elco PISCES MINIFILL E1/1 User guide

1

COMPACT, WALL MOUNTED, PRESSURISATION MANAGER

INSTRUCTIONS FOR INSTALLATION, SERVICING &

MAINTENANCE OF THE PISCES MINIFILL MODEL

E1/1 (Electronic Single Pump) Unit, E1/2

(Electronic Twin Pump) Unit, and

L250-E1/1

E1/2

PISCES

MINIFILL

Electronic Models

2

ELECTRONIC

E1/1 & E1/2

PISCES

MINIFILL

page

section

page

section

21.0 General Notes 10 11.1 Filling the System

3

4

2.0

3.0

Product Description

Technical Data and Dimensions

11 11.2

12.0

Introduction ofWater

Treatment

Control Panel

4.0

Delivery Consignment/

Unpacking

12

13.0

Standard Menu

5

5.0

6.0

Locating the PiscesMinifill

Installation Clearances

14.0

Maintenance /Commissioning

Menu

7.0

Wall Mounting

14

15.0

Error Codes

6

8.0

Water Connections

15

16.0

Internal Components –

9.0

ElectricalConnections

Single Pump Unit

7

9

9.1

10.0

Internal Wiring Diagram

Determining the ColdFill

16 16.1 Internal Components –

Twin Pump Unit

11.0

Pressure

First Filling

17

17.0

CommissioningForm

1.0 General Notes

These instructions are intended to assist the installer, commissioning engineer, maintenance engineer and the

end user with the usage of the Pisces Minifill (E1/1 & E1/2 Electronic) pressurisation manager.

Please read this manual fully before commencing the installation of the unit. The Pisces Minifill

pressurisation manager should only be installed by persons deemed to be competent. This manual shall be

handed to the unit user following completion of the installation. The unit shall not be left to operate without being

correctly commissioned.

Installation Requirements

The installation of Pisces Minifill pressurisation manager shall be in accordance with the relevant requirements of

all current Water Regulations, suchas;

Water Supply (Water Fittings) Regulations 1999 (Amended Dec2000),

Water Byelaws 2000-Scotland,

Local Water AuthorityByelaws,

IEE Electrical Regulations,

Health & Safety at Work Act,

BuildingRegulations,

Construction (Design & Management) Regulations1994,

National, Fire Regulations,and

Insurance Companyrequirements.

The following British Standards / Codes of Practice are alsoapplicable:-

•

BS 6644: 2011 Specification for gas fired hot water pressurisation units of rated inputs between 60kW

and 2MW.

•

BS 6880: 1988 Code of Practice for low temperature hot water heating systems of output greater than

45kW. Parts 1, 2 &3.

•

BS 7593: 1992 Code of Practice for treatment of water in domestic hot water central heatingsystems.

•

BS 7671: 1992 Requirements for electrical installations. IEE Wiring Regulations. Seventeenthedition.

3

ELECTRONIC

E1/1 & E1/2

PISCES

MINIFILL

2.0 Product Description

The Pisces Minifill compact cabinet housed pressurisation manager is suitable for filling and maintaining the cold

fill pressure in sealed heating, cooling, or chilled watersystems.

The unit may be wall or floor mounted, and has been designed to meet the needs of the commercial/large

domestic installations, where plant room space may berestricted.

Wall/Floor mounted with compact dimensions

At 600mm High, 382mmWide, and 280mm Deep, the Pisces Minifill pressurisation managers allows for site

installation where space is of a premium, without compromising serviceability.

Versatility of Use

With the use of a powerful turbine peripheral pump the Pisces Minifill pressurisation managers canbe configured

to achieve and maintain a system Cold Fill Pressure from as low as 0.8bar up to 3.0bar.

The unit detailed in this manual utilizes a Type AF Air Gap, and is therefore compatible for use with both

Fluid Category 3 (C-3) In-House, and Fluid Category 4 (C-4) Other Than In-House systems.

Fill Function

The Microprocessor has a FILL function. This allows the Installing Engineer to fill the system without the need for

additional peripheral components, such as a Quick-fill Loop, Fluid Category 3 (C-3) In-House; ora Reduced

Pressure Zone (RPZ) valve, Fluid Category 4 (C-4) Other Than In-Housesystems.

Building Management System (BMS) Compatible

Both versions of the Pisces Minifill (Electronic) pressurisation managers are supplied as standard with three Volt

Free Relays to indicate the following Alarms, General Alarm, Low Water Pressure Alarm, and High Water

Pressure Alarm.

These switches are rated to accept up to 240Volts AC, with a maximum current of 0.5Amps.

Self-Diagnostic

The Microprocessor is fully diagnostic. Should a problem occur with the operational function of the appliance, the

microprocessor will operate the General Fault relay, and a Flashing Error Code will be displayed on the LCD

Display indicating the faultidentified.

Guarantee

The warranties available on the range of Pisces Minifill Pressurisation Managers covered in this manual, is as

follows;

Supply Only - Parts Only Warranty, against manufacturing or material defects for a

period of 12 months from the date ofdelivery.

Supply and Commissioned

(By an Elco Engineer) - Parts and Labour Warranty, against manufacturing or material defects

for a period of up to 15 months from the date of delivery. Labour

provided by Elco appointed engineer.

4

ELECTRONIC

E1/1 & E1/2

PISCES

MINIFILL

3.0 Technical Data & Dimensions

Technical Data

Cold Fill Pressure Min

Max 0.8bar

3.0bar

Minimum Mains Cold WaterSupply 12 ltrs/min

Power Supply (240V, 50Hz)

Motor Rated FuseRequired 10 Amps

Start Current 9.0 Amps

Full Load Current 2.8 Amps

Break Tank Air Gap AF

Break Tank Capacity(Max) 7.6 Ltrs

Weight (Empty) E1/1 22.0 kg

E1/2 28.0 kg

Weight (Full) E1/1 30.0 kg

E1/2 36.0 kg

Connections

Mains Cold Water Inlet (A) 15mm BSP

Waste water Outlet/Overflow (B) 28mm COMP

Water Outlet (C) 15mm COMP

Electrical Cable Glands(D) 4 x 10mm

4.0 Delivery Consignment / Unpacking

The Pisces Minifill pressurisation manager is delivered as a single carton containing the Pisces and associated fittings.

The Pisces Minifill unit cartoncontains:-

•

Assembled and Tested Pisces Minifill unit.

•

Wall mounting bracket.(Supplied attached to the front of the water tank.)

•

Installation Template (part of the carton).

To unpack the Pisces Minifill pressurisation manager, carefully cut along the taped seams of the carton. The carton will then

un-fold to reveal the unit. Do not discard of the packaging as this can be used as a template to assist the installation of the unit

5.0 Locating the Pisces Minifill

The Pisces Minifill pressurisation manager is not suitable for installation external to a building. The position chosen for the

appliance shall be a structurally sound wall capable of supporting the filled weight of the appliance and all associated

ancillary equipment. The wall shall be truly plumb vertical to ensure correct operation.

View

Side View (Left)

5

ELECTRONIC

E1/1 & E1/2

PISCES

MINIFILL

6.0 Installation Clearances

For ease of installation, commissioning, servicing and maintenance the following clearances should be observed.

NOTE: These distances are MINIMUM and MUST NOT be reduced. Failure to observe these

clearances could result in the warranties on the appliance becomingVOID.

7.0 Wall Mounting

The Pisces Minifill pressurisation manager can be floor

mounted, however it is recommended to be wall mounted, via

the wall-mounting bracket supplied. This bracket interlocks

into the cutout on the rear of theappliance.

A template, detailing the fixing positions and clearances, is

printed onto the appliance packaging, cut along the dotted

lines and position the template in the desired location to

ensure that all minimum clearances can beachieved.

The wall-mounting bracket should be securely fixed to the

wall using suitable fixings for the wall construction and

appliance filled weight. The wall-mounting bracket positioning

detail is shown in fig 7.

The Pisces Minifill pressurisation manager should be carefully

lifted so that the cutout on the rear of the Pisces Minifill

unit is just above the mounting bracket, and then gently

lowered to engage the bracket into the cutout. DO NOT lift the

Pisces Minifill unit by any of the internal parts orcomponents.

Important Notice

When viewed from the side, the North / South axis of

the Pisces Minifill unit must be vertical

Fig 7

6

ELECTRONIC

E1/1 & E1/2

PISCES

MINIFILL

8.0 Water Connections

The Mains Cold Water Supply connection (A) shall be able

to supply at least 12 litres per minute of clean water;

otherwise the operation of the appliance may empty the break

tank of water.

An integral low level water switch will prevent the unit from

operating and display a ‘L3’ fault message on the LCD

panel.

The Waste Water Outlet/Overflow (B) shall be routed to a

safe discharge location that will not cause harm to persons,

nor property, but shall be clearly visible, so that any water

discharge will be identified and remedial action taken,

ensuring that any wasted water is kept to a minimum. See Fig

8.1

The Waste Water Outlet/Overflow shall not be connected

directly to any foul water system without a suitable warning

method being incorporated, asabove.

After the warning method, and before connection to the foul

water system a suitable trap shall be incorporated to prevent

the release of any vapour/effluent from the foul water

system.

The Waste Water Outlet/Overflow shall be routed

in such a way to minimize the risk of blockage

through freezing.

If any part of the Waste Water Outlet/Overflow is to

be run external to the building or is at risk of

freezing, then the pipe shall be suitably insulated to

protect against freezing.

The System Connection (C) shall be connected to the

system pipework in such a manner so that the

suction/discharge pressure of any circulation pumps shall not

influence the appliance. It is recommended that the System

Connection be routed in such a manner to include/incorporate

the supply connection to any system expansion vessels. See

Fig 8.2

9.1

Electrical Connection

The Pisces Minifill pressurisation manager is supplied with a

fly lead for the Mains Power Connection; this cable should not

bereplaced.

The appliance power supply, fused spur or fused plug

socket, shall be positioned within 1 metre of the unit, See Fig

9.0.

The cable size serving the unit shall be sized in accordance with

the IEE ElectricalRegulation.

After the outer casing has been removed, the Electrical

Connection rail can be located on the front-hinged innerdoor.

See Fig 9.1 & 9.2, for connections details.

Please Note the Appliance Serial Number when

referring to these ConnectionDetails.

Fig 8.1

Fig 8.2

Fig 9.0

7

ELECTRONIC

E1/1 & E1/2

PISCES

MINIFILL

9.2

Internal Wiring Diagram.

Drawn by:

Date:

Title.

Version:

Drg Nr

Pages:

1.1

MHS 1.1

1

Jim Wyborn

27

th

August 2015

Elco Heat ing Solutions

3 Jun ipe r West, Fenton Way

SouthfieldsBusinessPark

Basildon, Essex

SS15 6SJ Tel 01268 546700

Pisces

Minifill Wiring

Electronic

1 2

345678910 11 12 13 14 15 16 17

Gr Bl

Yw Rd

1

2

3

4

5

6

7

8

9

10

11

12

Healthy

Healthy

Healthy

Input

Input

Input

Fault

Fault

Fault

Live

Neutral

Earth

Low

Pressure

Alarm

Volt Free

240v 0.5 amp

High

Pressure

Alarm

Volt Free

240v 0.5 amp

General

Alarm

Volt Free

240v 0.5 amp

Mains

Supply

240v 50 Hz

10 amps

Pressure

Transducer

Water tank

Level Switch

Main and display PCB

Within Control Panel

Charging

Pump No 1

Charging

Pump No 2

Chassis Base

Earth Tag

Front Door

Earth Tag

Bk

Br

Gy

Bk

Bk

Br

Br

Br

Gy

Gy

GY

Bl

The High and Low Pressure Alarm switches have been wired to allow Volt Free indication of Faults

If PowerInterruption of the associated Boiler / Chiller plant is required, the 240v 50Hz power supply for the associated Boiler /

Chiller plant should be routed as follows;

Interlock Circuit IN - Term 2

Link Wire Required - Terms 1 & 5

Interlock Circuit Out - Term 6

If a general alarm is required Link Terminal 6 to Terminal 8. Then the Interlock Circuit Out is Terminal 9

In this manner, if one of the Alarm Switches are activated, the power supply to the associated Boiler / Chiller plant will be

interrupted.

8

ELECTRONIC

E1/1 & E1/2

PISCES

MINIFILL

10.0 Determining the Cold Fill Pressure

The Cold Fill Pressure is critical to the correct operation of any Pressurisation Unit and associated system. This pressure

needs to be calculated from the Static Pressure of the system (measured height in metres from the base of Pressurisation Unit

to the top of the highest part of the heating system, divided by 10 to convert to bar pressure), and an allowance for venting and

vapour pressure.

Therefore the Cold Fill Pressure, for a system with a maximum operating temperature up to 90ºC, can be calculated as per

the example below:

Static Pressure

0.8 bar

(Height of 8.0metres, divided by10)

Venting Allowance

0.3 bar

(Allowance from Tablebelow)

Vapour Pressure

0.0 bar

(Allowance from TableBelow)

Cold Fill Pressure

1.1 bar

(Summation of Static, Venting & VapourPressure)

Venting and Vapour Pressure Allowances

Venting Allowance

0.3

Allowance to ensure system can be correctlyvented.

Vapour Pressure

Allowance

0.0

Max Operating Temp up to90ºC

0.2

Max Operating Temp 90ºC to95ºC

0.5

Max Operating Temp 95ºC to100ºC

0.8

Max Operating Temp 100ºC to105ºC

1.2

Max Operating Temp 105ºC to110ºC

1.6

Max Operating Temp 110ºC to115ºC

2.0

Max Operating Temp 115ºC to120ºC

11.0 First Filling

Before attempting to FILL THE SYSTEM, Section 11.1, please ensure that the following checks have been completed;

1) Check the Heating / Chilled Water system expansion vessel air charge. This vessel charge should be equal to the

calculated Cold Fill Pressure (+/- 0.2 bar) when the vessel is empty of water. See Section 10.0.

2) The Quarter Turn Isolation Valve on the underside of the Break Tank is in the CLOSEDposition.

3) The Quarter Turn Isolation Valve on the Water Outlet (on the end of the flexible pipe) is in the CLOSED position.

4) The Mains Water Supply has been connected, vented, and the appliance Break Tank has been filled with clean

water. Any foreign bodies/debris are to be removed before the appliance is set to work.

5) The Electrical Supply has been connected and tested for correct polarity.

Power should not be applied to the appliance at thisstage.

6) The Heating / Chilled Water system has been fully flooded and vented as detailed in Section 11.1below.

On completion of the above checks the unit is ready to be Set Up to the system requirements, and the following procedure shall

be followed.

To Prevent duplication of setting activities, it is advisable to undertake the testing/setting of the High and Low Pressure

Alarm Switches prior to setting the Cold Fill Pressure. To Prevent potential over pressurizing or loss of water treatment, the

following test shall be undertaken with the outlet value of the appliance CLOSED.

ELECTRONIC

E1/1 & E1/2

PISCES

MINIFILL

9

11.1

Filling the System

Before attempting to FILL THE SYSTEM, please ensure that the procedure in Section 11.0 has been fully completed.

The Microprocessor of the Minifill (Electronic) has a FILL function, which utilizes the internal pumps to introduce water into the

Heating / Chilled Water System. This function negates the need for a separate filling method such as a Fill Loop, Fluid

Category 3 (C-3) In-House; or a Reduced Pressure Zone (RPZ) Valve, Fluid Category 4 (C-4) Other Than In-House.

The FILL function will introduce water into the Heating / Chilled water system for up to 6 hours, or until the Cold Fill Pressure

of 1.8bar (Factory Default Setting) has been achieved.

To Fill the Heating / Chilled water System, the following procedure shall be followed;

1) Ensure that the Cold Water Supply has been cleaned of any air or installation debris. Turn ON the Mains Cold

Water Supply to the appliance. Remove any debris from the Water Tank, and check the Ball Float Valve for correct

operation.

2) Open the Quarter Turn Isolation Valve on the underside of the BreakTank.

3) Vent The Pump. Located on the top of the center pipe connection of the pump assembly, is a vent valve. Undo

this vent valve with a vent Key and release any air. When all the air has been released, securely close the vent

valve.

4) Ensure that all drain valves, bleed points, etc, on the Heating / Chilled Water System are FULLY CLOSED, andthat

there are not any open ended pipes.

5) Open the Quarter Turn Isolation Valve on the Water Outlet (on the end of the flexiblepipe).

6) To activate the FILL function, the MAINTENANCE MENU of the Microprocessor must be accessed, this can be

done by Pressing & Holding the UP program button, and turning ON the POWER SUPPLY to theunit.

After a few seconds the LCD will display AUTO / Fault Code.

Using the DOWN program button, scroll through the settings until the word FILL appear on the LCD display. Press

the ENTER button to activate the FILL function. (The unit may operate upon power application if the sensed

pressure is below the set point of the unit. The FILL function should be used to prevent incorrect alarm activation.)

7) The PUMP will now operate and introduce water into the Heating / Chilled Water System.

8) Check the operation of the Ball Float Valve, and that the Main Cold Water Supply is suitably replenishing the water

into the Water Tank.

If the Mains Cold Water Supply cannot replenish the water sufficiently, then the LOW WATER SWITCH fitted to the

Water Tank will fall to OPEN, and the PUMP will turnOFF.

When the water level has risen the LOW WATER SWITCH will rise to CLOSE, and the PUMP will turn ON again.

9) The PUMP will introduce water into the system until the COLD FILL PRESSURE of 1.8bar (Factory Setting) is

achieved, 6 HOURS has been exceeded, or the LOW WATER SWITCH on the Water Tank falls toOPEN.

10) To terminate the Fill function press ANY BUTTON, and turn OFF the POWER Supply until the unit has been fully

commissioned, as detailed in Section 14.0

PLEASE NOTE:

Great Care should be observed when using the FILL function to ensure that all water joints

etc are sound and leek-free. MHS Boilers cannot be held responsible for any damage that

may result from water leaks. To terminate the FILL function turn OFF the POWERSupply.

ELECTRONIC

E1/1 & E1/2

PISCES

MINIFILL

10

11.2

Introduction of Water Treatment

The Mains Cold Water Supply pipework MUST be thoroughly cleaned and flushed to remove debris, flux residues, etc.

before opening the isolation valve and flooding the Pisces Minifill pressurisation manager.

After the Heating / Chilled Water system has been filled, flushed, and cleaned in accordance with BS 7593:1992, the

system will need to be treated with a suitable Water Treatment for the prevention of corrosion, scale formation and micro-

biological growth.

Some Water Treatments are supplied in a concentrated liquid form; it is therefore recommended that the treatment be

added to the water in the Water Tank in small doses. Drain an amount of water from the system (at a position some distance

from the Pisces Minifill pressurisation manager), so that the system pressure drops and the Treated Water in the Water Tank

is introduced to thesystem.

As the Water Tank is replenished with fresh water, gradually add the water treatment (at the correct concentration) until the

appliance turns off. Repeat this process until the entire water treatment chemical has been fully introduced. Let the system

circulate for a minimum of 1 hour, and then undertake a water analysis to ensure the correct dosage level has been obtained.

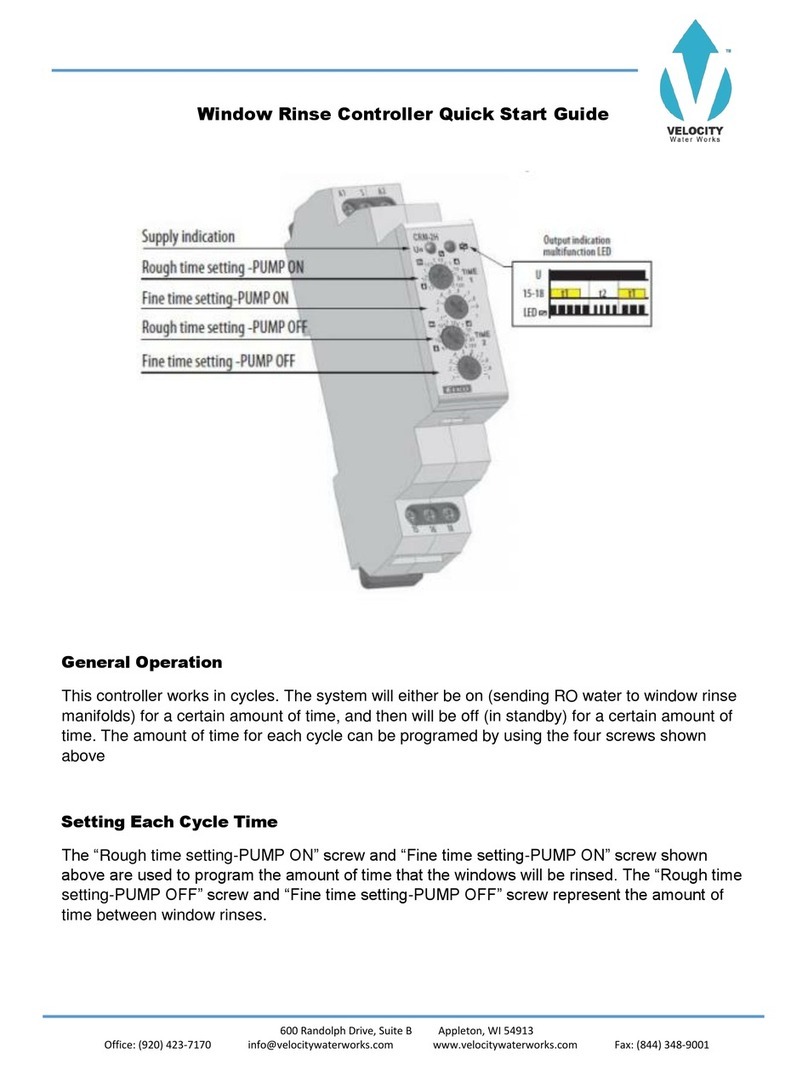

12.0 Control Panel

The Control Panel can be accessed with the case On or Off, and has two access levels, Standard & Maintenance.

These levels can be accessed using the UP, DOWN and ENTERbuttons.

Standard Menu – For the End User.

Maintenance Menu – For the Commissioning / ServiceEngineer.

ig 12.0

11

ELECTRONIC

E1/1 & E1/2

PISCES

MINIFILL

13.0 Standard Menu

When the POWER supply has been turned ON to the appliance, the LCD will display the STANDARD MENU, asdetailed below.

Review of the ID Lines is done by using the UP or DOWN buttons

Please note, P2 is the only ID line that can be altered at this level, all other data displayed is READ ONLY.

Comments

Actual Value - Review Only

Can be altered using the + / -

buttons.

L2 Volume of Water Introduced

Actual Value - Review Only

Review Only

Actual Volume = XX x10 Litres

(Since last rest.) 0 – 999.9 *** Actual Value - Review Only

C1 Number of Pump Cycles 0 – 999 *** Actual Value - Review Only

H1 Hours Operation of PUMP1 00.00 –

99.59

H2 Hours Operation of PUMP2 00.00 –

99.59

** : ** Actual Value - Review Only

** : ** Actual Value - Review Only

*

The pump fitted within this unit is capable of a maximum Cold Fill Pressure of 3.0Bar

14.1

Maintenance / Commissioning Menu

The Maintenance / Commissioning of a Pressurisation Manager shall only be undertaken by a competent person, as

various safety items associated with the safe operation of the Heating / Chilled Water System need to be checked and

confirmed for correct operation. We would therefore recommend that a Qualified Gas Safe registered engineer undertake

these works.

The Maintenance / Commissioning of the Pisces Minifill Pressurisation Units should only be undertaken after the following

sections of this manual have been given careful consideration;

Section 10.0 Determining the Cold FillPressure

Section 11.0 First Filling

Section 11.1 Filling the System

Section 11.2 Introduction of Water Treatment

On completion of the above Sections, the appliance is ready to be commissioned for automatic operation. The appliance is

factory set, and should not require many adjustments, other than those required to suit the particular requirements of the

system, such as COLD FILL PRESSURE, and HIGH / LOW WATER PRESSURE ALARMS.

To review / alter the operational settings, the MAINTENACE MENU of the microprocessor needs to be accessed, by

undertaking the followingprocedure;

1) Turn OFF the Mains POWER supply, and wait approximately 30 seconds, then;

2) Press and HOLD the UP Program Button, and then turn ON the Mains Power Supply.

After a

few seconds the LCD will display P0.

The LCD Display will display “Auto / Fault Code”, using the UP or DOWN program buttons the other parameters can be re-

viewed.

To amend a Parameter, select the ID Line required, Press the ENTER button, to select that parameter, then use the UP

or DOWN buttons to change the value, and then Press the ENTER button to confirm the change.

To return to normal operation, turn OFF the Mains POWER supply, wait 30 seconds, then turn ON the Mains POWER

supply.

ID

Line

Description

Range

Factory

Default

P0

Current System Pressure

0.0 – 6.0 bar

**

P2 Cold Fill Pressure (PUMP Cut-Out) 0.7 – 6.0 bar

*

1.8

L0 Volume of

W

a

ter

Introduced 0 - 9999 ***

L1

W

a

ter Introduc

tion Alarm 01 – 99 99

12

ELECTRONIC

E1/1 & E1/2

PISCES

MINIFILL

14.0 Maintenance / Commissioning Menu (cont’d)

Detailed below is a list of the ID Lines, their descriptions, along with the operating range and Factory Default settings.

These Parameters should only be accessed by a Qualified engineer.

ID Line

Description

Range

Factory Default

Comments

P0

Current System Pressure

0.0 – 6.0 bar

**

Actual Value - Review Only

P2

Cold Fill Pressure

(PUMPCut-Out)

0.7 – 6.0 bar*

1.8

L0

Volume of WaterIntroduced

0 - 9999

***

Actual Value - Review Only

L1

Water Introduction Alarm

1 – 99

99

Actual volume is value x 10

(ie 10 = 100 litres)

L2

Volume of Water Introduced

Since last reset

0 – 999.9

***

Actual Value - Review Only

Pressing the ENTER button will

reset

counter back to 000.0

C1

Number of PumpCycles

Since last reset

0 – 9999

***

Actual Value - Review Only

Pressing the ENTER button will

reset

counter back to 000.0

H1

Hours Operation of PUMP1

Since last reset

00.00 – 99.59

** : **

Actual Value - Review Only

Pressing the ENTER button will

reset

counter back to 000.0

H2

Hours Operation of PUMP2

Since last reset

00.00 – 99.59

** : **

Actual Value - Review Only

Pressing the ENTER button will

reset

counter back to 000.0

P1

Pump Cut-INpressure

0.5 – (P2 - 0.2)

1.4

Recommended Value

P1 = P2 –

0.4

A1

Low Pressure Alarm

0.0 – 5.6

1.2

Recommended Value. Safety Valve

Setting, Plus 0.3 bar

A2

High Pressure Alarm

0.9 – 6.2

3.6

Recommended Value. Safety Valve

Setting, Minus 0.3 bar

t1

Pump Minimum Run Time

In seconds

1.0 – 9.9

1.0

Minimum operating time of the

pump.

t2

Pump Maximum Run Time

In seconds

01 – 99

99

Maximum operating time of the

pump.

t3

Pump Minimum Cycle Time

In minutes

00 – 99

00

Minimum OFF TIME of pumpto

stop pump hunting ON/OFF

t4

Pump Duty Cycle Time

In minutes

00 – 99

30

Number of days pump is idle, then

pump

operated for 1 second.

(00 = No Duty Cycle)

FI

Pump Selection

1,2, Au

Au

1 = Pump 1 ONLY

2 = Pump 2 ONLY

Au = Automatic Rotation

SC

Password

Y, N

N

Pass Code = 21

F2

Pump Failure Time

01- 99 Min

03 Min

Allowable time delay before Pressure

Sensor records minimum pressure

rise

of 0.05 bar

FILL

Automatic Filling Function

-

-

Pressing ENTER on this menu

operates this function, See Section

11.1

Please Note:

These Setting will affect the operational function of the appliance, hence, alterations shouldonly

be undertaken by a competentperson.

*

The pump fitted within this unit is capable of a maximum Cold Fill Pressure of 3.0Bar

13

ELECTRONIC

E1/1 & E1/2

PISCES

MINIFILL

15.0 Error Codes

In the unfortunate occasion that a fault should occur, the microprocessor will display a FLASHING error message on the LCD

display. The causes of these Error Codes, with suggested solutions are listed below; If more than one fault is present the

respective fault codes will flash inturn.

Error

Code Description of Error Possible Remedy ofError

E : A1 System Water Pressure below that of the

LOW PRESSURE ALARMsetting.

(Low Press Alarm RelayActivated)

E : A2 System Water Pressure above that of the

HIGH PRESSURE ALARMsetting.

(High Press Alarm RelayActivated)

E : L1 Volume of Water introduced into the

System has exceeded set volume.

(General Alarm RelayActivated)

This Error Code will Auto Reset when the System Water Pressure is

increased above the Low Water Pressure Setting {A1}. Check the following

items;

•

System has Water Leaks of a greater level than the unit can replenish.

•

Low Pressure Switch Setting {A1} is too close to Pump Cut-In Pressure

{P1}, adjust as necessary.

•

System Circulation Pump is incorrectly sited resulting in a negative

pressure being applied to the unit, either re-position System Pump, or

the Cold Fill connection position.

This Error Code will Auto Reset when the System Water Pressure is reduced

below the High Water Pressure Setting {A2}. Check the followingitems;

•

System Expansion Capacity is Insufficient. Check expansion vessel for

correct size, air pressure charge & possible ruptured bladder/diaphragm.

•

Cold Fill Pressure too High for the System Expansion Capacity, check

and adjust as per Section 10.0.

•

High Pressure Switch Setting {A2} is too close to Pump Cut-Out

Pressure {P2}, adjust as necessary.

This Error Code can only be reset by in the MAINTENACE Menu, refer to

Section 14. (Reset L2 or increase L1)

E : L3 Level of Water within Tank is too low, and

level switch has dropped open.

(General Alarm RelayActivated)

E : P1 The power drawn on Pump 1 is in excess

of limits.

(General Alarm RelayActivated)

E : P2 The power drawn on Pump 2 is in excess

of limits.

(General Alarm RelayActivated)

E : F1 Pump 1 has not increased the pressure

by a sufficient amount within the

designated period of time.

(General Alarm RelayActivated)

E : F2 Pump 2 has not increased the pressure

by a sufficient amount within the

designated period of time.

(General Alarm RelayActivated)

This Error Code will Auto Reset when the Water Level within the Water Tank

has risen above the level of the switch. Check the following items;

•

Mains Cold Water Supply is OFF, or insufficient to supply the required

amount of water, minimum required 12 Ltrs/min.

•

Ball Float Valve not operating or blocked. Clean, Repair, Replace as

needed.

•

Float Level Switch defective, check for loss electrical connection, and

‘Closed-Circuit’ when switch is in the UP position. Repair/replace as

needed.

Pressing the ENTER button will reset this fault, Pump 1 will operate again, if

the fault message re-occurs, check thefollowing;

•

Pump 1 Motor/Armature dry, jammed or seized. Check, vent, or replace

as needed.

Pressing the ENTER button will reset this fault, Pump 2 will operate again, if

the fault message re-occurs, check thefollowing;

•

Pump 2 Motor/Armature dry, jammed or seized. Check, vent, or replace

as needed.

Pressing the ENTER button will reset this fault, Pump 1 will operate again, if

the fault message re-occurs, check thefollowing;

•

Pump 1 Air Locked. Ensure pump is fully flooded

•

Pump 1 Motor/Armature jammed or seized. Check, replace as needed.

•

Pump 1 Motor Fault. Check across Pump electrical terminals L & Nfor

circuit (9.2 Ω at 20ºC)

•

Pump Failure Time (F2) is set too low. Check setting and resetto

Factory Default Or higher.

•

The transducer/brass connector has become blocked. Clear and reset .

Pressing the ENTER button will reset this fault, Pump 2 will operate again, if

the fault message re-occurs, check thefollowing;

•

Pump 2 Air Locked. Ensure pump is fully flooded

•

Pump 2 Motor/Armature jammed or seized. Check, replace as needed.

•

Pump 2 Motor Fault. Check across Pump electrical terminals L & Nfor

circuit (9.2 Ω at 20ºC)

•

Pump Failure Time (F2) is set too low. Check setting and resetto

Factory Default Or Higher.

•

The transducer/brass connector has become blocked. Clear and reset .

ELECTRONIC

E1/1 & E1/2

PISCES

MINIFILL

16.0

Internal Components – Single Pump Unit

15

Please Note:

The Pump Assembly (Item 2) is mounted onto a removable pump tray. To remove, disconnect all water joints,

remove the three M10 bolts, slightly lift the front of the pump tray and slide the tray forward, this will dis-

engage the three location posts at the top of the tray. The tray and pump assembly can then be removed from the

appliance.

Item

No

Description

Part

Number

Item

No

Description

Part

Number

1

Pressure Transducer

PM870001

6

Plastic Pipework Assembly

Including Isolation Valve

PM010034

2

Pump Assembly (complete)

PM010044

7

Control Panel

PM860003

3

Pump Inlet Isolation Valve

CP920011

8

Water Level Switch

PM840004

4

Outlet Drain Valve

PF920005

9

Water Tank

PM090008

5

Outlet Isolation Valve with

Flexible Connector

PF940005

10

Ball Float Valve

CP000001

10

9

8

7

6

3

2

5

2x M10

Bolts

4

1

Single Pump Unit

ig 16.1

16

ELECTRONIC

E1/1 & E1/2

PISCES

MINIFILL

16.1

Internal Components – Twin Pump Unit

Please Note:

The Pump Assembly (Item 2) is mounted onto a removable pump tray. To remove, disconnect all water joints,

remove the two M10 bolts, slightly lift the front of the pump tray and slide the tray forward, this will dis-engage the

three location posts at the top of the tray. The tray and pump assembly can then be removed from the appliance.

Item

No

Description

Part

Number

Item

No

Description

Part

Number

1

Pressure Transducer

PM870001

6

Plastic Pipework Assembly

Including Isolation Valve

PM010034

2

Pump Assembly (complete)

PM010044

7

Control Panel

PM860003

3

Pump Inlet Isolation Valve

CP920011

8

Water Level Switch

PM840004

4

Outlet Drain Valve

PF920005

9

Water Tank

PM090008

5

Outlet Isolation Valve with

Flexible Connector

PF940005

10

Ball Float Valve

CP000001

10

9

8

7

6

3

2

5

2x M10

Bolts

4

1

Twin Pump Unit

ig 16.1

ELECTRONIC

E1/1 & E1/2

PISCES

MINIFILL

17

17.0 Commissioning Form

The commissioning engineer should complete this section on the day of Setting Up theappliance;

so that a record is kept of the settings made for futurereference.

RESULTS SETTING

System Static Height metres

Cold Fill Pressure bar

System Vessel Size litres

System Vessel AirCharge bar

Maximum System Operating Temperature ºC

System Safety Valve Setting bar

Final Working Pressure of System (Hot) bar

High Pressure Alarm SwitchSetting bar

Low Pressure Alarm SwitchSetting bar

High Pressure Fault Test Yes/No

Low Pressure Fault Test Yes /No

Hour Run Meter Reading Hours

3 Juniper West, Fenton Way, Basildon, Essex, SS15 6SJ. Tel: 01268 546700. Fax: 01268888250

This publication is issued subject to alteration or withdrawal without notice. The illustrations and specifications are not binding in detail.All

offers and sales are subject to the Company’s current terms and condition of sale. 05/01/16

Comments:

ENGINEER: COMPANY:

DATE: SERIAL NO:

This manual suits for next models

1

Table of contents

Other elco Controllers manuals

Popular Controllers manuals by other brands

Grundfos

Grundfos VGA-113 Installation and operating instructions

Simply Automated

Simply Automated Pre-Configured SimplySmart Series Getting started

Festo

Festo LRP-1/4 Series operating instructions

ZIGBEE

ZIGBEE YPHIX 50208701 installation manual

Honeywell

Honeywell N20010 manual

C.E. Nierhoff & Co

C.E. Nierhoff & Co C726 troubleshooting guide

Elan

Elan S6 Specifications

Carrier

Carrier SYSTEM PILOT 33PILOT-01 owner's manual

Victron energy

Victron energy BlueSolar MPPT 150/70-Tr manual

Eurotherm

Eurotherm Invensys 3216 user manual

Champion Irrigation Products

Champion Irrigation Products WATER CHAMP R-120 operating instructions

JUMO

JUMO diraTRON Series Interface description