EIJKELKAMP CBR User manual

M-0615SCE

Penetrologger CBR

© 2022-06

Meet the dierence

User manual

Serial number :

Hardware version : 6.00

Sotware version : 2.21

Penetroviewer version : 6.13

NSN : 6635-12-396-3995

Royal Eijkelkamp

Nijverheidsstraat 9, 6987 EN

Giesbeek, the Netherlands

T +31 313 880 200

E info@eijkelkamp.com

I royaleijkelkamp.com

2

Contents

About these operating instructions.........................................................................................................................................4

Introduction ...................................................................................................................................................................................4

1. CBR (Californian Bearing Ratio)...........................................................................................................................................4

1.1 Average CBR value; calculation per penetration......................................................................................................5

1.2 Influence of the soil moisture content and the content of the organic contents.........................................5

1.3 Influence of the spatial variability ...............................................................................................................................5

2. Description ................................................................................................................................................................................5

3. Technical specifications.........................................................................................................................................................6

4. The procedure........................................................................................................................................................................... 7

5. Planning the measuring for field measurements ..........................................................................................................8

5.1 Creating a plan ...................................................................................................................................................................8

5.2Example................................................................................................................................................................................8

6. Creation of a plan on the PC................................................................................................................................................9

6.1 Installation of the sotware............................................................................................................................................9

6.2Starting and ending the Penetroviewer....................................................................................................................10

6.3Set-up..................................................................................................................................................................................10

6.4Standard parameters.......................................................................................................................................................11

6.5Creating a measurement plan.......................................................................................................................................11

6.5.1 Entering a measurement plan..........................................................................................................................11

6.5.2 Saving and ending the measuring plan ....................................................................................................... 13

6.5.3 Opening and processing a measuring plan................................................................................................. 13

6.6Transferring a measuring plan to the penetrologger ..........................................................................................13

7. Creating a plan with the aid of the penetrologger......................................................................................................14

7.1 Operating the penetrologger .......................................................................................................................................14

7.2 Standard parameters and settings.............................................................................................................................16

7.3 Creating a measurement plan.......................................................................................................................................17

7.4 Processing a measuring plan.......................................................................................................................................19

8. Carrying out the measurements........................................................................................................................................19

9. Processing the measuring data.........................................................................................................................................25

9.1 Reading out on the PC....................................................................................................................................................25

9.2 Display on the PC ............................................................................................................................................................25

9.2.1 Opening and closing a project file.................................................................................................................25

9.2.2 Graphic depiction................................................................................................................................................26

9.2.3 Numeric depiction ..............................................................................................................................................28

9.2.4 External processing of the measuring results............................................................................................29

9.3 Display on the penetrologger......................................................................................................................................30

9.4 Printing out on a PC........................................................................................................................................................ 31

9.5Programmable Administrator User.............................................................................................................................32

3

Nothing in this publication may be reproduced and/or made public by means of print, photocopy, microfilm or any other means without

previous written permission from Royal Eijkelkamp. Technical data can be amended without prior notification.

Royal Eijkelkamp is not responsible for (personal) damage due to (improper) use of the product.

Royal Eijkelkamp is interested in your reactions and remarks about its products and operating instructions.

10.Problems and their removal...............................................................................................................................................33

10.1 Communication between thePC and the penetrologger...............................................................................33

10.2 Operating the penetrologger.................................................................................................................................33

10.3 Creating a measurement plan...............................................................................................................................34

10.4 Carrying out the measurements...........................................................................................................................34

10.5 The Penetroviewer CBR ...........................................................................................................................................35

10.6 Resetting the penetrologger..................................................................................................................................35

11. Power supply GPS, LCD and servicing .............................................................................................................................35

11.1 Power supply ..............................................................................................................................................................35

11.2 GPS Receiver...............................................................................................................................................................36

11.3 LCD screen with background lighting..................................................................................................................36

11.4 Service ..........................................................................................................................................................................36

Literature ..................................................................................................................................................................................37

Appendix 1 penetrologger menus.........................................................................................................................................38

Declaration of Conformity......................................................................................................................................................... 41

4

About these operating instructions

Symbols(as shownlet) aremeantfortechnicalrequirements ofwhich the usermust takespecialnote.

Caution (symbol shown at let) is meant for work and operation processes that must be strictly

adhered to in order to prevent danger to persons. The user is responsible at all times for complete

personal protective equipment.

Refers also to working and operation processes that must be strictly adhered to in order to prevent

damage to or destruction of the penetrologger.

Text between inverted commas “….” (or italics) means that the text is exactly as shown on the screen.

Introduction

The CBR-penetrologger is a device specially designed for measuring the CBR value (= Californian Bearing Ratio)

of the soil; at the same time this instrument automatically saves the measuring results obtained and thus makes

possible their further processing on a PC.

The penetrologger is distinguished by an ergonomic design, its low weight and its user-friendliness. It permits

measurements up to a depth of 70 cm. The penetrologger displays the CBR value for each measurement.

The penetrologger contains a GPS system for exact determination of the measurement position. The coordinates

displayed by the penetrologger can be allocated with the aid of certain sotware (or somewhat less accurately

over the Internet) to a site or a map.

Optionally a soil moisture sensor (Art.-No.: 061550) can be connected to it in order to determine and save the

soil moisture percentage (single-point measurement) of the measuring position.

The penetrologger permits the direct storage and processing of 1500 measuring data (CBR data including GPS

and soil moisture data). For this reason this instrument is suitable above all for comprehensive test series.

The penetrologger possesses a built-in arrangement for displaying the penetration speed, as a too-quick or

impact method of advance will result in values that are not representative of the measured soil. This method

is precise and possesses a measuring range of von 668 N (15% CBR).

1. CBR (Californian Bearing Ratio)

The Californian Bearing Ratio investigation (short CBR) is a method of testing with the help of which the

carrying capacity of soils and hydraulically bound layers (rather seldom) can be investigated. The procedure

was originally developed for compaction of airport surfaces and is meanwhile also used in road construction.

It was developed by the “Californian Department of Transportation“. Basically the investigation displays the

force needed by a plunger pressed into a sample of soil in order to achieve a defined penetration speed up to

a defined depth. The better the carrying capacity of the soil sample, the higher the generated plunger pressure.

A soil CBR value is an index of the shear resistance under standard loading as compared to the shear resistance

of a standard material (crushed limestone) under the same loading.

The CBR investigation is described in the MIL CRD-C 654-95, ASTM Standards D1883-05 (for samples prepared

in the laboratory) and D4429 (for field soils) and AASHTO T193.

It is necessary to carry out measurements in depths, taking into account deviations, of the soil capacity for air

trac with and without prepared start and landing strips.

The measuring results of the penetrologger are validated in order to characterize the CBR values of the soil as

described in the TTRL Report 901.

Text

5

1.1 Average CBR value; calculation per penetration

The penetration depth (70 cm) is divided into 5 customer-specific,

adjustable depths. The CBR value (1 to 5) is measured at these depths.

CBR 1 (first value) and CBR 5 (last / deepest measurement) are the

determining CBR values and saved as individual values per cm. Values

2, 3 and 4 are supplementary information.

1.2 Inluence of the soil moisture content and the

content of the organic contents

The penetration resistance of the soil depends, among others, on the

soil moisture content. The higher the degree of moisture of the soil,

the lower its penetration resistance and the lower its carrying capacity.

In the comparison of penetration resistances that are measured at

dierent points in time (for instance before and ater a particular soil

processing), one must ensure that the soil moisture conditions during the

measurement are comparable. In practice, comparable moisture values

are best ensured in that the penetration resistance is determined at field capacity (pF-2). The soil moisture

content of the measuring point can be defined and saved with the aid of the optional soil moisture sensor

(Art.-No.: 061550).

1.3 Influence of the spatial variability

In the determination of the penetration resistance the spatial variability of the soil must also be taken into

account. The dierences with regard to texture, the structure or content of organic content can dier substantially

on a parcel level. As all these factors determine the penetration resistance, it is first necessary to make repeat

measurements in order to receive a representative value. The number of necessary repeat measurements is

oriented to the desired precision and the natural variability of the soil. The literature (for instance Campbell &

O’Sullivan, 1991) recommends 10 measurements per plot because of the soil formation due to the impression of

the cone. The spacing between the individual measuring points is at least 50 to 60 cm. The Netherlands standard

for electrical penetrations (NEN 5140, 1996) promotes a spacing of at least 100 cm between penetrations.

2. Description

The CBR penetrologger is normally supplied as a complete set for measurements to a depth of up to 70 cm. Such

a set is comprised of the penetrologger itself, suitable CBR cones, conecheck key, probe rods, a depth reference

plate, cable, sotware and a test protocol. Accessories such as soil moisture sensor (061550) are obtainable as

option. All these parts are packed into a carrying bag.

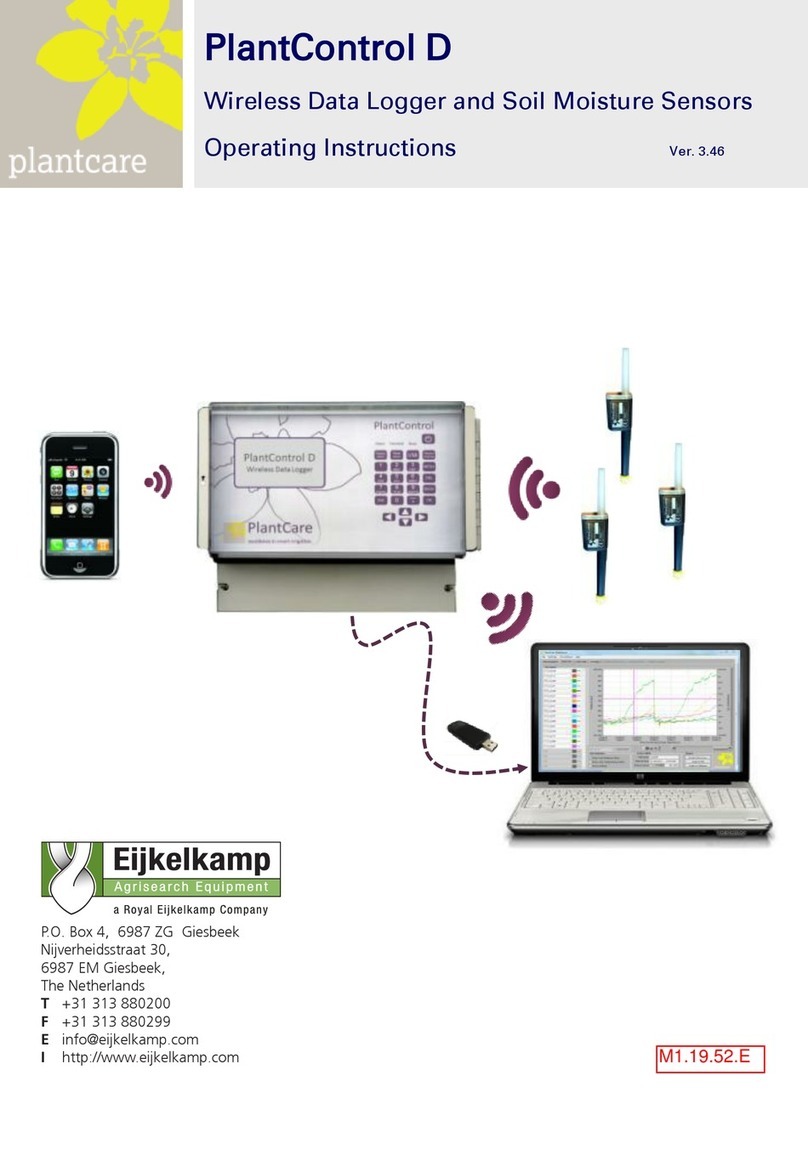

The complete penetrologger (see picture) consists of a housing (a) with GPS antenna (7), a LCD display (8), a key

pad (9), a level (10), and a force absorber (2). The logger has a spray-water protected housing with hand grips

(11). The penetrologger is provided with power by means of batteries.

The cone-shaped point or “Cone” (4) is screwed on below the three-part probe rod (3).

When the cone is forced into the soil, the penetrologger registers the depth up to 70 cm with great precision

by means of an internal ultrasound sensor whereby the depth reference plate (5) comes into use.

The measured penetration resistance, the GPS data and – if the optional soil moisture sensor is connected to the

communication port (6) – the percentage of soil moisture are saved into the internal Logger of the penetrologger.

The average value of the CBR values and the standard deviation can be calculated automatically. If the cable

(13) is connected to the communication connection port (6) and to the PC, then data can be exchanged between

the Logger and the PC. The accompanying sotware permits the reading out of the data to the PC, the graphic

and numerical representation and the printing out of the data.

The conecheck key (12) is used for checking the wear on the cones. The cone must be replaced when it fits

through the hole.

Measuring soil moisture

6

3. Technical specifications

Environment

Temperature -10 to +70 °C

Moisture 0..100%RH

Temperature shock 50 °C

Physical

Dimensions of bag 30x25x15 cm (h x w x d)

Total weight 5.5 kg

IP classification IP 54 (spray water / watertight)

The cone is CBR standard with adherence to NATO specification.

Diameter 0.5 inch (1.27 cm) /upper edge of cone

Top angle 30 °

Surface 0.2 Inch2(1.27 cm2) cone

Penetration depth 0-70 cm

Penetration resolution 1 cm

Penetration speed 1-5 cm/sec

Penetration force 0 - 700 N (0 - 15% CBR)

Penetration resolution 0.1% CBR

Penetration accuracy 2% (re-calibration with error >5%)

GPS accuracy 2 m CEP Circular Error Probable

3.5 m SEP Spherical Error Probable

(Egnos compensated)

CEP, 50% 24-hour static, - 130 dBm

(type Blox LEA-6H)

Display LCD monochrome green/black

Background lighting LED intensity + contrast adjustable

Power supply Battery pack Lithium SEM52 8.4 V or BH8AA 12 V

Battery life > 600 measurements

Memory 1500 penetration measurements

Levelling Spirit level (bubble level)

Moisture Optional sensor available

Measuring mode

Calculating the average value: Ø CBR = (measuring values CBR depth 1 (X) to measuring values CBR depth 4 (Y))

/ n (= No. of measuring values between X and Y = per centimetre of a measurement).

Ø CBR average value is rounded down (e.g. CBR 7.9 CBR 7)

Range for calculations: Ø CBR average value can be entered for 2 (CBR depth 1 (X) and CBR depth 4 (Y)) users.

1

4

3

2

78

9

10

11

Penetrologger

6

5

12

Penetrologger set

13

7

4. The procedure

Before starting the measurements with the penetrologger, a plan for the field measurements must first be

established (Chapter 5. Plan for field measurements). Such a measurement plan contains the definition of the

field measurement positions, the number of measurements that will take place at the individual measuring

points, and the settings of the penetrologger (for instance the speed of penetration).

If desired, the desired measuring plan can be created on the PC or on the penetrologger itself (Chapter 7. Creating

a plan with the aid of the penetrologger). Practically, it is more convenient to make use of a PC (Chapter 6. Creating

a plan on the PC). To this purpose the Penetroviewer CBR sotware needs to be installed on the computer. If

the PC is now connected to the penetrologger via the communication cable, then the created measuring plan

is transferred from the PC to the penetrologger.

Ater creating the plan, the penetrologger is ready for use and thus permits the measurement of the penetration

resistance. Now the prescribed measurement are carried out at each measuring point in the field (Chapter

8. Carrying out the measurements). The corresponding results are automatically saved in the logger where

there is an upper limit of 1500 measurement results. It is also possible to adapt the measurement plan in the

penetrologger on site (Paragraph 7.4).

The measuring results can be called up on site on the penetrologger in graphic or in numerical depiction

(Chapter 9. Processing the measuring data). The sotware also permits the reading out of the data on the PC,

the processing of these data, transfer to other programs, and printing out on a printer.

8

5. Planning the measuring for field measurements

5.1 Creating a plan

This type of plan consists of a hierarchical structure

of projects, plots and penetrations (see picture).

A project consists of several plots (measuring

positions). A penetration resistance is determined at

each individual plot. In this, one or more penetrations

(measurements) are carried out per plot in order to

arrive at a representative average value for the plot.

The following general parameters are created for

each project:

Project designation

User name (e.g. BW)

Plot designation

Penetration speed

Number of plots

Quantity of soundings per plot (max. 20)

5.2 Example

An example of one such measuring plan is

“Plan X”:

PLAN X

Project 1

Plotname 1

Penetration 1

Penetration 2

Penetration 3

Penetration 4

Plotname 2

Penetration 1

Penetration 2

Penetration 3

Penetration 4

Plotname 3

Penetration 1

Penetration 2

Penetration 3

Penetration 4

Project 2

Plotname 1

Penetration 1

Plotname 2

Penetration 1

PLOT 1

PLOT 2

PLOT 1

PLOT 2

Project 1 (Strip 1) Project 2 (Strip 2)

PLOT 3

Example of a measuring plan

9

6. Creation of a plan on the PC

The creation of a plan on the PC and the later transfer to the penetrologger has the advantage that the entry via

the keyboard of the PC is oten easier. This method saves much time, especially when special plot designations

are to be used, which can be time-consuming as regards the typing eort. One or more projects can be defined

per plan, in fact up to a maximum of 1500 penetrations.

Several plans can be saved on the PC and these can be called up later as required. However, the penetrologger

can only save one plan. This plan can contain several projects. In the case that several plans are used in the

field, then it is advisable to use a Laptop.

6.1 Installation of the sotware

System requirements:

Windows 7, 8 or 10

1. First insert the “Penetroviewer CBR” DVD into the drive. The Auto-Run program starts, follow the instructions

of the screen. If the Auto-Run program does not start, then the Setup file can be started manually.

Select “Setup” and click on “Open”. To confirm, click on the command button “OK”.

When downloaded: Install the Penetroviewer sotware. Click on the Setup. exe file and the installation starts,

follow the instructions on the display.

2. In order to select a dierent folder for the Penetroviewer, click on “Change” and enter the desired folder.

The standard target folder is “C:\Program Files\PenViewer”.

To confirm, click on the “OK” command button.

3. Click on “Next” in order to start the installation or “Abort” to stop the installation process.

4. The PC must be restarted to activate the changes. Click “YES” to start automatically or “NO” if it is intended

to start later.

Penetroviewer main window

10

6.2 Starting and ending the Penetroviewer

1. To start the Penetroviewer, click the Eijkelkamp Penetroviewer shortcut in the Windows Start menu under

Programs, Eijkelkamp Penetroviewer, Penviewer.

Then a window with the Eijkelkamp logo appears and disappears again a few seconds later to be replaced

by the main window of the Penetroviewer (see picture).

2. When used for the first time, the main window has an English language menu bar. If the German language

is desired, select “Language” under “Tools” in the menu bar and place an X in the “German” box.

3. To close the Penetroviewer, click “Close” in the menu bar under “Project” or click the X at the top right of

the window.

6.3 Set-up

The following parameters are shown in the Set-up

Export

Language

Comm.Port

Info

When used for the first time, the main window has an English language menu bar. If instead the German language

is desired, select “Language” under “Tools” in the menu bar and place and tick in the “German” box.

The sotware automatically finds the available communication ports on the Computer. The correct communication

ports must be selected when the penetrologger is first connected.

Connect the penetrologger to the computer and switch it on. Go to Tools Comm. Port and select one of the

available communication ports.

When you have selected the correct port a green tick (‘’) appears in the small depiction of the penetrologger

(top right in the picture). If the incorrect port is selected, a red X will appear instead and another port must

be selected.

Setting up the communication port

11

Either a long or a short version can be selected as export format. The long version is suitable for further

processing in Excel. For this, select Export TXT file pro cm depth under Set-up / Export in the menu bar (for

further information see 9.2.4).

The short version is suitable for the “Go-book”. For this, select Export TXT Average value under Set-up/Export

in the menu bar (for further information see 9.2.4).

6.4 Standard parameters

Certain standard parameters are set before the creation of a measuring plan. The corresponding values are

filled in automatically in a time-saving method when creating a plan

The following standard parameters are filled in for “Standard” under “Plan” in the menu bar:

Company Enter a maximum 8-character company name – withoutspacing. A dierence is made here

betweenupperandlowercaseletters.Normallythenameappearsbetweensquarebrackets

In the first use, this is: [COMPANY].

Number of plots Here the desired number of plots that will be used within the scope of a given project is

entered with a max of 1500. Normally this number appears in square brackets. In the first

use, this is: [1].

Pen. per Plot Select the desired number of penetrations that are to be carried out per plot. Normally the

number of penetrations per plot is: [1] (max. 20)

Pen. speed Select the desired penetration speed (cm/sec) for the measurements. The recommended

value is 2 cm/sec (see Paragraph 7.2).Normally the penetration speed is set to: [2].

CBR depth Normally all values between 0 cm and 60 cm are used for average calculations of the CBRs

per penetration. It is possible for the project to pre-select other areas (e.g. measurements

between 10 cm and 50 cm).

Type of cone The CBR cone type is pre-selected.

6.5 Creating a measurement plan

6.5.1 Entering a measurement plan

1. A plan is created by selecting “New Plan” in “Plan” in the menu bar.

This opens the “Add Project” window.

If a new plan is to be created, thenno other plan must have already

been loadedin the Penetroviewer. Therefore first close thealready

loaded plan (see Paragraph 6.5.2).

2. In the next step, click New Project in order to define a new project within

the plan.

This opens the “EDIT PROJECT” window.

Add project window

12

3. Now the following entries can be changed

Project name Normallybasedon thedate(Year-Month-Day)and the sequentialnumber; entera

unique designation, maximum 8-character entry.

Company Maximum 8-character entry.

Type of cone CBR cone (cannot be changed)

CBR depth CBR-1 (X) starting depth average calculation Ø CBR

CBR-4 (Y) End depth average calculation Ø CBR

CBR-5 (End depth penetration)

Penetr. speed 1, 2, 3, 4 or 5 cm/s.

No. of plots 1 ... 1500

No. of penetrations per plot 1 ... 20

Plot name Normallyallplotswithinagivenprojectpossessauniquename,i.e.theyarenamed

on the basis of a sequential number. These numbers have a maximum length of

8 characters.

The same penetration speed should always be used with several measurements in order to ensure

that the results are reproducible.

4. The project is defined by a mouse click on “OK” when everything is entered as desired (also the whole project

can be removed with Back).

5. Repeat steps 2-4 until all the desired projects have been entered.

In this connection, it should be pointed out that a total of maximum 1500 penetrations can be reserved in the

penetrologger. If this limit is reached during creation (the Penetroviewer calculates this automatically), then

the New Project button no longer appears in the “SELECT PROJECT” window. Also, in this case no additional

plots and penetrations can be defined anymore.

6. Save the completed plan (see Paragraph 6.5.2).

Edit Project window

13

6.5.2 Saving and ending the measuring plan

As soon as the changes of the settings have been carried out, a window appears (irrespective how)

with the query whether the changes should be saved or not (Yes/No/Abort). The saved plan can then

later be used again or can be processed (see Paragraph 6.5.3)

1. Now select the “Save” option in “Plan” in the menu bar and enter a name for the plan. Then select the desired

folder in which the plan file is to be saved. The file will have the sux ”pla”.

If the file name already exists, then the operating guide in the dialogue window asks whether the existing

file is to be overwritten. If the file is to be overwritten, confirm by means of a mouse click on Yes; otherwise,

click No and enter a new name.

2. If (ater successful saving) the plan is to be closed, select Close in “Plan” in the menu bar.

Then a dialogue window appears with the query whether you really want to close the plan. With Yes the plan

is closed and No annuls the command (this does NOT delete the plan from the hard disk!).

Ater successfully closing the plan, the Penetroviewer can be used to create a new plan or to load an existing plan.

6.5.3 Opening and processing a measuring plan

1. If an already existing plan is to be opened, select “Open” in “Plan” in the menu bar.

However, the Penetroviewer can only save one plan at a time. For this reason, if a processed plan is already

open, a dialogue window will appear with the request to save the current plan.

2. Now open the desired folder in which the file with the “pla” sux is located and select the file. The file is

loaded with Select and the process is aborted with Abort.

3. If the loaded plan is to be processed, select “Edit Plan” in “Plan” in the menu bar. Ater successful selection

of a plan, the settings can be adapted using Edit project.

6.6 Transferring a measuring plan to the penetrologger

The plan created on the PC can now be transferred to the penetrologger. For this purpose, the penetrologger

must first be connected to the PC.

1. Remove the protective cap on the communication connection of the penetrologger. Then connect the

communication cable to the communication connection. The connection only fits if properly installed. Insert

the plug firmly and fasten the connection by screwing up the rotating ring.

2. Connect the other end of the communication cable to a serial communication connection of the PC.

3. Place an X next to the correct communication connection for the Penetroviewer at Comm. Port under “Tools”

in the menu bar.

4. Now the penetrologger can be switched on by pressing the top white button. If there are no batteries in the

penetrologger, these must now be inserted (see 11.1 “Power supply”).

The PC will now automatically recognise the penetrologger and activate the Datalogger menu in the menu

bar.

5. In the next step, select Identify under Datalogger in the menu bar.

Then the penetrologger is recognised by the PC. The display of the penetrologger then shows the text

“COMMUNICATION WITH YOUR PC WAS SUCCESSFULLY ESTABLISHED!”.

14

The Penetroviewer possesses a “LOGGER INFORMATION”

window with the serial number of the hardware and sotware

versions.

Close this window to continue.

6. Use Send plan in Datalogger in the menu bar to transfer the

plan to the penetrologger.

In a window, the operator guidance asks whether the plan

is really to be transferred to the penetrologger. Transfer the

plan with Yes; abort the procedure with No.

When transferring a plan to the penetrologger, all existing data in the penetrologger (the plan

including the possibly existing measuring data) are deleted. This is because the penetrologger can

only save one plan at a time. Before this, a warning will appear on the screen.

The penetrologger is now ready for operation and can carry out measurements. If desired, the plan in the

penetrologger can still be adapted (see 7: “Creating a plan with the aid of the penetrologger”).

7. Finally remove the communication cable and screw the protective cap back on again.

7. Creating a plan with the aid of the penetrologger

The direct creation of a plan in the penetrologger has the advantage that the measuring plan can be created or

processed in the field. This is of help, above all if one does not know exactly in advance how many and which

plots are to be measured or which cone is to be used. As the default parameters can be used in the creating,

the creation on site need not necessarily be time consuming.

The creation or processing of a measuring plan can only be carried out by means of Admin or PC

sotware!

7.1 Operating the penetrologger

The penetrologger has 7 function buttons. The functions of

the individual buttons can be seen in the display; in this

the text appears in a dark block besides the respective

keys. All menu functions are described in Appendix 2.

Key Function

1 Switch-on button

2 Menu selection

3-7 Dependent on the selected menu

1. Press Key 1 to switch on the penetrologger. The start

menu appears.

Logger Information window

12

3-7

Communication

Operation of the penetrologger

15

2. If desired, set the contrast and brightness of the LCD display with the arrow buttons.

A brighter screen adversely aects the battery life.

3. Open the main menu with “MENU” (ater the plan has been created either by means of Admin or PC sotware!)

* PLAN and EDIT, only visible as ADMIN

MEASR, only visible when a plan has been created.

VIEW, only visible ater a measurement.

4. If a dierent language is desired, you can switch into your preferred language.

1. For this, activate EDIT in the menu bar (depending on the current language).

2. With the aid of the arrows, go to SPRACHE [DEUTSCH], German, IDIOMA Español, LANGUE Français or

LANGUAGE [ENGLISH] and confirm your choice with OK.

3. In the next step, select ENGLISH depending on the chosen language. Ater a short period of time, the

English language is activated.

PEN6/CBR

Main menu screen

SELECT ITEM...

7

PLAN

MEASR

VIEW

EDIT

INFO

QUIT

Contrast +

Contrast -

Eijkelkamp

www.eijkelkamp.com

Brightness +

Brightness -

PEN6/CBR

Setting contrast and brightness screen

MENU

↑

↓

↑

↓

ADMIN

16

7.2 Standard parameters and settings

Certain parameters are prescribed before creating a measuring plan. The corresponding values are then

automatically applied during the creation of a plan and this saves a lot of time. In addition, certain settings of

the penetrologger can be defined.

1. Activate the “EDIT” key in the main menu. The “EDIT SYSTEM MENU” appears.

2. In the “EDIT SYSTEM MENU“, enter the standard parameters and the setting data of the penetrologger. Here

it is pointed out that the standard values are set without reference to the Penetroviewer. Thus, it is possible

that there are dierent standard values on the PC and the penetrologger!

However, the individual objects can be reworked in that the selected entry is chosen using the arrow buttons

and confirmed with “OK“. In the next step, use the horizontal arrows to go to the desired position and change

the sign using the vertical arrows. The changes are confirmed with “OK“ and the processing is ended; with

“MENU” the display returns to the previous menu. The following is an overview of the “EDIT SYSTEM MENU”.

Standard parameters

COMPANY [BUNDESWR] User name

DEPTHS CBR CBR-1 (X) starting depth average calculation Ø CBR

CBR 2 and 3 inactive

CBR-4 (Y) End depth average calculation Ø CBR

CBR-5 (End depth penetration)

PEN. SPEED [2] Penetration speed in cm/s The recommended constant speed is 2 cm/s with

a maximum deviation of 0.5 cm/s (according to NEN 5140, 1996)

NR. OF PLOTS [1] No. of plots for the project (1 … 1500).

PENETR./PLOT [1] No. of penetrations per plot (1… 20).

SHUT-OFF TIME [10] Time in minutes ater which the penetrologger shuts itself o. Choice poss.

1… 60 Min. Five beeps are heard immediately prior to the automatic shut-o

function.

GPS [On] Switching the GPS function On and O

MOISTURE [O] Switching the optional soil moisture sensor On and O.

LANGUAGE [English] Languages: Dutch, German, French, Spanish or English

DATE [13-04-11] Current date

TIME [11:48:21] Current time

CALIBRATION The user cannot calibrate the penetrologger himself!

Edit system menu screen

MENU

↑

↓

OK

EDIT SYSTEM MENU

COMPANY BUNDESWR

DEPTHS CBR 10 / 40 CM

PEN. SPEED 2

NR. OF PLOTS: 4

PENETR./PLOT: 3

SHUT OF TIME : 38

GPS: On

MOISTURE: O

LANGUAGE: ENGLISH

DATE 13-04-11

TIME 11.48.21

CALIBRATION

CLEAR MEMORY

17

The user cannot calibrate the penetrologger himself. The calibration occurs in the factory and usually

does not need to be adapted by the user.

Royal Eijkelkamp recommends an annual works calibration control.

CLEAR MEMORY Deleting the penetrologger memory. Ater selection a box will appear with the question

“DO YOU REALLY WANT TO DELETE THE MEMORY?” Confirm this with “YES” and depress

this button for 5 seconds (whereby five beeps can be heard) in order to delete the

memory of the penetrologger. The procedure can be aborted with NO and the display

returns to the “EDIT SYSTEM MENU“.

The memory should only be deleted when it is certain that the current data (the plan and the possible

measuringdata) inthe penetrologgerwillno longerbe used. Theexisting dataarecompletely deleted!

7.3 Creating a measurement plan

1. In the penetrologger only 1 plan can be created and saved at any one time. Therefore, before creating a new

plan a possibly existing plan must be removed from the penetrologger (if desired, first save the existing plan

on a PC). The procedure is as follows:

Delete the memory of the penetrologger (see Paragraph 7.2), or

Create the plan on the PC and transfer this to the penetrologger, whereby the memory of the

penetrologger will first be automatically deleted.

2. In the next step, select “PLAN” in the main menu. This brings up the “PLAN MENU”.

3. Now select a project and a plot with PROJ, PROJ, PLOT or PLOT.

Except for an already defined project, there now exists a new undefined project that can be recognised by the

text “NEW PROJECT” at the bottom of the display. The corresponding project designation consists of a unique

number that contains the following information: Year number – Month – Time - sequential number. A new

project is created on the basis of this undefined “Empty project”.

Plan menu select project screen

MENU

↑ PROJ

↓ PROJ

OK

PLAN MENU

SELECT PROJECT

PROJECT: 11041316

COMPANY: BUNDESWR

PLOT: PLOT-001

CONE CBR: 1.2 cm230°

PEN. SPEED: 2

NR. OF PLOTS: 4

PENETR./PLOT: 3

DEPTHS CBR: 10 - 20 - 30

40 - 50 cm

NEW PROJECT

↑ PLOT

↓ PLOT

18

The desired project is created with “OK”. The “EDIT PROJECT” sub-menu now appears.

4. To edit the project, process the entries with “EDIT“. There now appears the sub-menu with which various

items can be adapted.

The entries in the sub-menu can be changed with the aid of the arrow buttons. The changes are saved with

“OK” or are aborted with ”MENU“ whereby the display returns to the “SELECT ITEM“ menu.

At this point it is pointed out that only the plot designations of the plot selected under point 3 can be

changed.

Plan menu Edit project screen

MENU

↑

↓

PLAN MENU

EDIT PROJECT

PROJECT: 11041316

COMPANY: BUNDESWR

PLOT: PLOT-001

CONE CBR: 1.2 cm230°

PEN. SPEED: 2

NR. OF PLOTS: 4

PENETR./PLOT: 3

DEPTHS CBR: 10 - 20 - 30

40 - 50 cm

NEW PROJECT

SAVE

EDIT

PLAN MENU

PROJECT: 11041316

Plan menu Edit screen

MENU

←

→

↑

↓

OK

19

5. The created project is defined with “SAVE”.

Now the text “PROJECT DEFINED” appears at the bottom of the display.

The project is definitely saved with the definition. Ater this, neither the number of plots nor the

number of penetrations per plot can be changed!

6. With “OK” or “MENU” the display returns to the “SELECT PROJECT” menu. If desired, the remainder of the

plot designations of the defined project can be changed with the working steps 3 and 4.

7. If desired, more projects can be created with the process steps 3-5.

8. Return to the main menu with “MENU“ and end the plan data entry.

7.4 Processing a measuring plan

Once a project has started, the number plots and the number of penetrations per plot can no longer

be changed. It is also not possible to remove an individual project from the plan.

1. Switch on the penetrologger and open the main menu.

2. Now run through the steps 3 and 4 of Paragraph 7.3.

If measurements within the scope of a project have already taken place, then the project can no longer be

changed. However, the aected project can still be selected with “PLAN MENU” but in this case the OK button is

not active. The text “PROJECT ACTIVATED” appears at the bottom of the display and “PLOT ACTIVATED” appears

under the relevant plot.

3. Return to the main menu with “MENU”.

Information

in the case that a project is unusable due to an entry error or a changed situation, then two possibilities present

themselves:

Definition of a new project, whereby the unusable project remains in the plan. However, here it must be

ensured that only valid projects are selected for the measurements.

Deletion of the whole plan in that the memory of the penetrologger is deleted and a new plan is created.

But here one must not forget that all the data saved in the memory of the penetrologger (the plan as well

as all the measuring data) will be deleted! Details on deleting the Logger memory can be found in Paragraph

7.2.

8. Carrying out the measurements

Before the measurement, certain aspects should be checked in the “SYSTEM INFO MENU“ (select “INFO” in the

main menu for this):

GPS satellite information

The current date and time

The battery. The type of battery and the remaining capacity of the battery in % (is shown based on the battery

voltage). A value of 100% corresponds to a full battery.

Service counter: Overall counter.

The serial number of the penetrologger

The sotware version.

The hardware version.

The number of carried out measurements (penetrations) in the memory.

The number of remaining measurements (“Reserved”).

20

Background lighting and contrast settings menu is selected with the accompanying button.

Switch loudspeaker On or O with the relevant button.

1. Install the associated (three-part) probe rod and screw the cone on tightly. Use suitable tools for tightening.

Then screw the probe rod with the coupling into the penetrologger and tighten the screw.

The fastening should be carried out by light hand-tightening (in order to avoid damaging the force

sensor).

The cone wears out with use. For this reason, its dimensions must be checked before use with the Conecheck

key. If the cone can be pushed through the Conecheck key (see 2 “Description”), then the cone is unsuitable

for reliable measurements. Also asymmetrically worn sounding points are impermissible.

3. Optional: Connect the soil moisture sensor to the communication port of the penetrologger.

The instrument is ready for use ater completed data entry (Plan/project/plot) and installation of the

penetrologger.

4. Switch on the penetrologger.

The GPS determination takes longer when the penetrologger is used in a particular area for the first time.

The time for subsequent measurements is shorter (< 8 seconds),

5. Select “MEASR” in the main menu.

This brings up the “MEASUREMENT MENU“in which the desired project is selected. Also the project settings

entered appear here.

Now select the desired project and confirm your choice with “OK“.

Measurement menu window

MENU

↑ PROJ

↓ PROJ

OK

MEASUREMENT MENU

SELECT PROJECT

PROJECT: 11041316

COMPANY: BUNDESWR

PLOT: PLOT-001

CONE CBR: 1.2 cm230°

PEN. SPEED: 2

NR. OF PLOTS: 4

PENETR./PLOT: 3

DEPTHS CBR: 10 - 20 - 30

40 - 50 cm

PROJECT DEFINED

Table of contents

Other EIJKELKAMP Data Logger manuals