Electrolab 2110EX-A User manual

EL29300 Version V.000

Last Updated: 01/2022 © 2022, Electrolab, Inc. All Rights Reserved.

USER MANUAL

Explosion Proof Housing - Analog

Model 2110EX-A

EL29300 Version V.000

Last Updated: 01/2022 © 2022, Electrolab, Inc. All Rights Reserved.

© 2022 Electrolab, Inc. ALL RIGHTS RESERVED.

This document may not be reproduced, copied (except for a single archive copy), used, disclosed,

transferred (including sold, leased, or rented) adapted or modified except in accordance with the

terms andconditions of the License Agreement between the user and Electrolab, Inc.

Electrolab, Inc. makes no representations of warranties with respect to the contents hereof and

specificallydisclaims any implied warranties of merchantability of fitness for any particular purpose.

Electrolab, Inc. reserves the right to revise this publication and to make changes from time to time

in its content without the obligation to notify any person or organization of such revision or

changes.

USER MANUAL

Page 3of 15

Document # EL29300

Version: V.000

Model 2110EX-A Explosion Proof Housing

CHARACTERISTICS

General Desription:

The Model 2110EX-A is NRTL certified explosion proof for use in hazardous

locations/environments (Class I, Division 1, Group D) in accordance with UL1203, UL61010-

1, CSA C22.2 No. 30, and CSA C22.2 No. 61010-1. The device is also certified to provide

Intrinsically Safe output for use in hazardous locations (Class I, Division 1, Group D) in

accordance with ANSI/UL 913, CSA C22.2 No. 60079-0 and CSA C22.2 No. 60079-11.The

Barrier Unit actively limits the current and voltage to protect intrinsically safe equipment from

power spikes and to maintain the intrinsic safety. The barrier provides intrinsically safe power

and intrinsically safe power and communication or I/O lines for devices located in Hazardous

Areas.

Functions:

The 2110EX-A is capable of delivering safe levels of supply power and 2-wire RS485 digital

signals to a device located in Class I Division 1 location and also provides two 4-20mA(3 wire

configuration) analog signal output channels.

SPECIALWARNINGS

Use only NRTL – listed NEC Class 2 power supply. Voltage should not exceed 24VDC

Use only with certified Explosion Proof conduit or certified Explosion Proof cable and

connector (eg. CLX and TMCX products).

Always attach the cables to the connector strain relief plate with cable ties. This will

ensure that cables do not migrate in the enclosure if they are disconnected from connector

by accident.

Always lock the cover by fastening its hex screw with a hex socket; use a hex spanner of

1.5mm.

AVERTISSEMENTS SPÉCIAUX

N'utilisez que des blocs d'alimentation limités NEC class 2 répertoriés d‘une Laboratoire

d'essai reconnu à l'échelle nationale. La tension ne doit pas dépasser 24VDC

Utilisez uniquement des conduits certifiés antidéflagrants ou des câbles et connecteurs

certifiés antidéflagrants (par exemple, les produits CLX et TMCX).

Fixez toujours les câbles à la plaque de décharge de traction du connecteur avec des

colliers de serrage. Cela garantira que les câbles ne migreront pas dans le boîtier s'ils sont

déconnectés du connecteur par accident.

Verrouillez toujours le couvercle à l'aide d'une vis à six pans creux à l'aide d'une clé

hexagonale de 1,5 mm de diamètre.

TECHNICAL DATA

Supply (X1-4):

Voltage: 12 to 24 VDC max

Maximum input current: 200 mA

Current consumption: 80 mA max

USER MANUAL

Page 4of 15

Document # EL29300

Version: V.000

Communication analog output lines (X1-2 and X1-3):

Voltage: 5 VDC nom / 24 VDC max

Output current:

Maximum: 50 mA max - fuse limited

Normal operation range: 0 to 20mA

Um:

24 VDC (Should be supplied only from NRTL-listed limited power supply)

Environmental Conditions:

Temperature:

Operating -40 to 70 °C

Storage -40 to 85 °C

Atmospheric conditions:

Pressure 1 atm.

Oxygen concentration not greater than 21%

Maximum Altitude 2000m

Approvals:

UL1203 Explosion-Proof and Dust-Ignition-Proof Electrical Equipment for Use in

Hazardous (Classified) Locations

UL61010-1 Standard for Safety Electrical Equipment For Measurement, Control, and

Laboratory Use

CSA C22.2 No. 30 Explosion-proof enclosures for use in Class I hazardous locations

CSA C22.2 No. 61010-1 Safety requirements for electrical equipment for measurement,

control, and laboratory use

UL 91 Standard for Intrinsically Safe Apparatus and Associated

Apparatus for Hazard (Classified) Locations

UL 60079-11 (Intrinsic Safety "i" Zones 0 and 1)

CSA C22.2 No. 60079-0 Explosive atmospheres - Part 0: Equipment - General requirements

CSA C22.2 No. 60079-11 Explosive atmospheres - Part 11: Equipment protection by

intrinsic safety "i"

Mounting:

Weight: approx. – 1.5Kg (3 Lbs.)

Connection: WAGO polarized plug-in disconnect/connect cage clamp

connection terminal blocks to accomodate terminations up to 1.5mm2

Location: Class I Div 1 Group D Temperature code T4

Dimensions: PCB: 3.17“ x 3.17“

Enclosure: 4.2“x5.7“x 5“ (HxLxW)

USER MANUAL

Page 5of 15

Document # EL29300

Version: V.000

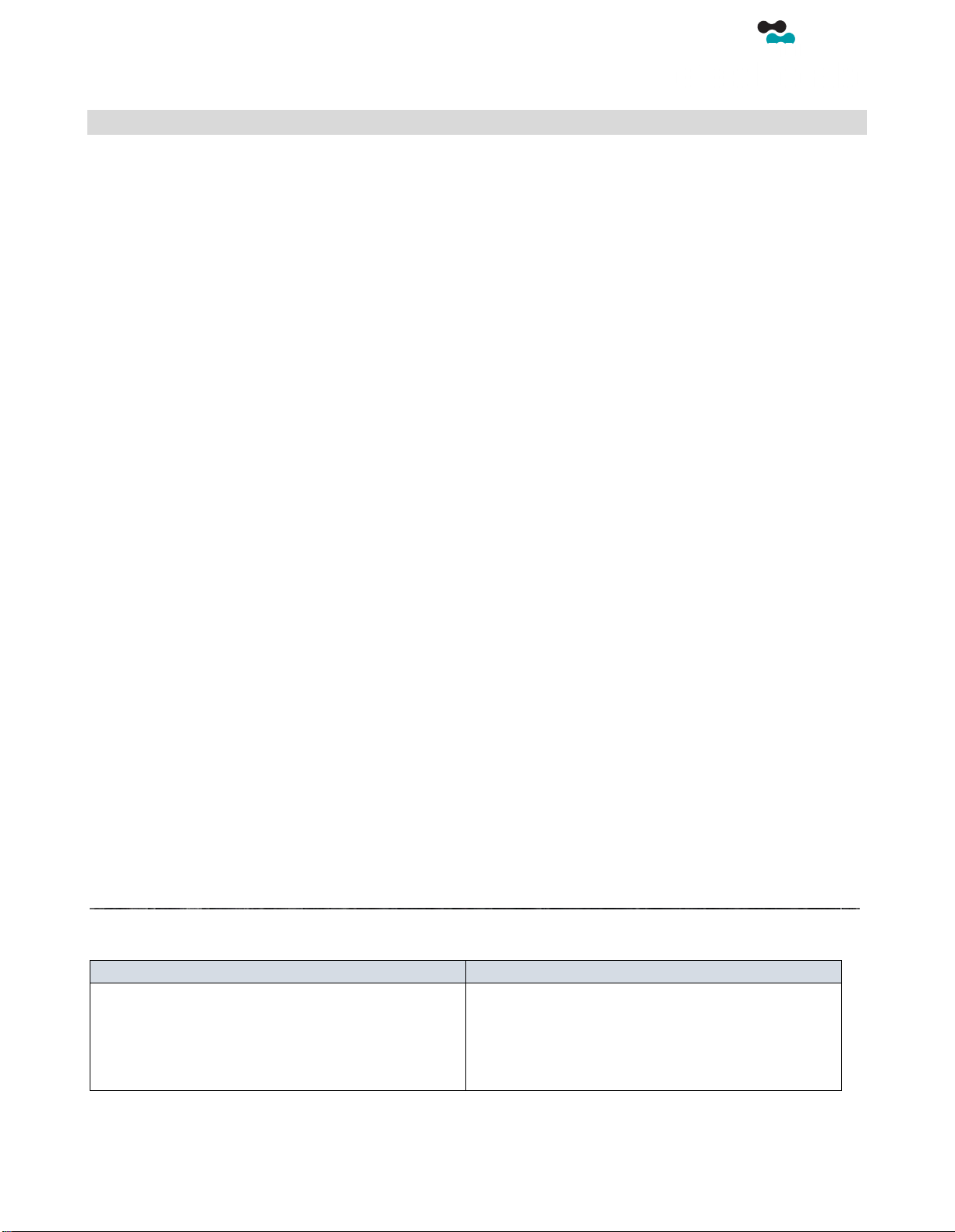

TERMINAL CONNECTIONS

Table 1.

EXPLOSION PROOF CONNECTION

INTRINSICAL

L

Y SAFE CONNECTION

X1-L1 → GND

X1-L2 → I2

X1-L3 → I1

X1-L4 → +VCC

X

1

-

L5

→

GND

J1-1 → Tx/Rx+

J1-2 → DC_GND

J1-3 → Tx/Rx-

J1-4 → VDC

Table of contents