Electric Dynafile 11021 Quick guide

Parts Page Reorder No. EUR-99-8

Effective May, 1999

Models:

11021 – 230V / 50Hz / 0,6 KW

11022 – Kit 230V / 50Hz / 0,6 KW Abrasive Belt Machine

Electric Dynafile®

Always operate, inspect and maintain this tool in accordance with the safety standards established by

OSHA, Underwriters Laboratories, Inc., The Canadian Standards Association and The American National

Standards Institute (ANSI). Dynabrade, Inc. assumes no responsibility for any damage or accidents

resulting from the misuse of this tool, its misapplication or nonadherence to precautionary safety measures.

WARNING

!

General Safety Rules

Read and save all instructions before operating this power tool.

Warning:

When using electric tools, basic safety precautions should always be followed to

reduce the risk of a fire, electric shock, and personal injury, including the following:

1. Keep work area clean. Cluttered areas and benches invite accidents.

2. Consider work area environment. Do not expose tools to rain. Keep

work area well lit. Do not use power tools in damp or wet locations.

Do not use tools in the presence of flammable liquids or gases.

3. Guard against electric shock. Prevent body contact with grounded surfaces.

For example; pipes, radiators, ranges, refrigerator enclosures.

4. Keep children away. Do not let visitors contact tool or extension cord.

All visitors should be kept away from work area.

5. Store idle tools. When not in use, tools should be stored in a dry, or locked

place - out of the reach of children.

6. Do not force tool. It will do a better and safer job at its intended rate.

7. Use the right tool. Do not force a small tool or attachment to do the job of

a heavy duty tool. Do not use tool for purposes not intended.

8. Dress properly. Do not wear loose fitting clothing or jewelry. Clothes can

be caught inmovingparts. Rubbergloves andnon-skidfootwear are

recommended when working outdoors. Wear protective hair covering to

contain long hair.

9. Use safety glasses. Alsouse face-shieldordust maskifoperation areaisdusty.

10. Do not abuse cord. Never carry tool by cord or yank it to disconnect from

receptacle. Keep cord from heat, oil and sharp edges.

11. Secure work. Use clamps or a vice to hold workpiece. It’s safer than using

your hand and it frees up both hands to operate tool.

12. Do not overreach. Keep proper footing and balance at all times.

13. Maintain tools with care. Keep tools clean for better use and safer

performance. Follow instructions for lubricating and changing accessories.

Inspect tool cords periodically and if damaged, have repaired by authorized

service facility. Inspect extension cords periodically and replace if damaged.

Keep handles dry, clean and free from oil and grease.

14. Do not leave tool running. Disconnect tools when not in use, before

servicing, when changing belts, contact arms, etc.

15. Remove keys and wrenches. Form a habit of checking to see that all

keys and adjusting wrenches are removed from tool before turning it on.

16. Avoid accidental starting. Do not carry around plugged in tool with finger

on switch. Be sure switch is off when plugging in.

17. Out-door use extension cords. When tool is used outdoors, use only

extension cord suitable for outdoor use. They should be marked with the

suffix W-A(for UL) or W (for CSA in Canada).

18. Stay alert. Watch what you are doing. Use common sense. Do not operate

tool when you are tired.

19. Check damaged parts. Before further use of the tool, a guard or other part

that is damaged should be carefully checked to determine that it will operate

properly and perform its intended function. Check for alignment of moving

parts, breakage of moving parts, binding of moving parts, mounting and any

other conditions that may affect its operation. Aguard or other part that is

damaged should be properly repaired or replaced by an authorized service

center unless otherwise indicated elsewhere in this instruction manual.

Have defective switches replaced. Do not use tool if switch does not

turn tool on or off.

20. Avoid gaseous areas. Do not operate portable electric tools in

gaseous or explosive atmospheres. Motors in these tools normally

spark, and the sparks can ignite fumes.

21. Do not alter or misuse tool. This tool is precision built. Any

alteration or modification not specified is misuse and may result in a

dangerous condition. Only these accessories and attachments that

are found in this instruction manual are acceptable for use with this

tool. The use ofany otheraccessoryorattachmentmight present a risk

totheoperator.

22. Replacement parts. When servicing, use only identical replacement

parts. When ordering replacement parts, please specify model and

serial numbers of your machine.

Voltage Warning

Before connecting the tool to a power source (receptacle, outlet, etc.),

be sure the voltage supplied is the same as what is specified on the

nameplate of the tool. Apower source with greater than that specified

for tool can result in serious injury to the user as well as damage to

the tool. Using a power source with voltage less than the nameplate

rating is harmful to the tool’s motor. If in doubt, do not plug in the tool.

Insulation

Electric Dynafile® is insulated according to DIN 57740/VDE 0740

and CEE-publication 20. Radio-shielded according to DIN 57875/VDE

0875 and CISPR. To protect the insulation do not drill any hole in

motor housing to fit any labels, use only stickers when it is required, to

give you added safety. Tools built with this type of insulation system are

not intended to be grounded. As a result, your Electric Dynafile® is

equipped with a two prong plug which permits you to use extension cords

without concern for maintaining a ground connection.

Note: Insulation does not take the place of normal safety precautions when

operating this tool. The insulation system is added for protection against

injury resulting from a possible electrical insulation failure within the tool.

Caution: When servicing insulated tools, use only identical replacement

parts. Repair or replace damaged cords.

Extension Cords

Insulated tools have two-wire cords, and can be used with either two-

wire or three-wire extension cords. Only round jacketed extension cords

should be used, and we recommend that they be listed by Underwriters

Laboratories (UL) - (CSAin Canada). If the extension cords will be used

outside, the cord must be suitable for outdoor use. They should be

marked with the suffix W-A(for UL) or W (for CSA in Canada). Any cord

marked as an outdoor cord can also be used for indoor work.

Important: To increase the life of the electrical motor it is absolutely

necessary to clean the inside by blowing carefully compressed air

through the ventilation channels.

Sound Level: 85 - 88 dBA.

Warning: Keep extension away from the immediate working area.

Full OneYear Warranty

Following the reasonable assumption that any inherent defect which might prevail in a product will become apparent to the user within one year from the date of

purchase, all equipment of our manufacture is warranted against defects in workmanship and materials under normal use and service. We shall repair or replace

at our factory any equipment or part thereof which shall, within one year after delivery to the original purchaser, indicate upon our examination to have been

defective. Our obligation is contingent upon proper use of Dynabrade tools in accordance with factory recommendations, instructions and safety practices. It

shall not apply to equipment which has been subject to misuse, negligence, accident or tampering in any way so as to affect its normal performance. Normally

wearable parts such as bearings, contact wheels, rotor blades, etc., are not covered under this warranty.

Important Operating and Safety Instructions

Carefully read all instructions before operating or servicing any Dynabrade®Abrasive Power Tool.

Warning: Hand, wrist and arm injury may result from repetitive work motion and overexposure to vibration.

Operating Instructions:

Warning:Eye, face and body protection must be worn while operating power tools. Failure to do so may result in serious injury or death.

Follow safety procedures posted in workplace.

1. With power source disconnected from tool, securely fasten abrasive/accessory on tool.

2. Connect power source to tool. Be careful not to switch on in the process.

3. Hold tool by the motor housing only. One or two hands may be used. Do Not hold tool by head/housing assembly. Keep hands away from all

grinding/sanding edges and moving parts.

4. Switch on to start tool, switch off to stop tool.

5. While tool is running,Adjust belt tracking by tuning 95218 RoughAdjustment Knob to the left or right accordingly, so as abrasive belt rides

evenly over contact arm.

6. Always work off the return-side of the abrasive belt. This will ensure superior tracking and reduce downtime of tool.

2

To Change Belt:

1. Disconnect power source.

2. Remove 11005/E Belt Guard by lifting up front “lip”and unhooking latches.

3Gently pull back on idler arm to expose internal workings of tool.

4. Depress idler arm lever and pll belt away from the contact wheel.

5. Slip belt over contact wheel.

To Replace Belt

1. Create a loop with belt by pinching together the sides of belt in the middle.

2. Slip one loop under the no. 12 Drive Wheel and around idler arm.

3. Depress idler arm lever and pull belt toward the contact wheel.

4. Slip belt over contact wheel, connect to power source.

5. Adjust belt tracking using 95218 Knob.

To Change Contact ArmAssembly:

1. Disconnect power source.

2. Remove 11005/E Guard by lifting up front “lip” and unhooking latches.

3Gently pull back on idler arm to expose internal workings of tool.

4. Depress idler arm lever and pull belt away from the contact wheel.

5. Slip belt over contact wheel.

6. Remove 95218 RoughAdjustment Knob.

7. Remove contact arm and replace with desired arm, making sure that

the tab on the end of the arm is facing forward.

8. Replace 95218 knob.

9. Install abrasive belt and replace belt guard.

10. Connect power source and adjust belt tracking by turning 95218 knob.

Abrasive Belt/Contact Arm Change Instructions

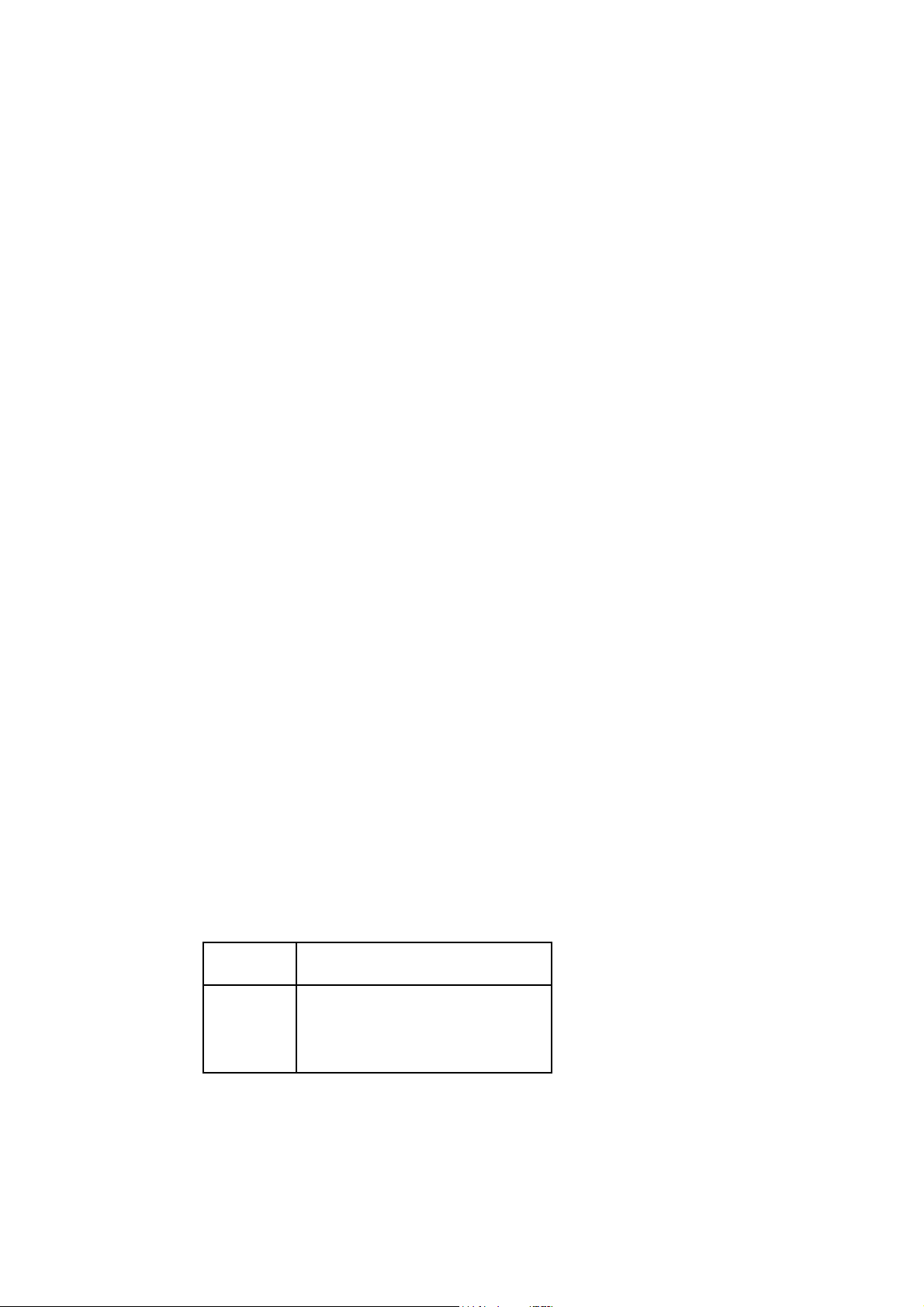

Grounded tools require a three wire extension cord. Double insulated tools can use either a two or three wire extension cord. As the distance from the

supply outlet increases, you must use a heavier gauge extension cord. Using extension cords with inadequately sized wire causes a serious drop in

voltage resulting in loss of power and possible tool damage. Refer to the table below to determine the required minimum wire size.

The smaller the gauge number of the wire the greater the capacity of the cord. For example a 14 gauge cord can carry a higher current than a 16 gauge cord.

When using more than one extension cord to make up the total length, be sure each cord contains at least the minimum wire size required. If you are using

one extension cord for more than one tool, add the nameplate amperes and use the sum to determine the required minimum wire size.

Guidelines For Using Extension Cords

• If you are using an extension cord outdoors, be sure it is marked with the suffix“W-A” (“W” in Canada) to indicate that it isacceptable for outdoor use.

• Be sure your extension cord is properly wired and in good electrical condition. Always replace a damaged extension cord or have it repaired by a qualified

person before using it.

• Protect your extension cords sharp objects, excessive heat and damp or wet areas.

Read and save all instructions for future reference

Nameplate Extension Cord Length

Amperes 25' 50' 75' 100' 150' 200'

0–5.0 16 16 16 14 12 12

5.1–8.0 16 16 14 12 10 –

8.1–12.0 14 14 12 10 – –

12.1–15.0 12 12 10 10 – –

15.1--20.0 10 10 10 – – –

*Based on limiting the line voltage

drop to live volts at 150% of the

rated amperes

Extension Cords

Safety Instructions:

Warning:Eye, face and body protection must be worn while operating power tools. Failure to do so may result in serious injury or death.

Follow safety procedures posted in workplace.

Important: User of tool is responsible for following accepted safety codes such as those published by theAmerican National

Standards Institute (ANSI).

•Operate machine for 30 seconds before application to workpiece to determine if machine is working properly and safely before work begins.

•Always disconnect power supply before changing abrasive or making machine adjustments.

•Inspect abrasives and accessories for damage or defects prior to installation on tools.

•Please refer to Dynabrade’s Warning/Safety Operating Instructions Tag (Reorder No. 95903) for more complete safety information.

Warning:Hand, wrist and arm injury may result from repetitive work, motion and overexposure to vibration.

95216 Pivot Pin

(for IdlerArm)

95311 Screw

95218 Knob

(For mounting contact

arm and adjusting belt tracking)

95070 Threaded Insert

Dynapad

11007 IdlerArmAssembly (Incl. 11008 IdlerArm

and (2) 11011 Idler WheelAssemblies)

11008 IdlerArm with 95070 Threaded Insert

11105/E Guard

95162 Idler Wheel Mount Screw (2)

11010 Tension Spring

(for IdlerArm)

11011 Idler Wheel BearingAssembly (2)

(Incl. 95162 Screw, 11013 Bearing and 11006 Idler Wheel.)

11040 Spring

11102/E Housing

3

Head/Housing Assembly ContactArm Assemblies

(see page 4)

40029 Cam Lock

Black

Black

Black

Red

Yellow

Yellow

Yellow Yellow

Transparent

24 23

20

19

38

29

28

27

36 37

22

13

39

40

41

26

42

18

16

15

21

14

13

3

4

5

6

7

12

9

17

Electric Motor Assembly

25

1

2

Index Key

No. Description

1 Rubber Suspension Ring

2 Bearing

3 Rotor

4 Snap Ring

5 Snap Ring

6 Bearing

7 End Plate

8 Screw

9 Aluminum Ring

12 Drive Wheel

13 Screw

14 Stator

15 Housing

16 Brush Holder

17 BrushAssembly

18 End Cape

19 Screw

Index Key

No. Description

20 Cord Clamp

21 Interference Capacitor

22 Strain Relief

23 End Cap

24 Cord and Plug Set

25 Ventilation Ring

26 Switch

27 Electronic Board

28 Potentiometer Shaft

29 Speed Regulator

36 Screw

37 Magnetic Ring

38 Adapter

39 Stranded Hook-Up Wire

40 Stranded Hook-Up Wire

41 Stranded Hook-Up Wire

42 Stranded Hook-Up Wire

Electric Dynafile®Standard Contact Arms

7/16" (11 mm)

Belt Size:

1/4" (6 mm) x 24" (610 mm) Belt Size:

1/4" (6 mm), 1/2" (13 mm) x 24" (610 mm)

Belt Size:

1/2" (13 mm) x 24" (610 mm)

Belt Size:

1/2" (13 mm) x 24" (610 mm)

Belt Size:

1/2" (13 mm) x 24" (610 mm)

Belt Size:

1/2" (13 mm) x 24" (610 mm)

11066:

5/16"(8 mm) x 1/8" (3 mm)

11027: 1/2"(13 mm)

11219

11212

11213 11228

11231

11214

11068: 5/16"(8 mm) x 3/8" (10 mm)

11070: 7/16"(11 mm) x 3/8" (10 mm)

11034: 1/4"(6 mm)

11135: 1/2"(13 mm)

11025: 1/2"(13 mm)

11080: 1" (25 mm) x 3/8"(10 mm)

11078: 5/8" (16 mm) x 3/8"(10 mm)

11084: 3/4" (19 mm) x 1/2"(13 mm)

11025: 1/2"(13 mm)

Belt Size:

1/8" (3 mm), 1/4" (6 mm) x 24" (610 mm)

Belt Size:

1/2" (13 mm) x 24" (610 mm)

Belt Size:

1/2" (13 mm) x 24" (610 mm)

Belt Size:

1/4" (6 mm) x 24" (610 mm)

Belt Size:

1/4" (6 mm) x 24" (610 mm)

Belt Size:

1/2" (13 mm) x 24" (610 mm)

11215

1/2" (13 mm) x 1/2" (13 mm)

11216

11217

9/16" (14 mm)

11232

11239

11243

11072: 7/16"(11 mm) x 1/8" (3 mm)

11074: 5/8"(16 mm) x 1/8" (3 mm)

11076: 7/16"(11 mm) x 3/8" (10 mm)

11027: 1/2"(13 mm)

11135: 1/2"(13 mm)

11086: 1" (25 mm) x 3/8"(10 mm)

11068: 5/16" (8 mm) x 3/8"(10 mm)

11084: 3/4" (19 mm) x 1/2"(13 mm)

11034: 1/4"(6 mm)

11032: 1/4"(6 mm)

11027: 1/2"(13 mm)

5/16" (8 mm) x 3/4 (19 mm)"

Belt Size:

1/2" (13 mm) x 24" (610 mm)

11218

11078: 5/8"(16 mm) x 3/8" (10 mm)

11025: 1/2"(13 mm)

11262

Belt Size:

1/2" (13 mm) x 24" (610 mm)

11078:5/8" (16 mm) x 3/8"(10 mm)

11026: 1/2"(13 mm)

DYNABRADE®

DYNABRADE EUROPE, S.àr.l. •ZoneArtisanale •L-5485 Wormeldange—Haut, Luxembourg

Phone: 352 76 84 94 •Fax: 352 76 84 95 •E-mail: [email protected] •Web Site: http://www.Dynabrade.com

11237 & 11238 Turbine Blade Arms 11255 Cross-Bow Arm

•I.D. polishing or deburring

with one 180° wrist turn.

•Deburr leading radius of

1" (25 mm) to 4" (102 mm)

round openings.

Belt Size: 1/2" (13 mm)

x 34" (864 mm).

•Grind, blend and polish turbine blades.

•Reach areas as small

as 5/16" (8 mm) wide.

11237: 1/4" (6 mm) x 24" (610 mm) belts

11066 Contact Wheel, 5/16" (8 mm) dia. x 1/8" (3 mm) wide steel.

11238: 1/2" (13 mm) x 24" (610 mm) belts.

Contact Wheel: 1/4" (6 mm) dia. x 3/8" (10 mm) wide steel (with three 11051 Bearings).

1-1/2"

38 mm

STRAP POLISH AREA

11234 Double-Burrer Arm •Deburrs both edges of

workpiece simultaneously.

•Contact wheels adjust for

material 1/8" (3 mm) to

5/8" (16 mm) thick.

Belt Size: 1/2" (6 mm) x 34" (864 mm).

11080 Contact Wheels: 1"(13 mm) dia. x 3/8" (9 mm) wide, rubber.

11257: Custom-made. To order, specify usable length up to 32" (813 mm).

Specify 11068 – 5/16" (8 mm) diameter steel, or 11078 – 5/8" (16 mm)

diameter rubber contact wheel.

11178: 9" (229 mm) reach with 11068 – 5/16" (8 mm) dia. steel contact wheel.

Belt Size: 1/2" (13 mm) x 34" (864 mm). 45 PSI / 3 Bars Max.

11179: 9" (229 mm) reach with 11078 – 5/8" (16 mm) dia. rubber contact wheel.

Belt Size: 1/2" (13 mm) x 34" (864 mm).

11257, 11178 and 11179 Spear Arms

•Up to 32" (813 mm) reach. Enter

slots as narrow as 3/8" (9 mm).

•Deburr 1/2" (13 mm) to

1" (25 mm) tubing.

11253 and 11254 Big Wheel Arms

11253 Arms (specify width)

11377 Contact Wheel: 2-1/8" (54 mm) dia. x 1/2" (13 mm) wide, urethane.

11378 Contact Wheel: 2-1/8" (54 mm) dia. x 1/2" (13 mm) wide, urethane.

11254 Arms (specify width)

11375 Contact Wheel: 4-3/4" (121 mm) dia. x 1/2" (13 mm) wide, urethane.

11376 Contact Wheel: 4-3/4" (121 mm) dia. x 1/4" (6 mm) wide, urethane.

Belt Size:

1/4" (6 mm) to 1/2" (13 mm)

x 34" (864 mm).

•Grinds and polishes deep slots or narrow groves.

•Choose 1/4" (6 mm) or 1/2" (13 mm) wide wheels in 2-1/8"

(54 mm) dia. (11253), or 4-3/4" (121 mm) dia (11254).

This manual suits for next models

1