4. OPERATION

4.1. Regulator - The output pressure is controlled by the knob. Before pressurising the air system for the

first time, pull out and rotate the knob anticlockwise to remove any loading on the regulator spring.

Pressurise the system and then rotate knob clockwise to set required output pressure, as shown on

gauge. When the required pressure is achieved push in knob to prevent inadvertent adjustment.

Note: For correct pressure setting always adjust up from a lower pressure. Therefore to reset from

90 to 70psi for example, reduce pressure from 90 to 60psi and then increase to 70psi.

4.2. Filter - The bowl should be drained regularly to prevent an excessive build-up of water/oil. Pull down the

drain valve at the bottom of the bowl, allow to drain and then release. Drain valve has female 1/8” BSP

outlet. (SA206FRAD and SA206FAD have Auto drain feature. When pressure in bowl drops, float valve

opens and drains condensation. Drain valve has male 1/8” BSP outlet).

4.3. Lubricator - Remove the filler plug (fig.2.A) and fill bowl up to max. level, with air tool oil. This

can be done with the air line pressurised. With air flowing through the lubricator the oil delivery rate

can be adjusted by screw (fig.2.C) whilst watching the drip rate through the sight dome (fig.2.B).

The oil delivery rate will automatically increase or decrease in line with the air flow.

4.4. Both the filter and the lubricator are supplied with a metal bowl guard. To remove the guard, pull down

the latch (fig.3.D) and rotate the guard until either of the two pairs of lines (fig.3.E) on the guard align

with the similar marks (fig.3.F) on the head. The guard can now be removed.

To refit, slide the top of the guard into the head with the guard and head markings aligned, and then

rotate the guard so that the latch aligns with the marks on the head. The latch will lock into place.

5. PARTS

6. DECLARATION OF CONFORMITY

Declaration of Conformity We, the sole importer into the UK, declare that the products listed here are in conformity with the following standards and directives.

The construction files for these products are held by the Manufacturer and may be inspected, by a national authority, upon

request to Jack Sealey Ltd.

For Jack Sealey Ltd. Sole importer into the UK of Sealey Power Products.

Air Regulator, Filter & Lubricator Range.

Models: SA206, SA206FR, SA206F,

SA206L, SA206R, SA206FAD, SA206FRAD

97/23/EC Pressure Equipment Directive

98/37/EC Machinery Directive

93/68/EEC Marking Directive

Signed by Mark Sweetman Date: 12th April 2006

3. CONTENT & INSTALLATION

3.1. Confirm that all items are present and undamaged. If any parts are missing or damaged please contact the supplier.

SA206 - Combined filter, regulator with gauge, lubricator and mounting bracket.

SA206FR - Combined filter, regulator with gauge and mounting bracket.

SA206F - Filter.

SA206L - Lubricator.

SA206R - Regulator with gauge and mounting bracket.

SA206FAD - Filter with Auto Drain,

SA206FRAD - Combined filter with auto drain, regulator with

gauge and mounting bracket.

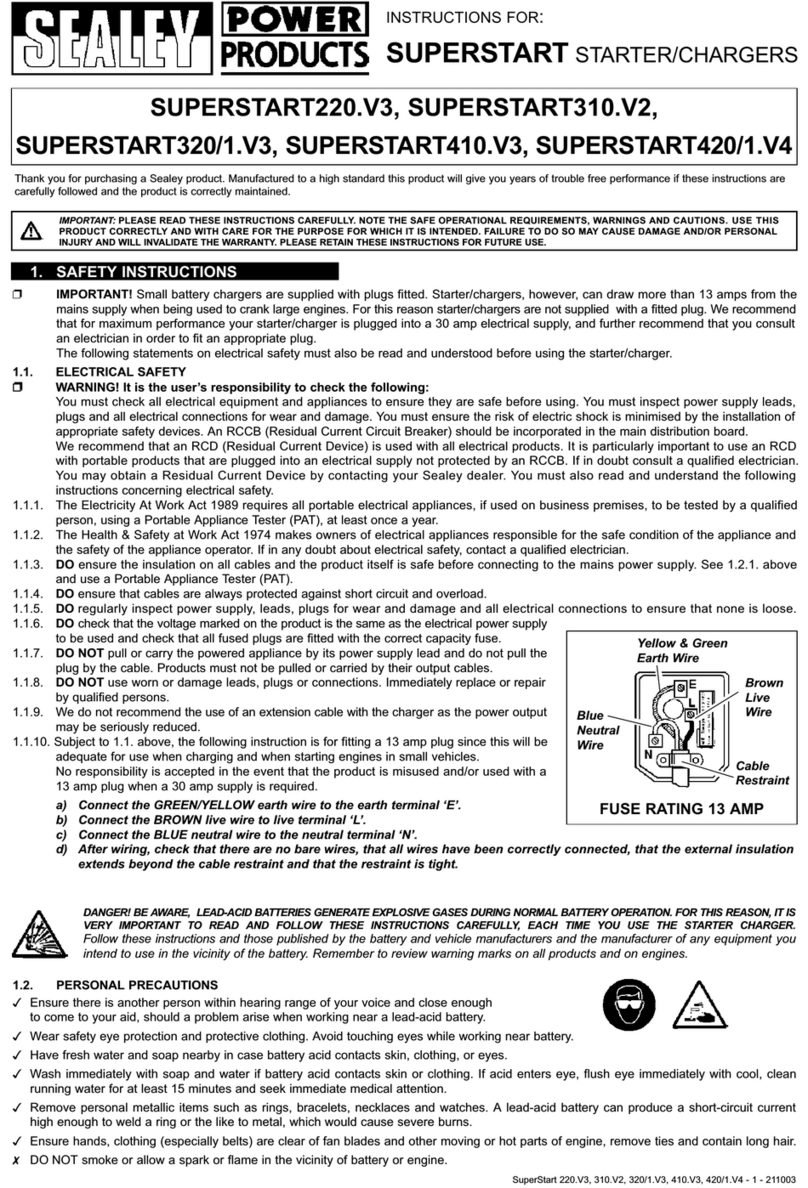

3.2. Fig.1 shows a typical air line installation. The filter is located

upstream of the regulator - unless combined, as in SA206

and SA206FR - and the lubricator downstream.

3.2.1. Filter/regulator - Install using the mounting bracket provided.

Before connecting system piping ensure that gauge is visible,

unused gauge port is sealed with plug provided and that flow

direction arrow matches system air flow.

3.2.2. Filter and Lubricator - Install into air piping or connect directly to bracket mounted regulator using fittings provided. Always check that

flow arrows are correct and that filter is upstream, and lubricator downstream, of regulator.

Note: To ensure air-tight joints, use PTFE tape.

fig.1

fig.2

fig.3

SA206/206FR/206F/206L/206R/206FAD/206FRAD Issue: 2 - 05/09/08

01284 757500

01284 703534

sales@sealey.co.uk

Sole UK Distributor

Sealey Group,

Bury St. Edmunds, Suffolk.

www.sealey.co.uk

Web

email

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our catalogue and latest promotions call us on 01284 757525 and leave your full name, address and postcode.

MODEL: SA206 SA206FR SA206F SA206L SA206R SA206FAD SA206FRAD

Filter Bowl: SA206.B SA206.B SA206.B --- --- SA206.B SA206.B

Lubricator Bowl: SA206.B1 --- --- SA206.B1 --- --- ---

Regulator gauge: SA206.G SA206.G --- --- SA206.G --- SA206.G

Plastic Ring: SA206.PR SA206.PR --- --- SA206.PR --- SA206.PR

Wall Bracket: SA206.WB SA206.WB1 --- --- SA206.WB1 --- SA206.WB1

Sight Dome: SA206.SD --- --- --- --- --- ---

Retaining Nut: SA206.RN --- --- --- --- --- ---

The following fittings are also available from your supplier:

SA1/1212 1/2”BSP male - 1/2” BSP male connector

SA1/1414 1/4”BSP male - 1/4”BSP male connector

SA1/1214F 1/2”BSP male - 1/4”BSP female reducer

SA1/3814F 3/8”BSP male - 1/4”BSP female reducer

SA1/1238F 1/2”BSP male - 3/8” BSP female reducer