aci DUCT Series Installation instructions

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 1

Version: 1.0

I0000855

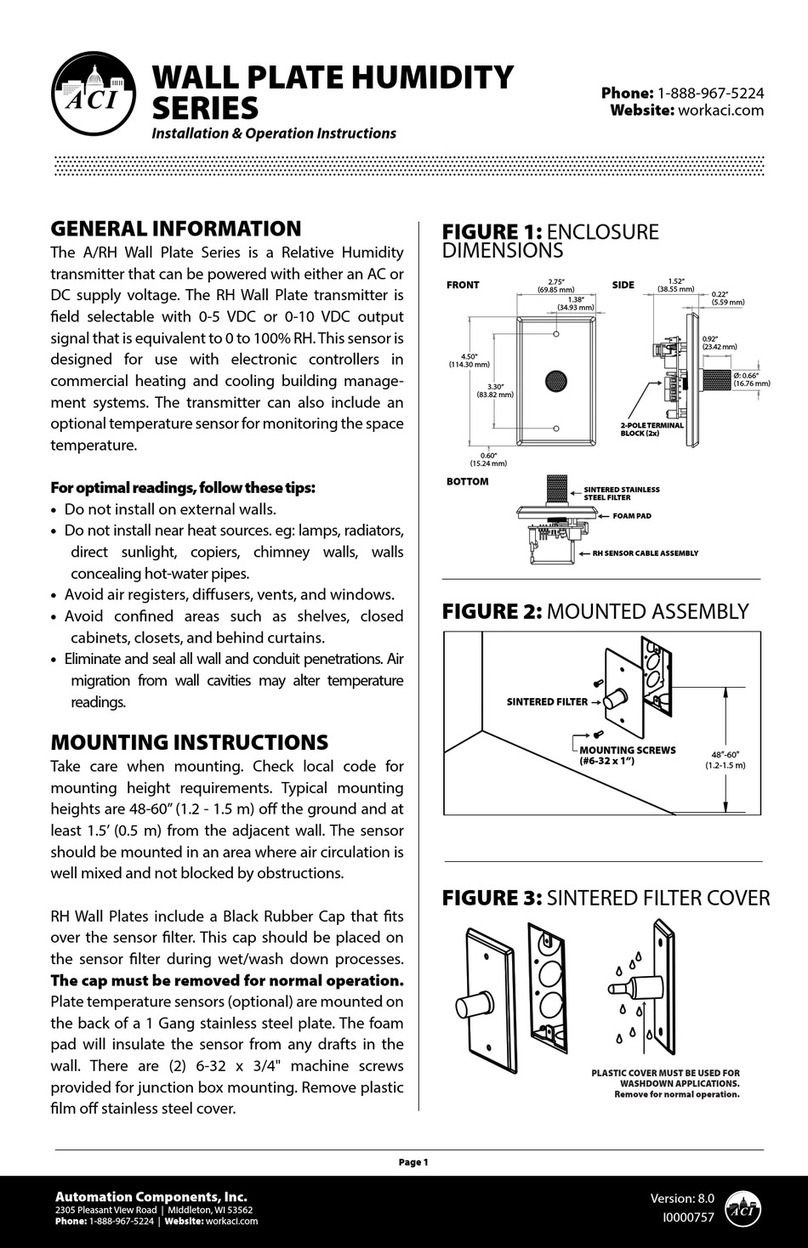

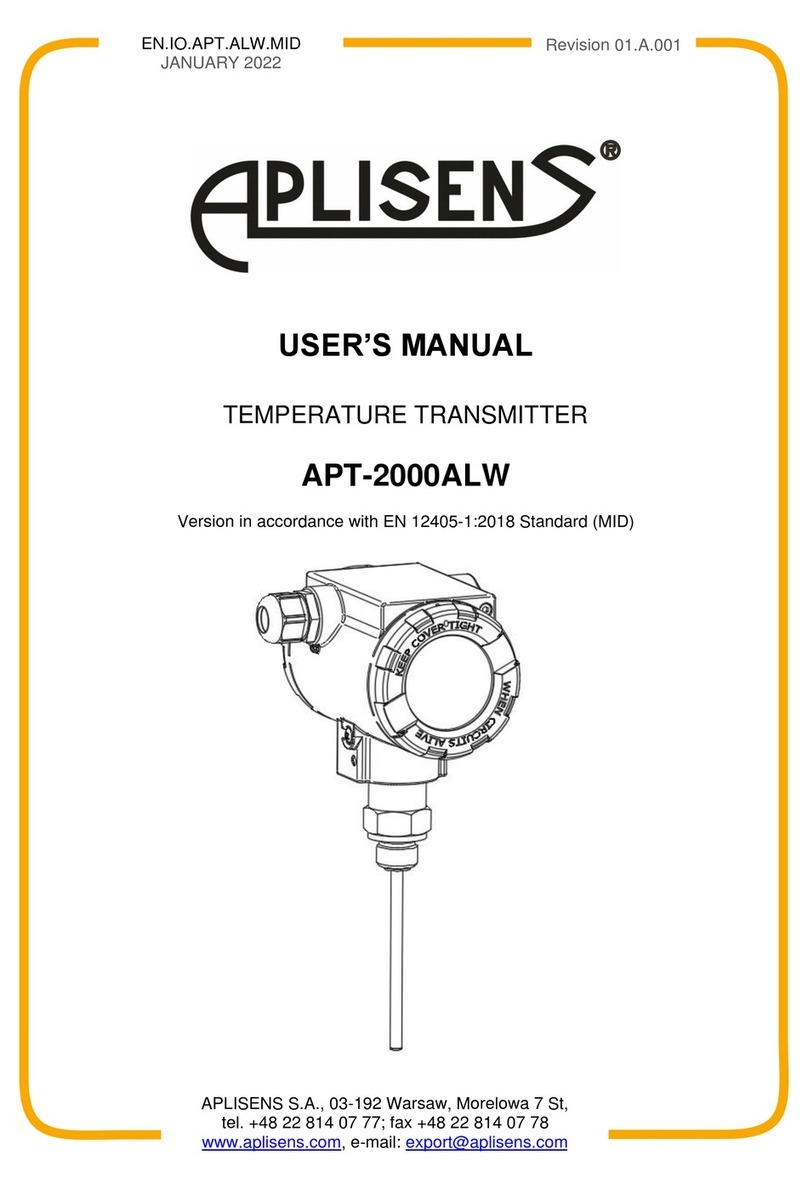

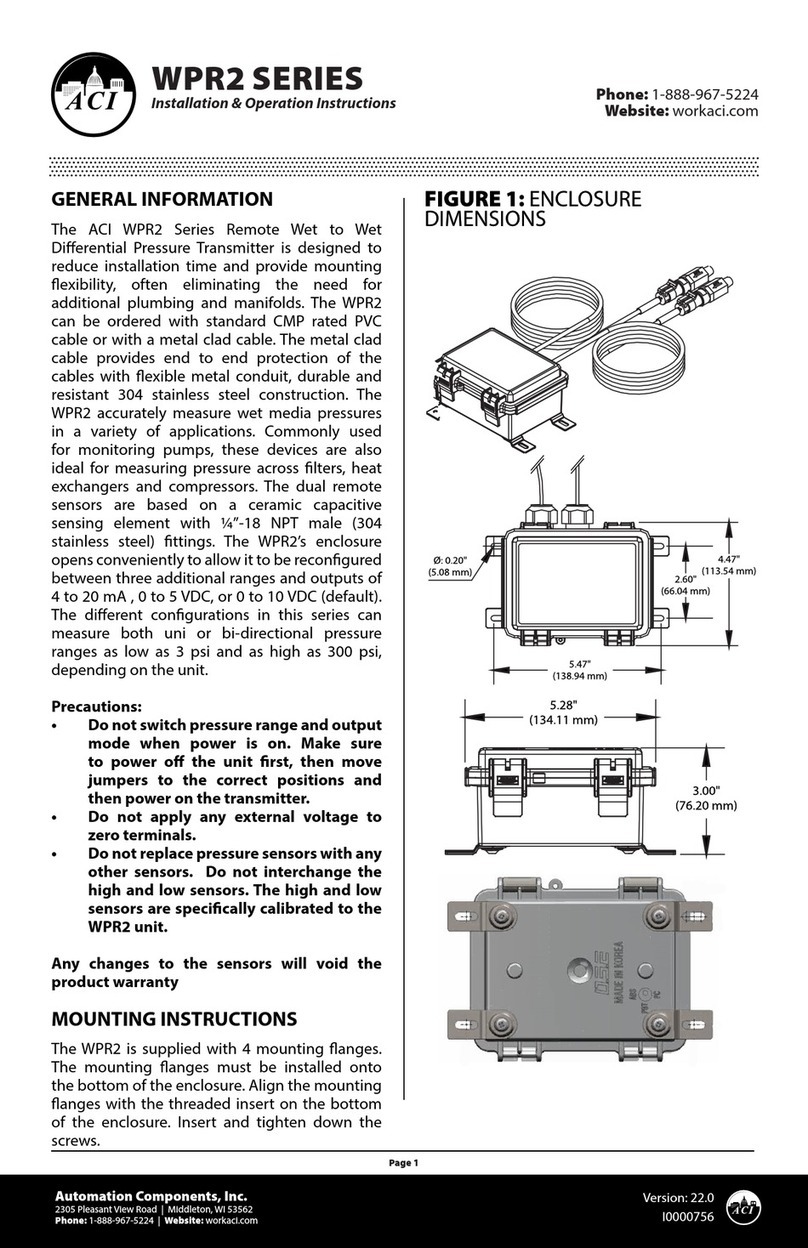

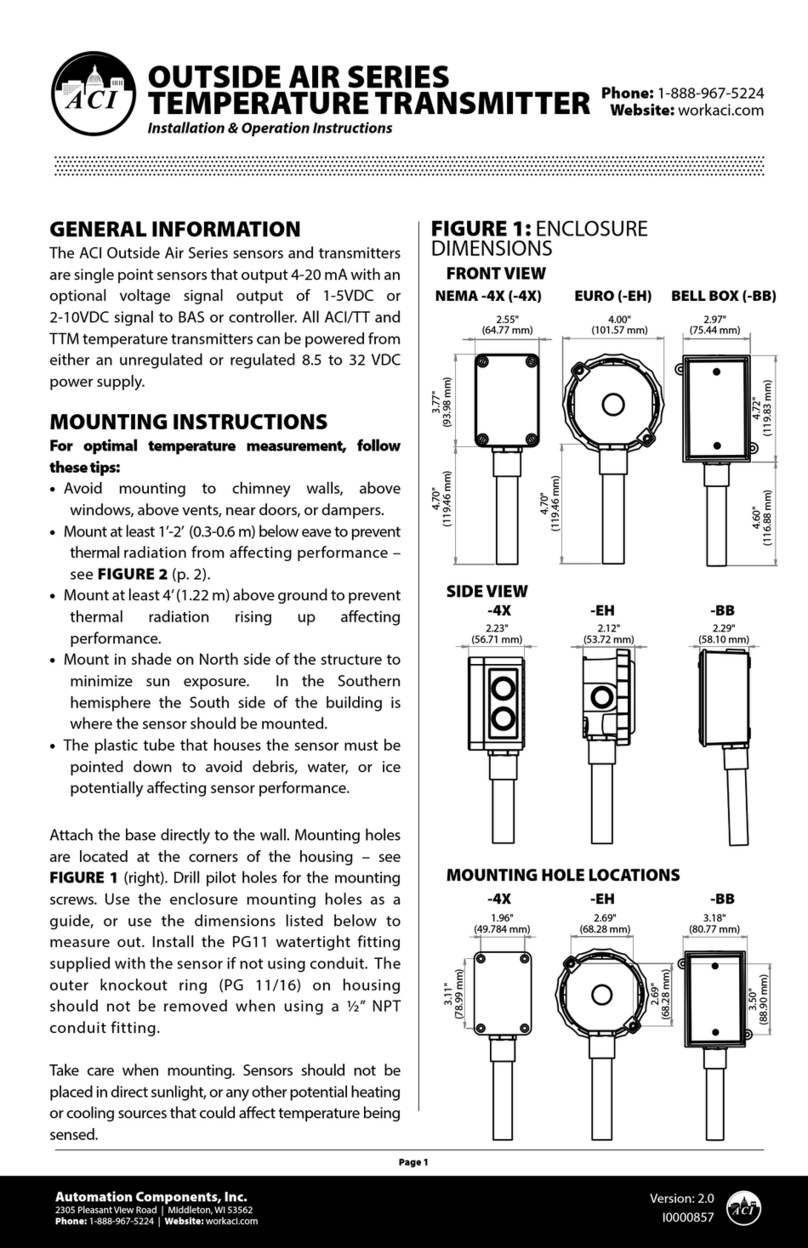

FIGURE 1: ENCLOSURE

DIMENSIONS

DUCT SERIES TEMPERATURE

TRANSMITTER

Installation & Operation Instructions

Phone: 1-888-967-5224

Website: workaci.com

GENERAL INFORMATION

The ACI Duct Series sensors and transmitters are

single point sensors that output 4-20 mA with an

optional voltage signal output of 1-5VDC or

2-10VDC signal to BAS or controller. All ACI/TT and

TTM temperature transmitters can be powered

from either an unregulated or regulated 8.5 to 32

VDC power supply.

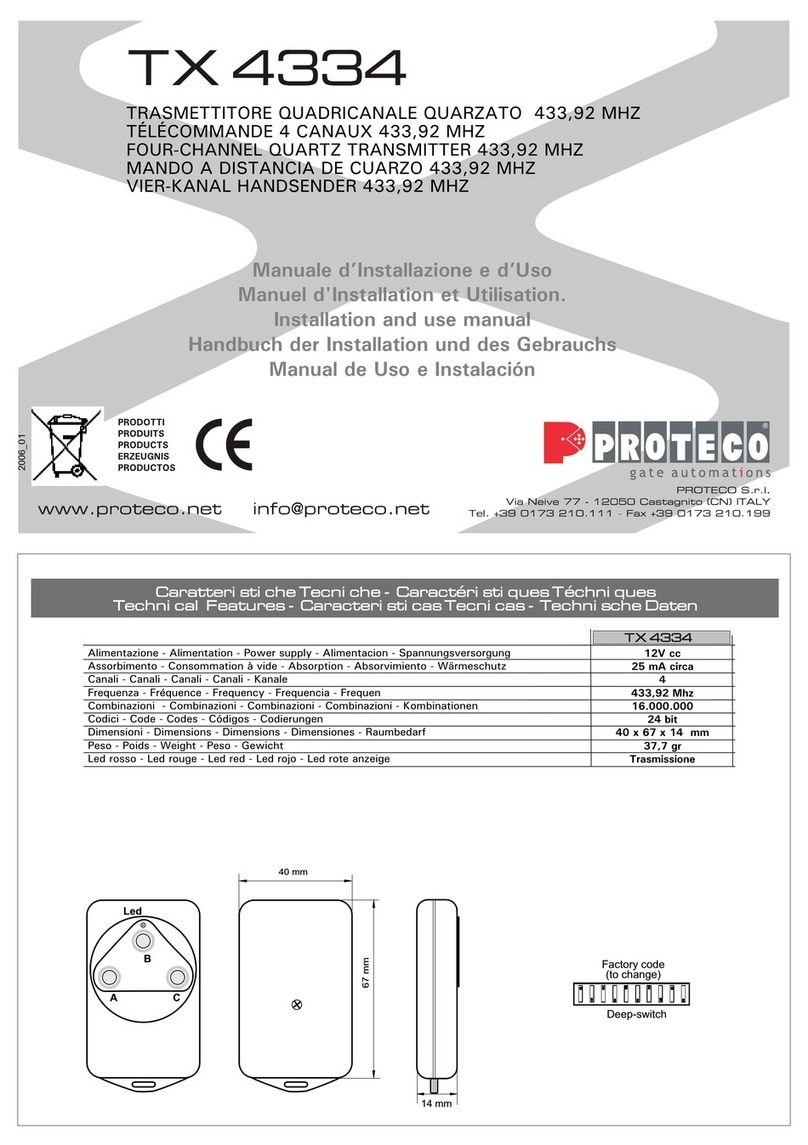

MOUNTING INSTRUCTIONS

For optimal temperature measurement, follow

these tips:

•Duct probe should be placed (3) to (4) duct

segments down from any bend or obstructions

and away from 90° bends.

•Mount the sensor on the top or sides of duct

work; mounting on the bottom risks damage

due to moisture.

•The sensor should be mounted in the middle of the

duct where air circulation is well mixed (no

stratication), and not blocked by obstructions.

Stratication and obstructions can cause sensing

errors. An example is downstream from a heating

or cooling coil.

Drill a 3/8” hole in the duct and insert the probe

through the hole until the foam pad is tight to the

duct. Drill pilot holes for the (2) mounting screws. Use

the enclosure ange as a guide, or use the

dimensions listed below to measure out.

Now fasten and insert (2) screws #8 x 3/4" TEK

(provided and recommended) through the

mounting holes in the ange and tighten until the

unit is held rmly to the duct. Make sure the foam

pad is tight to the duct to eliminate any possible

air leaks.

Note: All enclosures have the foam pad attached. For

the“DO”(no enclosure), the foam pad is included, but

not installed. The foam pad must be installed prior to

mounting.

WIRING INSTRUCTIONS

PRECAUTIONS

• Transmitter is powered by 24 VDC only.

• Remove power before wiring. NEVER connect or disconnect wiring with power applied.

• When removing the shield from the sensor end, make sure to properly trim the shield to prevent any

chance of shorting.

GALVANIZED (-GD)

PLASTIC BOX (-PB)

BELL BOX (-BB)

NEMA 4X (-4X)

3.60"

(91.44 mm)

2.25"

(57.15 mm)

4.79"

(121.55 mm)

2.35"

(59.80 mm)

4.20"

(106.68 mm)

3.88"

(98.60 mm)

2.41"

(61.21 mm) 1.78"

(45.18 mm)

2.95"

(75.00 mm) 2.34"

(59.38 mm)

4.72"

(119.83 mm)

3.88"

(98.60 mm) 2.19"

(55.69 mm)

2.55"

(64.77 mm)

3.70"

(93.980 mm)

1.51"

(38.25 mm) 3.01"

(76.51 mm)

1.54"

(39.12 mm)

3.08"

(78.23 mm)

1.59"

(40.39 mm)

3.18"

(80.77 mm)

1.54"

(39.12 mm)

3.08"

(78.23 mm)

VAC

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 2

Version: 1.0

I0000855

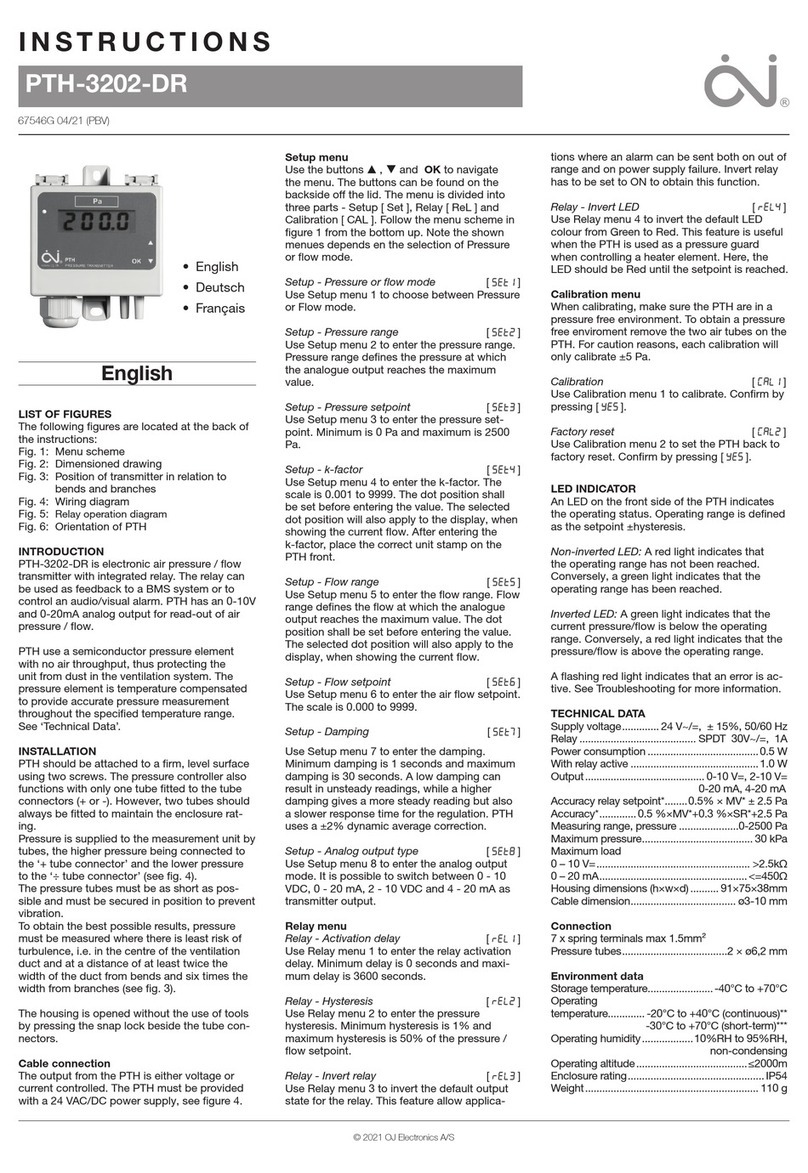

+VDC (Red Wire)

4 to 20mA Output

(White Wire)

RTD Wires

(100 Ohm RTD Brown Wires)

(1K Ohm RTD Black Wires)

+VDC (Red Wire)

GND (White Wire)

Voltage Output

(Yellow Wire)

(1 to 5, 2 to 10VDC)

RTD Wires

(100 Ohm RTD Brown Wires)

(1K Ohm RTD Black Wires)

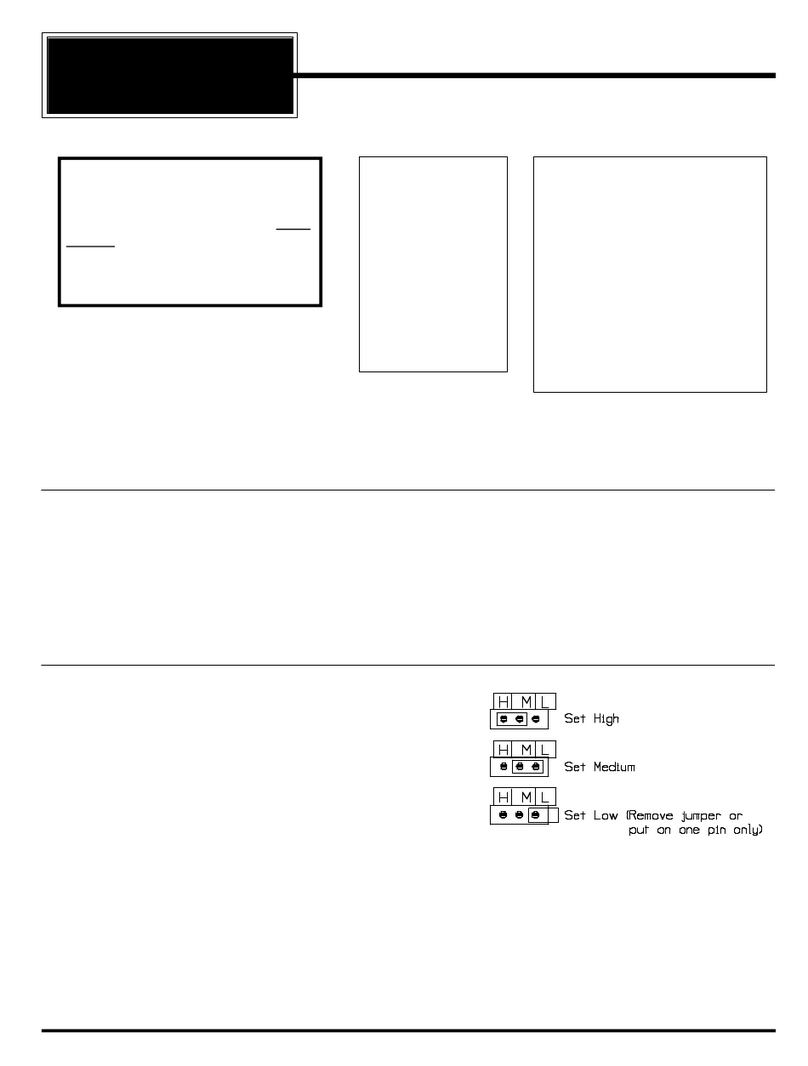

Current Output

(4 to 20 mA)

Current Output

(4 to 20 mA)

Voltage Output

(1 to 5, 2 to 10VDC)

Voltage Output

(1 to 5, 2 to 10VDC)

+VDC

4 to 20mA Output

+VDC

GND

Voltage Output

(1 to 5, 2 to 10VDC)

+-GND VOUT

RTD

+-RTD

SPAN

ZERO

SPANZERO

SPAN

ZERO

SPANZERO

POTTED UNITS

STANDARD UNITS

FIGURE 4: WIRING DIAGRAMS

0.375"

(9.525 mm)

FIGURE 2: DUCT MOUNTING

WIRING INSTRUCTIONS

PRECAUTIONS

• When using a shielded cable, ground the

shieldONLYatthe controllerend. Grounding

both ends can cause a ground loop.

• If the 24 VDC power is shared with devices

that have coils such as relays, solenoids, or

other inductors, each coil must have an MOV,

DC Transorb, Transient Voltage Suppressor

(ACI Part: 142583), or diode placed across the

coil or inductor.The cathode, or banded side

of the DC Transorb or diode, connects to the

positive side of the power supply. Without

these snubbers, coils produce very large

voltage spikes when de-energizing that can

causemalfunctionordestructionofelectron-

ic circuits.

Open the cover of the enclosure. ACI recommends

16 to 26 AWG twisted pair wires or shielded cable

for all transmitters. Twisted pair may be used for

2-wire current output transmitters or 3-wire for

voltage output. Refer to FIGURE 4 (right) for wiring

diagrams. All wiring must comply with local and

National Electric Codes. All ACI TT and TTM

temperature transmitters can be powered from

either an unregulated or regulated 8.5 to 32VDC

power supply. The TT and TTM DO NOT support an

AC input. All TT and TTM temperature transmitters

are reverse polarity protected. After wiring, attach

the cover to the enclosure.

The minimum voltage at the transmitter power

terminal is 8.5V after load resistor voltage drop.

•249 Ω load resistor (1-5 VDC output) = 13.5 V min supply

voltage

•499 Ω load resistor (2-10 VDC output) = 18.5 V min

supply voltage

Note: Adding extra wire length between the

sensor and transmitter board may aect accuracy.

Note: All RTD’s are supplied with (2) or (3) ying lead wires. ACI’s transmitters are supplied with a 2 pole

terminal block for RTD sensor connections. When wiring a 3 wire RTD, connect the (2) common wires (same

color) together into the same terminal block.

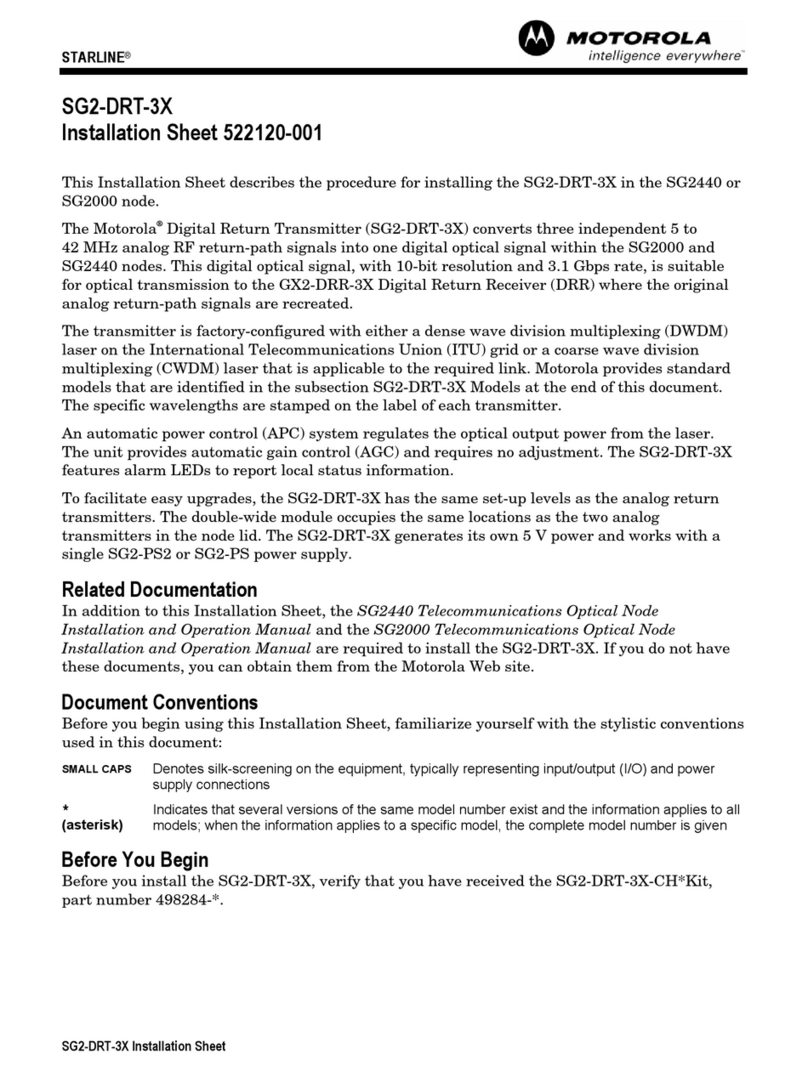

FORMULA FOR NUMBER OF TRANSMITTERS

Several transmitters may be powered from the same supply as shown in FIGURE 6 (p. 3). Each transmitter draws

25mA; refer to the following equation to obtain the number of permissible transmitters: [# Transmitters] =

[Current] / (25 mA).

WARRANTY

The ACI Duct Series temperature sensors are covered by ACI’s Five (5) Year Limited Warranty, which is located in

the front of ACI’S SENSORS & TRANSMITTERS CATALOG or can be found on ACI’s website: www.workaci.com.

W.E.E.E. DIRECTIVE

At the end of their useful life the packaging and product should be disposed of via a suitable recycling

centre. Do not dispose of with household waste. Do not burn.

TROUBLESHOOTING

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 3

Version: 1.0

I0000855

FIGURE 5: MULTIPLE TRANSMITTER CONNECTIONS

P

ower Supply

+ -

+ -

+ -

Temp.Transmitter #1

Temp.Transmitter #N

Temp.Transmitter #2

-

VDC

+

Controller

Gnd In1 In2 In3

= Connections

I

n1 = Controller Input #1

I

n2 = Controller Input #2

I

n3 = Controller Input #3

TEMPERATURE PROBLEM

No Reading

•No power to board - check voltage at power terminal - should be between +8.5 and 32 VDC.

Reading too Low

•RTD wires shorted. Disconnect wies from terminal block and check with ohmmeter. Reading should be close to 100 Ωor 1 KΩ.

•RTD Improper range of transmitter (too low). Check current or voltage - should be between 4-20 mA, 1-5 V, or 2-10 V.

Reading too High

•RTD opened. Disconnect sensor wires from terminal block and check with ohmmeter. Reading should be close to 100 Ωor 1 KΩ.

•Improper range of transmitter (too high). Check current or voltage - should be between 4-20 mA, 1-5 V, or 2-10 V.

Reading is Inaccurate

•Sensor check: Disconnect sensor wires from terminal block and check with ohmmeter. Compare the resistance reading

to the Temperature vs Resistance curves located on ACI’s website.

•Transmitter check: Make sure sensor wires are connected to terminal block. Determine that the proper output is being

transmitted based on predetermined span:

1. Go to ACI Website, Span to Output Page: http://www.workaci.com/content/span-output

2. Enter the low end of the span

3. Enter the high end of the span

4. Click on the output of the transmitter. This will generate a span to output chart.

5. Measure output of transmitter.

6. Compare measured output to calculated output

PRODUCT SPECIFICATIONS

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 4

Version: 1.0

I0000855

Note: Transmitter’s calibrated at 71ºF (22ºC) nominal | Note: Thermal Drift is referenced to 71ºF (22ºC) nominal calibration temperature

SENSOR NON-SPECIFIC

Storage Temperature Range:

Operating Humidity Range:

Lead Length | Conductor Size:

Lead Wire Insulation | Wire Rating:

Conductor Material:

Enclosure Specifications: (Operating

Temperature, Material, Flammability,

NEMA/IP Ratings):

SENSOR

Sensor Type | Sensor Curve | Sensing Points:

Sensor Output @ 0°C (32°F):

RTD Tolerance Class | Accuracy:

Din Standard | Temperature Coefficient:

Sensor Stability:

Response Time (63% Step Change):

Sensor Operating Temperature Range:

Probe Diameter | Probe Material:

TRANSMITTER

Transmitter Supply Voltage |

Supply Current:

Maximum Load Resistance:

Output Signals:

Calibrated Accuracy | Linearity1:

Thermal Drift2:

Min./Max. CalibratedTemperature Spans:

TTM100/TTM1K Certification Points:

Warm Up Time | Warm Up Drift:

Transmitter Operating Temperature Range:

Transmitter Operating Humidity Range:

Connections | Wire Size:

Terminal Block Torque Rating:

-40 to 80 °C (-40 to 176 °F)

10 to 90% RH, non-condensing

14” (35.6 cm) | 22 AWG (0.65mm)

Etched Teon (PTFE) Colored Leads | Mil Spec 16878/4 Type E

Silver Plated Copper

“-GD” : Galvanized Steel, -40 to 121 °C (-40 to 250 °F), NEMA 1 (IP10)

“-PB” : ABS Plastic, -30 to 90 °C (-22 to 194 °F), UL94-HB, Plenum Rated

“-BB” : Aluminum, -40 to 121 °C (-40 to 250 °F), NEMA 3R (IP 14)

“-4X”: Polystyrene Plastic, -40 to 70 °C (-40 to 158 °F), UL94-V2, NEMA 4X (IP 66)

Platinum RTD | PTC (Positive Temperature Coecient) | One

A/TT100/TTM100: 100 Ωnominal | A/TT1K/TTM1K: 1 KΩ nominal

+/- 0.06% Class A | (Tolerance Formula: +/- ºC = (0.15 °C + (0.002 * |t|))

where |t| is the absolute value of temperature above or below 0 °C in °C)

DIN EN 60751 (IEC 751) | 3850 ppm / °C

+/- 0.03% after 1000 Hours @ 300 °C (572 °F)

8 Seconds nominal

-40 to 200 °C (-40 to 392 °F)

0.250” (6.35mm) | 304 Stainless Steel

+8.5 to 32 VDC (Reverse Polarity Protected) | 25 mA minimum

250 ΩLoad: +13.5 to 32 VDC | 500 ΩLoad: +18.5 to 32 VDC

(Terminal Voltage - 8.5 V) | 0.020 A

Current: 4-20 mA (2-Wire) | Voltage: 1-5 VDC or 2-10 VDC (3-Wires)

T. Spans < 500 °F (260 °C): +/- 0.2%

T. Spans < 100 °F (38 °C): +/- 0.04%/ °F | T. Spans > 100 °F (38 °C): +/- 0.02%

Min. T. Span: 50 °F (28 °C) | Max T. Span: 400 °F (204 °C)

3 Pt. NIST: 20, 50, & 80% of span | 5 Pt. NIST: 0, 20, 50, 80, & 100% of span

10 Minutes | +/- 0.1%

-40 to 185 °F (-40 to 85 °C)

0 to 90%, non-condensing

Screw Terminal Blocks | 16 AWG (1.31 mm2) to 26 AWG (0.129 mm2)

0.37 ft-lb (0.5 Nm ) nominal

Other aci Transmitter manuals

aci

aci Room Series Installation instructions

aci

aci WPR2 Series Installation instructions

aci

aci B5 User manual

aci

aci CTS-M5 User manual

aci

aci B5C User manual

aci

aci OUTSIDE AIR Series Installation instructions

aci

aci ACI/DP Series User manual

aci

aci STRAP ON Series Installation instructions

aci

aci Room Series Installation instructions

aci

aci Room Series Installation instructions

Popular Transmitter manuals by other brands

HomePro

HomePro ZIR010 quick guide

EUTECH INSTRUMENTS

EUTECH INSTRUMENTS ALPHA PH 200 PHORP CONTROLLERTRANSMITTER instruction manual

Honeywell

Honeywell XNX-AM Series Technical manual

Avantree

Avantree Priva user manual

Linear

Linear DOOR/WINDOW TRANSMITTER DXT-31 installation instructions

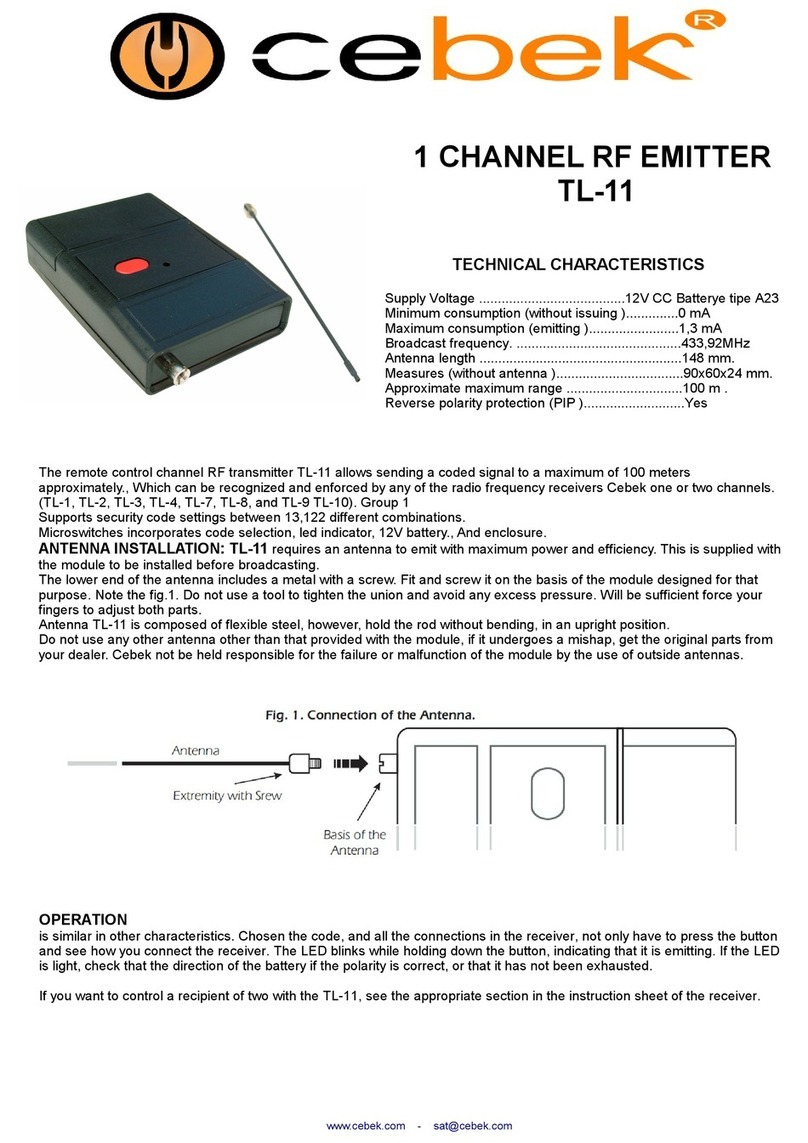

CEBEK

CEBEK TL-11 manual