The F27 controller is a conventional 1" BSP paddle flow

switch with a built in micro electronic controller that gives a

fully adjustable override on start function and an

independently adjustable paddle bounce ignore, or run on

function. A pump under the control of an F27 can start in

spite of no initial flow; it will ignore paddle bounce and can run

on for up to 5 minutes after flow stops. The run on function is

very useful for pressurising air cells and for pumping down

low yield bores.

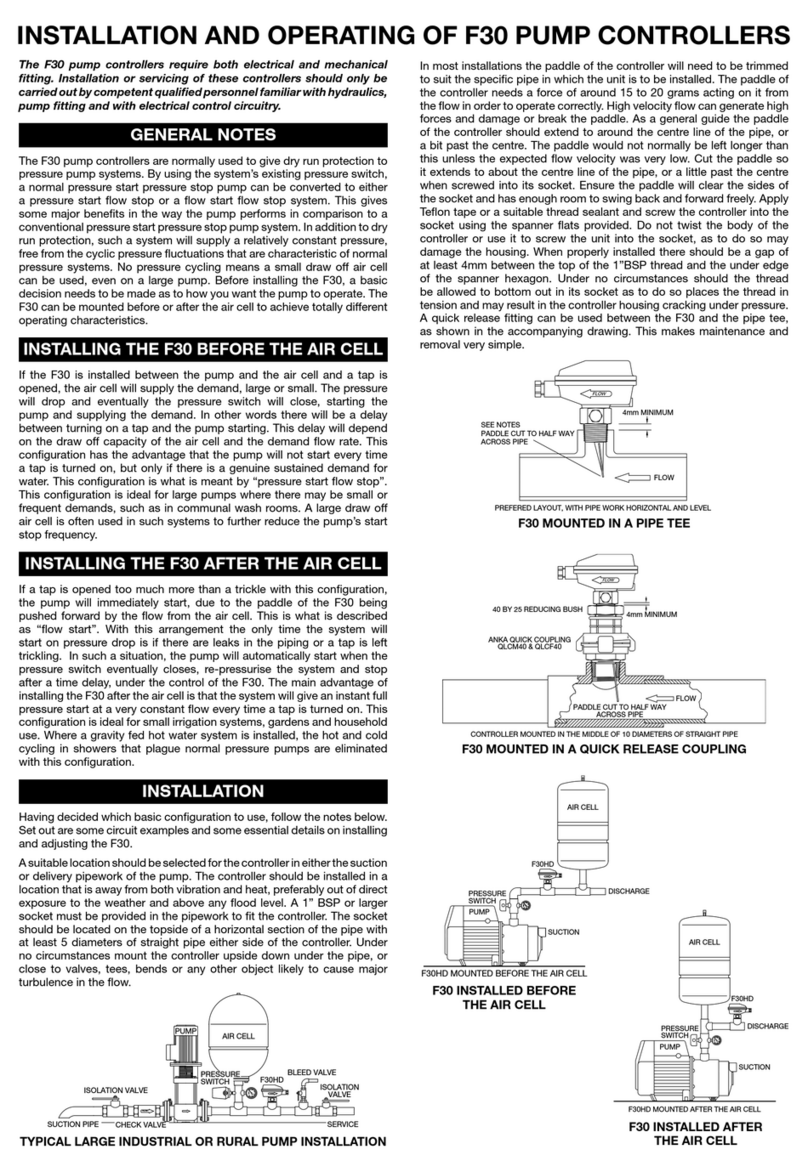

The F30 pump controller operates in exactly the same way as

the F27 but in addition can accept an input from an external

pressure switch. The auxiliary input allows the F30 to read both

flow and pressure, and means that a pump under its control will

start automatically on a pressure drop as well as on a flow

demand. By monitoring pressure the F30 can identify a dry run

situation and shut down the pump. The F30 is very versatile

and can be used in many innovative ways in automatic tank

filling systems and in industrial pump control.

Time delay adjustment is by means of two 16 position rotary

switches. The time delays are individually programmed into

the controllers to give the rotary switches the following delays.

TIMER DELAY IN SECONDS

Start up Timer 0, 1, 2, 3, 4, 5, 10, 15, 20, 25, 30, 40, 50, 60, 120, 180

Run on Timer 0, 1, 2, 3, 4, 5, 10, 15, 20, 25, 30, 40, 50, 60, 180, 300

ADJUSTING TIMER SETTINGS

After adjusting the timer settings, the power to the controller

must be reset, that is, it must be turned off for a minimum of

0.5 seconds and then turned on again, before any changes

will take effect. This applies to all the controllers under all

operating conditions.

BASIC FLOW SWITCH FUNCTION

Both the F27 and F30 pump controllers have two independent

timers and are individually adjustable in steps. With both

timer dials set to zero, the controllers behave like a basic flow

switch and respond solely to paddle movement. On power up,

the only indication of activity will be the paddle light slowly

blinking red to indicate the power is on. If the paddle is

pushed into the on position, the output relay will energise and

the paddle light will turn green. If the paddle swings to the off

position the output relay de-energises immediately, the pump

will stop and the paddle light will revert to slowly blinking red.

OVERRIDE ON START

Set the run-on timer to zero. Set the start-up timer to 5

seconds. Reset the power for the change to take effect. On

power up the pump should start. The green timer light will

come on and stay on for the 5 seconds. If the paddle is

pushed into the on position the main green paddle light will

come on. At the end of the time out, the green timer light will

go out but if the paddle is on the pump will continue to run. If

the paddle then swings to the off position the paddle light will

turn off and the pump will stop. The start-up timer should be

set to a few seconds longer than the time it takes for the

paddle light to come on. By watching the timer and paddle

lights on power up, it is a simple matter to correctly set the

start-up timer.

RUN-ON TIMER

Set both the start-up and run-on timers to 5 seconds. On

power up the pump should start and the green timer light

should come on. If the paddle swings into the on position the

green paddle light will also come on. After 5 seconds the green

timer light will go out but the pump will continue to run and the

paddle light will remain green. If the paddle then swings to the

off position the green paddle light will go out and the timer light

will turn on red indicating the pump is running on the run-on

timer. The pump will continue to run while the run-on timer is

running. If the paddle swings back to the on position before the

run-on timer times out, the pump will continue to run

seamlessly. If the paddle fails to return to the on position within

the 5 seconds the pump will stop. The run-on timer’s red light

will go out and the green paddle light will also go out. Every

time the paddle swings back to the off position the run-on timer

will re-run and keep the pump running while it times out.

Set the pressure switch so its low-pressure contacts close on

a falling pressure at 8 to10M head or 80 to 100kPa above the

systems static pressure. In a pressurised system with a slow

bleed off the pressure switch contacts must close before all the

pressure leaches away. In addition, the pressure switches

differential setting must be set to a minimum. The object is to

have the pressure switch start the pump only and then for its

contacts to open as soon as the pressure starts to rise and

before the run-on timer times out. If the recommended bleed

valve and pressure gauge have been included in the

installation the job of adjusting the pressure switch and testing

the system is made very simple.

Given that the pressure switch has been correctly adjusted, an

F30 will function in the following manner. The paddle light will

blink slowly red indicating power is on. If the bleed valve is

slightly opened so as not to actuate the paddle then as soon

as the pressure reaches the cut in pressure of the pressure

switch and its contacts close, the pump starts. The blue

pressure switch light and the red run-on timer light will turn on.

As the pressure rises, the pressure switch contacts should

open, the blue light will go out and the pump will continue to

run under the control of the run-on timer. When the run-on

timer times out the pump will stop and the red run-on timer

light will go out. The paddle light will again blink slowly red.

The net effect has been to re-pressurise the system. If the

pressure is allowed to leach away again, the process will

repeat and then the F30 will return to standby mode.

It is important to note that the pressure switch is only used to

start the system, not to stop it as in a conventional pressure

system. The result is a constant pressure system not

constrained by the need to pump up to a high cut out pressure

simply because the pressure switch requires it. A multi stage

pump can be de-staged, or a pump with a substantially flat

constant flow curve can be selected to operate under the

control of the F30. This can result in substantial savings in

running costs and in many applications provide a highly

useful constant pressure flow, essentially free of the pressure

fluctuations that plague conventional pressure systems.

The first time the system is started, the pressure switch contacts

will be closed, due to lack of pressure. When power is applied,

the pressure switch will control the start-up timer and not the

run-on timer. Only after the initial time out of the start-up timer

does the pressure switch control the run-on timer. It is important

to understand this, because it means that the start-up timer will

need to be set to a value slightly longer than the time it takes for

TIMER SETTINGS

F27 PUMP CONTROLLER

F30 PUMP CONTROLLER

SETTING UP THE PRESSURE SWITCH

F30 DRY RUN PROTECTION