www.elecro.co.uk

6

ENGLISH

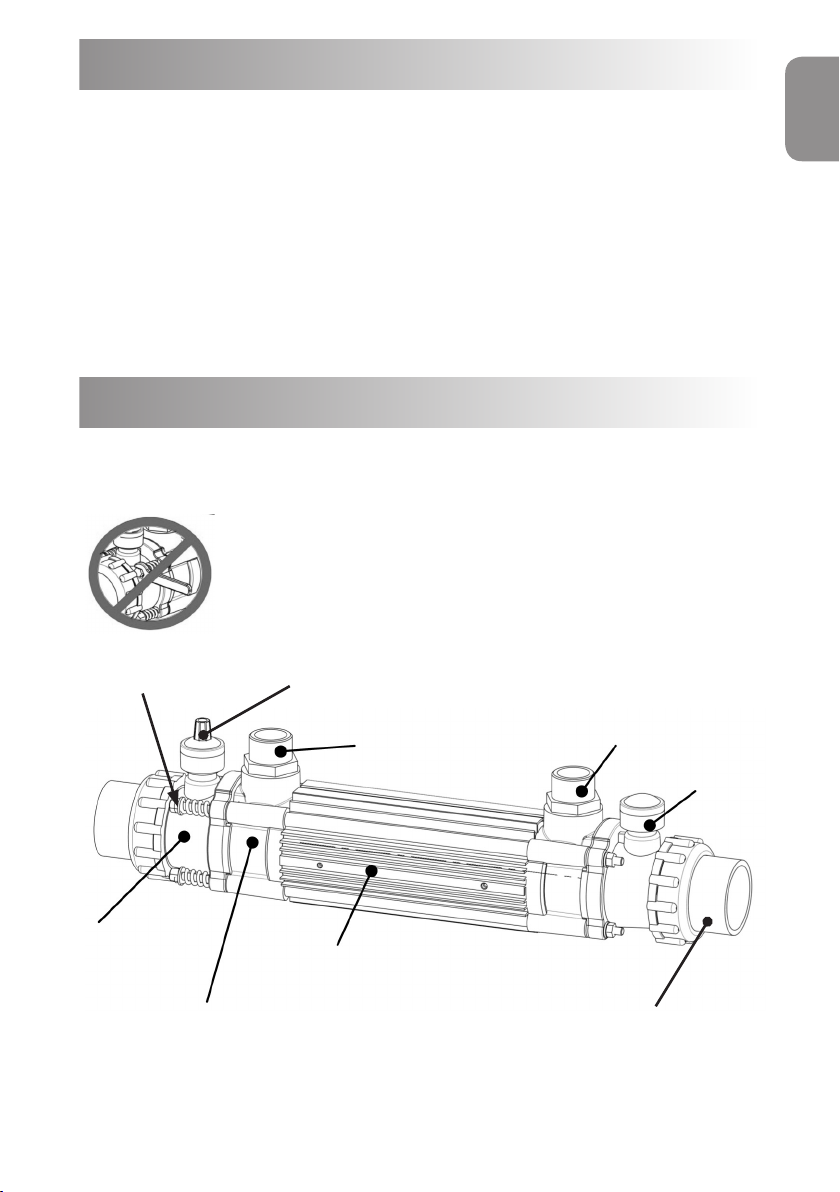

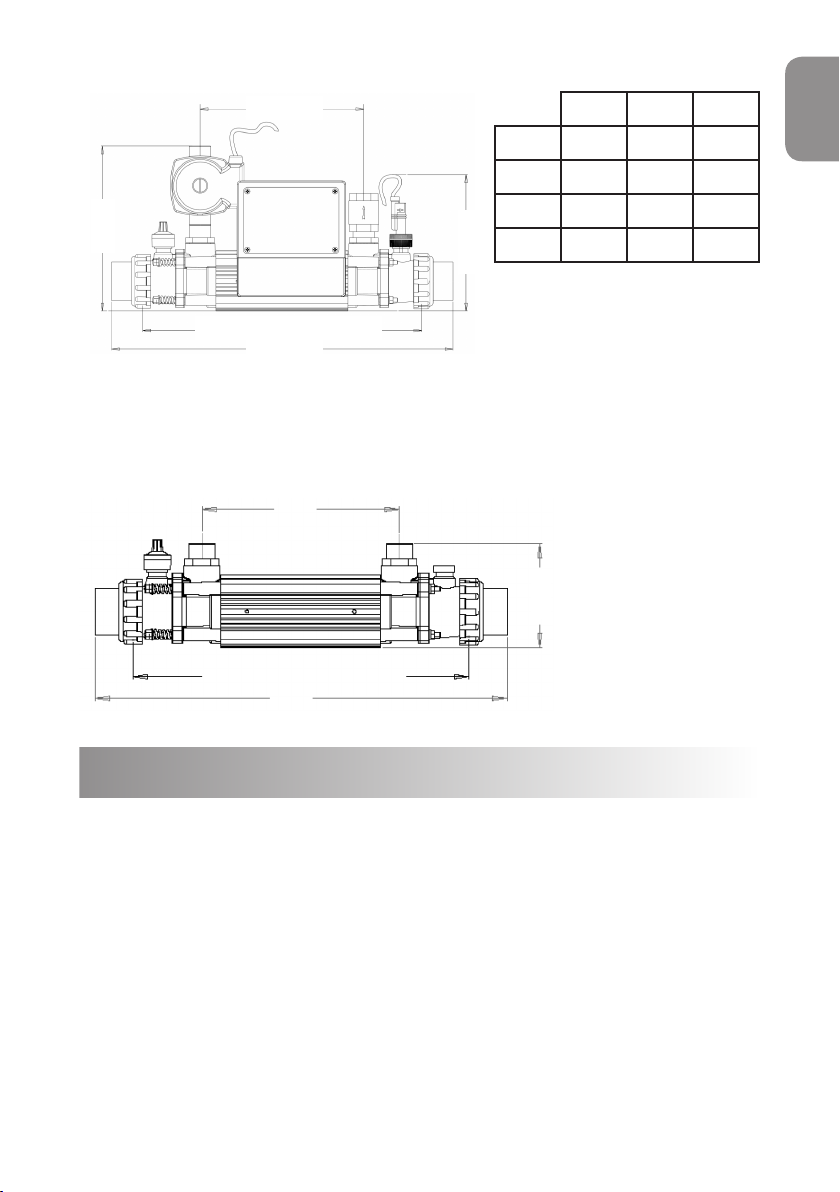

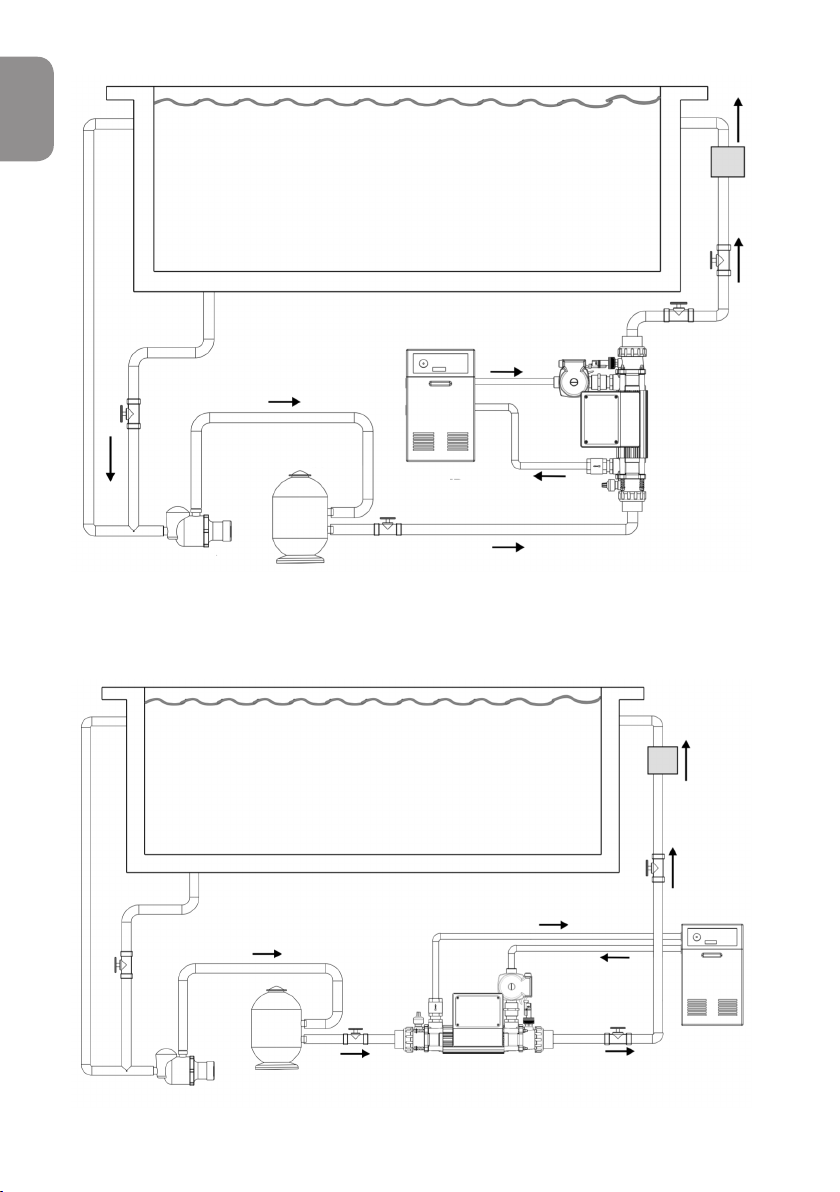

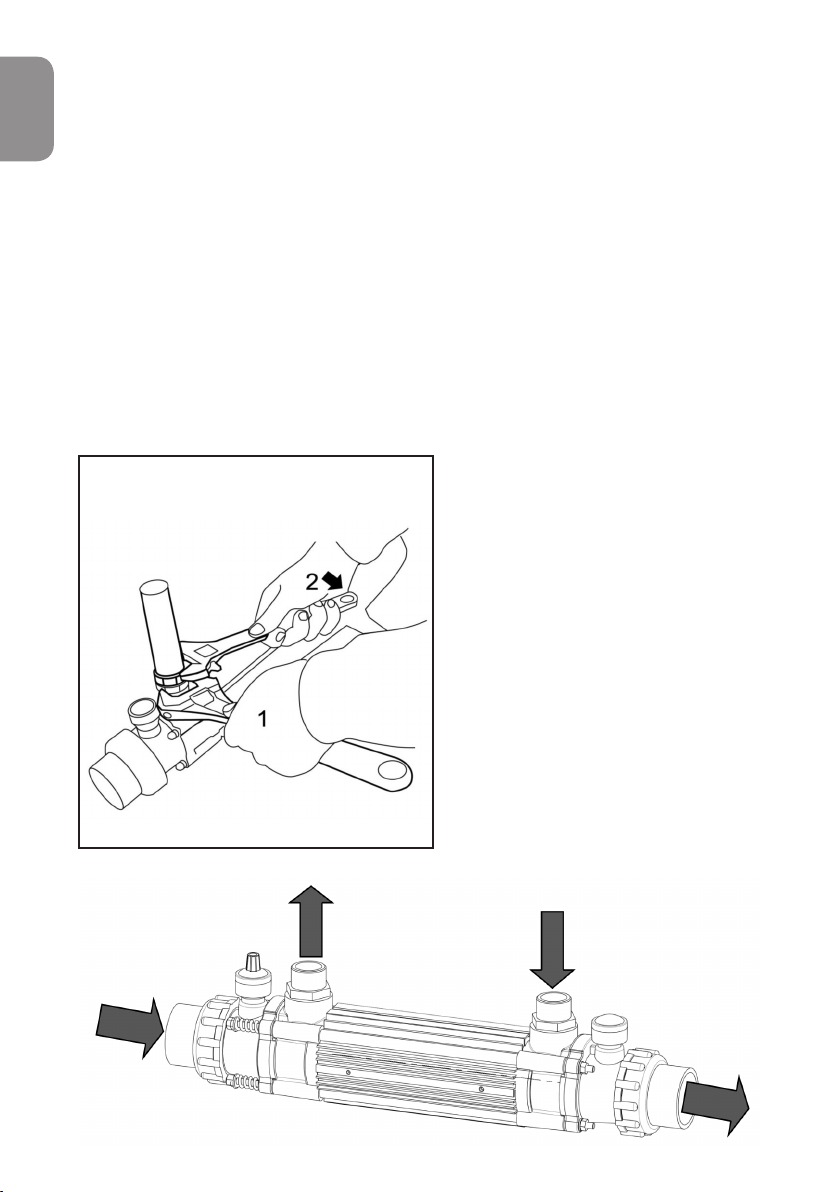

2. Connection to Heating or Cooling Circuit (Primary)

The heat exchanger should be connected directly to the primary heating

circuit i.e. boiler, via the provided 1” BSP male brass connectors, see

diagram below.

NOTE: The circulation pump of the primary circuit should be

controlled by a thermostat, which should be connected via the

ltration pump to allow heating only when the ltration pump is

running.

Air bleed valves should be installed at the high points of the primary

circuit. To ensure correct temperature detection, it is essential that

the thermostat / thermistor is positioned at the water inlet of the heat

exchanger. The thermostat pocket and ow switch use a common port,

and can thus be swapped as required.

Use two wrenches to fasten ttings.

Wrench No. 1 should remain steady. NOTE: The Thermostat Control is

only included with the ’Optional’

fully equipped kit. The standard

unit is supplied only with a

Thermostat pocket and blanking

cap.

Care should be taken not to over

tighten any connections, as this

could result in damage to the heat

exchanger. Only use the supplied

brass connectors as other uncertied

connectors may leak or cause

damage to the unit.

Fig 7.

Fig 8.