Elcon SA10A User manual

www.elcon.se

2018-03-21

Rev 1

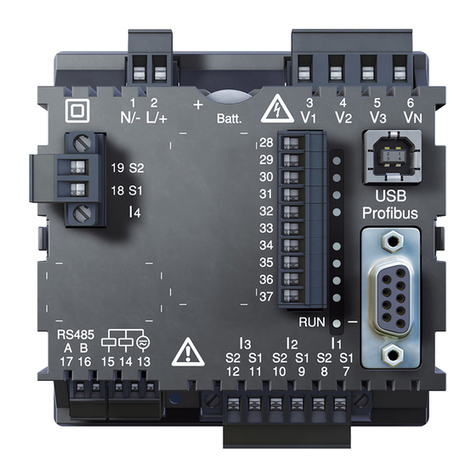

SWITCH ANALYZER SA10A

USER MANUAL

Page 2 (40)

Rev 1 2018-03-21 www.elcon.se

Go to INDEX.

INDEX.

INDEX. ........................................................................................................................................... 2

1 General description. .................................................................................................................... 4

2 Safety regulations Important!.............................................................................................. 5

2.1 General safety regulations......................................................................................................................................5

2.2 Connection of SA10A to mains power.....................................................................................................................7

3.0 Connections.............................................................................................................................. 7

3.1 Connections for time measurement. ......................................................................................................................7

3.1.1 Safety regulations. ..................................................................................................................................................7

3.1.2 Principals for connections to SA10A. ......................................................................................................................7

3.1.3 Connections for one breaking unit per phase.........................................................................................................7

3.1.4 Connections for two or more breaking units per phase. ........................................................................................8

3.1.5 Connection for a breaking unit with a pre-insertion resistor..................................................................................8

3.2 Connections for a resistance measurement of a breaking unit. ..............................................................................9

3.2.1 Safety regulations. ..................................................................................................................................................9

3.2.2 Connection. .............................................................................................................................................................9

3.3 Connections for resistance measurement of a pre-insertion resistor....................................................................10

3.3.1 Safety regulations. ................................................................................................................................................10

3.3.2 Principal of measurement.....................................................................................................................................10

3.3.3 Connection. ...........................................................................................................................................................10

3.4 Connection of the breaker operating mechanism. ................................................................................................11

3.4.1 Safety regulations. ................................................................................................................................................11

3.4.2 Connection of operating coils. ..............................................................................................................................11

3.4.3 Connection of motor.............................................................................................................................................11

3.5 Connection of transducers. ...................................................................................................................................12

3.6 Connection to windows PC ...................................................................................................................................12

4 Using SA10A stand alone ........................................................................................................... 13

4.1 Before operation Important! ........................................................................................................................13

4.2 Standalone operation of SA10A ............................................................................................................................ 13

5 Technical Specification............................................................................................................... 15

6 Maintenance. ............................................................................................................................ 18

6.1 Before use. ........................................................................................................................................................... 18

6.2 After use............................................................................................................................................................... 18

Page 3 (40)

Rev 1 2018-03-21 www.elcon.se

Go to INDEX.

6.3 Storing the SA10A................................................................................................................................................. 18

6.4 Every year or when necessary. .............................................................................................................................18

6.5 Battery Fuse .........................................................................................................................................................19

6.7 Upgrading SA10A internal software......................................................................................................................20

6.8 SA10A PROGRAM LOADER in display....................................................................................................................21

7 Adjustments. ............................................................................................................................. 22

7.1 General.................................................................................................................................................................22

7.1.1 Instrument needed. ..............................................................................................................................................22

7.2 Calibration and functional test. ............................................................................................................................23

7.2.1 Check voltage measurement inputs Uc, Uk, Ul, Um. .........................................................................................23

7.2.2 Check current measurement inputs Ic, Im...........................................................................................................24

7.2.3 Check transducer inputs T1, T2, T3.....................................................................................................................25

7.2.4 Check resistance measuring inputs Ur, Ir..............................................................................................................26

7.2.5 Grounding. ............................................................................................................................................................27

7.2.6 Check main contact inputs. 1A,1B,1C,1D,2A,2B,2C,2D,3A,3B,3C,3D. .........................................................27

7.2.7 Check auxiliary contact inputs. 1a, 1b, 2a, 2b, 3a, 3b. .......................................................................................27

7.3 Recalibration procedure. ......................................................................................................................................28

7.3.2 Calibration wizard for current measurement inputs Ic, Im..................................................................................31

7.3.3 Calibration wizard for analogue transducer inputs T1, T2, T3............................................................................33

7.3.4 Calibration of resistance measurement input Ur.................................................................................................35

7.3.5 Calibration of resistance measurement input Ir...................................................................................................37

7.3.6 Enter Password. ....................................................................................................................................................38

8 Transportation/SCRAPPING/Recycling. ...................................................................................... 39

9 SA10A Accessories. .................................................................................................................... 39

10 CE-declaration. ........................................................................................................................ 40

Page 4 (40)

Rev 1 2018-03-21 www.elcon.se

Go to INDEX.

1 GENERAL DESCRIPTION.

The is a portable instrument, especially designed to analyze Circuit Breakers in the field.

Even though is intended for use together with a computer, it can be used stand-alone for some simpler

measurements. To be handy in field works, the is built into a small and robust metal carry case. On the cover

section of the carry case, a notebook computer can be placed while testing.

The measurements that can be made without a Windows computer are: voltage and current for both motor and coils,

time for three independent contacts in, open, close and close-open operations and static resistance of main contacts.

Contact time measurements.

There are three groups, each of four main and two auxiliary contact indication inputs. Main contact max output 30 mA

during operations and can also indicate pre-insertion resistors simultaneously. Auxiliary contact inputs can handle both

free and live contacts. All contact inputs are of type semi protected banana-jacks and are protected against faulty

connections and high voltage discharges.

Travel transducers.

Up to three, digital or analogue, travel transducers, in any combination, can be used for simultaneous measurements.

Resistance measurement.

Main contact resistance measuring can directly be done with an internal 200 Amp current generator. Both static and

dynamic measuring is possible. Pre-insertion resistor resistance can be measured with use of a reference resistance

Operating coil control.

With an external power supply connected through this section the operating coils can be fully controlled. The current flow

through the coils and the supply voltage are measured.

Motor monitoring.

In the Auxiliary section there is provisions to monitor current and voltage from an external motor supply.

Internal sampling.

Sampling frequency for analogue and digital functions can be programmed for frequencies up to 50 kHz. Note! The PC-

software sets the sampling frequency.

Power supply

The SA10A must powered with an external AC- or DC- power supply.

Environmental

SA10A is built in a small metal carry case designed for rough handling in tough outdoor environments. All connections are

protected for any possible type of electrical discharges and disturbances. Some of the inputs are even protected against

faulty connections up to 300V peak.

PC-Computer

In most cases a standard windows notebook computer can be used but for tougher environments an outdoor type is

recommended. For recommended minimum requirements for the notebook computer. See BTS11 User manual

PC-software

See separate manual BTS11 User manual for more information.

Page 5 (40)

Rev 1 2018-03-21 www.elcon.se

Go to INDEX.

2 SAFETY REGULATIONS

IMPORTANT!

This instrument shall only be used by authorized and educated personnel.

It is the operator’s responsibility to read and follow all operating and safety instructions for connecting and using this

instrument. Always keep the below safety instructions in mind when using the instrument.

2.1 GENERAL SAFETY REGULATIONS.

•Local safety regulations.

Always follow local safety regulations for work on high-voltage circuit breakers.

•Ground connection.

Always connect the separate ground terminal (green/yellow) on SA10A to protective ground before any other

connections.

The SA10A unit can only be used in electrical system with a single ground.

If there is a High voltage ground and Low voltage ground make sure that there is no potential voltages difference

between these grounds. If a voltages difference exists between grounds, consult local safety regulations.

Check that the separate protective ground wire is in good condition before connection.

Make sure that the power socket for mains is a grounded outlet and that the power cable is in good condition before

connected the main power to the control unit SA10A.

•Connections.

Before connecting the SA10A to a high-voltage circuit breaker, make sure that the breaker poles are in position CLOSE,

and disconnected from the power line at both sides. The breaker must also be grounded on at least one side.

Follow local safety regulations for work on high-voltage circuit breakers.

To avoid unintentional breaker operation!

Never do any work on a circuit breaker unless the control circuits of the breaker are disconnected from the SA10A

control outputs or from any other remote control device.

All cables shall first be connected to the SA10A before any connections to the test object.

Use of touch-protected connectors is required for personal safety.

Only use original cables for connection and make sure that the cables are in good conditions.

When the SA10A is connected to a wall socket, the socket must be a grounded power outlet.

Note! The inputs for coils “Uc” and motor “Um” are not fused!

Make sure that the output powers to these inputs are fused with maximum 32A.

Take care when working near bare connectors and bus bars. Contact with a conductor may cause an electrical shock.

Take special care at wet conditions.

Page 6 (40)

Rev 1 2018-03-21 www.elcon.se

Go to INDEX.

•Testing the circuit breaker

Make sure that surrounding personal can’t touch the breaker during an operation.

If a test sequence shall be running in automatic mode it’s absolutely necessary to have a security circuit that prevent

surrounding personal to touch the test object during the sequence.

The power supplies for coils and motor must be interlocked to a security circuit that cut the power if the security

circuit is open.

Read also additional safety regulations presented in sections below.

3.1.1 Safety regulations. 3.2.1 Safety regulations.

3.3.1 Safety regulations. 3.4.1 Safety regulations.

Page 7 (40)

Rev 1 2018-03-21 www.elcon.se

Go to INDEX.

2.2 CONNECTION OF SA10A TO MAINS POWER.

The SA10A can be powered from any AC source 100-240V or DC source 100-240 VDC (with a ground connection).

When the SA10A is connected to a wall socket, the socket must be a grounded power outlet.

IMPORTANT!

The SA10A have a separate grounding terminal (green/yellow) that must be grounded to the nearest protective earth

(ground) with a separate wire.

3.0 CONNECTIONS

3.1 CONNECTIONS FOR TIME MEASUREMENT.

3.1.1 SAFETY REGULATIONS.

When only one side of the breaker is connected to earth (ground), special precautions must be observed. To protect

service personnel and the measuring equipment from surges, two important rules must be followed closely.

•The SA10A case must be grounded.

•All circuit breaker connections and disconnection’s must be made while the breaker poles are closed and connected

to earth (ground) on least one side.

•To avoid unintentional breaker operation! Never do any work on a circuit breaker unless the control circuits of the

breaker are disconnected from the SA10A control outputs.

•Use of touch-protected connectors.

3.1.2 PRINCIPALS FOR CONNECTIONS TO SA10A.

To get a useful protocol and to fit to the PC-software it is necessary to connect contacts in a certain way:

•Use separate contact groups ("Contacts 1" - "Contacts 3") for separate phases.

•Use contacts "A" - "D" for separate breaker elements in each phase.

•Use contacts "a" and "b" for connection of auxiliary contacts (live or free)

Note! Do not exceed the input voltage limit of 250 V AC or 300 V DC.

3.1.3 CONNECTIONS FOR ONE BREAKING UNIT PER PHASE.

Figure 2.1 Connections for a one breaking unit per phase

Page 8 (40)

Rev 1 2018-03-21 www.elcon.se

Go to INDEX.

3.1.4 CONNECTIONS FOR TWO OR MORE BREAKING UNITS PER PHASE.

Note!

Only one phase is shown

Figure. 2.2 Connections for four breaking units per phase

3.1.5 CONNECTION FOR A BREAKING UNIT WITH A PRE -INSERTION RESISTOR.

The contact inputs "A" -"D" in each contact group have two levels of resistance sensitivity.

There is no difference between connecting a breaker unit with a pre-insertion resistor and connecting a breaker unit

without a pre-insertion resistor.

Note!

The value of the pre-insertion resistor must be in the range 50 - 5000 ohm

Figure. 2.3 Connections for a breaking unit with a pre-insertion resistor

Page 9 (40)

Rev 1 2018-03-21 www.elcon.se

Go to INDEX.

3.2 CONNECTIONS FOR A RESISTANCE MEASUREMENT OF A BREAKING UNIT.

3.2.1 SAFETY REGULATIONS.

When only one side of the breaker is connected to earth (ground), special precautions must be observed. To protect

service personnel and the measuring equipment from surges, the following important rules must be followed closely.

•The SA10A case must be earthen (grounded).

•All circuit breaker connections and disconnection’s must be made only while the breaker poles are closed and

connected to earth (ground) on least one side.

•To avoid unintentional breaker operation! Never do any work on a circuit breaker unless the control circuits of the

breaker are disconnected from the SA10A control outputs.

•Use of touch-protected connectors is required for personal safety.

•200A Red Pole of SA10A is connected to chassis ground, and must be connected to the grounded side of the breaking

unit. See figure 2.4 below

3.2.2 CONNECTION.

Use a connection cable with an area of 25mm² or more, to connect from the 200A current generator to the

breaking unit that is going to be measured.

Important!

200A Red Pole of is connected to chassis ground, and must be connected to the grounded side of the breaking

unit. See figure 2.4

Important!

Keep the two measuring wires connected to Ur+ and Ur-near together (twisted) as long as possible to reduce

interference and get a good measuring result.

Note!

If there is a current transformer (CT) in the circuit, the 200A current from SA10A shall if possible be connected so that the

200A measuring current not go through the CT. If that not possible, the secondary windings of the CT must be short

circuit and the CT must be demagnetized after done test.

Figure. 2.4 Connections for a resistance measurement of a breaking unit

Page 10 (40)

Rev 1 2018-03-21 www.elcon.se

Go to INDEX.

3.3 CONNECTIONS FOR RESISTANCE MEASUREMENT OF A PRE-INSERTION RESISTOR.

3.3.1 SAFETY REGULATIONS.

When only one side of the breaker is connected to earth (ground), special precautions must be observed. To protect

service personnel and the measuring equipment from surges, the following important rules must be followed closely.

•The SA10A case must be grounded.

•All circuit breaker connections and disconnection’s must be made only while the breaker poles are closed and

connected to earth (ground) on least one side.

•To avoid unintentional breaker operation! Never do any work on a circuit breaker unless the control circuits of the

breaker are disconnected from the SA10A control outputs.

•The reference resistor itself and connections to the reference resistor must be well isolated.

•Warning! Do not short-circuit or touch the auxiliary voltages to and from the SA10A.

Use of touch-protected connectors is required for personal safety.

3.3.2 PRINCIPAL OF MEASURE MENT.

The auxiliary DC-voltage to the coils are used as a voltage source. The voltage division between the pre-insertion resistor

and a reference resistor is used to calculate the resistance of the pre-insertion resistor.

Selection of reference resistor.

Select the reference resistor in the same range (or lower) as the pre-insertion resistor. Use a power resistor (>= 10W).

Current will flow during a short time i.e. the pulse length set for coils.

The voltage across the reference resistor and the pre-insertion resistor are recommended to be greater than 20VDC and

must be less than 300VDC. Try to get as high current as possibly to avoid influence from surrounded capacitive current.

3.3.3 CONNECTION.

See figure 2.5. Make sure that the Resistor itself and connections to the reference resistor are well isolated.

Connect a wire between COILS:COM and AUX:COM

Connect a wire between output COILS:CLOSE and measuring input AUX:Uk.

Connect a reference resistor between output COILS:CLOSE and measuring input AUX:Ul.

Connect the pre-insertion resistor between AUX:Ul” and AUX:COM.

Connect the breaker coils to the SA10A for a normal CO-operation (not shown in figure 2.5).

Note! Do not connect the motor to SA10A. See 3.4.2 Connection of operating coils. for connections.

Figure. 2.5 Connections for resistance measurement of a pre-insertion resistor

Page 11 (40)

Rev 1 2018-03-21 www.elcon.se

Go to INDEX.

3.4 CONNECTION OF THE BREAKER OPERATING MECHANISM.

3.4.1 SAFETY RE GULATIONS.

•The case must be grounded.

•Warning! Do not short-circuit or touch the auxiliary voltage.

Use of touch-protected connectors is required for personal safety.

•The inputs for coils “Uc” and motor “Um” are not fused!

Make sure that the powers to these inputs are pre-fused with maximum 32A.

•Never do any work on a circuit breaker unless the control circuits of the breaker are disconnected from the SA10A

control outputs. (avoiding unintentional breaker operations)

Note!

The white 4 mm panel socket "ISOL" is an isolated connection that can be used to disconnect the control circuits of the

breaker.

3.4.2 CONNECTION OF OPERATING COILS.

See figure 2.6

•Connect the input coil voltage to the inputs Uc and COM.

Connection to COM is optional and is only used for monitoring the voltage.

•Connect the positive connection of the closing coil and the positive connection of the opening coil to the outputs

CLOSE and OPEN.

•Connect the negative connections of the operating coils to the negative connection of the coil voltage.

3.4.3 CONNECTION OF MOTOR.

See figure 2.6

•Connect the auxiliary voltage to the inputs Um and COM

•Connect the motor connections to the output MOTOR and to the negative connection of the auxiliary voltage.

Note!

The connection of the motor circuit is optional and is only necessary for monitoring the voltage and current

+

~

-

~

+

~

-

~

Coil Voltage

<=32A

Motor Voltage

<=32A

Motor

Close Coil

Open Coil

Coil interlocking

Figure. 2.6 Connection of the breaker operating mechanism

Page 12 (40)

Rev 1 2018-03-21 www.elcon.se

Go to INDEX.

3.5 CONNECTION OF TRANSDUCERS.

Up to three pulse- or analog transducers can be connected to the inputs T1,T2,T3.

The connection must be done with a special cable connector:

Connector: LEMO FGG.2K.308.CLCK90

Pin Description for a digital pulse transducer.

1 Pulse 1.

2 Pulse 1 inverted.

3 Pulse 2.

4 Pulse 2 inverted

5 +5 VDC

6 Ground.

Pin Description for an analog transducer

5 +5 VDC

6 Ground

7 Analogue measurement (Wipe)

8 Is not used.

Tip!

Use prefabricated cables for connection.

3.6 CONNECTION TO WINDOWS PC

Any standard Windows PC with one free RS232, USB 2.0, USB 3.0 port can be connected.

The can be connected with 3 different methods.

•USB Mini to USB cable. (Max 1 meters)

•RS232 9 Pol Male to 9 Pol Female cable. (Max 2 Meters)

If computer is not equipped with RS232 port an USB to RS232 adapter can be used.

•Bluetooth communication kit

Use a standard straight serial RS232 PC-cable with a 9 pole DSUB Male Female connectors, for connection to .

Page 13 (40)

Rev 1 2018-03-21 www.elcon.se

Go to INDEX.

4 USING SA10A STAND ALONE

The instruction below only handles the operating instruction for using the as a stand-alone instrument.

See separate BTS11 User manual for use of the PC-software

4.1 BEFORE OPERATION IMPORTANT!

Read chapter 2 Safety regulations before any connections.

4.2 STANDALONE OPERATION OF SA10A

The SA10A LCD-display and two operation buttons "OPEN" and "CLOSE" for simpler operations and measurements.

Starting up the display will present the version of the internal software.

After unit is started the display shows, the next operation that can

be done: Ready for Open or Ready for Close"

Voltage value for inputs: Uc, Uk, Ul, Um.

Current value: Im for motor.

Symbol

Voltage type

V=

Volt DC

V~

Volt AC

A=

Ampere DC

A~

Ampere AC

Symbol

Meaning

Battery fully charged

blinking

Battery charging

blinking

Battery below 10Volt

When the display shows

Pressing Button

CLOSE: A close operation is done

OPEN: Nothing happens

CLOSE and OPEN: A close-open operation is done

Note! If enabled in service menu in BTS11 software. Internal temperature is

displayed in the top right corner in Celsius.

When the display shows

Pressing Button

OPEN: An open operation is done

CLOSE: A static resistance measurement is done.

Note! Resistance measurement can only be done when the SA10A is powered from a separate AC or DC source.

The results of the operation are automatically displayed after a made operation.

After a CLOSE, OPEN or CLOSE-OPEN operation.

Result will display operating times for contacts 1A, 2A, 3A,in milliseconds. (Ring marked contact inputs on the panel).

Maximum coil current during operation is displayed as X.XA^.

SWITCH ANALYSER

SA10A 5.11

2018-03-06

www.elcon.se

Ready for Open 32°

Uc 110 V= Uk 0 V=

Ul 0 V= Um 230 V~

Im 0.0 A=

Ready for Close 31°

Uc 110 V= Uk 0 V=

Ul 0 V= Um 230 V~

Im 0.0 A=

Ready for Close 21°

Uc 0 V= Uk 0 V=

Ul 0 V= Um 0 V=

Im 0.0 A=

Page 14 (40)

Rev 1 2018-03-21 www.elcon.se

Go to INDEX.

CLOSE

OPEN

CLOSE-OPEN

Pressing any of the operation buttons "CLOSE" or "OPEN" will get you back to monitoring mode where new operations

and measurements can be done.

After static resistance measurement

Result will display

R = Resistance measured in micro ohm.

I = Current measured in Amperes.

U = Voltage measured in millivolt.

Note! To prevent overheating of the unit and depletion of the batteries. A timer in the top right corner counts down until

next resistance measuring can be performed.

Contact times Close

A 51.52 ms 2.8A^

B 51.50 ms

C 51.48 ms

Contact times Open

A 42.66 ms 2.7A^

B 42.64 ms

C 42.62 ms

Contact times C-O

A 45.10 ms 2.8A^

B 45.08 ms

C 45.06 ms

Resistance 12s

R = 100.0 µΩ

I = 205.5 A

U = 20.55 mV

Page 15 (40)

Rev 1 2018-03-21 www.elcon.se

Go to INDEX.

5 TECHNICAL SPECIFICATION.

MAINS SUPPLY

Marked: MAINS

Input voltage: 100 –240 V DC / AC 50/60 Hz

Max power: 50W

Connector type: IEC Inlet Filter

Fuses: 2

Fuse type: 5x20mm

Fuse rating: T3.15A

INTERNAL BATTERY

Quantity: 1

Used for: Static and Dynamic Resistance measurement

Battery type: Hawker Lead Accumulator 6 V 5 A, 0809-0012 (XMB)

Battery rating 12Volt (2x6V 5A Lead accumulator)

Battery charging: 13.5-14.0V @ 0.5A

Battery float voltage: 13.6V @ 25°C

Life Time: <= 8 year

Fuses: 1

Fuse Panel mounted: BUSSMANN BY EATON 25A aM

MAIN CONTACTS

Marked: A1, A2, A3, A4, B1, B2, B3, B4, C1, C2, C3, C4.

Inputs: 12 independent.

Function: Measure contact timing of main and pre-insert resistor contacts

Voltage: 48Vdc

Current: Max 11 mA when load is between 24-48V

Max 30 mA when load is between 0-24V

Timing resolution: 20s at 50 KHz sampling.

Max Voltage between red and black output: 250VAC / 300VDC

AUXILIARY CONTACTS

Marked: 1a, 1b, 2a, 2b, 3a, 3b.

Inputs: 6 independent

Function: Measure contact timing of aux contacts

Voltage: 24Vdc

Current: Max 11 mA

Timing resolution: 20s at 50 KHz sampling.

Max Voltage between red and black output: 250VAC / 300VDC

TRAVEL INPUTS

Marked: T1, T2, T3.

Inputs: 3 digital or analog.

Digital input receiver: 2 RS422 quadrature inputs

Analog min resistance: 100 ohm.

Voltage measure: 5 V DC, accuracy 0,005V DC

Analog resolution: 14 bits. Resolution ≈0.6mV / Bit

Power output: +5 VDC 100 mA.

Page 16 (40)

Rev 1 2018-03-21 www.elcon.se

Go to INDEX.

RESISTANCE MEASUREMENT

Marked: Ur, Ir.

Inputs: 1 analog.

Outputs: 1 Current generator 200-210 A 4 V DC @ 200ms.

Voltage measure: Ur 0 - 225 mV DC, Accuracy < 0.2mV DC

Analog resolution: 14 bits. Resolution ≈0.0275mV / Bit

Current Out Ir 0 - 240 A DC. Accuracy < 2A DC

Analog resolution: 14 bits. Resolution ≈15mA / Bit.

Resistance meas.: Res 0 - 1000 Ohm. Accuracy < 2ohm.

COIL INPUTS

Marked: Uc, COM. Not fused, max 300V AC/DC, 32A

Inputs: 1 analog.

Voltage measure: Uc Range 0-300 V DC. Accuracy < 1% or 1V DC

Range 0 - 300 V AC. Accuracy < 1% or 1V AC

Analog resolution: 14 bits. Resolution ≈56mV / Bit.

COIL OUTPUTS

Marked: CLOSE,OPEN,COM. Supplied from Uc

Outputs: 2 Semiconductor controlled.

Protection: Short circuit current limit >= 35A.

Current measure: Ic 0 - 45A DC. Accuracy < 1% or 0.1A DC

0 -32A AC. Accuracy < 1% or 0.1A AC

Analog resolution: 14 bits. Resolution ≈5.7mA / Bit.

AUXILIARY VOLTAGE INPUTS

Marked: Uk, Ul, COM.

Inputs: 2 analog.

Voltage measure: Uk, Ul Range 0-300 V DC. Accuracy < 1% or 1V DC

Range 0 - 300 V AC. Accuracy < 1% or 1V AC

Analog resolution: 14 bits. Resolution ≈56mV / Bit.

MOTOR INPUT

Marked: Um, COM. Not fused, max 300V AC/DC, 32A

Inputs: 1 analog.

Protection: Internal isolated

Voltage measure: Um Range 0-300 V DC. Accuracy < 1% or 1V DC

Range 0 - 300 V AC. Accuracy < 1% or 1V AC

Analog resolution: 14 bits. Resolution ≈56mV / Bit.

MOTOR OUTPUT

Marked: MOTOR, COM. Supplied from input Um.

Outputs: 1 constant output

Protection: Internal isolated.

Not fused, max 300V AC/DC, 32A

Current measure: Im Range 0-90A DC. Accuracy < 1% or 0.1 A DC

Range 0 - 60A AC. Accuracy < 1% or 0.1 A AC

Analog resolution: 14 bits. Resolution ≈11.5mA / Bit.

Page 17 (40)

Rev 1 2018-03-21 www.elcon.se

Go to INDEX.

COMMUNICATION INTERFACE 1

Marked: RS-232.

Protection: Internal isolated

Baud rate 115.2 K baud

Data size 8-bit

Parity None

Stop bits 1

Flow control none

COMMUNICATION INTERFACE 2

Marked: USB 1.1 / USB 2.0 full-speed.

Protection: Internal isolated

Baud rate 115.2 K baud

Data size 8-bit

Parity None

Stop bits 1

Flow control none

DISPLAY

Type: LCD Backlit

Characters: 4 rows, 20 characters per row. 5x8 Dots Per Character

PUSHBUTTONS

Marked: CLOSE, OPEN

Close button: Make a Close operation if breaker is in Open position

Open button: Make an Open operation if breaker is in Close position

Close + Open button: Make a Close-Open operation if breaker is in Open position

INTERNAL SAMPLING Max time @ 10 Hz 52428.799 seconds

Max time @ 100 Hz 5242.879 seconds

Max time @ 250 Hz 2097.151 seconds

Max time @ 500 Hz 1048.575 seconds

Max time @ 1000 Hz 524.287 seconds

Max time @ 2500 Hz 209.714 seconds

Max time @ 5000 Hz 104.857 seconds

Max time @ 10000 Hz 52,428 seconds

Max time @ 25000 Hz 20.971 seconds

Max time @ 50000 Hz 10.485 seconds

DIMENSION AND WEIGHT: Dimensions 458*331*153 (With*Height*Depth)

Weight about 1.2 kg

ENVIRONMENT: Operating temperature -20 - 40 °C

Storing temperature -40 - 40 °C

Transport temperature: -40 - 40 °C

Relative humidity 20 - 85% non-condensing

Altitude operating 2 000 m

Altitude non-operating 12 000 m

OVERVOLTAGE CATEGORY: II

MANUFACTURER: Elcon AB

Hyttrisvägen 27

770 14 Nyhammar SWEDEN

Page 18 (40)

Rev 1 2018-03-21 www.elcon.se

Go to INDEX.

6 MAINTENANCE.

6.1 BEFORE USE.

•Unpacking and handling instructions.

The transporting case protects the SA10A from being damaged.

The Switch Analyzer is a field-test equipment and is constructed to withstand the handling it requires to fulfil its

purposes, although the front panel is sensitive for scratches and other marks. The display is the most sensitive point

of the SA10A, it will not tolerate harsh management. This should be considered during unpacking and handling of the

unit.

•Charge the battery for at least 10 hours.

Note!

The SA10A internal batteries may be need recharging, if it has been stored without charging for some time.

Recharge by connecting the mains power cable for at least 12 hours.

•Check battery condition.

By short circuiting the high current cables (2*10 m, 25 mm2) and make a resistance measurement. The measurement

current should be >195A.

If the value is lower than 195 A you have to charge the internal battery by connecting the mains input to a wall socket

for some hours. Make a new try and check the current value again.

If the value still is lower than 195 A the battery must be replaced.

Note! This is important if Resistance measurement shall be done.

6.2 AFTER USE.

•Clean the front panel and set the unit to dry.

•Charge battery by connecting the mains input to a wall socket.

6.3 STORING THE SA10A.

The SA10A should always be stored indoors in a dry place.

The SA10A should not be stored in subzero temperatures for a longer period of time.

It should not be stored in extreme environments either.

Storage temperature: -40 to 40 degrees

Transport temperature: -40 to 40 degrees

Note!

SA10A internal batteries may need recharging if it has been stored for several months.

Recharge by connecting the mains power cable.

6.4 EVERY YE AR OR WHEN NECESSARY.

•Check and calibrate the equipment as described in paragraph 7 Adjustments.

•Replace batteries every 5 year. Usually the batteries have a lifespan of about 5-8 years if properly charged.

Page 19 (40)

Rev 1 2018-03-21 www.elcon.se

Go to INDEX.

6.5 BATTERY FUSE

IMPORTANT READ THIS FIRST

Any electrical battery or battery powered device, equipment or vehicle having

the potential of dangerous evolution of heat must be prepared for transport

so as to prevent:

(a) a short circuit (e.g. in the case of batteries, by the effective insulation of

exposed terminals; or in the case of equipment, by disconnection of the

battery and protection of exposed terminals); and

(b) unintentional activation

1. To make sure that transport

regulations are met, the fuse for the

batteries is removed and placed in

the accessory box.

2. Locate the compartment lid.

3. Open the compartment lid

4. Open the accessory box.

5. Take out one of the two 25 A aM

fuses. (one is spare fuse)

6. Locate the battery fuse holder.

7. Unscrew the fuse holder cap (turn

counterclockwise)

8. Insert the fuse into the fuse holder

cap.

9. Insert the fuse with the cap into

the fuse holder.

10. Screw and tighten the fuse

holder. (Turn clockwise)

Page 20 (40)

Rev 1 2018-03-21 www.elcon.se

Go to INDEX.

6.7 UPGRADING SA10A INTERNAL SOFTWARE.

•Run BTS11 setup and install BTS11 software.

•Start BTS11

•Select what comport unit is connected to.

•In menu Service click Control Unit…

•Select tab About and click button Update…

•A dialog will appear to download the software.

Select SA10A V5.XX binary files.

Select the program. “SA10A_xxx.bin”

Open the file with the command button “Open”

•The new software will now be transferred to the

Control unit. This may take a while.

•When finished the following dialog will appear.

Table of contents

Other Elcon Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Piusi

Piusi MK325 Instructions for installation, use and maintenance manual

Sound Devices

Sound Devices Kashmir MixPre II Series user guide

TechVision

TechVision NS8P2P8 manual

Paragon

Paragon GUARDIAN Operation & maintenance manual

Anritsu

Anritsu Site Master S810D Maintenance manual

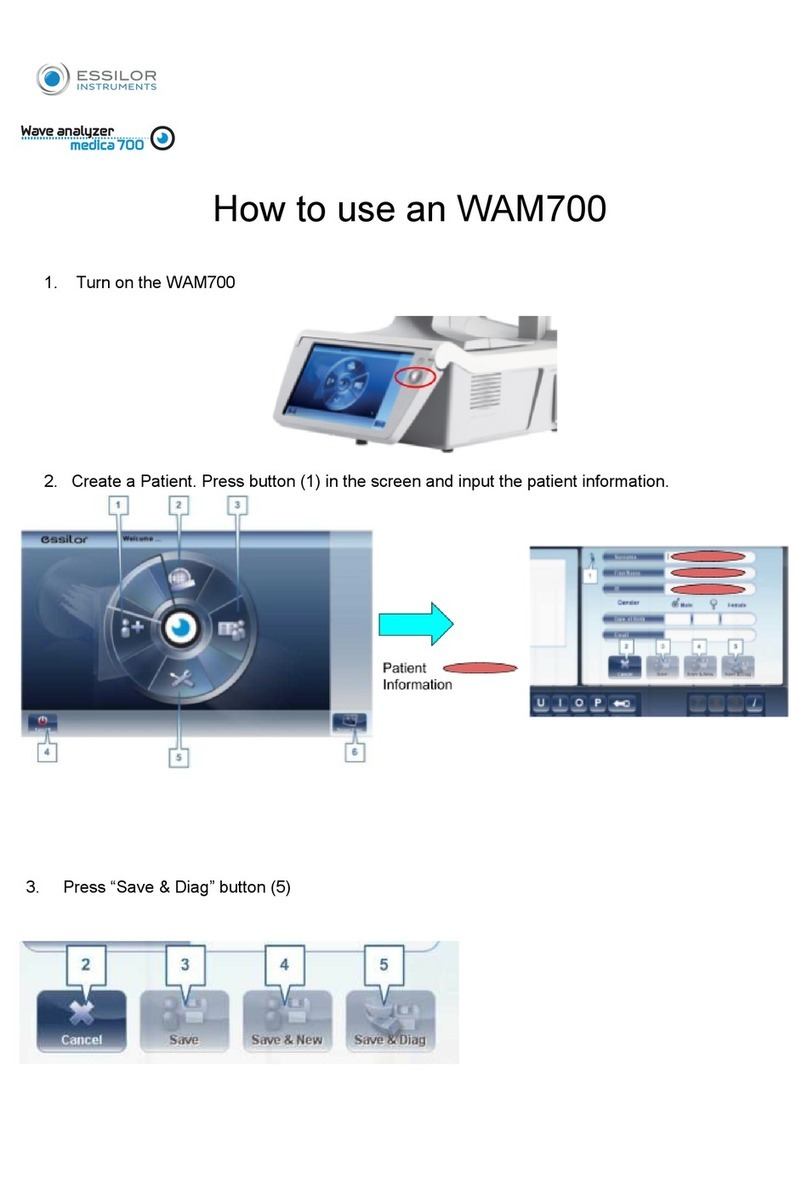

Essilor

Essilor WAM700 How to use