Ekolos EVL30SW Installation guide

R A N G E H O O D

SERIES EVL30SW

ESL30SW.BW

USE, CARE, AND

INSTALLATION MANUAL

Read all lnstructions before installing and operating the appliance

XP02293(1)

EVL36SW

ESL36SW.BW

EFL30GW

EFL36GW

ESQ30SW

ESQ36SW

1

SAFETY NOTICE .......................................... 2

INSTALLATION

Mounting Height & Clearance ........................ 3

Ducting Options ............................................. 4

Hood Specifications ...................................... 5-7

Mounting the Range Hood ............................. 8

Ductless Recirculating................................ 9

FEATURES & CONTROLS

Touch Controls .............................................. 10

MAINTENANCE

Cleaning and Metal Mesh Filter Care ............ 11

Lights ..............................................................12

13

TROUBLESHOOTING...................................

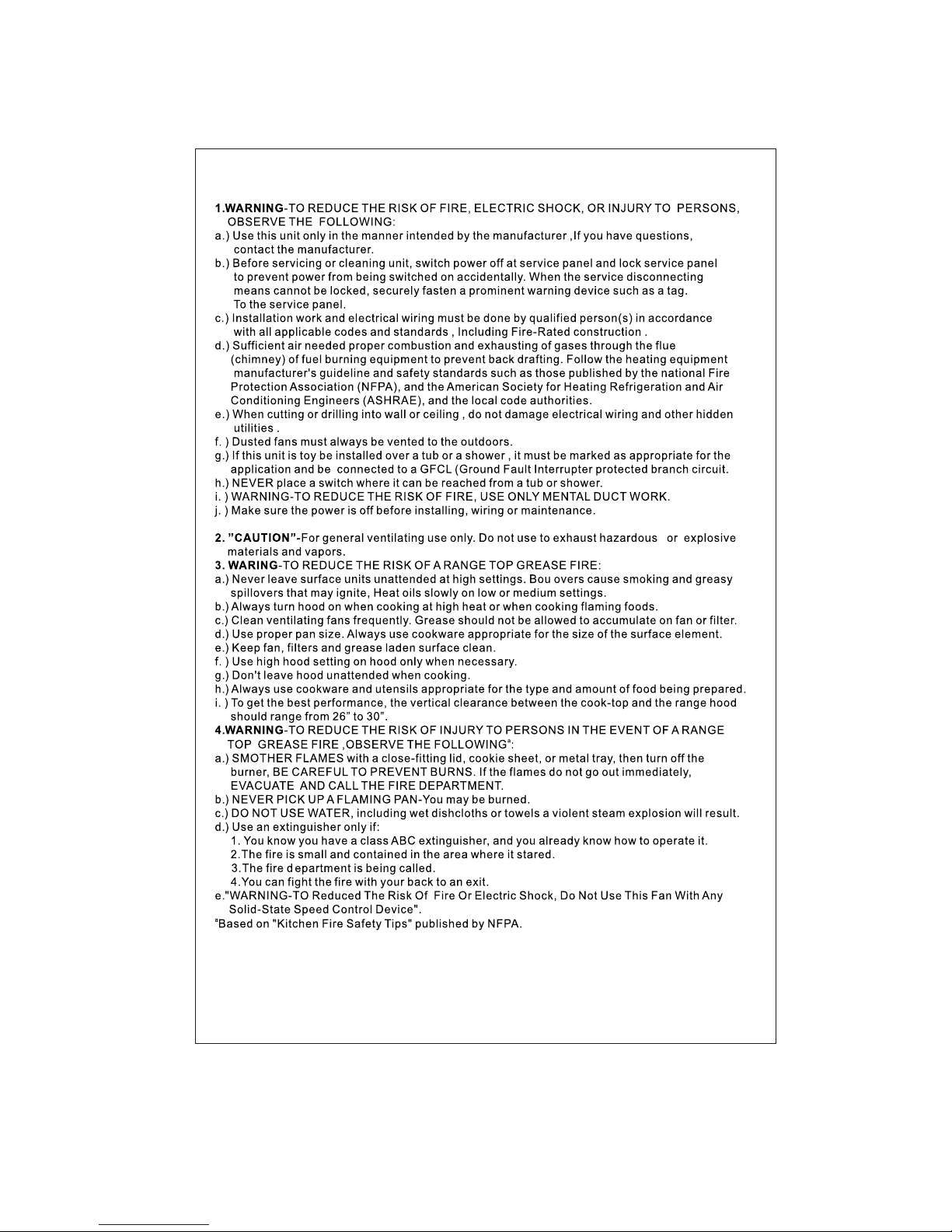

IMPORTANT SAFETY NOTICEIMPORTANT SAFETY NOTICE

2

3

InstallationInstallation

Minimum mount height between range top to hood

bottom should be no less than 28”

Maximum mount height should be no higher than

36”.

It is important to install the hood at the proper

mounting height. Hoods mounted too low could

result in heat damage and fi re hazard; while hoods

mounted too high will be hard to reach and will

lose its performance and effi ciency.

If available, also refer range manufacturer’s height

clearance requirements and recommended hood

mounting height above range. Always check your

local codes for any differences.

DUCTING

A minimum of 6” round or 3-1/4”x10” rectangular

duct must be used to maintain maximum air flow

efficiency.

Always use rigid type metal ducts only. Flexible

ducts could restrict air fl ow by up to 50%.

ALWAYS, when possible, reduce the number or

transitions and turns. If long duct run is required,

increase duct size from 6” to 7” or 8”.

If turns or transitions are required; install as far

away from opening and as far apart, between 2,

as possible.

- Mounting Height & Clearance

Minimum Mounting Height (Ducted)

8’. Hood mounted 28” above cooking surface;

64” from floor.

Minimum Mounting Height (Recirculating)

8’4”. Hood mounted 28” above cooking surface;

64” from floor.

Maxmimum Mounting Height

10’3”. Hood mounted 36” above cooking surface;

72” from floor.

Duct cover extension kit available for ceiling

heights up to 14 feet.

4

InstallationInstallation

WARNING FIRE HAZARD

NEVER exhaust air or terminate duct work into spaces between walls, crawl spaces, ceiling, attics

or garages.

All exhaust must be ducted to the outsid, unless using the recirculating option.

Use single wall rigid Metal ductwork only.

Fasten all connections with sheet metal screws and tape all joints with certified Silver Tape or Duct Tape.

Some Ducting Options

- Ducting Options

5

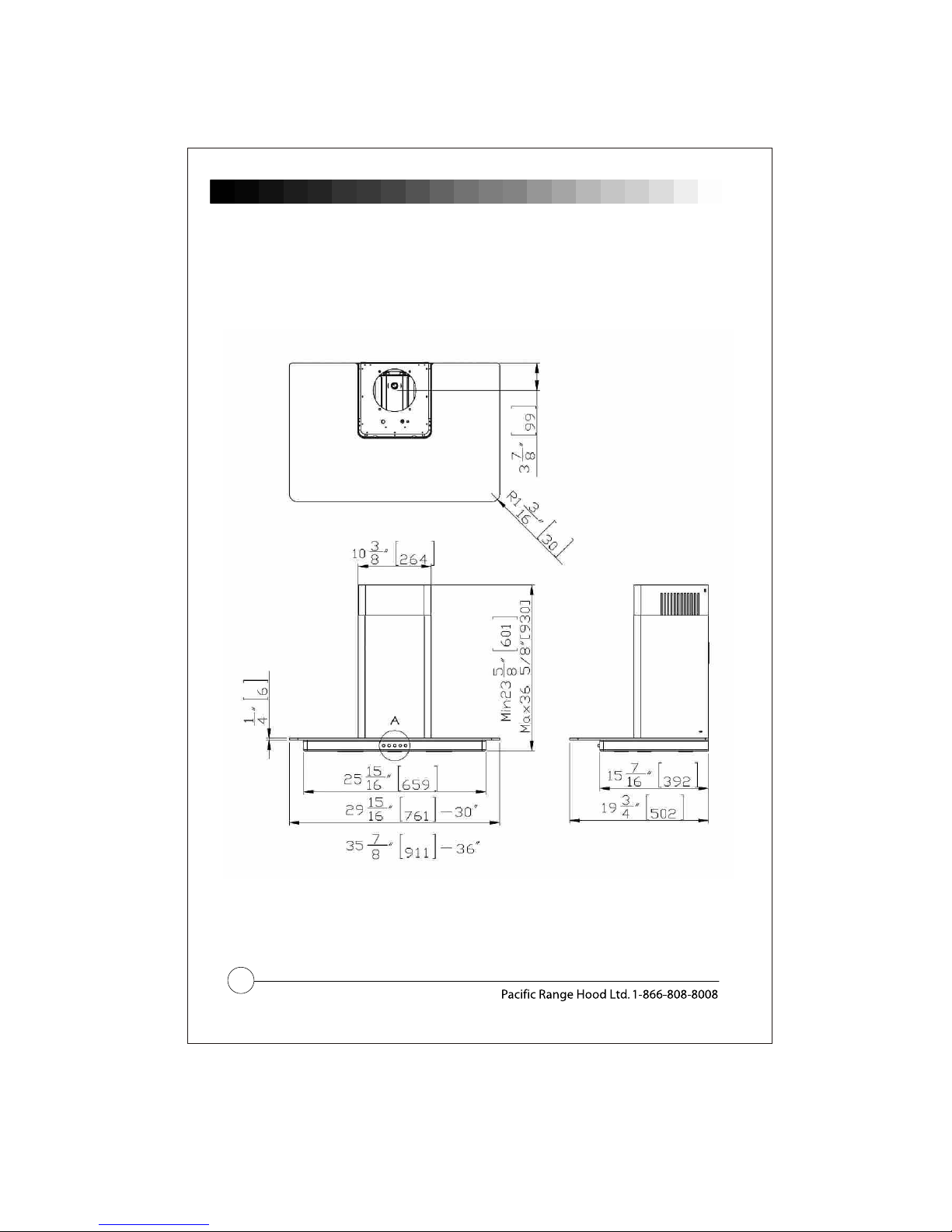

InstallationInstallation -Hood Specifications

ESQ-30/36 SW

ESL-30/36-SW.BW

6

InstallationInstallation -Hood Specifications

EFL-30/36GW

7

InstallationInstallation -Hood Specifications

EVL-30.36SW

InstallationInstallation

8

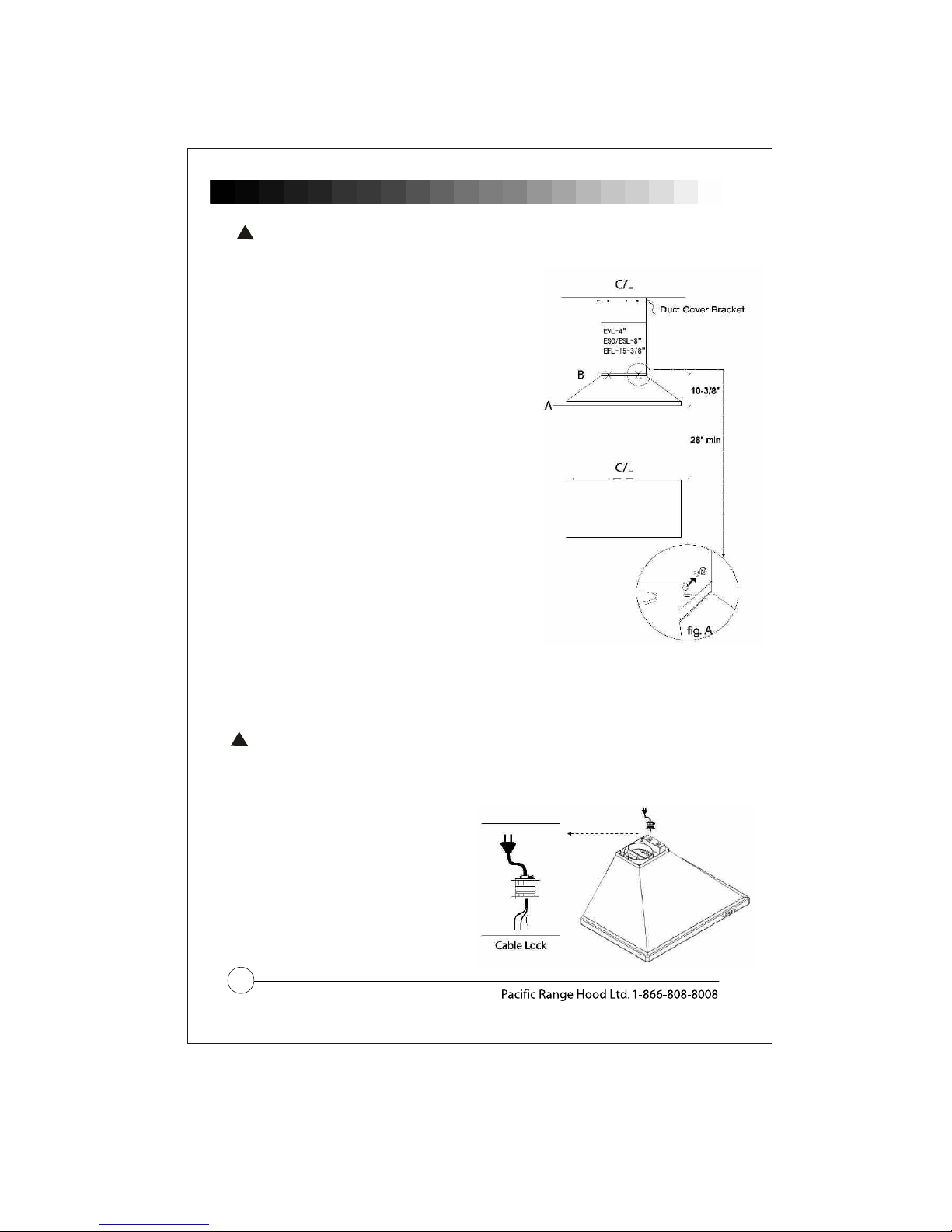

- Mounting the Range Hood

CAUTION: At least two installers are

required due to the weight and size of the

hood.

1. Measure from range top to hood bottom and mark line A.

(28”minimum from range top)

2. Plum and mark center line.

3. Mark mounting height line B. (10-3/8”from line A)

4. EVL series - Mark mounting spread from C/L on line B. (4”)

ESQ/ESL series - Mark mounting height line B. (8”)

EFL series -Mark mounting height line B. ( 15-3/8”)

5. Fasten (2) M4x1-1/4” screws into studs on line B. Do not

fasten screws all the way. note: wood blocking may

need to be added behind the drywall if no studs are

present. Wall anchors may also be used, check local

codes before using wall anchors.

6. Hang hood onto screws and hand tighten. (Fig.A) Use

the last M4x1-1/4”screw to further secure the hood to

the wall from inside the hood.

7.Center and attach duct cover bracket to wall below

ceiling or soffit using (2) M4x1” screws.

8.Install electrical.

9.*Install duct work and duct tape.

10.Power up hood and check for leaks around duct tape.

11.Place telescopic duct covers onto hood and extend

inner (top) duct cover upwards and secure to duct cover

bracket using (2) M4x3/8” screws.

*if using hood in recirculating mode you must secure air

diverter plate onto wall before installing duct work and

duct covers. Turn to page 9 for more details.

!

!

WARNING: Electrical wiring must be done by a qualified person(s) in

accordance with all applicable codes and standards. This range hood must be

properly grounded. Turn off electrical power at service entrance before wiring.

Cable Lock

A cable locking connector (not supplied) might

be required by local codes. Check with local

requirements and codes, purchase and install

appropriate connector if necessary.

9

InstallationInstallation

Ductless recirculating is intended for applications where an exhaust duct work is not possible to be

installed.When converted, the hood functions as a recirculating hood rather than an exhaust hood. Fumes

and exhaust from cooking are drawn and fi ltered by a set of optional charcoal fi lters. The air is then

purified and recirculated back within the home.

We recommend to ALWAYS exhaust air outside of the home by employing existing or installing new duct

work, if possible. The hood is most effective and effi cient as an exhaust hood. Only when the exhaust

option is not possible should you recourse to converting the hood into a recirculating hood.

When converted to be a recirculating hood, a set of charcoal fi lters are required on top of its standard

Metal Filter set. The standard Metal Filters are intended to

capture residue from cooking and the optional charcoal fi lters help to purify fumes exhausted from

cooking for recirculation.

- Ductless Recirculating

FEATURES & CONTROLSFEATURES & CONTROLS

10

B.

C.Speed

A.

" " is low speed.

" " is medium speed.

" " is high speed.

A.Power C Speed B Lamp

- Touch Controls

11

SURFACE MAINTENANCE:

Clean periodically with hot soapy water and clean cotton cloth. Do not use corrosive or abrasive detergent ,

or steel wool/scouring pads which will scratch and damage surface.

For heavier soil use liquid degreaser.

After cleaning it is recommended that you use non-abrasive stainless steel polish/cleaners, to polish and

buff out the stainless luster and grain. Always scrub lightly, with clean cotton cloth, and with the grain.

Do not use any product containing chlorine bleach. Do not use “orange” cleaners.

Metal Mesh Filters

The metal mesh filters installed by the factory are intended to fi lter out residue and grease from cooking.

They need not be replaced on a regular basis but are required to be kept clean.

Filters should be cleaned after every 30 hours of use or once a month.

Remove and clean by hand or in dishwasher on low heat. Spray degreasing detergent and leave to soak if

heavily soiled.

Dry fi lters and re-install before using hood.

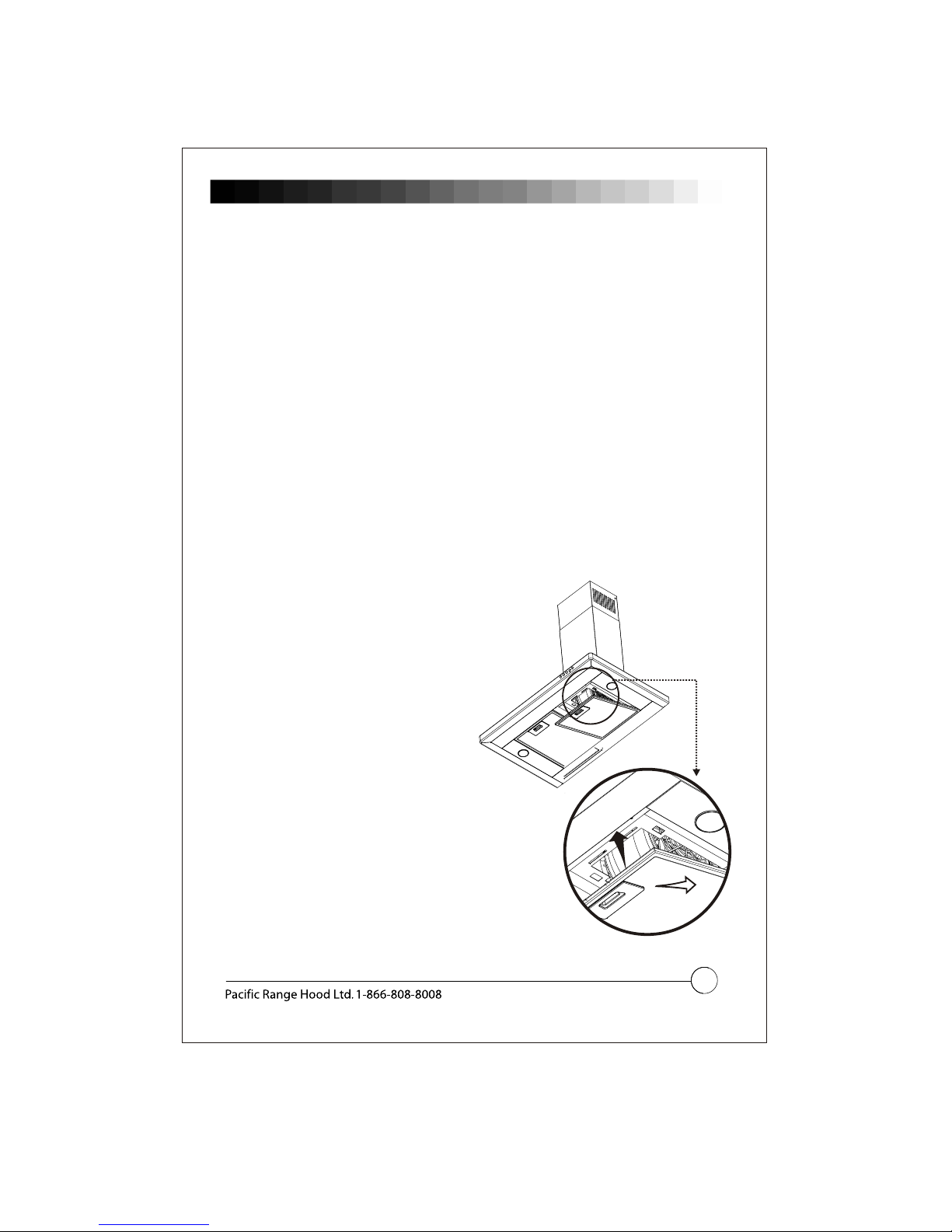

Removing Metal Mesh Filters

1. Push in on spring loaded handle

2. Pull down on fi lter hande to remove filter

Metal Mesh Filter Dimensions:

12 5/8in. x 10 3/16in.

321mm x 259mm

Maintenance-Maintenance- Cleaning and metal mesh filter care

12

Lights

Maintenance-Maintenance-

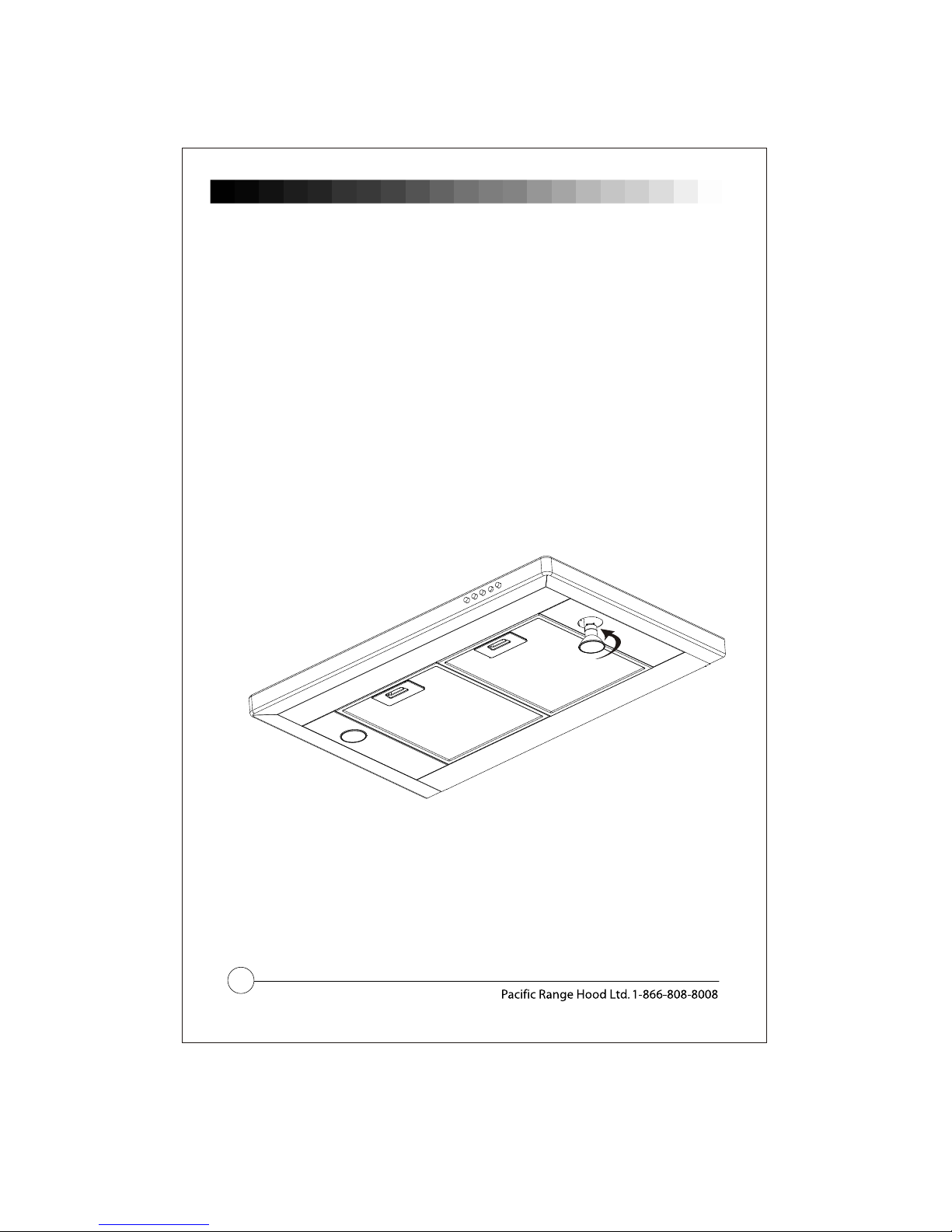

REPLACING LIGHT BULBS

CAUTION: Light bulb becomes extremely hot when turned on.

DO NOT touch bulb until switched off and cooled. Touching hot bulbs could cause serious burns.

Make sure all power is turned off and bulbs are not hot.

Remove by turning bulb counter clockwise. Note: Bulb does not unscrew; it turns 60 degrees,

stops and falls out.

If bulbs are diffi cult to turn due to prolonged use, fi rmly attach a glass suction cup

approximately the diameter of the bulb or use a rubber/latex glove and turn counter clockwise.

Replacement bulbs are available at specialty lighting stores. Purchase type

Mr16 (GU-10) 35W halogen.

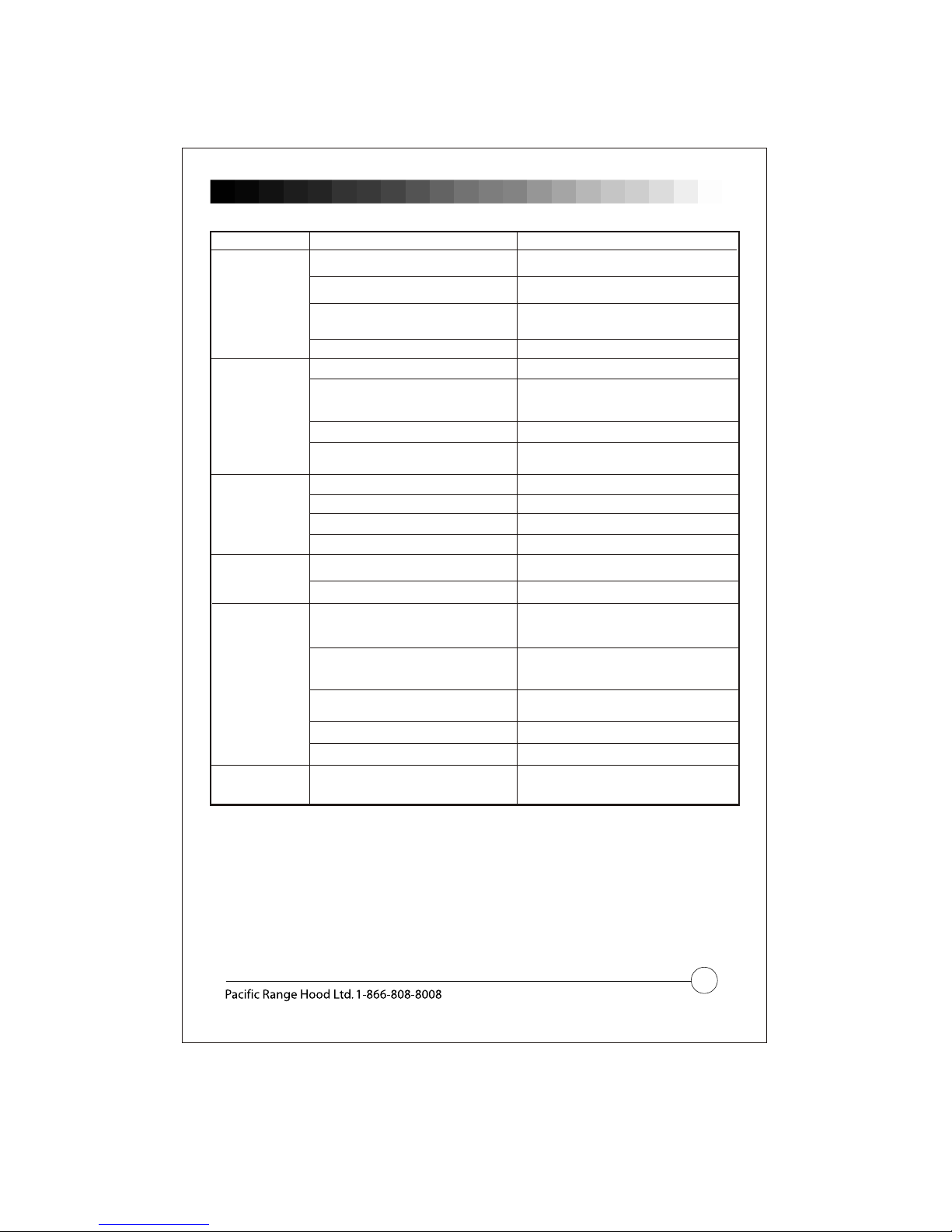

Issue Cause What to do

After installation,

the unit doesn’t

work.

2. The power line and the cable locking connector

is not connecting properly.

2. Check the power connection with the unit is

connected properly.

3. The switch board and control board wirings

are disconnected.

3. Make sure the wirings between the switch

board and control board are connected

properly.

4. The switch board or control board is defective. 4. Change the switch board or control board.

Light works,

but motor is

not turning.

1. The motor is defective, possible seized. 1. Change the motor.

2. The thermally protected system detects if

the motor is too hot to operate and shuts

the motor down.

2. The motor will function properly after the

thermally protected system cool down.

3. Damaged capacitor. 3. Change the capacitor.

4. The switch board or control board is

defective.

The unit is

vibrating.

1. The motor is not secure in place. 1. Tighten the motor in place.

2. Damaged blower wheel. 2. Replace the blower.

3. The hood is not secured in place . 3. Check the installation of the hood.

4. The switch board or control board is defective.

The motor is

working, but the

lights are not.

1. Defective halogen bulb. 1. Change the halogen bulb.

2. The light bulb is loose. 2. Tighten the light bulb.

The hood is

not venting out

properly.

1. The hood might be hanging to high from the

cook top.

1. Adjust the distance between the cook top and

the bottom of the hood within 26” and 36”

range.

2. The wind from the opened windows or

opened doors in the surrounding area

are affecting the ventilation of the hood.

2. Close all the windows and doors to eliminate

the outside wind ow.

3. Blockage in the duct opening or duct work. 3. Remove all the blocking from the duct work

or duct opening.

4. The direction of duct opening is against the wind.

5. Using the wrong size of ducting. 5. Change the ducting to correct size.

Metal lter is

vibrating.

TroubleshootingTroubleshooting

TROUBLESHOOTING PROCEDURES FOR EVL

1. The power source is not turned ON. 1. Make sure the circuit breaker and the unit’s

power is ON.

4. Adjust the duct opening direction.

1. Metal lter is loose. 1. Change the metal filter.

4. Change defective part.

4. Change defective part.

13

EVL30SW

ESL30SW

ESL30BW

EVL36SW

ESL36SW

ESL36BW

EFL30GW

EFL36GW

ESQ30SW

ESQ36SW

RANGE HOOD

PACIFIC RANGE HOOD LTD.

:

TO L L F R E E

1 - 8 6 6 - 8 0 8 - 8 0 0 8

Printed in Conada

This manual suits for next models

7

Popular Ventilation Hood manuals by other brands

AIRFORCE

AIRFORCE F179 Instruction on mounting and use

Siemens

Siemens LC21BA582 instruction manual

Electrolux

Electrolux EFTD26K user manual

Sirius Satellite Radio

Sirius Satellite Radio SIU3 installation instructions

JUNO

JUNO JDWF606E5 user manual

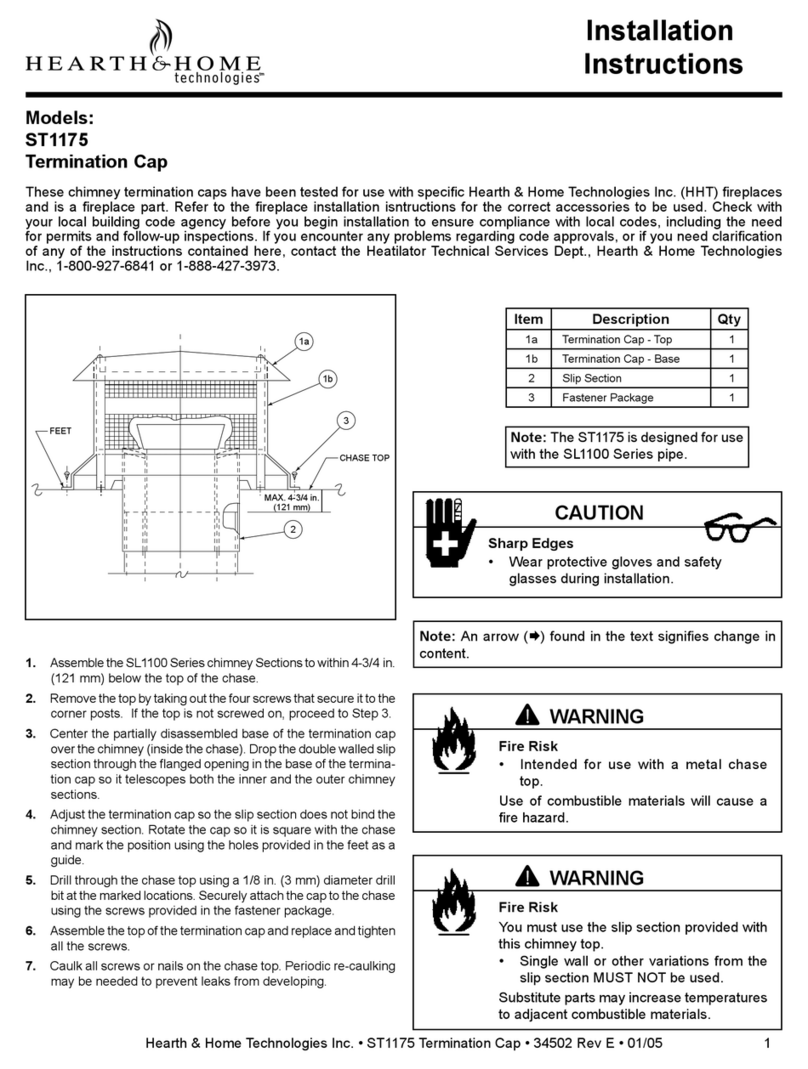

Hearth and Home Technologies

Hearth and Home Technologies Termination Cap ST1175 installation instructions