EL.MO. Spa NG-TRX LUPUS2K User manual

TECHNICAL MANUAL

LUPUS2K - VOLANS2K

AND BROWN VERSIONS

Radio transmitters for wireless NG-TRX

intrusion detection systems

090001113

IT08020000001624

LUPUS2K - VOLANS2K - TECHNICAL MANUAL - 090001113

elmospa.com

2

This product needs batteries for correct functioning. Exhausted batteries have to be delivered to dumping grounds

authorized for battery collection. The materials used for this product are very harmful and polluting if dispersed in the

environment.

EU DECLARATION OF CONFORMITY

DISPOSAL INSTRUCTIONS - INFORMATION FOR THE USER

FOREWORD

FOR THE INSTALLER:

Comply strictly with current standards governing the installation of electrical systems and security systems, and with the manufacturer’s

directions given in the manuals supplied with the products.

Provide the user with full information on using the system installed and on its limitations, pointing out that there are different levels of security

performance that will need to suit the user’s requirements within the constraints of the specific applicable standards. See that the user looks

through the warnings given herein.

FOR THE USER:

Check the system’s operation thoroughly at regular intervals, making sure the equipment can be armed and disarmed properly.

Make sure the system receives proper routine maintenance, employing the services of specialist personnel who meet the requirements

prescribed by current regulations.

Ask your installer to check that the system suits changing operating conditions (e.g. changes in the extent of the areas to be protected, change

in access methods, etc...).

-------------------------------

This device has been designed, built and tested with the utmost care and attention, adopting test and inspection procedures in accordance

with current legislation. Full compliance of the working specifications is only achieved in the event the device is used solely for its intended

purpose, namely:

The device is not intended for any use other than the above and hence its correct functioning in such cases cannot be assured.

Consequently, any use of the manual in your possession for any purpose other than those for which it was compiled - namely for the purpose

of explaining the product’s technical features and operating procedures - is strictly prohibited.

Production processes are closely monitored in order to prevent faults and malfunctions. However, the componentry adopted is subject to an

extremely modest percentage of faults, which is nonetheless the case with any electronic or mechanical product.

Given the intended use of this item (protection of property and people), we invite you to adapt the level of protection offered by the system to

suit the actual situation of risk (allowing for the possibility of impaired system operation due to faults or other problems), while reminding you

that there are specific standards for the design and production of systems intended for this kind of application.

We hereby advise you (the system’s operator) to see that the system receives regular routine maintenance, at least in accordance with

the provisions of current legislation, and also check on as regular a basis as the risk involved requires that the system in question is

operating properly, with particular reference to the control unit, sensors, sounders, dialler(s) and any other device connected. You must

let the installer know how well the system seems to be operating, based on the results of periodic checks, without delay.

Work involved in the design, installation and maintenance of systems incorporating this product should be performed only by personnel

with suitable skills and knowledge required to work safely so as to prevent any accidents. It is vital that systems be installed in accordance

with current legislation. The internal parts of certain equipment are connected to the mains and therefore there is a risk of electrocution

when maintenance work is performed inside without first disconnecting the primary and emergency power supplies. Certain products include

batteries, rechargeable or otherwise, as an emergency backup power supply. If connected incorrectly, they may cause damage to the product

or property, and may endanger the operator (explosion and fire).

In accordance with Directive 2012/19/EU on waste electrical and electronic equipment (WEEE), please be advised that

the EEE was placed on the market after 13 August 2005 and must be disposed of separately from normal household

waste.

IT08020000001624

Hereby, EL.MO. S.p.A. declares that the radio equipment LUPUS2K - VOLANS2K is in compliance with Directive 2014/53/

EU. The full text of the EU declaration of conformity is available at the following Internet address: elmospa.com – registration

is quick and easy.

Radio transmitters for wireless NG-TRX intrusion detection systems

090001113 - TECHNICAL MANUAL - LUPUS2K - VOLANS2K

elmospa.com

3

1. GENERALS

LUPUS2K and VOLANS2K are compact transmitters used for the control of fixtures or for perimetral protections. These

transmitters can be integrated in wireless systems managed by VIDOMO2K and VICOMPACT2K control units (belonging to

the NG-TRX system) or by other expressly compatible control unit models.

Their general features can be summarized as follows:

• LUPUS2K can transmit the state variations of magnetic contacts and of the roll-up shutter sensor wired to its terminals.

LUPUS2K is identified by the control unit as a multi-channel device; it occupies up to 3 zones for the transmission

of the anomaly/alarm states of the REED magnetic contact (located on housing side), the magnetic contact wired to

the terminal board and the roll-up shutter detector connected to the proper terminal. For the latter, you can properly

configure the number of pulses in a time slot. The detector is fully configurable via software.

• VOLANS2K can transmit the state variations of magnetic contacts and of the roll-up shutter sensor connected via

wires to its terminals. VOLANS2K is identified by the control unit as a multi-channel device; it occupies up to 4

zones for the transmission of the anomaly/alarm states of the REED magnetic contact (located on housing side), the

magnetic contact wired to the terminal board, the roll-up shutter detector connected to its related terminal and the

built-in inertial piezo sensor. You can properly configure the number of pulses in a time slot and the integration for the

roll-up shutter detector and the piezo sensor. The detector is fully configurable via software; only the sensitivity is

adjustable on the device itself.

The plastic housing features a design in line with current style trends.

Upon request, the “M” brown version is also available.

Note: the operative range for these devices is evaluated in open field with no obstacles, nevertheless the actual range

might be reduced in case the device is installed in indoor locations with peculiar architectural features. For further details,

consult the features table.

The autonomy is in the order of years of functioning, according to the features of each device.

LUPUS2K and VOLANS2K are IMQ - Security Systems certified.

2. FEATURES

Model LUPUS2K VOLANS2K

Protection class IP3X

IMQ certified EN50131-2-6: grade 2,

EN50131-5-3 (1)

Environmental class 2

Power supply voltage 3.6 V supplied by 1/2 AA 3.6 V lithium battery mod. ER14250 (supplied as standard eq.)

Low battery threshold 2.5 V with recovery to 2.9 V.

Minimum operating

voltage

2 V for the transmitter;

2.7 V for the LED indicator.

Power consumption @

3.6 V

8 µA idle,

23 mA max.

10 µA idle,

23 mA max.

TX frequency

3 channels (configurable via browser): 868.120 MHz, 868.820 MHz, 869.525 MHz for LPD devices.

Maximum transmitted

power

25 mW

Connection range

nominal/maximum

800 / 1900 m in open field; the range is subject to limitations depending on environmental

conditions. See note.

Note: the ranges refer to 99% reception of the transmitted packets, with the devices

in open field at an height of 1,5 m from the ground, respectively without and with the

orientation of the antenna in the best direction.

The activation of the “tx boost” option, if available, increases the effective range

between 10 and 30% but can significantly affect the battery life.

LUPUS2K - VOLANS2K - TECHNICAL MANUAL - 090001113

elmospa.com

4

Model LUPUS2K VOLANS2K

Average autonomy 5 years. 4 years.

Note: for the calculation, 20 total transmissions per day and a supervision transmission

every 20 min were considered.

Zones Managed as channels.

Tamper zone with NC terminals.

CH1: On-board magnetic contact.

CH2: NC zone for external magnetic contact.

CH3: NC zone for roll-up shutter detector.

Channels 2 and 3 can be configured via

software application (see “10. ELECTRICAL

CONNECTIONS”).

Managed as channels.

Tamper zone with NC terminals.

CH1: On-board magnetic contact.

CH2: NC zone for external magnetic contact.

CH3: NC zone for roll-up shutter detector.

CH4: built-in piezo sensor.

Channels 2, 3 and 4 can be configured via

software application, (see “10. ELECTRICAL

CONNECTIONS”).

Special operating

features and controls

Piezo sensor included in the printed circuit

board, with impact sensitivity control and

LED indicator for detected pulses.

The sensitivity can be adjusted using the on-

board trimmer; the integration can be set via

software application.

Wiring length with 2 ×

0.22 mm2 cable

Roll-up shutter zone: 1 or 8 m, configurable via software application;

magnetic contact zone: 20 m max.

Selections On-board REED magnetic contact enabling (on one side only).

LED indications Blue front LED. Yellow front LED, used also for piezo sensor

pulses visualization.

LED exclusion Via software application.

Sound signalling Built-in buzzer. It can be activated for alarm also in Walk test mode.

Supervision TX From 5 to 240 min (default) step between two consecutive supervision transmissions. It

can be modified via software application.

TX encoding The transmitter is provided with an identification code randomly chosen in test phase

among 2 milliard combinations (231).

Transmissions for Supervision (periodic, with step configurable via software application);

tamper events for housing opening;

low battery state;

alarm/reset for zones with magnetic contact;

alarm for roll-up shutter or piezo detector zones.

Operating temperature -10 / +55 °C guaranteed by manufacturer - 93 % Rh.

Dimensions Transmitter: W 150 × H 33 × D 39 mm;

magnet: W 47 × H 18.5 × D 15 mm.

Weight 75 g (battery and magnet). 79 g (battery and magnet).

Parts supplied 4 self tapping screw 2.9 × 13, 1/2 AA 3.6 V lithium battery mod. ER14250 to be installed

in the transmitter, magnet, technical manual.

(1) grade 1 if supervision time is set as lower than 60 min; grade 2 if supervision time is set as lower than 20 min

LUPUS2K and VOLANS2K are accessories for VIDOMO2K and VICOMPACT2K control units belonging to the Villeggio NG-TRX

system, and for other expressly compatible devices.

These transmitters are suitable for indoor installation only. Do not install them in locations where they may be

affected by condensation phenomena, for example directly on balconies.

090001113 - TECHNICAL MANUAL - LUPUS2K - VOLANS2K

elmospa.com

5

3. MECHANICAL FEATURES

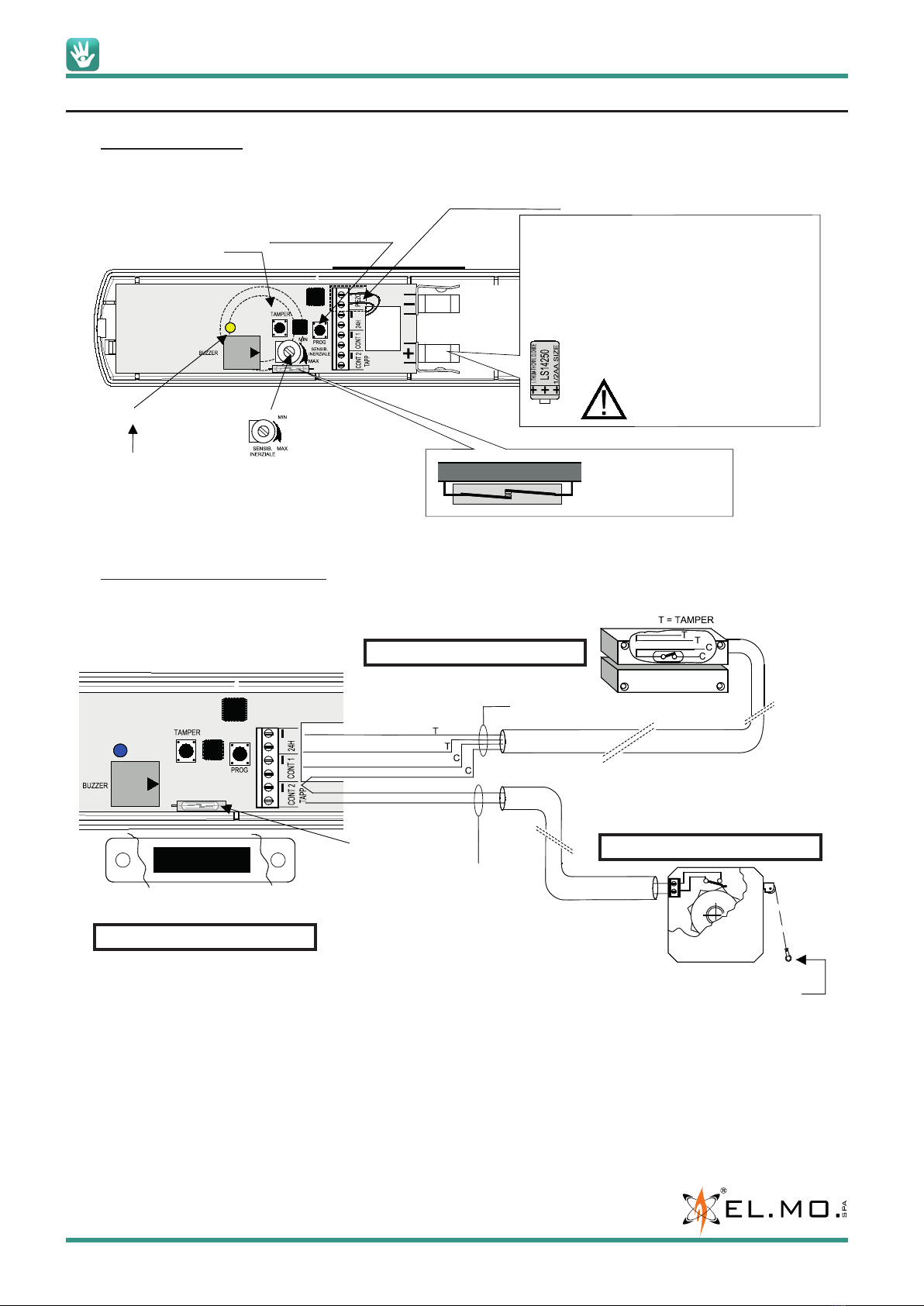

View of the transmitter plastic housing and of the external magnet.

4. HOW TO DISTINGUISH THE DEVICES

The following picture shows the differences between the two transmitters.

DIMENSIONS IN mm

COUNTERSUNK

HOLES

COUNTERSUNK

HOLES

HOLE FOR

CABLE FEEDING

BLUE LED FOR

OPERATION VISUALIZATION

AND TRANSMISSION

PIEZO SENSOR (AND

RELATIVE TERMINAL)

NOT MOUNTED

IDENTIFYING LABEL

STUCK ON THE

HOUSING SIDE

IDENTIFYING LABEL

STUCK ON THE

HOUSING SIDE

YELLOW LED FOR VISUALIZATION

OF THE DETECTED PULSES

AND TRANSMISSION

TRIMMER FOR ADJUSTING

IMPACT SENSITIVITY

THE BATTERY IS SUPPLIED

AS STANDARD EQUIPMENT,

INCLUDED IN THE PACKAGE.

AFTER INSTALLING THE DEVICE,

INSERT THE BATTERY BETWEEN

THE INDICATED CLIP TABS,

PAYING ATTENTION TO

RESPECT THE POLARITY.

DO NOT TOUCH THE BATTERY

POLES WITH THE FINGERS

DURING THIS PHASE.

LUPUS2K - VOLANS2K - TECHNICAL MANUAL - 090001113

elmospa.com

6

5. HOUSING OPENING AND CLOSING

Perform the following basic operations in order to open and close the transmitter housing.

Opening.

Closing.

6. FIRST POWER-ON OR BATTERY REPLACEMENT

Particular care is required during first powering. The operations to be performed are listed in the next steps:

1. Insert the 3.6 V battery (supplied as standard equipment) checking the correct polarity.

2. Press and release the Tamper button 3-4 times.

3. Reset any memory of low battery on the control unit or on the compatible receiving device.

WARNING: in case you use a new battery or a battery that has not been used for a long time, a wrong indication of

low battery may occur at first activations. Such issue is related to the chemical features of Lithium Thionyl Chloride

batteries and it can be solved implementing the above operations.

In case of usage in low temperature locations, we suggest that you keep the battery at room temperature before

insertion.

LEAN THE COVER HERE

IN ORDER TO ACCURATELY HOOK

THE TWO CLIPS CLOSE TO THE BATTERY

UNDERLYING SURFACE FOR THE PIEZO SENSOR

ACCURATELY

HOOK THE

FRONT CLIP

MAKE SURE THE TAMPER SPRING

PROPERLY FITS IN THE BLOCKING

POSITION ON THE COVER

MAKE SURE THE LED PROPERLY

FITS IN THE HOLE ON THE COVER

090001113 - TECHNICAL MANUAL - LUPUS2K - VOLANS2K

elmospa.com

7

7. INSTALLATION

The installer shall verify that no electrostatic charges are present upon housing

opening; internal electronic boards and accessory components may be damaged

by such charges.

The same care shall be used during installation, updates and maintenance

procedures.

The detector installation must comply with certain rules in order to avoid performance drops due to positioning errors.

Indeed, it is very important to define with the utmost care the operating area of the receiving system in which the detector is

installed, the actual coverage of the sensors and the correct installation, especially in relation to the nature of the materials

used in the building construction.

The following pictures show correct and wrong installation positions, objects that may attenuate RF signals and attenuation

in some building materials.

Installing situations:

Radio signal attenuation in some typical building materials:

WIRELESS CONTROL UNIT INSTALLED

IN DECENTRALIZED POSITION.

THE SENSORS TRANSMITTERS

POSITIONED AT THE OPPOSITE

SIDE OF THE HOUSE MAY BE TOO

FAR. THE RADIO SIGNAL MAY BE WEAK

BECAUSE OF ARCHITECTURAL

OBSTACLES.

WIRELESS CONTROL UNIT INSTALLED

IN CENTRAL POSITION RESPECT TO

THE SPACE TO SUPERVISE.

THIS POSITION ALLOWS TO

REDUCETHE DISTANCE

OF PERIPHERAL DEVICES.

DO NOT POSITION THE

WIRELESS CONTROL UNIT

BELOW GROUND LEVEL.

THE RECEIVER AND THE

TRANSMITTER SENSITIVITY

WILL BE CONSIDERABLY REDUCED.

POSITION THE

WIRELESS CONTROL UNIT

HIGHER THAN GROUND LEVEL.

THE RECEIVER AND THE

TRANSMITTER SENSITIVITY

WILL TEND TOWARDS THE MAXIMUM.

LUPUS2K - VOLANS2K - TECHNICAL MANUAL - 090001113

elmospa.com

8

Objects that can modify and/or reduce the range (example with a Villeggio NG-TRX control unit):

The device is not suitable for installation on doors/windows that are opened very often (more than 100 activations each

day), since this may cause a great amount of radio transmissions and the premature battery fail.

8. COVERAGE AND SENSITIVITY

Before installing the VOLANS2K sensor, carefully consider the

maximum sensitivity that can be obtained based on the surface to be

protected with its integrated piezo sensor.

For this purpose it is useful to refer to the following table:

Surface material Radius

Brick wall 1 m

Steel 3 m

Wood 3 m

Concrete 30 cm

Plywood 3 m

Glass * 3 m

* The glass test was conducted after sticking the sensor with very

adhesive double-sided tape. When installed on glass surfaces, the

VOLANS2K transmitter is suitable for detecting impact but not for

cuts and perforations.

METAL GRIDS AND

REINFORCED

CONCRETE WALLS

METAL DOORS

MIRRORS

VIDOMO2K OR VICOMPACT2K

CONTROL UNIT

IR DETECTOR

MOD.

SCORPIO2K

THE CONTROL UNIT CAN ALSO MANAGE

ACCESSORY DEVICES BELONGING TO

STANDARD VILLEGGIO AND HELIOS SERIES

SELF-POWERED

WIRELESS SIREN WITH

LITHIUM BATTERY PACK

MOD. GAIA2K

1

2

BIDIRECTIONAL

REMOTE CONTROL

MOD. ATLANTE2K

S2

S3

S1

S4

OUTDOOR

TRANSMITTER

WITH BUILT-IN

MAGNETIC CONTACT

MOD. VIRGO2K

DT DETECTOR

MOD. CONDOR2K

TRANSMITTER WITH

BUILT-IN MAGNETIC

CONTACT, PIEZO SENSOR

AND INPUT FOR EXTERNAL

ROLL-UP SHUTTER SENSOR

MOD. VOLANSC2K

TRANSMITTER WITH

BUILT-IN MAGNETIC

CONTACT AND INPUT

FOR EXTERNAL ROLL-UP

SHUTTER SENSOR

MOD. LUPUSC2K

TRANSMITTER WITH

BUILT-IN MAGNETIC

CONTACT AND INPUTS

FOR EXTERNAL MAGNETIC

CONTACT AND ROLL-UP

SHUTTER SENSORS

MOD. LUPUS2K

TRANSMITTER WITH

BUILT-IN MAGNETIC

CONTACT, PIEZO SENSOR

AND INPUTS FOR EXTERNAL

MAGNETIC CONTACT AND

ROLL-UP SHUTTER SENSORS

MOD. VOLANS2K

Installation of VOLANS2K transmitter on

a glass panel:

3 m radius

090001113 - TECHNICAL MANUAL - LUPUS2K - VOLANS2K

elmospa.com

9

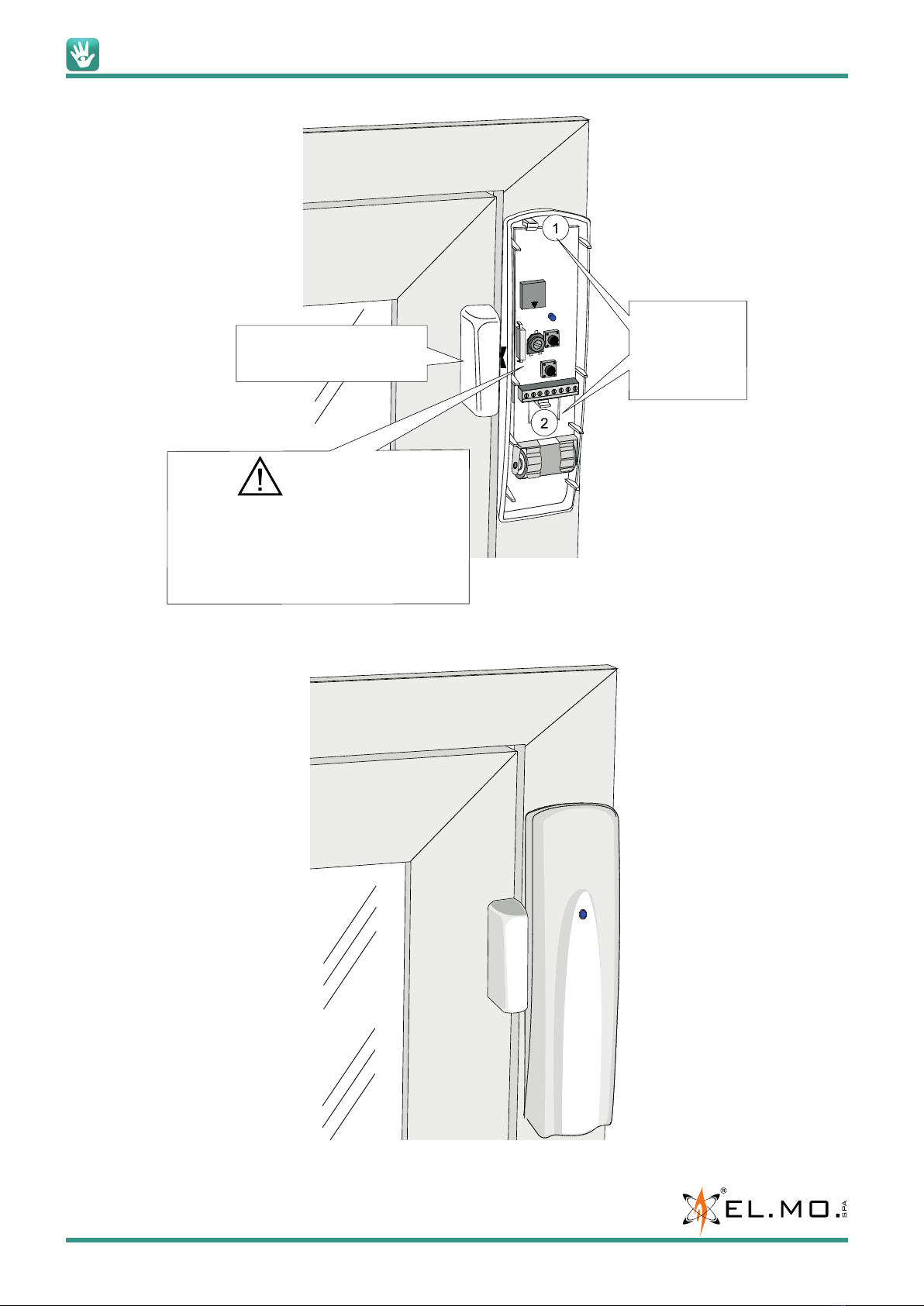

9. MOUNTING

Example of LUPUS2K transmitter mounting inside the housing of a

roll-up shutter. One of the possible fixing positions is indicated in the

picture on the right.

Search the best position in order to easily replace the battery when

needed: a possible position could be the external side of the box.

If you need an additional fixing support, avoid using a metal one in

order not to worsen the radio signal.

Note: the maximum distance from the roll-up shutter sensor can be

set via software to 1 or 8 meters: this is helpful in case of installation

with large windows, or in case you need to install the transmitter far

from the window.

Example of general mounting, phase 1.

HORIZONTAL

ADJUSTMENT

6.5 mm

MAX

NOMINAL

DISTANCE

5 mm

WARNING!

IN ORDER TO ACCESS THE UPPER FIXING

HOLE, PUSH OPEN THE PLASTIC CLIPS TO

UNHOOK THE ELECTRONIC BOARD AND

REMOVE IT.

FOR VOLANS2K, ALSO UNSCREW THE PIEZO

SENSOR WIRES FROM ITS TERMINAL BOARD.

TSV FIXING SCREWS

SUPPLIED WITH

WALL DOWELS

ALIGN THE REFERENCE ON

THE MAGNET BASE WITH

THAT ON THE SIDE OF

THE TRANSMITTER

LUPUS2K - VOLANS2K - TECHNICAL MANUAL - 090001113

elmospa.com

10

Example of general mounting, phase 2.

Example of general mounting, phase 3.

INSERT AND BLOCK THE CAP

WITH THE MAGNET.

HOOK THE BOARD

IN TO THE TWO

INDICATED CLIPS,

FOLLOWING

THE NUMBERING.

WARNING!

DURING THE INSTALLATION OF THE VOLANS2K

SENSOR, IT IS CONVENIENT TO REMOVE THE

BOARD.

AFTER CORRECTLY POSITIONING THE DEVICE,

CONNECT THE WIRES OF THE PIEZO SENSOR

(LOCATED ON THE BASE) TO ITS TERMINAL BOARD.

090001113 - TECHNICAL MANUAL - LUPUS2K - VOLANS2K

elmospa.com

11

9.1 Protection against removal from mounting surface

Compliance with EN 50131 regulation grade 2 requires that the device is protected against removal from the mounting

surface.

Install KSAS1013 kit (green) before fixing the detector base to the fixture.

A

- open pre-drilled area A

- cut the cable connector off

- feed the cable (from the free end) in the drilled hole

-

1 cm

fix a S4 dowel (supplied) to the wall at a height of 1 cm from the hole

- fix the eyelet to the dowel

- fix the detector base to the fixture

- connect the wires to the 24H terminals on board

LUPUS2K - VOLANS2K - TECHNICAL MANUAL - 090001113

elmospa.com

12

10. ELECTRICAL CONNECTIONS

10.1 Board general view

10.2 LUPUS2K general connections

Note: in order to ensure the product certification, it is necessary to connect the Tamper protection lines of the external

magnetic contact and of the roll-up sensor to the “24H” terminal.

USE THIS BUTTON AS

SPECIFIED IN THE CODE

ACQUISITION SECTION

TAMPER BUTTON FOR

PROTECTION AGAINST

HOUSING OPENING

EVENT DETECTION

INDICATOR

TX LED

IMPACT SENSITIVITY TUNING

ONLY FOR VOLANS2K MOD.

(THE PIEZO SENSOR IS LOCATED

ON BOARD BOTTOM)

SMD VIAL WITH MAGNETIC

CONTACT, NEXT TO THE

LED INDICATOR

THE PRODUCT IS PROVIDED WITH THE

BATTERY AS STANDARD EQUIPMENT.

AFTER INSTALLING THE PRODUCT, INSERT THE

BATTERY BETWEEN THE INDICATED TABS

RESPECTING THE POLARITY.

DO NOT TOUCH THE BATTERY TERMINALS

WITH YOUR FINGERS IN THIS PHASE.

1/2AA LITHIUM BATTERY MOD. ER14250 OR

EQUIV. REPLACE IT ONLY WITH A NEW

BATTERY OF THE SAME TYPE.

DO NOT REVERSE POLARITIES.

PAY ATTENTION NOT TO CAUSE

SHORT CIRCUITS.

DANGER EXPLOSION.

PIEZO SENSOR, RELATED TERMINAL

AND WIRING (ONLY FOR VOLANS2K)

ALL INPUTS CAN BE ENABLED AND

CONFIGURED VIA SOFTWARE

APPLICATION

ATTACH THIS TERMINAL TO THE LAST LAG WHEN

THE ROLL-UP SHUTTER LEANS ON THE WINDOW

MARBLE PLAN, EXTRACTING ALL THE THREAD AVAILABLE.

MAX LENGTH: 20 m

MAX LENGTH: 1 m

(DEFAULT)

OR 8 m

CONFIGURABLE

VIA SOFTWARE

ON-BOARD REED

CONTACT

MAGNET PROVIDED AS STANDARD EQUIPMENT.

INSTALL IT ON THE SIDE THAT HAS NO LABEL.

See Channel 1 software settings

See Channel 3 software settings

See Channel 2 software settings

090001113 - TECHNICAL MANUAL - LUPUS2K - VOLANS2K

elmospa.com

13

10.3 Allowed wiring types for LUPUS2K model

Using the software application, you can fully configure wiring types in order to optimize the device operations for the

required functions. The following screen is displayed in the “Zones” page, “Radio devices NG-TRX” tab corresponding

to the selected zone. For this zone, the specific model and information concerning the type of alarm generated and the

firmware version are displayed.

The “Enable Led” selection allows you to enable/disable the on-board LED according to the operational necessities.

Flag the “Buzzer activation functions” checkbox to apply to the specific channel the functional settings concerning the

internal buzzer that have been configured in the “Buzzer activation” selection displayed in the “Options NG-TRX” area.

During the detector learning phase, the channels are assigned to three consecutive zones; however, you can immediately

avoid memorizing an unused channel or you can disconnect such a channel from the browser application in order to

occupy less zones.

The software menu can also be used to move the channels to different zones, e.g. to group all roll-up shutter sensors on

consecutive zones. Click on the triangle located at the right of the zone number and choose a different zone from the list,

then click on the “Jump” button in order to move the channel (and the zone name) to the selected zone.

In case the zone is already occupied by other devices, the software application will signal the code conflict.

You can configure the type for channels 2 and 3 independently, choosing between magnetic and roll-up shutter type. For

the latter, you can define the wiring length (“Fast”: 1 m, “Fast 8 metres”: 8 m), the number of pulses and the timeout for

the detection of a valid alarm.

Timeout (s) = 5, 10, 15 (default) , 20.

Number of pulses = 1, 2, 4 (default), 8.

After configuring the settings, write the configuration to the control unit and then perform the functional test.

Note: use the “Fast 8 metres” option only if necessary: it may affect battery life.

LUPUS2K - VOLANS2K - TECHNICAL MANUAL - 090001113

elmospa.com

14

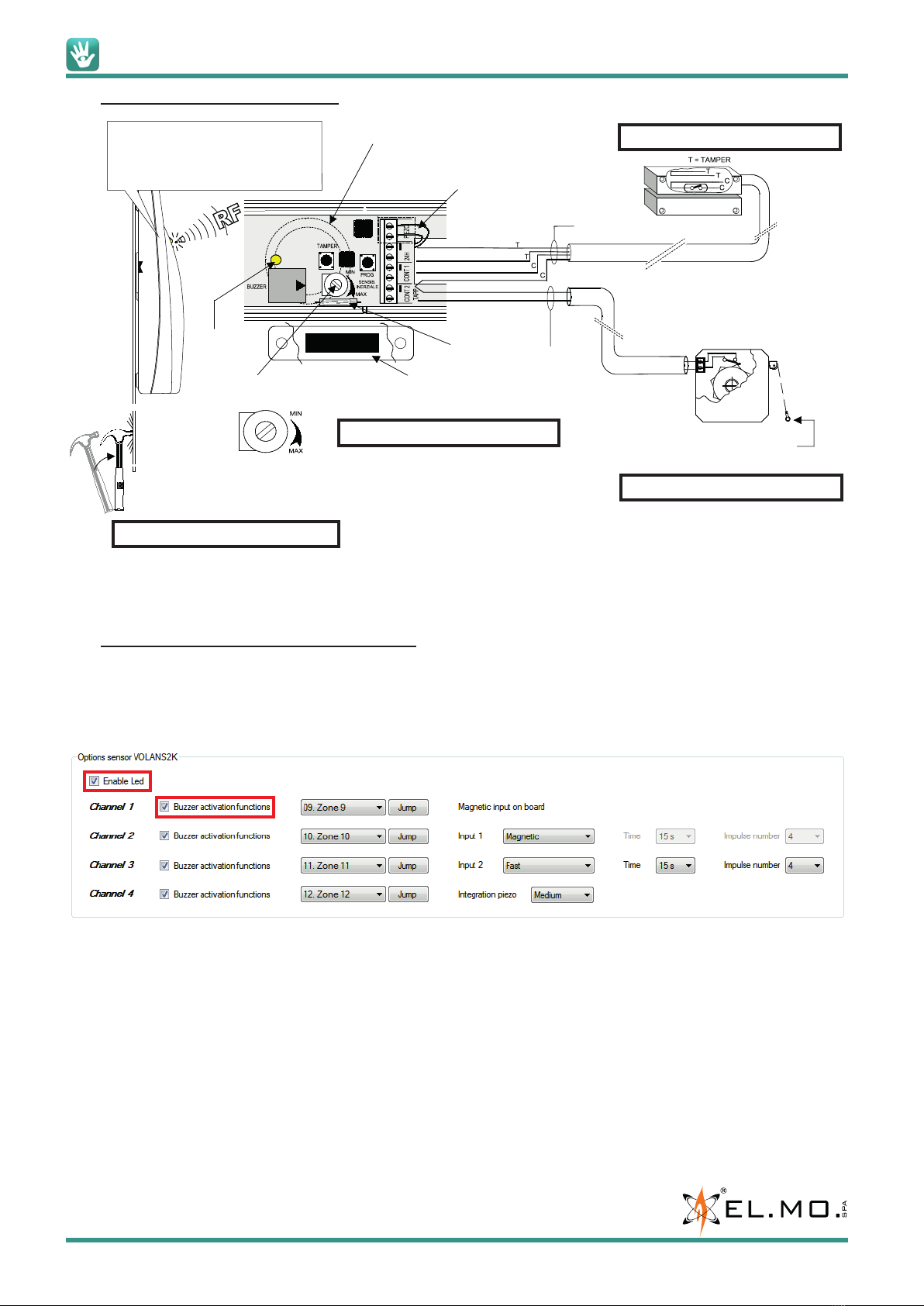

10.4 VOLANS2K general connections

Note: in order to ensure the product certification, it is necessary to connect the Tamper protection lines of the external

magnetic contact and of the roll-up sensor to the transmitter “24H” terminal.

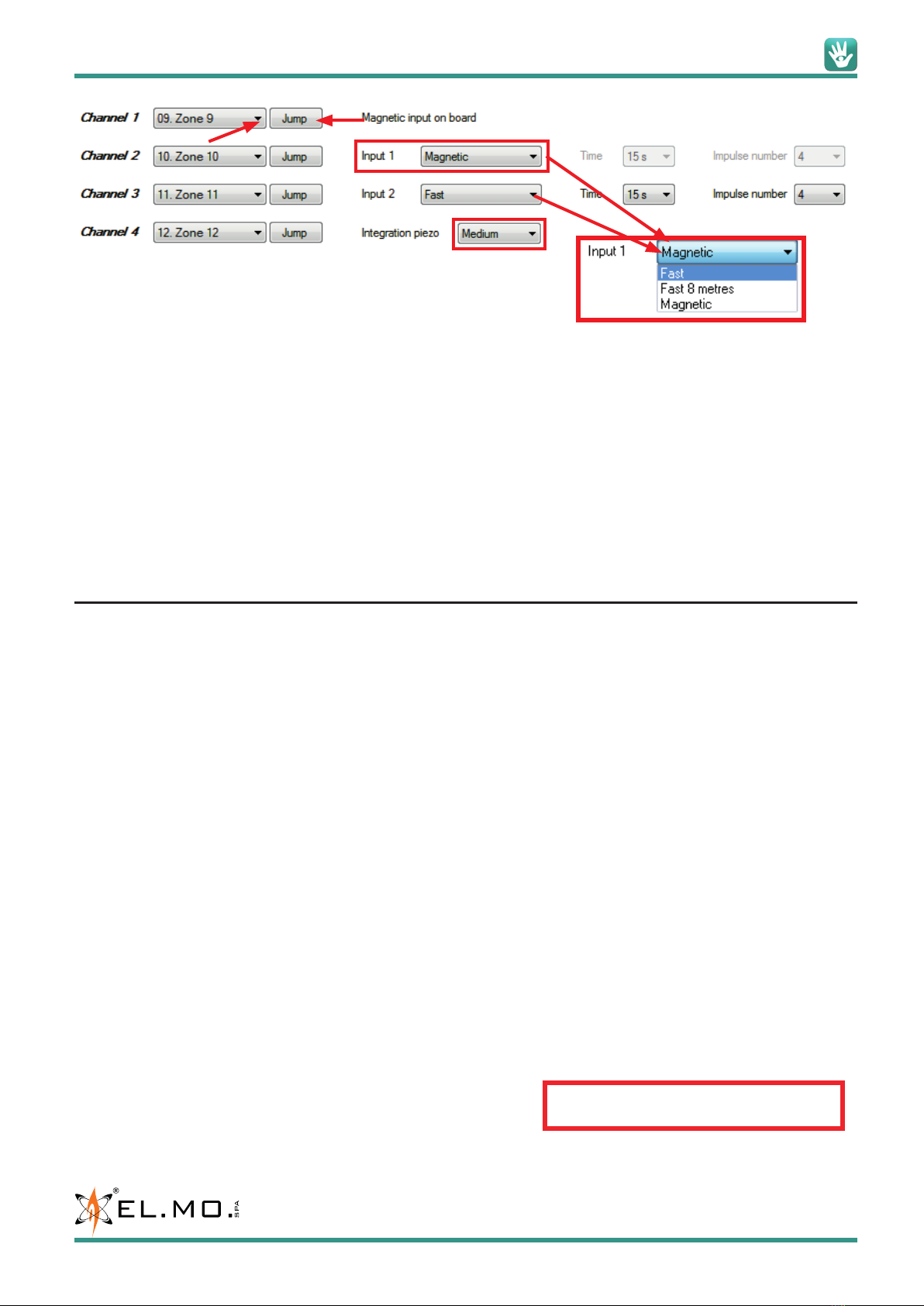

10.5 Allowed wiring types for VOLANS2K model

Using the software application, you can fully configure wiring types in order to optimize the device operation in the required

functions. The following screen is displayed in the “Radio devices NG-TRX” tab corresponding to the selected zone. For

this zone, the specific model and other informations concerning the type of alarm generated and the firmware version are

displayed.

The “Enable Led” selection allows to enable/disable the on-board LED according to the operational necessities.

The “Walk Test” and “Learning” phase indications will be visualized even when the LED is not enabled.

Checking the “Buzzer activation functions” allows to apply to the specific channel the functional settings of the internal

buzzer that have been configured in the “Buzzer activation” selection displayed in the “Options NG-TRX” tab right above

this one.

During the detector learning phase, the channels are assigned to four consecutive zones; however, you can immediately

avoid memorizing an unused channel or you can disconnect such a channel from the browser application in order to

occupy less zones.

The software menu can also be used to move the channels to different zones, e.g. to group all roll-up shutter sensors on

consecutive zones. Click on the triangle located at the right of the zone number and choose a different zone from the list,

then click on the “Jump” button in order to move the channel (and the zone name) to the selected zone.

In case the zone is already occupied by other devices, the software application will signal the code conflict.

PIEZO SENSOR POSITION.

WARNING:

TO GET THE HIGHEST SENSITIVITY, SET THE

HOUSING BOTTOM PERFECTLY IN CONTACT

WITH THE SURFACE TO BE PROTECTED

THE PIEZO SENSOR IS LOCATED IN THIS POSITION

ON THE BOARD BOTTOM

ALL INPUTS CAN BE ENABLED AND

CONFIGURED VIA SOFTWARE APPLICATION

ATTACH THIS TERMINAL TO THE LAST LAG WHEN

THE ROLL-UP SHUTTER LEANS ON

THE WINDOW MARBLE PLAN, EXTRACTING ALL

THE THREAD AVAILABLE.

MAGNET PROVIDED AS

STANDARD EQUIPMENT.

INSTALL IT ON THE SIDE

THAT HAS NO LABEL.

ON-BOARD

REED

CONTACT

THREE LEVELS OF INTEGRATION CAN BE SET VIA SOFTWARE

APPLICATION: MEDIUM (DEFAULT), LOW AND HIGH

IMPACT SENSITIVITY TUNING

(THE PIEZO SENSOR IS LOCATED

ON BOARD BOTTOM)

LED FOR

OPERATION

AND IMPACT

INDICATION

PIEZO SENSOR WIRES.

CONNECT THEM TO THE

“PIEZO” TERMINALS.

MAX LENGTH: 20 m.

MAX LENGTH: 1 m

(DEFAULT),

OR 8 m

CONFIGURABLE

VIA SOFTWARE.

See Channel 1 software settings

See Channel 3 software settings

See Channel 2 software settings

See Channel 4 software settings

090001113 - TECHNICAL MANUAL - LUPUS2K - VOLANS2K

elmospa.com

15

You can configure the type for channels 2 and 3 independently, choosing between magnetic and roll-up shutter type. For

the latter, you can define the wiring length (“Fast”: 1 m, “Fast 8 metres”: 8 m), the number of pulses and the timeout for

the detection of a valid alarm.

Timeout (s) = 5, 10, 15 (default) , 20.

Number of pulses = 1, 2, 4 (default), 8.

Note: use the “Fast 8 metres” option only if necessary: it may affect battery life.

The built-in inertial sensor response can be adjusted based on the material and the fixing position; the sensitivity can be

adjusted using the trimmer indicated in the electrical connection picture; the pulse integration can be set via software

application, choosing among 3 levels: Medium (default), Low, High. The picture refers to default settings.

After configuring the settings, write the configuration in the control unit and then perform the functional test.

11. CODE MEMORIZATION

Note: during the code acquisition phases, keep in mind that the control unit identifies LUPUS2K and VOLANS2K as multi-

channel devices.

The following procedure allows to memorize the transmitter to a Villeggio NG-TRX control unit.

1. Power up the transmitter by inserting the battery. Respect the polarity as indicated in the printed board and in this

manual.

2. Enter the programming menu by typing the installer code on a system keypad.

3. Press “OK”, then use the arrow buttons to browse to “Learn radio det.”.

4. Press “OK”, then either use the arrow buttons to browse through the available zones or type a zone address.

5. Press “OK”, then press 1 to store the code to the control unit. Press “OK” again.

6. Immediately press the “PROG” button of the transmitter (next to the magnet), and keep it pressed for at least 3 seconds.

7. A double beep of the internal buzzer and a double blink of the transmitter LED signal a successful memorization.

8. The control unit also beeps twice to confirm the successful memorization.

9. The display shows the channels identified by the control unit in this sequence:

CH1 with Alarm/Reset, referring to the built-in magnetic contact,

CH2 with Alarm/Reset, referring to the magnetic contact to be wired,

CH3 with Alarm event, referring to the roll-up shutter detector to be wired,

CH4 with Alarm event, referring to the built-in piezo sensor (available only for the VOLANS2K model).

For each channel, press “OK” for confirmation or # to switch to the next channel, up to the last available channel.

Note: during the acquisition phase, you can choose between the acquisition of either all or only some of the channels.

After a “partial” acquisition, the channels cannot be added to the control unit manually, but only using BrowserOne.

10. If the memorization fails, the internal buzzer plays a long, deep beep. Restart from point 6.

11. Exit the programming menu, pressing “OK” any time you are asked to save/memorize the new settings.

12. Use BrowserOne with the module for your NG-TRX control unit to read the configuration, change the settings for the

transmitter, then write the modified configuration. See the next chapter.

13. The new settings will be operative from after the next transmission.

14. Open and close the window or the roll-up shutter (or generate an

inertial alarm in case you are using the VOLANS2K detector) to test

that the transmitter is working. Since the internal buzzer is usually disabled (unless you activated it via browser in

order to ease the test), the only indication is given by the LED turning on.

Note: The device will not be memorized in

case of low battery.

LUPUS2K - VOLANS2K - TECHNICAL MANUAL - 090001113

elmospa.com

16

12. TRANSMITTER CONFIGURATION VIA SOFTWARE

The transmitter can be fully programmed by using BrowserOne v. 3.4.7 or higher with the module for the control unit v.

8.4.11 or higher. The control unit firmware must be 8.2.0.0 or higher.

See the specific technical documentation for information on other expressly compatible control unit models.

Perform the following operations:

• Start the connection as explained in the programming manual of the control unit.

• Read the current configuration, open the “Zones” page and identify the number of the zone that is assigned the

acquired code of the transmitter.

• Still in the Zones page, open the “Radio devices NG-TRX” tab.

On the side of the page concerning the NG-TRX wireless devices, some useful notes are displayed for the correct

configuration of the detector, depending on the selection of the “Supervision interval” and the “Tx Boost” function.

In the bottom page you can find the specific section for the transmitter channels configuration, described in chapter “10.

ELECTRICAL CONNECTIONS”.

Event type for each channel.

Press to delete the acquired code.

The picture highlights the

informations concerning the

radio NG-TRX system, the

firmware version and the

transmitter model.

Activates the internal buzzer of the transmitter in

alarm or reset for a local operation check of all

channels (unless differently set for each single

channel). Default: disabled (any anomaly is

signalled in any case).

Function available only if you set a precise

supervision interval; it allows you to delay the

anomaly signal generated by the “supervision

failure” signal.

Select to increase the power of the RF section.

WARNING: this causes a decrease in battery duration. Use only when the range is not

sufficient.

You can choose between “Automatic”, “Minimum

consumption” to maximize battery life when the

signal reception is sufficient, “Maximum power”

in case of high limitations due to adverse site

conditions (drawback: battery life reduction).

Default: Automatic.

Set the periodic transmission cadence necessary

for the control unit to detect the transmitter control

failure, with the consequent reporting and alert

actions settable from other software pages.

Setting a short interval will affect the battery

duration of the device. In the Default condition, the

general parameters will be used: they are set in the

“System options” page for the NG-TRX devices.

These two lines are

actually only one, whose

content changes.

Example

090001113 - TECHNICAL MANUAL - LUPUS2K - VOLANS2K

elmospa.com

17

Open the “System options” page, “Options NG-TRX” tab, where the general options of the NG-TRX devices are available.

Here you can select the settings that also involve the LUPUS2K and VOLANS2K transmitters.

The listed options are valid for all NG-TRX devices, except remote controls:

1. Delay supervision anomaly: NG-TRX devices generate the supervision failure event 6 supervision cycles later.

Example: if the default supervision timer is set to 240 minutes and the delay function is active, the supervision

anomaly is generated 24 hours later (240 minutes × 6).

2. Delay low battery signalling: if active, the devices run more thorough controls before sending the low battery signal.

3. Enable detection RF interference: this selection allows to detect interferences in the three 868 MHz channels and

to generate the event log. The interference detection on the preferred channel involves the transition to an other

channel if the same interference has already been detected and logged in the last 48 hours.

The general options selection about the 434 MHz interference detection does not concern NG-TRX devices.

4. RF Interference as Tamper: select this function to use an RF interference event to generate a tampering event, along

with the resulting management.

Selection of the multi-channel reception (3 channels), also involving the default/preferential channel selection and

the transmission strategy. In case the function is active but communication with the control unit is not possible, the

device will use one of the other two remaining channels. For more details see “13.4 Multi-channel reception and

strategy”.

The default channel shall be set by the installer, otherwise it is Ch1.

Note: the system uses the preferred channel based on the interference level; if there is no interference, the default

channel is used. Each channel change will be recorded in the event log.

Common supervision for all system devices,

except remote controls; if necessary, it can be

modified for each device.

1

2

3

4

LUPUS2K - VOLANS2K - TECHNICAL MANUAL - 090001113

elmospa.com

18

13. OPERATING MODES

13.1 Walk test - System test

The Walk test condition can be activated via keypad, from the SYSTEM TEST » ZONE TEST menu.

The beginning of the operating mode is indicated by three beeps of the internal buzzer and by the LED blinking.

After exiting the Walk test mode, the internal buzzer will enter operating mode, whose configuration depends on browser

programming.

13.2 Operation

In operative conditions, the detector only uses the cover LED, for both alarm or tamper conditions. These conditions can

also be indicated by the internal buzzer if it has been programmed for alarm or for alarm and reset. The buzzer is disabled

by default.

13.3 Supervision

In case you have made some changes in supervision times (with subsequent memorization in control unit), they will be

updated to the set values upon the first transmission. Therefore, if some devices are temporarily not powered, the control

unit will signal them considering a different supervision time than the one just set.

After the next power-on of the devices, the supervision time will be updated to the set value. In case of subsequent detector

power failure, the system will keep the current supervision time.

In case you change the supervision time after a control unit reset, it will be updated at the first transmission.

Namely, immediately after the main reset, the supervision time that will be considered is the current one; any devices that

are not aligned within that time will enter the missed supervision state.

13.4 Multi-channel reception and strategy

It can be set in the NG-TRX Options page.

If the function is ACTIVE (default), the control unit is able to receive on all channels; if it is not active, the control unit

receives on one channel at a time. It is possible to increase reliability, when there are interferences on a specific channel,

by turning off the multi-channel reception.

Note: We suggest that you disable the Multi-channel reception when you are aware of the existence of radio interference

on one or more channels. In this case the control unit will receive only on the default/preferential channel, although the

detector performs transmission attempts on all channels.

13.5 Default/preferential channel

Default channel

In case of radio interferences, it is recommended to set the most free channel as the default channel (you can check it

through the monitoring functions on the browser and control unit).

In case of strong interferences, it is possible to increase the reliability of the communication by disabling the multi-channel

reception.

Preferential channel

The variation of the preferential channel is performed in case of interference detection. The control unit can change the

preferential channel independently of the activation of multi-channel reception mode.

090001113 - TECHNICAL MANUAL - LUPUS2K - VOLANS2K

elmospa.com

19

14. BATTERY REPLACEMENT AND DISPOSAL

The LUPUS2K and VOLANS2K detectors use a Lithium 3.6 V 1.2 Ah battery mod. ER14250 or LS1425 (1/2AA). Replace

this battery only with a new one of the same model. Observe the following insertion instructions:

1. Remove the low battery.

2. Press and release 3-4 times the Tamper button to discharge any charged capacitors.

3. Check the distance of the battery clip tabs. In idle conditions, they have to take an inclination similar to that shown in

the figure. The distance between the two tabs should be about 25 mm; if more, you will have to push them inward to

obtain the indicated distance.

The correct position of the tabs allows an excellent electrical contact and avoids possible and erroneous signalling of

low battery.

4. Insert the new battery. Check the polarity.

5. Reset any low battery memories in control unit or in the compatible receiving device.

Dispose of the old battery in full compliance with the current regulations, using the appropriate containers.

The materials used are highly polluting and harmful if released to the environment.

25 mm

LUPUS2K - VOLANS2K - Radio transmitters for wireless NG-TRX intrusion detection systems

TECHNICAL MANUAL - August 2018 edition 090001113

The information and product features herein are not binding and may be changed without prior notice.

EL.MO. SpA Via Pontarola, 70 - 35011 Campodarsego (PD) - Italy

Tel. +390499203333 - Fax +390499200306 - Technical Ass. +390499200426 - www.elmospa.com - inter[email protected]

15. TABLE OF CONTENTS

1. GENERALS .................................................................................. 3

2. FEATURES................................................................................... 3

3. MECHANICAL FEATURES ...................................................................... 5

4. HOW TO DISTINGUISH THE DEVICES ............................................................ 5

5. HOUSING OPENING AND CLOSING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

6. FIRST POWER-ON OR BATTERY REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

7. INSTALLATION ............................................................................... 7

8. COVERAGE AND SENSITIVITY................................................................... 8

9. MOUNTING .................................................................................. 9

9.1 Protection against removal from mounting surface.............................................11

10. ELECTRICAL CONNECTIONS ..................................................................12

10.1 Board general view .....................................................................12

10.2 LUPUS2K general connections ............................................................12

10.3 Allowed wiring types for LUPUS2K model ...................................................13

10.4 VOLANS2K general connections...........................................................14

10.5 Allowed wiring types for VOLANS2K model ..................................................14

11. CODE MEMORIZATION .......................................................................15

12. TRANSMITTER CONFIGURATION VIA SOFTWARE .................................................16

13. OPERATING MODES..........................................................................18

13.1 Walk test - System test...................................................................18

13.2 Operation .............................................................................18

13.3 Supervision............................................................................18

13.4 Multi-channel reception and strategy .......................................................18

13.5 Default/preferential channel ..............................................................18

14. BATTERY REPLACEMENT AND DISPOSAL .......................................................19

15. REQUIREMENTS FOR COMPLIANCE TO THE EN50131 STANDARD ...................................19

16. TABLE OF CONTENTS ........................................................................20

This manual suits for next models

1

Table of contents