Electac MT800 User manual

FUME CONTROL EQUIPMENT

THE SAFEST WAY TO WELD

MTSOO & MT9OO MANUAL

manufactured by:

ELECTAC

Unit 7 /B,Studland Estate, Ball Hill,

N ewbU ry, berks. RG 1 5 OPO

Tel: (0OSS) 254900 Fax: (0635) 2s4OB2

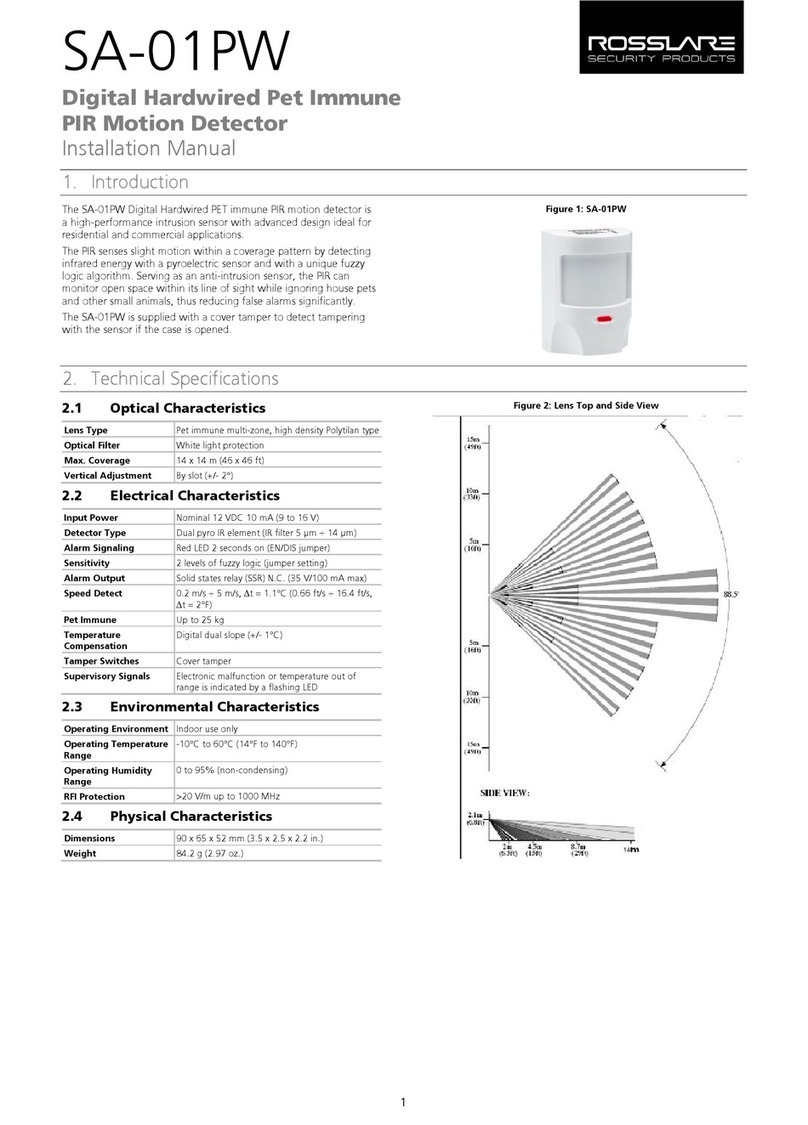

ELECTAC MT800 and MT900 WELDING FUME FILTBR

INTRODUCTION

Your MT800 or MT900 is a portable welding fume filter that uses a three stage

filtration system to filter welding fumes and return cleaned air to the work area.

The spark trap collects heavy particles, slag, pieces of mig wire etc. The fibreglass

insert inside the spark trap is supported by a steel gavze and stops sparks and very

hot pieces from damaging the main filter. It is important that the fibreglass is in good

condition and fitted correctly. Failure to replace the fibreglass when it is worn or

eaten away by hot sparks or molten metal can result in damage to the main filter or

in extreme oases a fire.

The disposable main filter cartridge, filters the welding smoke to 97oh efficiency,

99.996% to British Standard 3928 if the optional Hi-Efficiency filter is used.

MT800's have a single 1100 watt by pass motor, and MT900's have twin 1100

watt by pass motors to give extra suction and superior airflow.

OPERATION

Before operating your machine, it is important to check that your power supply is the

same as the machine, and that a suitable plug is fitted. All machines must be earthed.

Your machine is assembled at the factory, all that you have to do is to attach the flexible

hose to the spigot on the spark trap using the hose clip provided. The other end of the

flexible hose should be attached to anozzle with magnet, mig torch attachment, or the

take offspigot of mig extractor torch.

FILTER FULL LIGHT

All MT800 and MT900 models are now fitted with filter full indicators. This light is

situated adjacent to the on-offswitch. When illuminated the main filter cartridge should

be replaced immediately. It is always advisable to replace the fibreglass in the spark trap

at the same time as the filter cartridge.

ELECTAG

FUME GONTROL EQUIPMENT

THE SAFEST WAY TO WORK

FACTORY EXAMINATION OF LOGAL VENTILATION PLANT FOR THE

GONTROL OF SUBSTANGES HAZARDOUS TO HEALTH REGULATIONS

1988

Description of Plant

ModeL

Fan Tylpe

FiLter Type

Motor Power

Measured Airflow

Air Velocity

Perfor:mance

Equipment condition

SeriaL No.

P1ant Loeation

Date

Portable welding fume filter/fan unit

with flexible hose forrtat sourcerr

capture ( and capture nozzl-e)

MT900 single operator

Twin turbi-ne

Disposable cartridge

2.2 kW.

465m3 /hour

39m/sec @ 55mm0 hose end

B.Om/sec @ end of nozzle 200x80mm

Pass

New

206L6s

Welding Equipment & Cutting Servlces

Sheffield

2 February, 2004

P1ease note that equipment should be reteeted every L4

months. To arrange a retegt please contact:

ELEGTAG Ltd.

Unit 7 & 8, Studland Estate

Ball Hill, Newbury

Berkshire. RG2O OPW

Tel: O{635-254900 Fax: 0{635.2540A2

SWTTCH POSITIONS FOR DIFFERENT MACHINES

On Off

MTSOO

Auto Off

on/off Manual

on

MT800 fitted with auto

on/off relay

one Motor off Two motors

MT9OO MT900 fitted with

Auto on/off relay

USING THE FUME FILTER

MT800 and MT900 welding fume extractors can be used with a magnetic nozzle, with

a Mg torch attachment, or with a Mig extractor torch.

When used with the magnetic aoz,zle, the nozzle should be placed as near to the welding

arc as possible.

All.5"'^-

Auto on/off

two motors off Manual.

on two motors

tt2

\

i

tu )

n@>

)64

v

If the Mig torch attachment is used, it should be clipped onto the Mig nozzle

approximately 25mm from the end of the torch shroud. If weld porosity is experienced,

move the attachment further up the torch shroud.

When welding in combined situations, the attachments can be pushed either 90 degrees

to the left or the right to avoid porosity.

It is usually best to fix the 20mm diameter extraction hose to the Mig torch lead with tape

allowing a small loop where the extraction hose goes over the operators hand.

When using a Mig torch with built in extraction, follow the torch manufacturers

instructions, after connecting the extraction hose to the spigot adjacent to the Euro

connector ofthe torch.

i

I

I\

li

t

r

I

::

I

fi

,

1

f.

l"

t.i

I

MATNTENANCE

SPARK TRAP

In the spark trap of the MT800/I\4T900 is a

metal gauze and fibre glass surround. The

fibre glass surround should be cleaned every

1-2 days of welding depending on the size

of electrode or wire being used. If this fibre

glass becomes damaged, renew it im-

mediately. Failure to do so could result in

damage to the main filter. New fibre glass

surrounds are available from your dealer.

2. NEW FILTER

If the spark trap fibre glass has been cleaired and the suction of the machind is

poor, this indicates that a new filter is required.

Changing the filter cartridge

a) Switch offthe motor and disconnect from the mains.

b) Release the securing clips of the spark trap and remove the spark trap

and front plate.

c) Dispose of the used filter and fit a new filter(a smear of liquid soap on

the neoprene seal of the filter assists this operation.)

d) Push the front plate/filter assembly into the machine, ensuring that the front

pressure pipe is relocated in the rubber grommet in the front plate and

protruding into the spark trap.

e) Put the spark trap in place and secure with the clips.

0 Connect the machine to the mains and switch on.

3. CARBON BRUSHES

1

The carbon brushes in the motor should be changed after 1000 working hours from

new, and subsequent changes should be every 800 working hours.

T'itting New Rrushes

a) Switch offthe unit and disconnect from the mains

b) Undo the 4 no. M6 dome nuts that hold the back plate and swing the back plate

assembly to one side. This will enable access to the motor brushes.

c) Bend back the tags as shown in the above diagram, snip offand pull out the used

brushes.

d). Slide in the new brushes, ensure that the triangular catches on the side of the brush

holders locate in the slots of the caps.

e) Replace the machine back plate and secure with the dome nuts.

Connect the machine to the mains and switch on.

0

'I

r

I

:l

i

t

t

I

t

MTsOO/9OO SPARE PARTS LTST

DRG.NO PART NO DF'SCRIPTION QUANTITY

required per machine

1

2

J

4

991000

999001

999002

9990021A

991003 I

999004

99800s

998006

998007

998008

1009

l0l0

99t012

991014

991013

991015

998016

998017

9980rs

998018

998019

999020

999021

999023

998024

998025

2026

1026

9030

2031

2032

103 1

998026

998027

998028

998029

998030

99803 1

Carbon Brushes

Sheet metal case

Course Separator

Front Plate

Gauze

Hose Clip

Rubber foot

Foot Screws

Handle

Handle Screws

Filter FES

Filter FEH

Switch MT800

Switch MT900

Motor/Fan Assey 240Y By Pass motor

MotorlFan Assey 1lOV By Pass motor

Rubber Seal

Indicator light 240V

Indicator light l15v

Mounting screw

Grommet

Mains Lead

Back cover

Back Plate

Black Plate Foam

Back Cover Screws

65mm hose

45mm hose

65mm x 40mm reducer

65mmx45mm-45mmYpiece

65mm x 45mm reducer

Fibre glass insert FB I

Pressure sensor

Front sensor pipe

Rear sensor pipe

Retaining studding- 1 1 0mm.

Studding nuts

Cap nuts

214

I

I

1

1

2

4

4

I

2

1

1

1

1

u2

l2

l2

5

6

6

7

7

8

8

9

10

10

11

1

I

I

I

8

I

I

I

I

I

4

J.

J,

I

I

1

1

1

1

1

4

1

4

t2

6

J

4

I

1

I

,

I

I75m

75m

15

0

Motor I

Motor 2

Switch

-H

-cF

{a

Pressure switch

cg

t<

()

zFilter tull light

Live

WIRING DIAGRAM MT9OO

Pressure switch

Switch Filter tull light

Motor

Neutral

Live \\/TRING DIAGRAM N'I'I'8OO

.l

iI

I

I

II

{

J

1

rt

-)t

I

1

I

I

I

I

I

,!

I

t

l

i

rl

I

PURCIIASE REOIIISITION ORDER

r

\

Ur

On^b€nsl-s^ 9,/e-l(q-

u(asf 60 ?oorr$v* vuasl".S *y1rurL70r(.

\4.

SUPPLIER: ACCOUNT No :

DEL TO :ORDERNo:

BY: NOMINAL CODE:

AUTHORIZATION: DATE:

ITEM DESCRTPTIQN QTYREQ UNIT COST DATE REQ TOTAL

COST

LvecTac- M(nso

6\yq€ 6x'f0^p.c-ro(l

-<PAa<. I

A

ll

(= rS .-<o

II

I)'t

)5'u7rs Lt ( lA' cro \

IA) > 7J . ci'n

I!

l, I

4,L /L. .ro .

\.t

-\

Welding Equipment And Cutting Services Ltd

69 Tyler Street,Sheffield,South Yorkshire S9 1DH

Tel 01 142494141 Fax 01142490599

www.wecs{td.co.uk

WE ARE MOVING

uttlng

eMces Lro

I

PLEASE NOTE THAT AS FROM 24.1.05 WE ARE MOVING TO

NEW I.ARGER PREMISES.

PLEASE FIND BELOW OUR NEW DETAILS:

WELDING EQUIPMENT AND CUTTING SERVICES LIMITED

69 TYLER STREET

SHEFFIELD

SOUTH YORKSHIRE

59 1DH

TELEPHON E: 01 1 4 2424242

FAX: 0114 2424142

THANK YOU.

Master Distributor ForAll SAF and OERLIKON products

SAFOERLIKON National Equipment Service And Repair Centre ltrDllfol

';1,1i$uh #lrl"J aglcir"is8 gniilu0 bn.{ rnsrnryiunl EitrihioW

i r.il | 0e sr iita,t: rY rllr ru?, . Ir;eilierit, isei'ii& i6 t\.'T 0d

ggf tg},ss ' I vr .t;1 I F i' [0rrS$ l i .; .;;i'

>l u . og. btl -acsw.w\rt^il

.#b,IIVOfuI trF{A ilW

OT Oktlv0Irfi mfiA 3\&' *CI. f'.t\S lUC.fiE eA "fAh{T 3TOi4 SAASJ9

.ailelrvisHq fi 3CIfiAj W3t4

:eJlAT:${] UVII4 fiUCI WOJSS Ol4ll SAAIJq

03Tt Rit Ii e3 0 IVfi 3A O L4 ITTU 3 G 1,,1A T$43 M q I U03,9 yl I tlj 311f

]'H3fiTA fi3jYT e0

fi-l3lTq314t

SFIIh{AXfiOY HTUOE

HfiT EE

s.sSFS$s $f l0 :3l4OHq3J3T'

SII'SSSS Sf l0 :XAT

IJOY )it4AI"-11"

:l'iutlo:{ .4t}ai.ill,JO il:rr, ilr'{ rl/. ,i!'l :r)lf.rrjr; r',?i!: t';l;;i;li!

c:trr!i) 'ti;;rytQf LIrl,,::i;'i ,i h;Jilrlir , .l ii,rloitnll i'1()ii: i!:,'i(l'r/ /,

uffi#$j

i

SHEFFIELD

ENGLAND

SILVERWARE

CARRS OF SHEFFIELD (MANUFACTURING) LIMITED

' Troy House, 2 Holbrcjok Avenue, Holbrook, sheffield s20 3FH, Englancl.

Telephone: +44(o)Lt4251.0610 Fax: +44(o)tL4z51.o68j SalesofficeFax:i44(0)114 z5toB75

E.mail : customer.services@ carrs-of-sheffield.co.uk

www. cars-of-sheffield. co.u k

C SoUtJ C$-1-'' 6 Nf \"-\,€-.C,a .

(p>< N" o\\\2 \+1 o Sn1,

Qosr Sl*tus-\ UH\-r,Av6a AF Q\AS Sru{eR- i

3o /, to*

?r**== S.r?P.y 1-

Ex -(rz-n<c-lo R q*11 o trts et^ fugfr,Aq .s.lta€

11o Mr \cso I z2\_o.

S{t<. 6B se\6< \\o Zq \ 5 3

\*lt("\ t'ts.e.*rW s

C

I.l(\\y\'

tu r

I

S+x. Dtt L+loa1.q.

Illt!-qua",:nil!&_q!rs ,II

1^r <rDin D,S5e 0r- it+)' N Otu) t(

e,€A 4u.Ur\Lst'l!a'l't_0.N_u-sI_U&L-l:

liLJl'trltIt( :

, ..lt

-tf '.

r.,tiLt vLl( 1.o

ttt:QUliS't UD Ili,

Au'iltotuzn.i

' ,* .."

I\

s" .rZ€U( ..__ ACCt)UN'l'N()

0l(Dtll( I'tu :zs3

NOIVIINAL CODI.,

l)A'l'Lr :

l't'tinr

I)ti.SctUl,'t't oN

M(::r*> 0on:rnau6

t{"bgu (r*-r€

LZ4o

(

:,.1

\o

L

r)

t

Io c.-) (Jxr \-f

t+6sc qrrzix

r-iilhnE

l(l.iQUltU.rl) UNI'I'

cos'l' l(tiQUll(Et)

DA'l'11 'I'()'r'n t,

c0s't'

\3( {\

(;ltn l.Jt)'t'(') t'r\ I r

FUME CONTROL EQUIPMENT

THE SAFEiST WAY TO WELD

rrG t

2

I

I

I

P\,

operator twln motor

welding fume filter

100 watt motors

a

o

a

5or 22012301240 volt

ve range of

MT800 and

portability and

A

welding

MT9OO are

flexibility are required. Both machines can be

used with nozzles with magnetic upstands and,

System Ref. ',, Part No.

MTSOO fume filter

filter

x,45mm dia.

NOT INCLUDED.

115 volt:

220/240 vok:

Portable TWIN

standard filter

2 x 3.75m x 45mm dia.

NOZZLE NOT INCLUDED.

115 volt:

2201240 vok:

Part No.

277L

2242

1110

1240

welding fume filter

2 x 1100 watt motors

Prefilter, standard

Hose 3.75m x 55mm

NOZZLE NOT

115 volt:

2201240 vok: 110

2240

Filter System

'T.hc we ll-proven filtration s\/steln tlses |l s1-rrll-k

trilp to ct'lptLrre spirrks and hear.'r' pirrticlcs. Thc

nririn disl-rosable filter cartriclge caprtr-rrcs thc

rvclding sr-noke particul:lte.

Cooling System

A rnirjor cirLlse of premtrture f,rilr-rrc itr portablc

filter units is that thev rut-t loo hot clltc to trot

enough trir passing tl-rroLrgh the tttotttrs,

p:rrticularly wl-ren they' itre Lrsecl rt'irh rVllCi

extractor torches. To prrcl'ct-tt this hrrFtl-rgr1i11g,

ELECTA(l now Lrsc [r,vc-1'r,tss ttrotors, rvhich

take ir sepllrittc sLrpply of rtir to cool the

motors l-ronr that passing rhror,rgl-r the filrer

Sprt rk t rrr ;r

I

I

I

I

I

i

sYStent

l'r[.r. g,lrtss

l.rc irlrcr

Strrnrlrrrtl \l,rin lrrltcr

(l l iuh cf Iie re rrcr or

stlrnclrrrtl rvrtlt ;rctir c

chlrrcr,ltl ,rlsrr

:r v rr ila hlc )

fl

Accessories

A varierv of rrozzles rtttcl cxtrrrctittt-t attirchments

irre available for thc F-t-EC.'l-A(i portttble funre

extrrlct()r's.

Nozzles for the MT800 and

MT900 double operator

FN200 200mrn lvide fantail

FN300 300mm rvicle far.rtail

DN120 1?0um dia clish

Nozzle for the MT900

FN900 200nrnr rviclc frintail

All the abovc nozzlcs arc

complete with a magnet.

MIG Torch attachment.

Auto On/Off sensor using the

earth lead of the welder.

Tbchnical dtct

Width 255mm 255mm

Airflow 170m3/hour 340m'/hour

- @ 400mm WG -

I

I

iI

I

I

I

Hose size 45mm dia

Various

Filtration

(BS3e28)

MOEFT

ELECTAC rrobile filters have given rnany

years of trouble-free service in the most

clerrta rtd i ng c( )nd itiolrs ti rr tttanv conrpan ies

rhrourghor.rt the \World. The rugged steel

coustruction, the easy-to-adjust arm and the

lar:ge diarneter wheels are just a few features

that ha','e nacle these machines populal in

lilrge :rncl srnall rvorksl-rops. Available with

either nrecharnicrrl or electrosratic filters and

with a choice of ar-r-r-r lengths in single or clouble

ope[ator \/ersloTrs.

5

*.r F

Electrostatic - E Range

o Heavy duty industrial electrostatic cells

. No filter replacenlents. Filters easily washed

o Quiet operatiorr using a double inlet

centrifugal fan

o Door interlock protection - opening the cell

door cuts off the high voltage to the cell

o Fault indicator

. Double operator machine available

. Choice of self-supporting anrls:

Solid aluntinium tube constructittn uith

flexible joints (A type) or

Lighttueight flexible hose ruith internal

support (l- t1'pe)

. Choice of arm lengths - 2.5 metre, 3 nletre

or 4 metre

. Remote control frorn the hood ancl low

voltage light in the end of the l'rood available

Mechanical - EM Range

. Industrial standard mechanicill filter - easily

replarced

. Fif ter efficiency 99.996"1'

r Qr-riet operarion using zr double inlet

centrifugal fan

. Double operzltor machine available

. Choice of self-supportlng arms:

Solid aluminium tube construction with

/Texible joints (A type) or

Lightweight flexible hose with intcrnal

support (L rype)

. Cl-roice of arm lengths - 2.5 metre, 3 metre

or 4 metre

o Remote control fron-r the hood and low

voltirge light in the end of the hood available

. Recomrnended for stainless steel

Technical Data

Cabinet Dimensions: 970mm x 525mm x 515rnm

Weight: Kg

Motor: E1 & EM1: 0.75kW

E2 & EM2: 1.1 kW

E1 & EMl

E2 & EM2 1 900m'/hour; free blowing

2 1 60m'/hour, free blowing

6

Airflow

This manual suits for next models

1

Table of contents