

ring and is not only inserted into the cylindrical outer housing of the station, but

is also secured with an M4 screw against rotation and sliding.

When opening the station, the M4 locking screw is first turned out and then the

plastic cap with the PCB is pulled out of the stainless steel casing of the station.

The two opposite holes on the sides of the plastic cap are for fixing the cap if the

stainless steel casing of the station cannot be easily removed.

Remark:

The station can be supplied either without a SIM card or with an embedded flat-rate SIM

card on long-term loan from the station manufacturer. In this case, it is a flat-rate SIM

card from O2 with the M2M tariff, which already has 1 MB of data per month free of

charge in the basic price of CZK 40. Any overrun of this volume is subsequently invoiced

at 0.03 CZK/kB of data and sent SMS at 1.35 CZK/SMS (1.50 CZK/SMS outside O2).

Invoices from the operator for the transferred data are invoiced by the station manufac-

turer to individual station operators and are subsequently re-invoiced to the station op-

erators at monthly (quarterly in the case of a smaller number of stations) intervals to-

gether with the data hosting for the rental and server services.

To i n s e r t a S I M

c a r d

O r d e r i n g a s t a t i o n

i n c l u d i n g S I M c a r d

Hydro Logger H40

User manual

14

electronics for ecology

FIED L E R

3.3. GSM modem operational status

signalling

The plastic cap of the H40G station contains a signal

LED in addition to the GSM connector, communication

connector and connecting cable. By the speed at which

this LED flashes, the device indicates the current status

of the GSM module.

Tab. 1: Signalling LED.

LED status Meaning of signalling

The LED is not lit

GSM modem is switched off - normal idle state.

Flicker 1 Hz

The GSM modem logs into the network.

Short flash once

every 5 sec.

The GSM modem is logged into the network, no data trans-

fer is taking place.

Fast flashing 2 Hz

Receiving or sending an SMS message

Fast flashing 5 Hz.

Data transfer via GPRS data network

Before data transfer from the station to the server or before sending SMS from the sta-

tion, the modem of the station must be logged into the GSM network. If the GSM signal

is strong enough at the location of the station antenna, the station will be logged into the

network after about 20 seconds from switching on the GSM module (slow flashing of the

LED).

Data transmission to the server can take from a few seconds to 5-10 minutes, depending

on the amount of data transmitted and the quality of the GSM field. During the ongoing

data session, the signaling LED flashes at an increased frequency of 2 Hz.

Forced switching on of the modem during installation of the station can be triggered from

a PC (notebook) connected by cable under the MOST program. The procedure is de-

scribed in the following text.

3.4. Antenna and its location

The Hydro Logger H40 comes with a small GSM 1dB antenna that

connects to an SMA connector.

Reliable GPRS and SMS communication requires a GSM field strength

of at least 8 on a scale of 0 to 31 at the antenna location. With lower

signal strengths, it may happen that some GPRS data sessions do not

take place at the set time, but only on other days with better conditions

for GSM signal propagation.

When installing the station, it is therefore important to take care of the

appropriate location of the supplied magnetic GSM antenna with re-

spect to the GSM field strength. In most above-ground buildings, the

location of the antenna is not critical and it can be mounted vertically

almost anywhere on a suitable elevated location.

The simplest method of finding a suitable location for the antenna using

a scale on a mobile phone gives only approximate results. Remember

to use the SIM of the same operator that the telemetry set-up will be

using. This method can be used wherever the GSM field strength is

sufficient and no special requirements are placed on the location of the

GSM antenna.

L E D

G S M f i e l d i n t e n s i t y

A b o v e - g r o u n d

o b j e c t s

AGSM-9dB-SMA

Hydro Logger H40

User manual

FIED L E R electronics for ecology

15

When installing the station outdoors, it is

often the case that the station is placed in

a metal enclosure, in the head of a bore-

hole or otherwise shielded from the exter-

nal GSM field. In this case, it is advanta-

geous to use a special hemispherical an-

tenna that is placed on the outer surface

of the metal casing. This special type of

antenna can be ordered together with the

station from its manufacturer under the

designation AGSM-3db/P-SMA. The an-

tenna shall be fixed in a 12 mm diameter hole and secured against theft from below with

an overmolding nut.

In underground objects such as sumps, transfer shafts and similar objects equipped with

a metal inlet cover, it has proven useful to simply attach the magnetic antenna to the

lower metal part of the inlet cover frame (the rod antenna points downwards). Only when

this simple, and surprisingly often successful, solution fails, is it necessary to proceed to

external antenna placement. A suitable solution may be, for example, a plastic tube (pro-

tector) with a cap that contains the supplied rod antenna. The positioning of the protector

above the ground should take into account the height of the snow cover at the installation

site.

In locations with very weak GSM signal,

the supplied magnetic antenna with 6 dB

gain can usually be replaced by a larger

omnidirectional magnetic antenna with 9

dB gain or a small directional antenna with

12 dB gain (the long directional antenna

requires precise antenna pointing and ho-

mogeneity of the electromagnetic field and

its use has not been proven in practice).

Beware of the usual vertical polarization in

GSM networks when installing a directional antenna! A small directional antenna 60 cm

long can be ordered together with its bracket from the manufacturer of the telemetry

assembly.

Finding the optimal antenna location often requires exper-

imentation, sometimes with SIM cards from other opera-

tors. A coaxial extension cable can also help, which can be

ordered with the set or as an option. The length of this ex-

tension cable can range from 2 to 10 m.

TREATMENT OF THE GSM ANTENNA CONNECTOR AGAINST MOISTURE

PENETRATION

The used GSM antenna connector type SMA is waterproof after screwing and the mu-

tually adhering dielectric prevents the penetration of air moisture to the central antenna

conductor.

However, when installing the station in a humid environment, we recommend treating

this connector joint with a suitable insulating tape or applying a thin layer of silicone

petroleum jelly to the antenna connector before connecting it to the station.

M e t a l e n c l o s e d

o b j e c t s

U n d e r g r o u n d

o b j e c t s

M o r e p o w e r f u l G S M

a n t e n n a s

G S M e x t e n s i o n

c a b l e

AGSM-3dB/P-SMA

Directional antenna AGSM-12dB-SMA

Extension coaxial cable PK-GSM-5M-SMA

Hydro Logger H40

User manual

16

electronics for ecology

FIED L E R

GSM FIELD STRENGTH DETECTION USING MOST

When installing the station, it is advisable to place its antenna in the place with the high-

est GSM field strength. The modem in the station converts the current measured field

strength into a number on a scale from 0 to 30 (the higher the number, the better the

location for the antenna).

Although the H40G station does not include a display or any buttons, the optimal antenna

location can be found using a laptop connected to the station with a patch cable.

When looking for the optimal location of the GSM antenna, proceed as follows:

▪Connect a PC or laptop with the MOST software installed to the H40G using the

KP232/M12 cable.

▪Start the MOST program and use the COM icon to establish communication with

the station.

▪In the main menu select "Info" -> "Current values" and then in the "Main infor-

mation" window select the "Modem status" tab. This procedure will display the

following information window on your monitor:

▪The "Operator", "Signal strength" and "Modem status" fields will not be filled in

until you instruct the station to log into the GSM network by pressing the "Switch

modem on" button.

▪During login, the signal LED will flash at a frequency of approximately 1 Hz. After

the device has logged into the network, the regular flashing of the LED will

change to short light pulses with a period of about 5 s and the GSM operator

code and signal strength will appear in the "Modem status" information window.

For reliable transmissions it is advisable to find a location for the antenna such

that the field strength is 8 or more.

▪After installing the antenna in the optimal location and after completing the over-

all parameterization of the station according to chapter 4, you can use the "Send

data" button to transfer the current settings (valid parameter file) and the last

measured values to the database on the server.

▪Finally, don't forget to log off the device from the GSM network by pressing

the "Turn off modem" button.

If the H40G telemetry station is located in a place with a weak GSM field, it will be

forced to repeat some data calls, it will be difficult to log into the network and the

result will be a reduction in the above mentioned operation time. Therefore, when

installing the GSM antenna, always try to ensure its optimal location (see chapter:

Installation).

" M o d e m S t a t u s "

i n f o r m a t i o n w i n d o w

L E D s t a t u s

i n d i c a t i o n

Hydro Logger H40

User manual

FIED L E R electronics for ecology

17

3.5. Connecting sensors and transducers

RECORDING CHANNELS

The Hydro Logger H40 can record up to 8 physical quantities in its data memory. Each

measured quantity occupies one recording channel K1 to K8. Unoccupied recording

channels are not allocated and thus do not take up space in the data memory (so-called

dynamic channel occupancy).

Any recording channel, if it is to be active, must first be set up. Setup is done via the

MOST program from a PC connected by cable, or remotely via a web browser and spe-

cial data server services. During setup, one input is assigned to each recording channel.

In most cases, multiple recording channels can have one common input (RS485 data

line).

When setting the recording channel, in addition to the input, the type of the measured

quantity, the measurement method, the units of measurement, the number of decimal

places and other necessary parameters are selected. Setting up recording channels is

covered in detail in the chapter 0.

Parameter settings .

3.5.1. Connection connector K2

The measuring probe or sensor is connected to the Hydro Logger H40 via the K2 con-

nector, which is located in the axis of the instrument on the face of the stainless steel

housing. The K2 connector is a robust 7 pin connector with a high IP66 rating. The wiring

of the K2 connector tubes can be seen in the following figure and table.

K2 connector

Signal

Note

1

+Unap

Sensor power supply 6..15 VDC

2

AV1

analog input 0(4)-20 mA

3

NC

Unplugged

4

NC

Unplugged

5

RS485-B

RS485-B bus

6

RS485-A

RS485-A bus

7

GND

ground terminal (-sensor power

supply)

Connecting the K2 connector tubes - top view of the connector

The connector connection limits the number of sensors that can be connected to the

H40 and requires the addition of a cable from the sensor to the K2 connector. On the

other hand, the connector connection simplifies and speeds up the installation as well

as the possible servicing and calibration of the con-

nected sensor or measuring probe.

A counter-angled connector with pins C91-K7-P for

connecting a measuring probe or sensor can be or-

dered together with the Hydro Logger H40 from the

instrument manufacturer. However, in most cases

the H40 station is shipped in an assembly with the

measurement probe or sensor and the mounted

connector is already included in the assembly.

C91-K7-P opposed to K2 connector

All inputs are protected against overvoltage by an effective semiconductor barrier that

eliminates induced interference pulses up to 600 W.

R e c o r d i n g c h a n n e l

s e t t i n g s

4

Con n e c t o r f o r

s e n s o r s

S u r g e p r o t e c t i o n o f

i n p u t s

Hydro Logger H40

User manual

18

electronics for ecology

FIED L E R

3.5.2. Power supply for connected sensors and transducers

In addition to the inputs, the K2 connector contains tubes for powering connected probes

and sensors. The +Unap supply voltage (pin 1) is only briefly switched on during the

measurement period. The measurement interval is an adjustable parameter ranging from

1 min to 24 h.

Another adjustable parameter of the unit allows you to switch on this power supply in

advance of the actual measurement, so that the connected sensor can correctly adjust

the size of the output signal in proportion to the physical quantity being monitored.

The +Unap supply voltage is user adjustable from 6 to 15 V and its optimum setting

depends on the type of sensor or probe connected. A lower voltage setting saves the

lifetime of the power supply battery.

3.5.3. Analog input AV1

Input AV1 (pin 2 on connector K2) is used to connect sensors and transducers with

output signals of 4 - 20 mA, 0 - 20 mA, 1 - 5 mA, 0 - 5 mA and 0 - 1 mA.

The voltage drop across the AV input can be as low as 2 V at 20 mA. This drop should

be increased by the minimum supply voltage of the connected sensor declared by its

manufacturer on the +Unap power terminal. Conversely, an unnecessarily high +Unap

supply voltage will excessively deplete the capacity of the power supply battery.

The analog signal supplied to the AV1 input is measured by a precision transducer with

a digital filter that suppresses the interference voltage induced in the input cable and

performs automatic self-calibration of the set measuring range.

The measuring sensor can be connected to the AV1 input in both two-wire (pins: +Unap,

AV1) and three-wire (pins: +Unap, AV1, GND).

3.5.4. RS485 serial line

The RS485 communication bus is designed for connection of selected sensors and

measuring transmitters that communicate under FINET, HART or Modbus RTU proto-

cols. Such devices can be, for example, ultrasonic or submersible level sensors US1200

and TSH22, water conductivity sensors ESV11 and many other sensors and transducers

listed in the table on page 28.

When setting the parameters of the selected recording channel, it is necessary to enter

the communication address of the connected probe or sensor and the number of the

internal channel in the connected measuring probe (details about the types of sensors

and their settings can be found in chapter 4.3.1.).

+ U n a p

C o n n e c t i o n o f

LMP858 level

s e n s o r w i t h 4 - 2 0 m A

o u t p u t

T E P 0 6 t r a n s m i t t e r

c o n n e ct i o n

Hydro Logger H40

User manual

FIED L E R electronics for ecology

19

4. Parameter settings

All user-accessible parameters of the Hydro Logger H40 can be read from the instrument

and stored in a parameter file with the extension *.PRM. The user can further modify this

parameter file, archive and write the changed parameters back to the instrument. The

MOST program is designed for working with the parametric file.

Parameter setting can be done from the PC directly via RS-232 interface cable (from

USB port via converter, which can be ordered together with the station), or it is possible

to set parameters remotely from the server via GSM/GPRS network.

4.1. MOST programme

MOST is a universal communication, setup and

evaluation program common to all FIEDLER instru-

ments.

A detailed description of the program is given in a

separate manual. The user who will use this pro-

gram only for working with parameters will be sat-

isfied with the description of individual parameter

windows described in detail in the rest of this user

manual.

You can get the latest version of the program on the manufacturer's website.

The MOST program is not included in the standard delivery of the telemetry set.

4.1.1. Basic rules for working with parameters

After physically connecting the PC to the H40 station (via cable or dial-up modem con-

nection), the connection must first be made. For this purpose, either the menu in the

"Communication" menu or the "COM" or "Telephone" icons are used. Both the connec-

tion and the connection are not necessary if you use the server service to set or change

parameters.

When you start working with parameters, it is advisable to first read the parameters from

the connected device. You can also load the parameters from the database on the server

(if you have the appropriate permissions), where they are automatically saved after each

change, or from a backup file on the PC.

After setting the parameters, the new parameters must be saved in the instrument. This

can be done from the "communication" menu or by using the icon. When using a server,

simply save the new parameter file to the server and the station will download the file at

the next data communication. You can start the data communication immediately by

sending an SMS message in the form: HESLO, dial0 to the station's phone number (this

requires that the station's H40 modem is switched on at the time of sending the SMS).

4

Hydro Logger H40

User manual

20

electronics for ecology

FIED L E R

4.2. Basic parameters

A group of basic parameters for setting station identification, measurement frequency,

supply voltage control, data archiving and station communication with sensors

4.2.1. Identification

The basic parameters include the instrument nameplate, which can store a maximum of

17 ASCII characters characterizing the instrument. The name tag is preferably used to

visually check the affiliation of the open parameter file to the connected instrument and

can be seen at the beginning of the *.dta data file, inserted into sent SMS and serves as

a station identifier on the server.

Note: the "Device Name" parameter is automatically transferred to the station name

on the server. Therefore, if you need to rename a station on the server, just change

the name tag in the parameters and the next time the station has a data session with

the server, the name of the station on the server will automatically change.

The value of this parameter serves as a station identifier on the server and is assigned

by the server administrator. The identification number is stored together with the data in

one data file and thus uniquely identifies the origin of the measured data. The parameter

can take values in the range 1-65535.

Setting this parameter to a non-zero integer prevents further parameter changes without

knowing the password. The password value can take values from zero to 9999. A value of

zero disables the control and allows unlimited overwriting of the instrument parameters.

4.2.2. Time zone

By checking the "Automatic daylight saving time" option, you allow the station to auto-

matically adjust its internal functions during the time change, such as the regular sending

of SMS messages. This way, an informative SMS message will be sent automatically at

a fixed time throughout the year - for example, every Monday at 8:00 am.

The data will always be recorded in the station's memory according to standard time, re-

gardless of the parameter selection. This is so that the time sequence of the measured

values is not disturbed.

The setting of this parameter affects the calculation of daily leakage volumes, daily pre-

cipitation, etc. The parameter is used for example when loading data in an organization

using shift operation, where the calculation needs to start with the start of a new shift

(e.g. at 6:00).

I n s t r u m e n t

n a m e p l a t e

I d e n t i f i c a t i o n

n u m b e r

P a s s w o r d t o

c h a n g e p a r a m e t e r s

S u m m e r t i m e

S t a r t o f t h e d a y

The unit places the

name tag at the be-

ginning of the sent SMS

and in the data file.

A password value diffe-

rent from 0 will block ac-

cess to the parameters.

Interval when the instru-

ment is switched on and

all inputs are measured

For each channel, its

multiples for archiving

(average) can be speci-

fied.

Day boundaries for

calculating daily

leakage volumes or ra-

infall

SMS message archiving

including text, phone

number, date and time

Optimal AD converter

parameters

Parameter for setting

the altitude when mea-

suring the level in the

borehole

Delayed measurement

allows the connection

of sensors with longer

rise times.

Adjustable supply vol-

tage for connected

sensors (range 6 to 15

V DC)

When the capacity of

the supply battery

drops below the set li-

mit or the current

drawn from the Unap

terminal is exceeded,

a warning is stored in

the station's error tray.

Table of contents

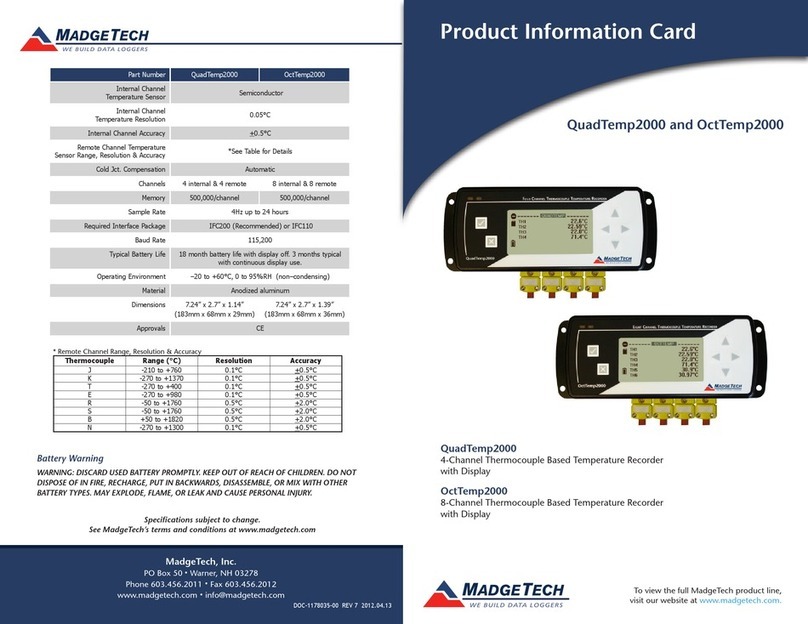

Other FIEDLER Data Logger manuals

Popular Data Logger manuals by other brands

MadgeTech

MadgeTech QuadTemp2000 Product Information Card

Eddyfi Technologies

Eddyfi Technologies TSC Amigo2 Getting started

Theodor Friedrichs

Theodor Friedrichs COMBILOG 1020 Hardware manual

Peak

Peak PCAN-Router Pro FD user manual

Geosense

Geosense GEOLOGGER G8 PLUS Advanced instruction manual

Huato

Huato S1500 Series user guide