Elcometer 4340 User manual

English

Elcometer 4340

Motorised Film Applicator

Operating Instructions

4340_TMA_0319_00_06.fm Page -1 Thursday, January 21, 2010 10:15 AM

R

English

This product meets the Electromagnetic Directive, Low Voltage

Directive and the Machinery Directive.

The product is Class A, Group 1 ISM equipment according to CISPR 11

Group 1 ISM product: A product in which there is intentionally generated and/

or used conductively coupled radio-frequency energy which is necessary for

the internal functioning of the equipment itself.

Class A product are suitable for use in all establishments other than domestic

and those directly connected to a low voltage power supply network which

supplies buildings used for domestic purposes.

is a registered trademark of Elcometer Limited.

All other trademarks acknowledged.

© Copyright Elcometer Limited. 2010.

All rights reserved. No part of this Document may be reproduced, transmitted,

transcribed, stored (in a retrieval system or otherwise) or translated into any

language, in any form or by any means (electronic, mechanical, magnetic,

optical, manual or otherwise) without the prior written permission of

Elcometer Limited.

A copy of this Instruction Manual is available for download on our Website via

www.elcometer.com.

Doc.No. TMA-0319 Issue 06

Text with Cover No: 19335

R

4340_TMA_0319_00_06.fm Page 0 Thursday, January 21, 2010 10:15 AM

1

R

CONTENTS

Section Page

1 About your applicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Getting started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 The parts of your applicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Power input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 The control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4 Product overflow tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5 Caution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.6 Setting the carriage start and stop positions . . . . . . . . . . . . . . . . . . . . . . 8

2.7 Fitting attachments to the carriage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Mounting the substrate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1 Mounting using the spring clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 Mounting using vacuum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4 Using film applicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Using spiral bar coaters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6 Producing a specimen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.1 Before you start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.3 After application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7 Heated tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7.1 Water heated table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7.2 Electrically heated table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

9 Technical specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

10 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

11 Related equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4340_TMA_0319_00_06.fm Page 1 Thursday, January 21, 2010 10:15 AM

2

R

hank you for purchasing this Elcometer Motorised Film Applicator.

Welcome to Elcometer.

Elcometer are world leaders in the design, manufacture and supply of

inspection equipment for coatings and concrete.Our products cover all aspects

of coating inspection, from development through application to post application

inspection.

The Elcometer Motorised Film Applicator, is a world beating product. With the

purchase of this product you now have access to the worldwide service and

support network of Elcometer. For more information visit our website at

www.elcometer.com

1 ABOUT YOUR APPLICATOR

The Elcometer Motorised Film Applicator is a robust, reliable and extremely

flexible machine. The machine is used to prepare a wide variety of product

samples including paint, varnish, cosmetics, glue, etc., on various substrates

such as contrast charts, sheet steel, plastic foils and glass.

The Motorised Film Applicator is designed for use with spiral bar coaters and

film applicators (depending upon attachments specified at time of ordering).

The substrate is held securely in place on the table of the machine by clamp or

vacuumaand the machine spreads the product in a consistent and reproducible

film across the surface.

1.1 These instructions

These instructions describe the operation of the following Elcometer Motorised

Film Applicators:

Model No. Vacuum table type Table heating

Elcometer 4340/10- non-vacuum none

Elcometer 4340/11- non-vacuum external water bathb

Elcometer 4340/12- non-vacuum internal electric element

Elcometer 4340/100 perforated none

Elcometer 4340/101 single channel none

Elcometer 4340/102 double channel none

Elcometer 4340/110 perforated external water bathb

a. Substrate securing method depends upon model.

b. Supplied ready to be fitted with a temperature bath. Temperature bath not included.

T

4340_TMA_0319_00_06.fm Page 2 Thursday, January 21, 2010 10:15 AM

3

R

Elcometer 4340/111 single channel external water bathb

Elcometer 4340/112 double channel external water bathb

Elcometer 4340/120 perforated internal electric element

Elcometer 4340/121 single channel internal electric element

Elcometer 4340/122 double channel internal electric element

1.2 Standards

The Elcometer Motorised Film Applicator can be used in accordance with the

following standard, ASTM D 823-C.

1.3 What the box contains

• Elcometer Motorised Film Applicator

• Substrate securing clip on table

• Bubble spirit level

• Operating instructions

Your Motorised Film Applicator may be supplied with additional attachments,

depending upon which options were specified at the time of ordering:

• Film applicator attachment (with weight and hexagonal wrench)

• Spiral bar coater attachment (with weight x 2, hexagonal wrench, rubber

mat x 2, and zero bar)

• Film applicator and spiral bar coater attachment (with weight x 3, hexagonal

wrench, rubber mat x 2 and zero bar)

The Elcometer Motorised Film Applicator is packed in a cardboard and foam

package. Please ensure that this packaging is disposed of in an

environmentally sensitive manner. Consult your local Environmental Authority

for further guidance.

To maximise the benefits of your new Elcometer Motorised Film

Applicator please take some time to read these Operating Instructions. Do

not hesitate to contact Elcometer or your Elcometer supplier if you have

any questions.

4340_TMA_0319_00_06.fm Page 3 Thursday, January 21, 2010 10:15 AM

4

R

2 GETTING STARTED

This section of the instructions is intended for first-time users of the Motorised

Film Applicator. It contains information on the parts and controls of your

Applicator and advice on safe use of the equipment. When you have finished

reading this section you will be ready to start using the Applicator.

2.1 The parts of your applicator

Figure 1. Parts of the Applicator

(this model fitted with spiral bar coater attachment)

2.2 Power input

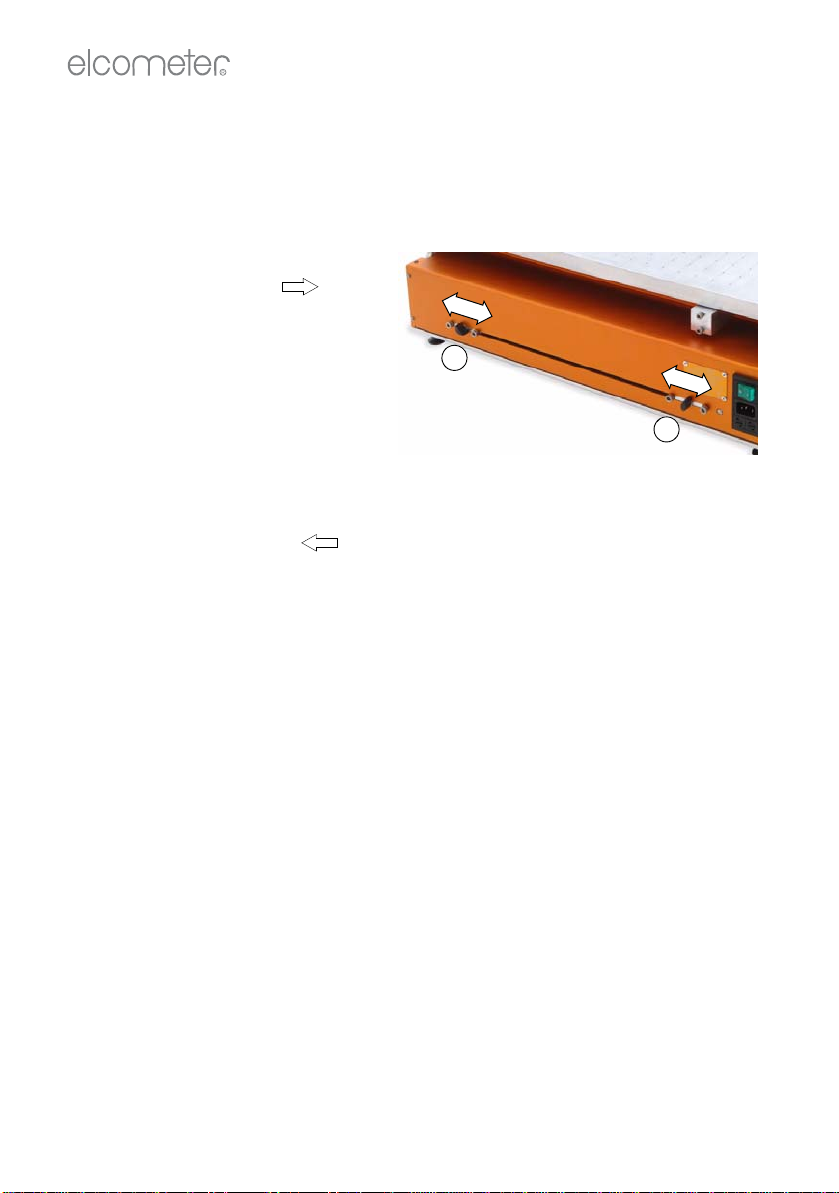

The power input socket at the rear of the Applicator (Figure 2) is protected by

two fuses - see “Technical specification” on page 19 for fuse rating.

Figure 2. Power input socket, main on/off switch and fuse holder

Table

Controls

Carriage Substrate

4340_TMA_0319_00_06.fm Page 4 Thursday, January 21, 2010 10:15 AM

5

R

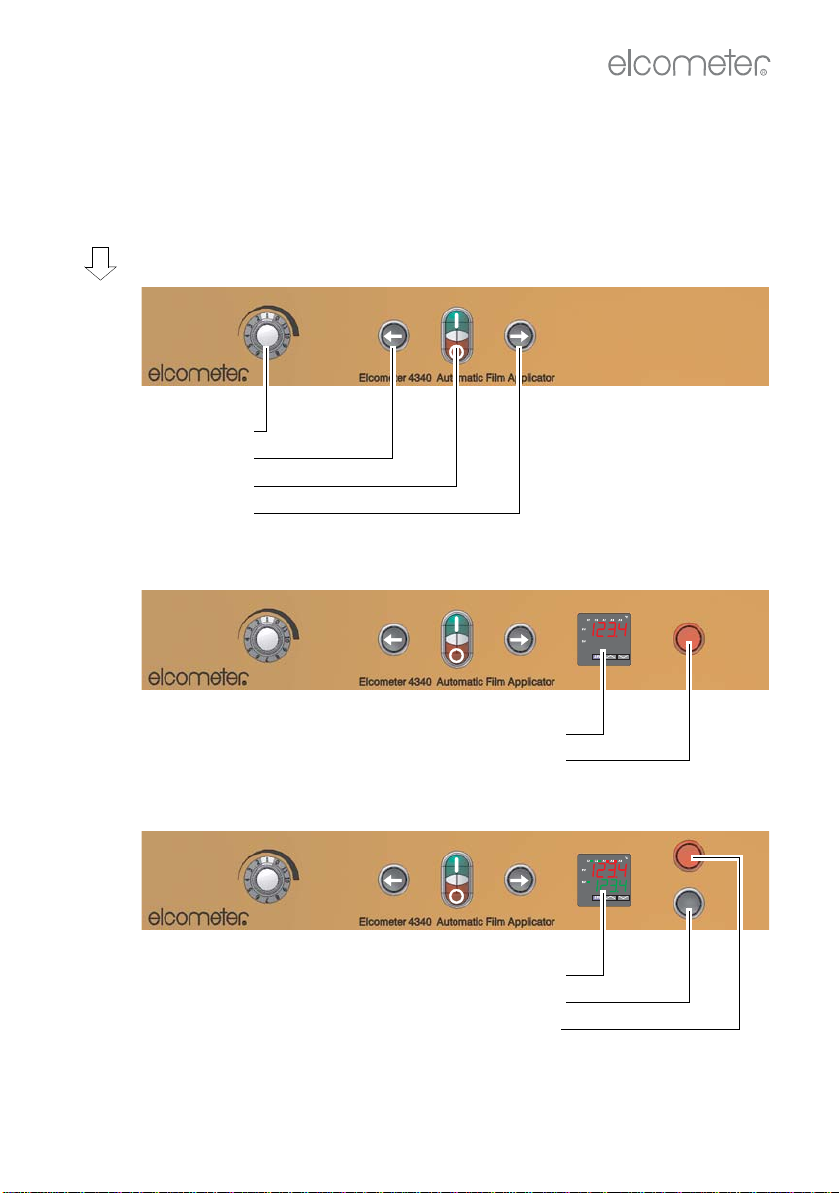

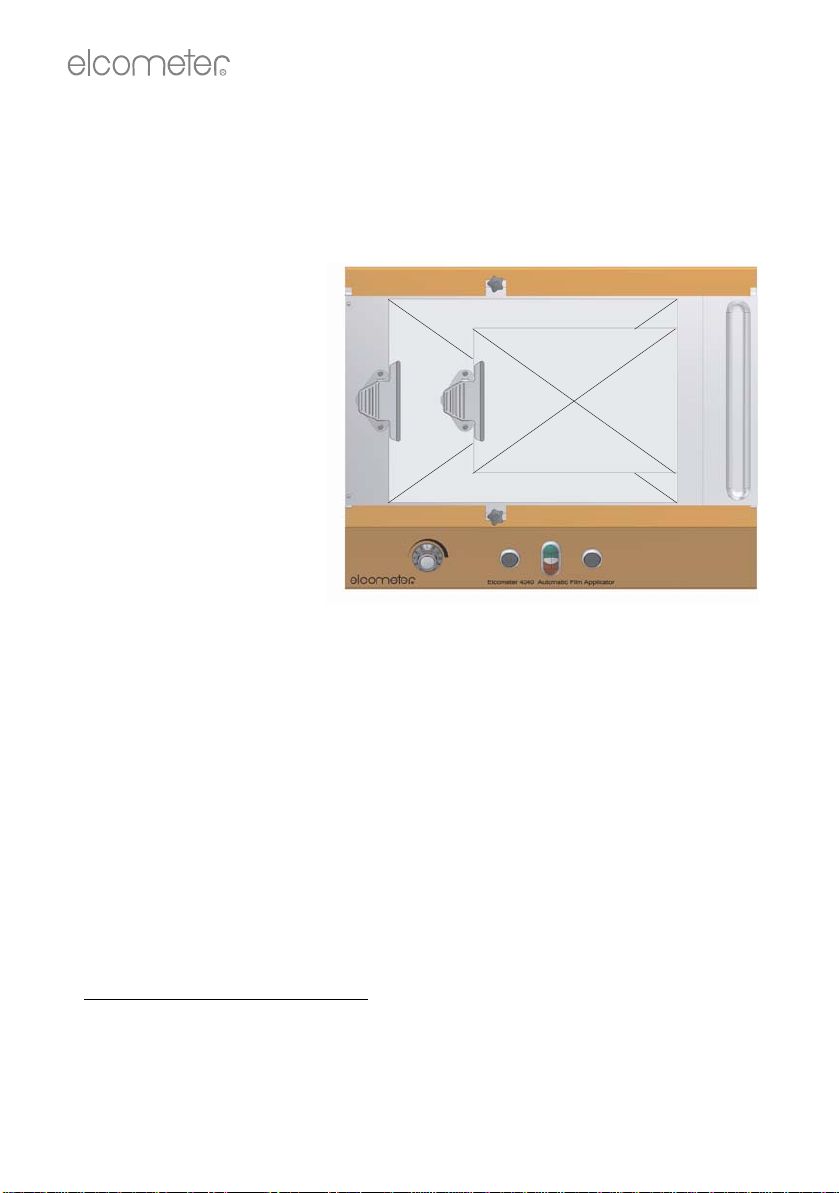

2.3 The control panel

The Applicator is operated using the controls mounted on the front panel of the

machine. The controls fitted to your Applicator depend upon model number:

Figure 3. Control panels - all models

10-

100

101

102

Carriage speed

Carriage return

Power on/off

Carriage start

Model

Number

11-

110

111

112

Temperature display

Hot surface warning lamp

12-

120

121

122

Temperature control/display

Electrically heated table on/off

Hot surface warning lamp

4340_TMA_0319_00_06.fm Page 5 Thursday, January 21, 2010 10:15 AM

6

R

2.3.1 Power on/off

To switch on the Applicator, ensure the main power on/off switch at the rear of

the Applicator is in the ‘on’ position and then press the green button on the

control panel. The indicator light in the centre of the button will illuminate.

To switch the Applicator off, press the red button on the control panel.

2.3.2 Carriage start and return

To start the carriage, press carriage start . The carriage will stop when it

reaches the stop position.

To return the carriage to the start, press carriage return . The carriage will

stop when it reaches the start position.

To stop the carriage movement at any time, press the red button on the control

panel.

The start and stoppositions can be adjusted-see“Settingthecarriagestart and

stop positions” on page 8.

2.3.3 Setting the carriage speed

Carriage speed is adjustable; there are 11 preset speeds which are selected by

rotating the carriage speed selector knob.

Note: Do not adjust the carriage speed while the carriage is moving.

Carriage speed

selector position Carriage speed

(mm per second)

15

210

320

430

540

650

760

870

980

10 90

11 100

4340_TMA_0319_00_06.fm Page 6 Thursday, January 21, 2010 10:15 AM

7

R

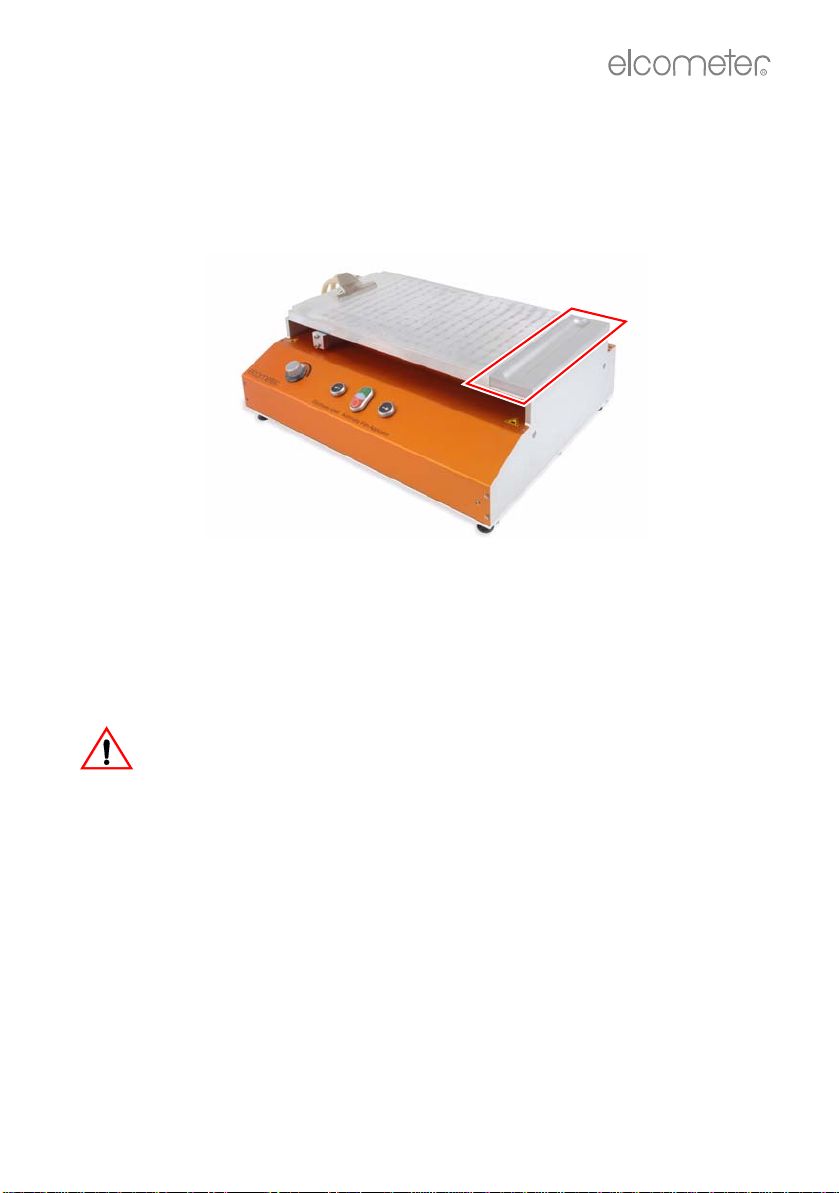

2.4 Product overflow tray

(These instructions apply only to models fitted with a vacuum table)

The product overflow tray acts as a small reservoir to catch waste product which

is pushed off the end of the table by the applicator. The tray can be removed to

allow waste product to be cleaned off.

Figure 4. Product overflow tray

2.5 Caution

The Elcometer Motorised Film Applicator has been manufactured with your

safety in mind. However, improper use can result in damage to the Applicator.

Please observe the precautions discussed in these operating instructions.

To reduce the risk of electric shock do not open the housing of the

Applicator. There are no user-serviceable parts inside.

To reduce the risk of fire or electric shock, do not expose the Applicator to rain

or excess moisture.

The mains plug on your Applicator may be fitted with a fuse. When replacing

this fuse, ensure a fuse of the correct rating is used.

4340_TMA_0319_00_06.fm Page 7 Thursday, January 21, 2010 10:15 AM

8

R

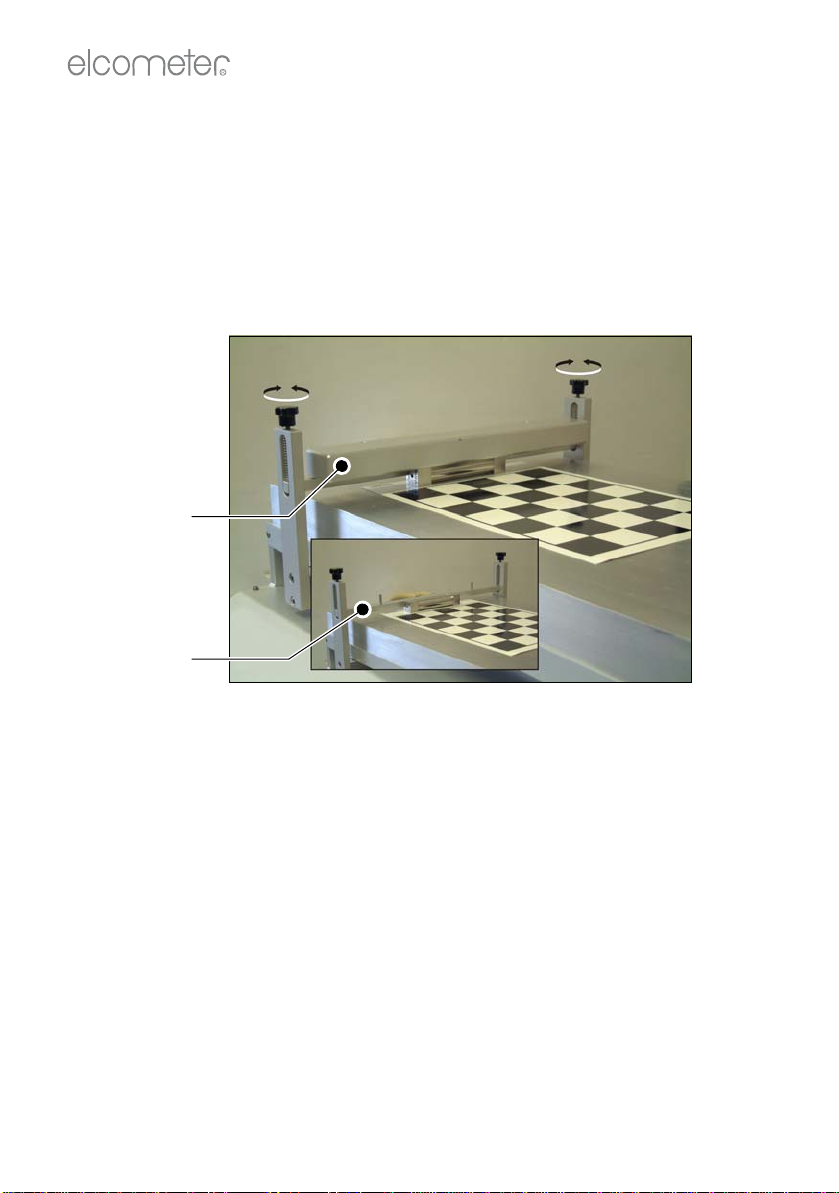

2.6 Setting the carriage start and stop positions

Set the start and stop positions of the carriage to adjust the distance the

carriage travels during operation.

To adjust start position

1. Switch machine on.

2. Press carriage start . The

carriage will stop automatically

when it reaches the stop

position.

3. Unscrew knob (2), (Figure 5).

4. Slide knurled knob to new

position and tighten.

To adjust stop position

1. Switch machine on.

2. Press carriage return . The carriage will stop automatically when it

reaches the start position.

3. Unscrew knob (1), (Figure 5).

4. Slide knurled knob to new position and tighten.

Figure 5. Rear of machine showing

carriage start and stop adjustments

1

2

4340_TMA_0319_00_06.fm Page 8 Thursday, January 21, 2010 10:15 AM

9

R

2.7 Fitting attachments to the carriage

Any additional attachments which may have been ordered with your Motorised

Film Applicator are supplied loose and must be fittedto the carriage before use.

Three attachments are available: Film Applicator, Spiral Bar Coater and

Combined Film Applicator/Spiral Bar Coater - See “Accessories” on page 20.

All the attachments are fitted to

the carriage in an identical

manner using the four screws

shown (A).

To fit an attachment:

• Using the hexagonal wrench

supplied with the attachment,

loosen and remove the four

screws.

• Place the attachment onto the

carriage, align the mounting

holes, refit the four screws and

then tighten.

The illustration shows the Spiral

Bar Coater attachment fitted to the

carriage and secured by the

screws (A). The Film Applicator is

fitted to the carriage using the

same procedure.

Note: The table fitted to your Motorised Film Applicator may be different to the

table shown in the images above, but the attachments are fitted to the carriage

in the same way.

A

A

A

4340_TMA_0319_00_06.fm Page 9 Thursday, January 21, 2010 10:15 AM

10

R

3 MOUNTING THE SUBSTRATE

To ensure an even application of the product film, the substrate must be

mounted carefully on the table.

3.1 Mounting using the spring clamp

1. There are two

mounting positions for

the clamp. Screw the

clamp onto the table in

the position which suits

the dimensions of the

substrate (Figure 6).

2. Clean the surface of

the table and the

underside of the

substratec.

3. Position the substrate

on the table and clamp

in place; A3 size

substrate occupies

virtually all of the table,

A4 size substrate

should be positioned

on the right side of the

table as shown (Figure 6).

3.2 Mounting using vacuum

These instructions apply to models fitted with a perforated vacuum table. A

channelled vacuum table only works with A3-size substrates.

1. Clean the surface of the table and the underside of the substrate.

c. When using a spiral bar coater to apply the product film, place the soft rubber mat supplied

with your applicator between the table and the substrate. Use of the rubber mat raises the

substrate sufficiently to ensure it comes into contact with the spiral bar coater. Ensure both

sides of the rubber mat are clean before use.

A3

A4

Figure 6. Clamp and substrate positioning

4340_TMA_0319_00_06.fm Page 10 Thursday, January 21, 2010 10:15 AM

11

R

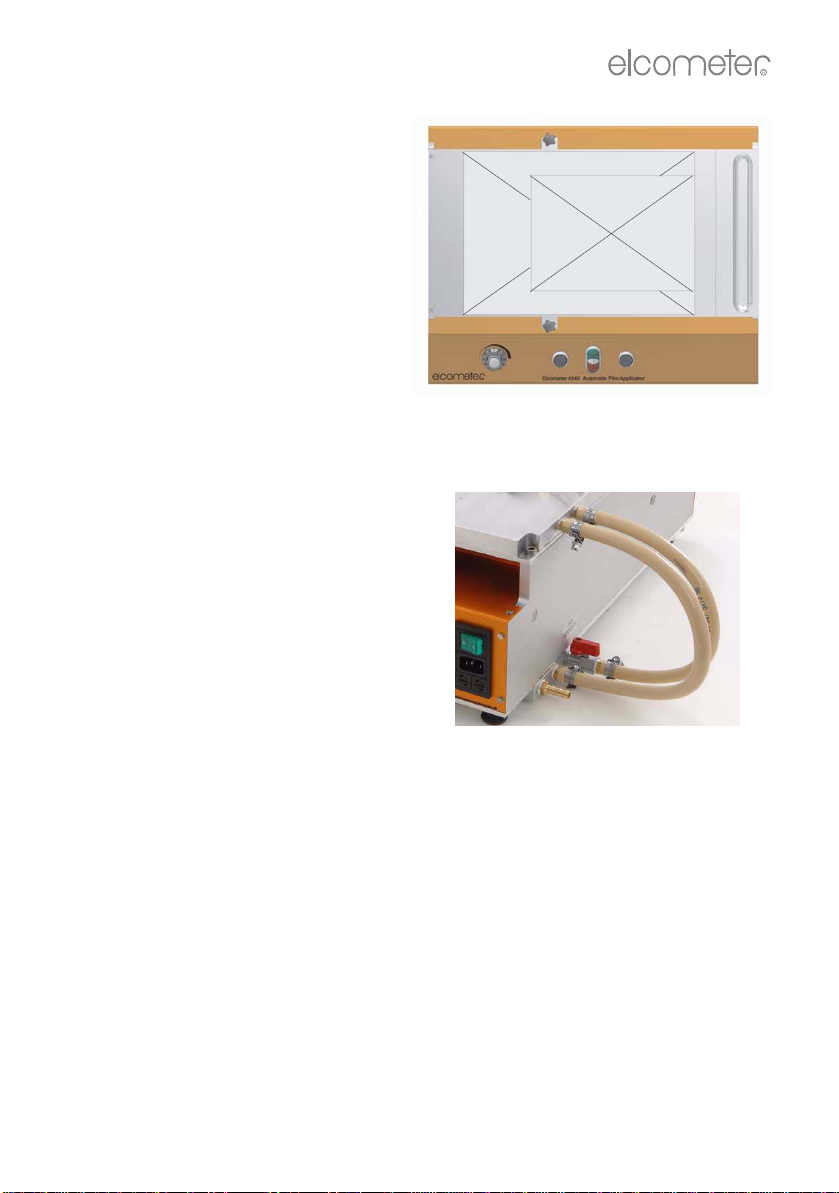

2. Position the substrate on the

table; A3 size substrate

occupies virtually all of the

table, A4 size substrate should

be positioned on the right side

of the table as shown (Figure

7).

3. Attach the vacuum pump (see

“Accessories” on page 20)

using the hose to the

connection on the left hand

side of the machine (Figure 8).

4. If the specimen size is A3, turn

the vacuum control marked ‘A3

ON/OFF’ to the ‘on’ position

(in-line with the hose), as

shown in Figure 8.

If the specimen size is A4, turn

the vacuum control marked ‘A3

ON/OFF’ to the ‘off’ position (at

right angles to the hose).

5. Switch on the vacuum pump.

The substrate will then be drawn onto the table and held firmly.

6. Mask off areas of the table not covered by the specimen. Use ‘Scotch Tape’

or a similar removable thin tape. This prevents product getting into the

vacuum table or into the gap between the end of the table and the product

overflow tray.

Note: The single channel and double channel vacuum tables are used for thin

substrate materials such as paper (single channel) and foils (double channel)

A3

A4

Figure 7. Substrate positioning on

vacuum table

Figure 8. Vacuum pump connection

and control valve

4340_TMA_0319_00_06.fm Page 11 Thursday, January 21, 2010 10:15 AM

12

R

4 USING FILM APPLICATORS

4.1 Film applicators with a film applicator carriage

1. Mount substrate on table (see “Mounting the substrate” on page 10).

2. Place film applicator on substrate until it is touching the pushing bar.

3. Check to ensure the top surface of the pushing bar is below the top of the

film applicator tool. If adjustment of the height of the pushing bar is

required, rotate the knobs (Figure 9) an equal amount.

Figure 9. Standard carriage

Rotate knobs to adjust height of pushing bar

4. When using a light applicator such as the Baker, place the weight onto the

two locating pegs. The weight rests on top of the film applicator and holds it

firmly in contact with the substrate.

The film applicator is now mounted correctly and is ready for application of the

product film.

Pushing bar

Weight

4340_TMA_0319_00_06.fm Page 12 Thursday, January 21, 2010 10:15 AM

13

R

4.2 Film applicators with a spiral bar coater carriage

1. Rotate carriage to raised position.

2. Fit applicator pushing bar into position

and tighten knurled screws (Figure

10).

3. Mount substrate on table (see

“Mounting the substrate” on page 10).

4. Place applicator onto substrate in front

of pushing bar (Figure 11).

5. Check that the top surface of the

pushing bar is below the top surface of

the applicator. Adjust the height of the

pushing bar if necessary.

6. When using a light applicator such as

the Baker, place the weight onto the

two locating pegs. The weight rests on

top of the film applicator and holds it

firmly in contact with the substrate

(Figure 12).

Your film applicator is now mounted

correctly and is ready for application of the

product film.

Figure 10. Applicator

pushing bar

Figure 11. Applicator in

position on substrate

Figure 12. Weight pressing

down on applicator

4340_TMA_0319_00_06.fm Page 13 Thursday, January 21, 2010 10:15 AM

14

R

5 USING SPIRAL BAR COATERS

Spiral bar coaters can only be used on Motorised Film Applicators fitted with a

bar coater carriage. The rubber mat must be placed on the table when using a

spiral bar coater.

1. Rotate carriage to raised position.

2. Remove weights.

3. Open clamps.

4. Fit spiral bar coater.

5. Close clamps.

6. Refit weights.

7. Clean the surface of the table and the rubber mat.

8. Position the rubber mat on the table and secure using the clamp.

Note: The rubber mat must be positioned accurately along the centre line of the

table. Ensure that the carriage does not touch the rubber mat during its travel.

9. Rotate carriage to lower position.

Check to ensure the spiral bar coater

is touching the surface of the rubber

mat. To adjust the height of the spiral

bar coater, rotate the two screws (1) at

the rear of the carriage (Figure 13).

10.Clean the underside of the substrate,

position the substrate on the rubber

mat and secure using the clamp.

Note: Never start the carriage without a

substrate in place on the rubber mat.

Friction between the rubber and the bar/

spiral bar coater will cause the carriage to

become jammed.

1

Figure 13. Bar height

adjustment screw

Figure 14. Bar coater carriage

with spiral bar coater

4340_TMA_0319_00_06.fm Page 14 Thursday, January 21, 2010 10:15 AM

15

R

6 PRODUCING A SPECIMEN

6.1 Before you start

•Ensure the Applicator table is level.

Place the supplied bubble level on the table and adjust the feet of the

Applicator until the table is level.

•Select carriage speed.

See “Setting the carriage speed” on page 6.

•Set carriage travel distance.

See “Setting the carriage start and stop positions” on page 8.

•Mount the substrate.

See “Mounting using vacuum” on page 10.

•Mount the applicator tool.

See “Using film applicators” on page 12 and “Using spiral bar coaters” on

page 14.

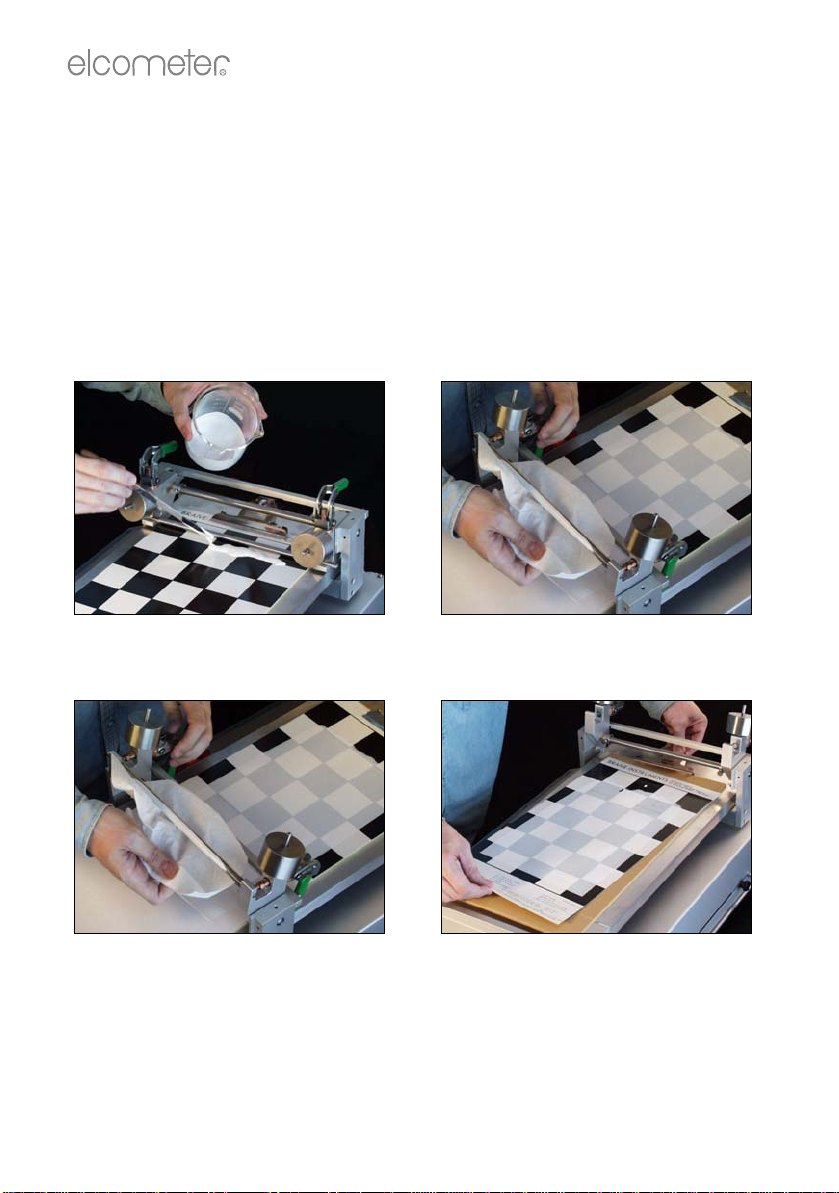

6.2 Procedure

See Figure 15.

1. Apply the product

Pour the product onto the substrate in front of the applicator tool. Use a

brush or similar tool to spread out the product across the width of the

substrate.

2. Start the carriage

Press the green button to switch on the Applicator. Press carriage start

. The carriage will travel across the substrate and will stop

automatically when it reaches the stop position.

3. Clean the applicator tool

If using a spiral bar coater, rotate the carriage to its raised position and

immediately wipe away any excess product to prevent product dripping on

the substrate.

If using a film applicator, lift the film applicator from the substrate and wipe

away any excess product to prevent product dripping on the substrate.

4. Return carriage

Press carriage return . The carriage will return to the start position.

Press the red button to switch off the Applicator.

4340_TMA_0319_00_06.fm Page 15 Thursday, January 21, 2010 10:15 AM

16

R

5. Remove substrate

Switch off the vacuum pump (vacuum table models only) and remove the

substrate from the table.

6.3 After application

1. If your Applicator is fitted with a product overflow tray, lift the tray off the

machine, remove all product residue and refit.

2. Clean all splashes of product off the machine.

3. Clean your applicator tool very thoroughly.

Figure 15. Film application procedure (using spiral bar coater)

Apply the product Start the carriage

Clean the applicator tool Remove the substrate

4340_TMA_0319_00_06.fm Page 16 Thursday, January 21, 2010 10:15 AM

17

R

7 HEATED TABLES

Some Elcometer Motorised Film Applicator models are fitted with vacuum and

non-vacuum heated tables. Heating is either by an external water bath or

internal electrical elements.

Take care when using a heated table. The temperature of the table can

reach 200°C and can cause serious burns.

The outlet pipe of the vacuum pump must be located in a safe place to

avoid burns caused by the waste hot air.

The vacuum pump must be compatible with operation at temperatures

up to 100°C or 200°C (depending upon model). It is advisable to switch

the pump on when the equipment is ready for applying the coating on the

substrate and to switch the pump off immediately after the coating

application. Extended use of the pump at high temperature can cause

grease in bearings to dissolve and pipes to soften.

When using a rubber mat with a heated table, do not allow the

temperature of the table to exceed +50°C. Temperatures in excess of

+50°C can cause the rubber to degrade.

Always bear in mind that the low thermal conductivity of the rubber material will

tend to insulate the substrate from the heat of the table. A temperature probe

placed on the top surface of the rubber mat will provide a more accurate

measure of temperature than the temperature display on the front panel of the

instrument (contact Elcometer or your Elcometer supplier for details of our wide

range of digital thermometers).

7.1 Water heated table

Elcometer models 4340/11-, 110, 111 & 112 include a table designed to be

heated by water (maximum temperature 100°C).

These models have a temperature display mounted on the front panel. This

display does not control the temperature of the table, it only displays the

temperature. The buttons and controls on the temperature display have no

function.

A red indicator will illuminate (when the Applicator is switched on) when

the table is above 50°C.

Do not touch the table when the red indicator is illuminated.

Control of the temperature of the hot water must be provided by an external

water heating system (not supplied with the instrument).

4340_TMA_0319_00_06.fm Page 17 Thursday, January 21, 2010 10:15 AM

18

R

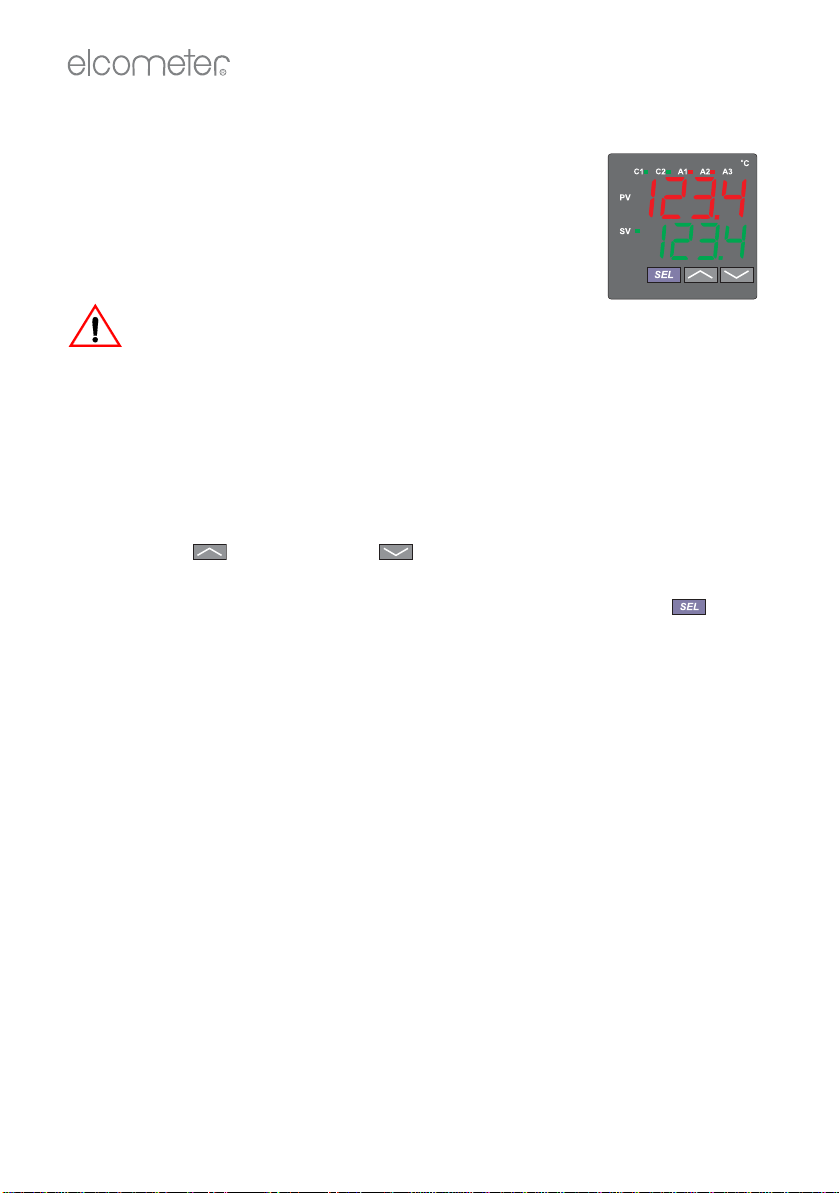

7.2 Electrically heated table

Elcometer models 4340/12-, 120, 121 & 122 include a table

heated by electricity (maximum temperature 100°C or

200°C).

This model has a temperature display/controller mounted on

the front panel.

A red indicator will illuminate (when the Applicator is

switched on) when the table is above 50°C.

Do not touch the table when the red indicator is illuminated.

Operation

1. To switch on the Applicator, press the green start button and the heat switch

located below the hot surface temperature indicator.

2. The temperature display will show the current temperature of the table (PV).

3. To adjust the temperature of the table:

• Use the (increase) and (decrease) buttons to adjust the set-

point temperature (SV).

• When the desired set-point temperature is displayed press . The

temperature PV will increase up to SV.

4. Place the substrate on the table and leave the Applicator and the substrate

to reach the set temperature:

At 50°C: allow 20 minutes

At 100°C: allow 60 minutes

At 200°C: allow 90 minutes

The film applicator must also be heated to the correct temperature. This

can be done in an oven or by placing the applicator on the table and leaving

it long enough to heat through completely.

Note: The temperature of the table will always be slightly lower than the set

point shown on the temperature controller. This is due to heat loss from the

surface of the table. For accurate temperature measurement it is advisable to

use a digital thermometer with a probe to measure the temperature of the

surface directly.

Note: Take care and observe the following limitations when using a rubber mat

on a heated table; the rubber has a maximum working temperature of 50°C and

it will provide an effective layer of insulation between the specimen and the

heated table.

4340_TMA_0319_00_06.fm Page 18 Thursday, January 21, 2010 10:15 AM

Other manuals for 4340

1

Table of contents

Other Elcometer Industrial Equipment manuals