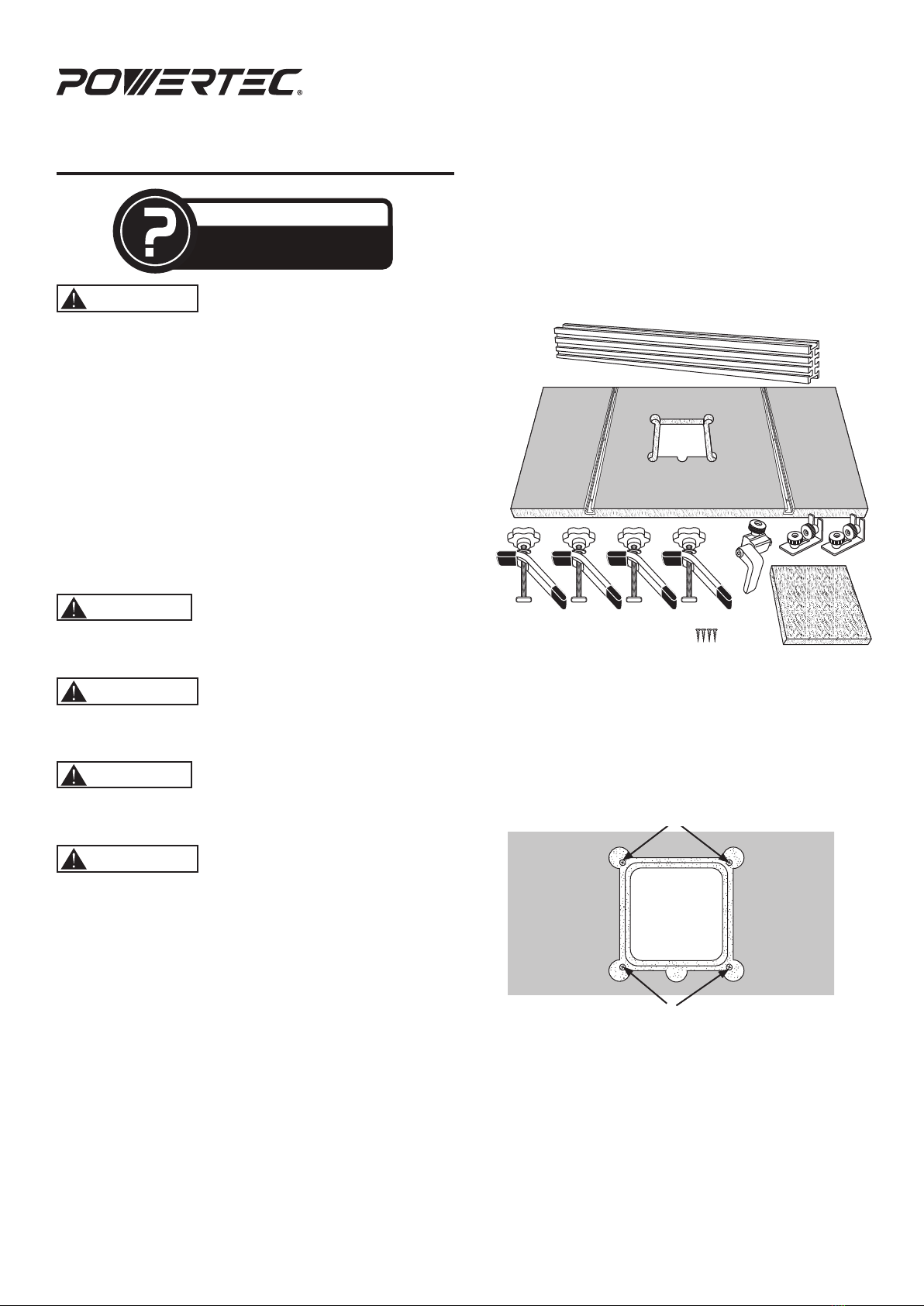

2. Slide two additional T-Bolts into the bottom T-Slot of the

extruded fence, place the T-Bolt through the open slot in the

bracket and assemble the washer and knob.

NOTE: The fence has a 24" laser etched scale and can be

used on either side of the workpiece as required. Simply

reverse the fence.

Figure 7

Bottom T-Slot

of Extruded

Fence

Open Slot in

Bracket

Knob

Washer

Etched

Scale

3. Position the fence perpendicular to the drill press table

T-Track, use a tape measure to make sure each end of the

fence is the same distance from the end of the table.

2

1345678910 11

Figure 8

4. When in position, tighten all four knobs of the brackets.

Flip Stop

Refer to Figure 9 and 10

The POWERTEC 71367 3" fence flip stops are extremely

versatile and quickly convert from inboard to outboard

position for a variety of applications. In addition, the flip

arm can be moved from right to left to match your feed

direction requirements.

• Slide the T-Bolt on the bottom of the flip stop into the T-Slot on

the top of the fence. See Figure 10.

• In the inboard position, the stop works with the supplied multi

T-Track fence and functions as an easily adjustable stop.

• In the outboard position, the body rotates and the flip arm

moves out. In this position the stop can work with the supplied

multi T-Track fence and a 3/4" sacrificial wood board.

To Convert from Inboard to Outboard Position

Remove the knob and T-Bolt and rotate the stop body 180°.

Replace the knob and T-bolt. See Figure 9.

inboard outboardtransition

Figure 9 Knob

Stop Body

T-Bolt

Hold Down Clamps

Refer to Figure 10

Slide the T-Bolts on hold-down clamps into the upper table

T-Track slots and clamp as required.

Figure 10

Hold-Down

Clamp

Upper Table

T-Track Slot

Flip Stop

T-Slot

TIPS

• Turn the feed handles on the drill press to makes sure they do

not interfere with the fence system. If needed, one or more of

the feed handles may need to be removed.

• Periodically check and make sure all knobs are tight

and secure.

• Clean the drill press table/fence system after each use:

-Wipe the drill press table and vacuum all T-Slots in

the table and fence.

-To prevent condensation and rust between the two

tables, DO NOT leave the drill press table mounted

on the drill press for long periods of time.