Electro Plastics EPI-LX-R Series User manual

EPI-LX-R 4/17/12 1/2

One (1) power supply

Four (4) self-drilling screws (#8-18)

Four (4) recessed bumpers

Description

1.

Supplied Parts

EPI-LX-R

Power Supply Series with Regulator

Low Voltage, High Efficiency

The EPI-LX-R power supply series is built to the highest safety standard,

with built-in circuit breakers on the primary and secondary sides. The

load, which is divided into separate circuits to provide SELV (Safety

Extra-Low Voltage), is connected to an interface board. Additionally, a

built-in regular board serves as an intelligent switch to enable/disable the

line voltage in such a way that switching/pulsing does not harm the power

supply’s toroidal coil(s). The interface and regulator boards are both

RoHS compliant.

Design

The power supply’s mechanical design is both functional and installation

friendly. This slim and congenial design is made from extruded aluminum

profiles providing a high performance cooling structure as well as an

enclosure eliminating air sound. Sound is also reduced by the high

quality winding of the coils themselves, thus making the power supply

essentially silent. All vibrating parts are isolated, thereby eliminating

transmittal of noise to the building structure.

Surge

Traditional power supplies / transformers have a high starting current which

creates a surge that is many times higher than a nominal current. The

larger EPI-LX-R power supplies have a unique parallel connection that

reduces the surge by one third for a 1500 VA power supply and one half for

a 1000 VA power supply. For certain areas (particularly residential

applications), NEC requires AFCI circuit breakers on 120 VAC systems. To

simplify wiring and circuit breakers, use 230 VAC models.

Controls

Controls are to be chosen carefully, as power supplies started up often in

quick succession will be ruined as a result of the large amount of heat

developed in the primary coil. The heat developed in the power supply

increases by I2R, so when the starting current occurs, the heat developed

can be up to 1000 times normal. A power supply is not ruined by the load

but by the starting current which generates an abundant amount of heat.

This causes the insulation in the transformer to be destroyed. To ensure

long life and maximum efficiency, use only recommended controls for the

EPI-LX-R power supply series.

Derating of Power Supplies and Wires

Power Supplies that are exposed to high ambient temperatures above

77°F (25°C) must be derated, i.e., the maximum permitted load must be

reduced. It is also very important not to bundle up wires carrying high amps

as they will overheat, thereby inhibiting the ability to carry the intended

current.

The power supply must not be in contact with flammable materials,

as it is completely normal for power supplies to heat up, and it is not

unusual for the surface of the enclosure on a power supply to be hot

to the touch.

The power supply must not be covered with an insulating material.

It is preferable not to place the power supply in 'quiet' areas, such as

bedrooms and reading rooms, as the magnetization of the iron core

may generate a low noise which could be annoying.

Avoid placing the power supply on large surfaces, which may

transmit vibration; good mounting points are concrete pillars, brick

walls and steel girders.

Do not place the power supply in the vicinity of monitors and

television screens, as it can affect the picture's positions.

The power supply must be positioned so that it can easily be

accessible for servicing and repairs.

Installation Procedure

3.

The installation must be carried out by an electrician and comply

with electrical codes.

Turn off power at the main electrical panel to avoid electrical shock.

If needed, unhinge and remove cover of power supply.

Remove snap bushing from positioning hole on power supply.

Mark a center point at the top of the mounting location. Drive a

screw (with head diameter less than positioning hole) partially into

center point. Screw head should be offset enough so as to hang

power supply.

Hang power supply on center screw and align power supply

accordingly. The center screw is a

temporary placehold while

mounting screws and bumpers along outer flanges are secured. Do

not rely on center screw to fully support weight of power supply.

Air vents

(Do not block)

Snap bushing

Install bumpers on underside of power supply along outer flanges as

shown below. Secure power supply to mounting surface with

included mounting screws. Remove center screw once power

supply is secured.

Reinsert snap bushing into positioning hole. Route signal cable(s)

through this hole.

Wire the EPI-LX-R power supply according to your application. See

the wiring diagram in Section 5.

Apply power to the EPI-LX-R power supply.

NOTE: Bumpers will reduce

vibration transmitted from

power supply chassis.

24

COM

TRG

GND

SLV

Positioning hole

with Snap bushing

Regulator

board

Signal cable

Installation Guidelines 3.

To ensure optimum conditions and a long service life for the

EPI-LX-R power supply it is important to:

Mount the power supply in a vertical position (with load wires routing

from bottom panel) so that heat is dissipated effectively.

Never put a power supply where the ambient temperature is higher

than 77°F (25°C), unless specified otherwise on the power supply's

rating plate.

Mount chassis

VERTICALLY

for proper heat

dissipation

Positioning hole

Bumpers

(Install with recessed hole

facing flange underside)

Mounting

screws

EPI-LX-R 4/17/12 2/2

Electro Plastics, Inc. warrants this product, excluding circuit breakers, to be free from

defects in the workmanship or materials, under normal use and service, for a period

of ten (10) years (transformer coils) and two (2) years (internal electronics) from the

date of purchase by the consumer. If during the warranty period the product is

determined to be defective, Electro Plastics, Inc. (at its sole discretion) shall repair or

replace it. Please refer to the Terms & Conditions of Sale, located at

www.electroplastics.com for complete details.

L1 L2

GND

1 2 N N

}

Model Voltage Frequency

, ,

, , 60HzEPI-LX-R-500 120/24V

Wiring Diagram

3.

The EPI-LX-R power supply series has 2 types of PCB interface boards.

5.2 EPI-100

+

EPI-210 PCB

EPI-LX-R (1000, 1500 VA) Wiring Diagram

Service Panel

Circuit Breaker

2

Two-Pole Switch

(Optional – Recommended)

Stranded Wires

Stranded Wires

L1 1A 2A 1B 2B 1C 2C

L2

GND

N N N N N N

}

}

}

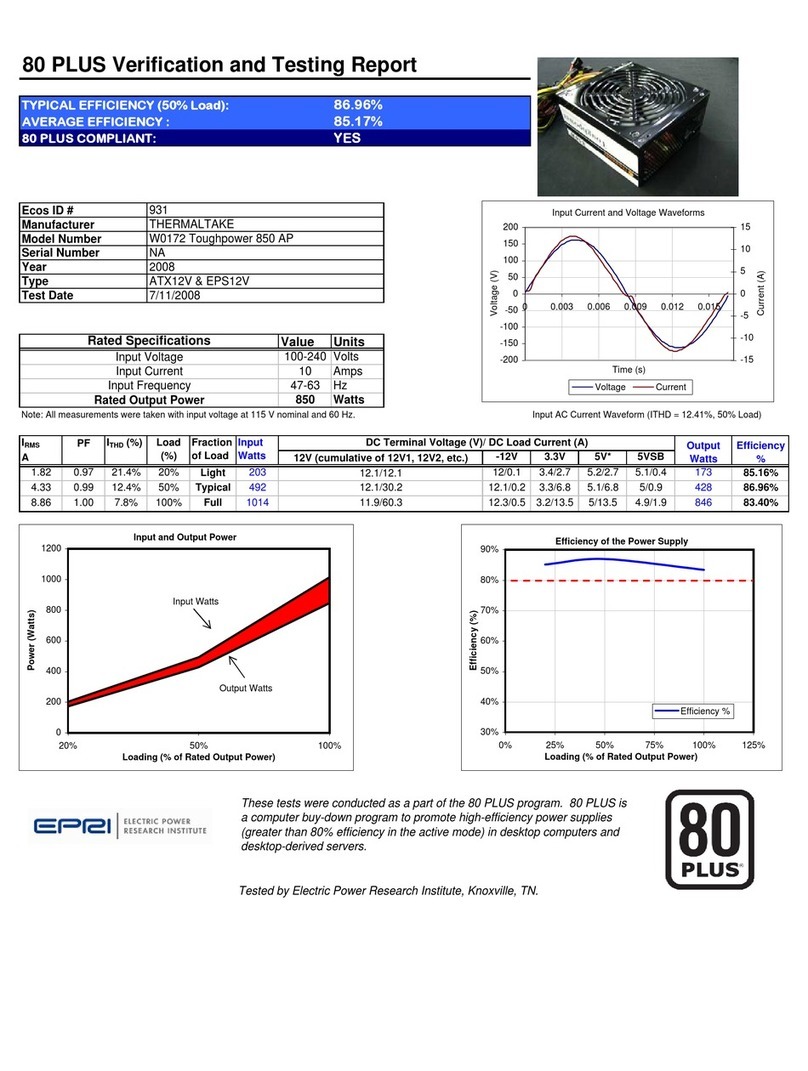

Power supply type: Low voltage dry type isolation power supply

Primary voltage: 120, 208, or 230 VAC

Secondary voltage: 24 VAC

Frequency: 60 Hz (50/60 Hz for 230 VAC models)

Efficiency: 96%

Insulation class: B (130°C)

5.

Technical Specifications

Ordering Information

(Example)

For any questions regarding product installation or operation, contact us

at:

11147 Dorsett Road

Maryland Heights, MO 63043-3505, USA

Phone: (314) 426-3555

Toll-free: (877) STEP-TEC

Fax: (314) 426-3556

E-mail: info@electroplastics.com

www.electroplastics.com

Warranty & Approvals

10.

Customer Assistance

11.

Service Panel

Circuit Breaker

2

Two-Pole Switch

(Optional – Recommended)

Circuit protection: Circuit breakers on primary and on secondary

Enclosure: For indoor use only

Wire gauge (EPI-100/110 PCB): 14 to 10 AWG (2.5 to 6 mm

2

)

Wire gauge (EPI-210 PCB): 20 to 14 AWG (0.5 to 2.5 mm

2

)

Maximum signal load: 2.5 A / 24 VAC

To 3-Wire, Low Voltage

Thermostat (24 VAC)

5.1 EPI-110

+

EPI-210 PCB

EPI-LX-R (250, 500 VA) Wiring Diagram

To 3-Wire, Low Voltage

Thermostat (24 VAC)

NOTE: Use only

stranded wires in

PCB terminals. Strip

0.25" (6mm) of

insulation from wire

ends, and insert wires

in a straight (rather

than twisted) fashion

for best contact.

NOTE: Up to 20 power supplies can be connected to one control unit with a turn on delay

of 1.5 seconds between each power supply.

Maximum control (per master signal):

20 EPI-LX-R power supplies linked via GND

and SLV terminals on each EPI-210 PCB

Circuit X

250 / 500 VA*

*Refer to the Circuit Allocation table in Section 6

for more details.

Circuit C

500 VA*

Circuit B

500 VA*

Circuit A

500 VA*

*Refer to the Circuit Allocation table in Section 6

for more details.

= Circuit applicable = Circuit not applicable

Product Specifications

*Variable load refers to a PTC type of draw (e.g. STEP Warmfloor™ self-regulating heating

elements) as the load will draw less after startup for continuous duty cycles.

Circuit Allocation

6.9" (175 mm)

3.5" (89 mm)

H

1.5" (38 mm)

1.5" (38 mm)

Replacement

Circuit Breaker

Snap Action

Miniature C.B.

(Type MB1)

Model MB1-XX-PH

(where XX = Amps)

Current Ratings:

2.5A, 5A, 10A, 15A, 20A, 25A

(AC/DC) Voltage:

250 VAC (maximum)

32 VDC (maximum)

Interrupting Capacity:

1000 A @ 250 VAC

2000 A @ 125 VAC

200 A @ 32 VAC

Circuit Breaker Designation

Dimensions & Weight

Product Classification

Conforms to: CENELEC EN 61558-1, IEC 61558-1, IEC 61558-2-2, UL 5085-1, UL 5085-2-2, CSA C22.2 No. 66

2

Terminals marked with an “L2” can be used as neutral terminals.

For certain

areas, NEC requires

AFCI circuit breakers on

120 volt systems. To simplify wiring and circuit breakers, use 230 volts.

1

To bypass thermostatic control, place a shunt wire between the terminals marked and

on the EPI-210 PCB. Switching can also be implemented between these two terminals.

(24 )

(TRG)

1

1

GND

SLV

Master

EPI-LX-R

GND

SLV

Slave

EPI-LX-R

COM

TRG

GND

SLV

Slave

EPI-LX-R

COM

TRG

...

(Example)

Delay = 1.5 seconds Delay = 1.5 seconds

Model

Circuit I.D.

Maximum

Output

Max. Capacity Per Circuit

X A B C Constant Load Variable Load*

EPI-LX-R-250

1 x 250 VA 80% 90%

EPI-LX-R-500

1 x 500 VA 80% 90%

EPI-LX-R-1000 2 x 500 VA 80% 90%

EPI-LX-R-1500 3 x 500 VA 80% 90%

Model

Primary Circuit Breaker

Secondary Circuit Breaker

120 VAC 208 VAC 230 VAC 12 VAC 24 VAC

EPI-LX-R-250

5A 2.5A 1 x 25A 1 x 15A

EPI-LX-R-500 10A 5A 5A 1 x 25A

EPI-LX-R-1000 15A 10A 10A 2 x 25A

EPI-LX-R-1500 20A 15A 15A 3 x 25A

Model Height "H" Weight

in mm lb kg

EPI-LX-R-250

11.5 292 14 6.4

EPI-LX-R-500 14.375 365 17 7.7

EPI-LX-R-1000

22.375 568 28 12.7

EPI-LX-R-1500

28.375 721 41 18.6

Model Primary Voltage Secondary Voltage Frequency

12 VAC 24 VAC

EPI-LX-R-250 120 VAC

60 Hz

230 VAC

50/60 Hz

EPI-LX-R-500

120 VAC

60 Hz

208 VAC 60 Hz

230 VAC 50/60 Hz

EPI-LX-R-1000

120 VAC

60 Hz

208 VAC 60 Hz

230 VAC 50/60 Hz

EPI-LX-R-1500

120 VAC

60 Hz

208 VAC 60 Hz

230 VAC 50/60 Hz

= Voltage available = Voltage not available

24

COM

TRG

GND

SLV

24

COM

TRG

GND

SLV

(Optional)

(Optional)

This manual suits for next models

4

Popular Power Supply manuals by other brands

Elgar

Elgar Sorensen DCS 3kW Series Operation manual

ASL INTERCOM

ASL INTERCOM PS 280 user manual

TDK-Lambda

TDK-Lambda CM4 Application notes

Pico Macom

Pico Macom MPC12 Installation and operation manual

Solar Stik

Solar Stik 24VDC HyPR 3000 Operator and maintenance manual

Siemens

Siemens SITOP PSU100S operating instructions