Contents

Contents.......................................................................................................1

Chapter 1 Introduction........................................................................................2

1. Features...................................................................................................2

2. Package checklist.....................................................................................2

Chapter 2 Installation..........................................................................................3

1. ELAN Display writer .................................................................................3

2. Hardware requirements............................................................................6

3. Hardware Installation................................................................................7

4. Software Installation.................................................................................7

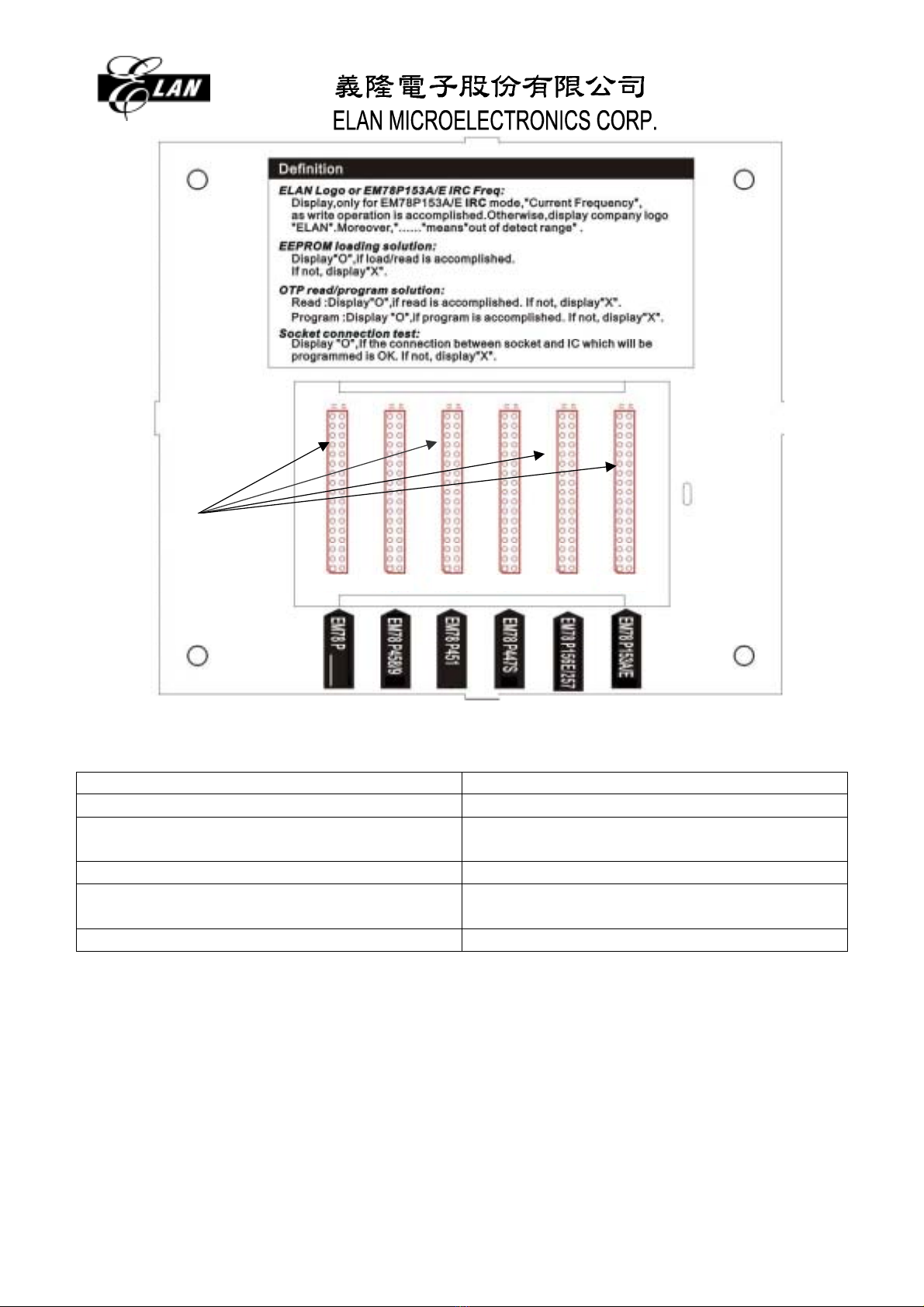

5. What is the self-diagnosis? ......................................................................7

Chapter 3 Introduction of the DWTR environment .............................................8

1.Getting start...............................................................................................8

Procedure 1: Start DWTR ......................................................................8

Procedure 2: Open a CDS file................................................................9

Procedure 3: Program..........................................................................11

2.Introduction of environment.....................................................................12

(1) Menu...............................................................................................12

(2) Tool bar...........................................................................................12

(3) File menu........................................................................................13

(4) View menu......................................................................................16

(5) Program menu................................................................................17

(6) Read menu .....................................................................................19

(7) Tool menu.......................................................................................21

(8) Window...........................................................................................22

(9) About ..............................................................................................22

3.IRC Frequency Calibration......................................................................23

4.Error message.........................................................................................24

Chapter 4 Q & A ..........................................................................................28

1. How to check a failed buffer?.................................................................28

2. What is “Frequency Mode”?...................................................................28

3. What is “Code Protected”?.....................................................................28

4. What is status of LED?...........................................................................28

5. How to update your DWTR window software?.......................................28

1