ONLINE ELECTRONICS LTD

600_5001_A01 Page 8 of 12

4. OPERATION

Familiarise yourself with all of the rules for the safe operation of this equipment as described in

Section 3 RULES FOR SAFE OPERATION.

4.1. FUNCTION TEST

An acoustic receiver system, such as the OEL 2001 Acoustic Receiver and hydrophone, is

required in order to function test a 600 Series Pinger.

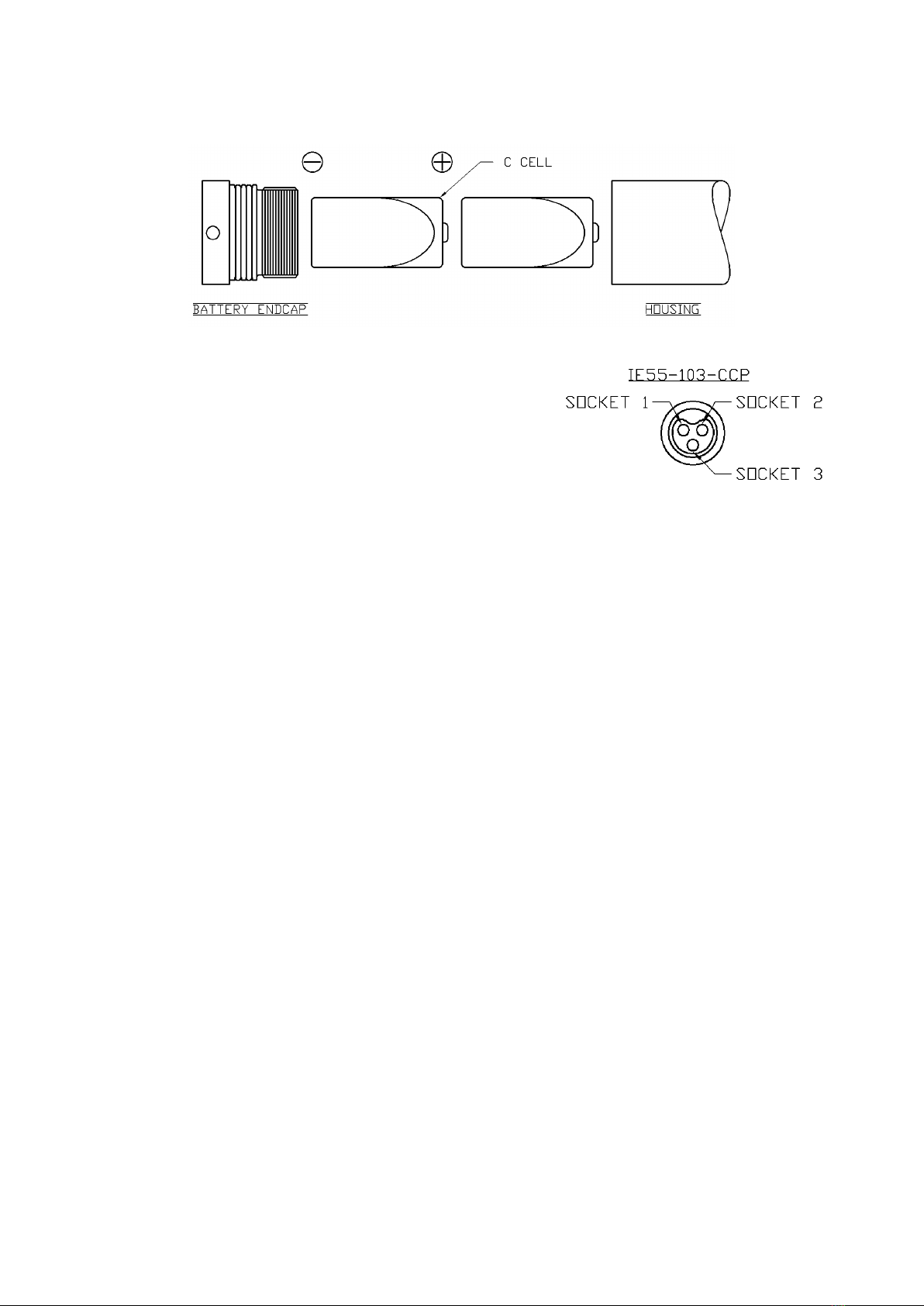

1. Ensure the battery end cap is tightened.

2. Activate the pinger by closing the saltwater links using the mechanical link provided, or by

simply bridging the links with bare fingers. NOTE: if using the mechanical link to bridge the

contacts, the heat shrink will need to be removed beforehand.

3. Set the frequency of the acoustic receiver system to match the frequency of the pinger

(refer to the label on the front of the unit for the configured frequency). Set the receiver

sensitivity to maximum and position the hydrophone approximately 30cm from the front of

the pinger (in air). With the pinger activated, confirm that transmitted signal is being

picked up by the acoustic receiver. If a 2001 acoustic receiver system is being used, the

received signal should be at approximately 50% of the maximum level.

4. Ensure that the acoustic pulses received by the acoustic receiver system match the

expected PING RATE of the pinger. Refer to Page 2 of this manual for the PING RATES of

the unit supplied.

5. If a pinger with the dual rate option is being tested, then either PING RATE 1 or PING

RATE 2 will be transmitted, depending on whether the DUAL RATE contact is open or

grounded. Refer to Section 4.5 DUAL RATE for further information. If the wrong ping rate

is being transmitted, this would suggest that the external equipment is either damaged or

not connected properly. If this happens, contact OEL for advice before initiating any

investigation process.

DISCLAIMER –Any investigation without taking advice could potentially damage the

pinger/external equipment.

6. Providing the PING RATES and SIGNAL LEVEL are correct, the system operation has been

verified and the function test is complete.

4.2. INSTALLATION

The PINGER TRANSDUCER must be left protruding from the PIG body in order to minimise

attenuation of the acoustic transmission.

1. Ensure the BATTERY ENDCAP is fully tightened.

2. Place the pinger within the cavity of the PIG, ensuring that it is secure and cannot move

around.

3. Wedging blocks of PU should be used as required to reduce any movement or vibration of

the pinger within the pig. NOTE: The wedging blocks should be in contact with the pinger

body only, not with the transducer.

4. The transducer head must be protected against physical impact.

5. If the mechanical link is not going to be used, ensure that there is adequate access for

water to flood the saltwater links.