Contents

Contents

1 Safety Precautions ..............................................................................................................................5

1.1 General safety information..........................................................................................................6

1.2 Commercial use only..................................................................................................................6

1.3 Symbols....................................................................................................................................6

2 Warranty terms and exclusions.............................................................................................................7

3 Technical data.....................................................................................................................................8

3.1 Drawing ....................................................................................................................................8

3.2 Technical data ...........................................................................................................................9

3.3 Connections ..............................................................................................................................9

4 Setup ...............................................................................................................................................10

4.1 Unpacking...............................................................................................................................10

4.2 Siting ......................................................................................................................................10

4.3 Mechanical installation ............................................................................................................. 11

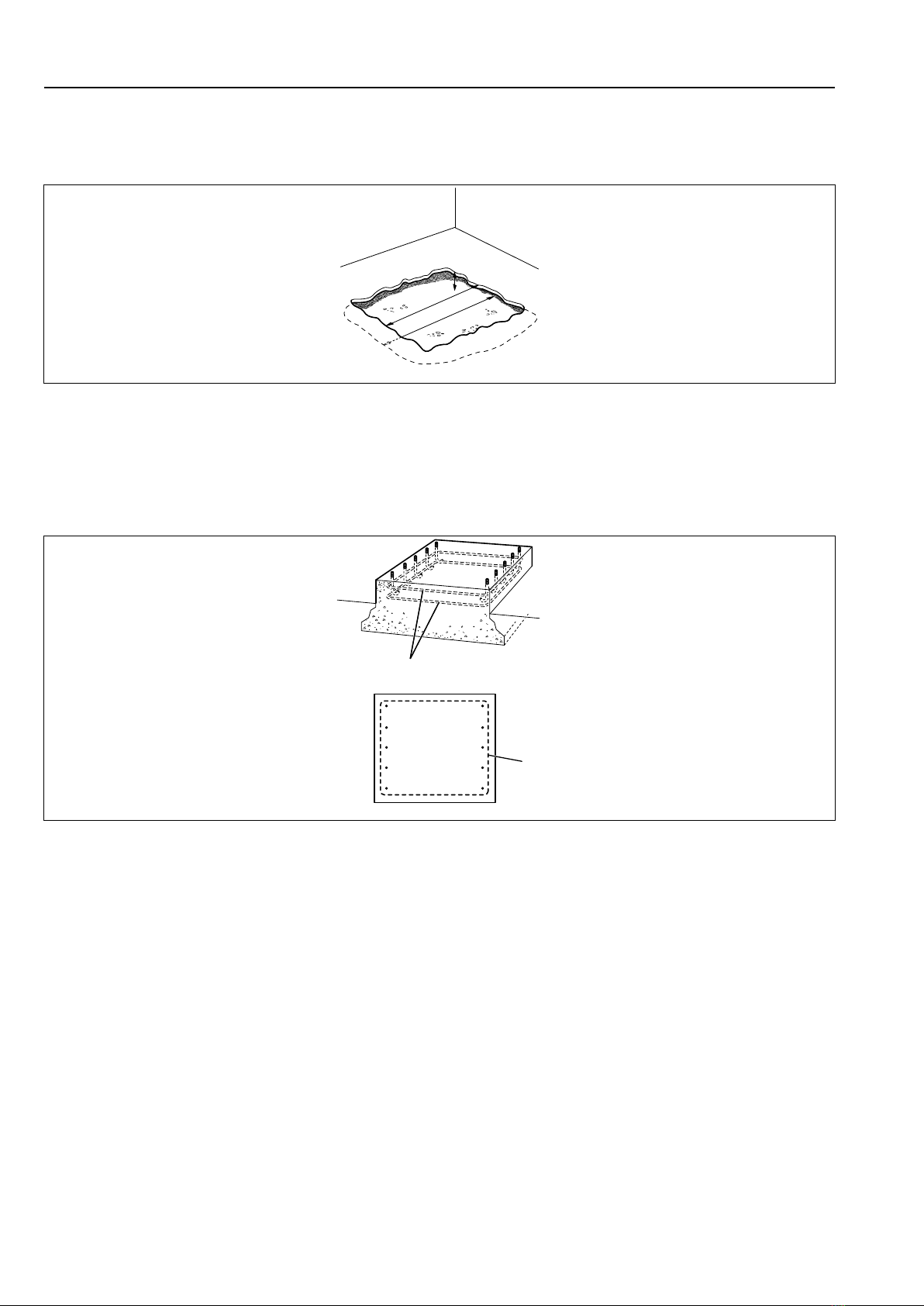

4.3.1 Foundation .................................................................................................................... 11

4.3.2 Casting a foundation.......................................................................................................12

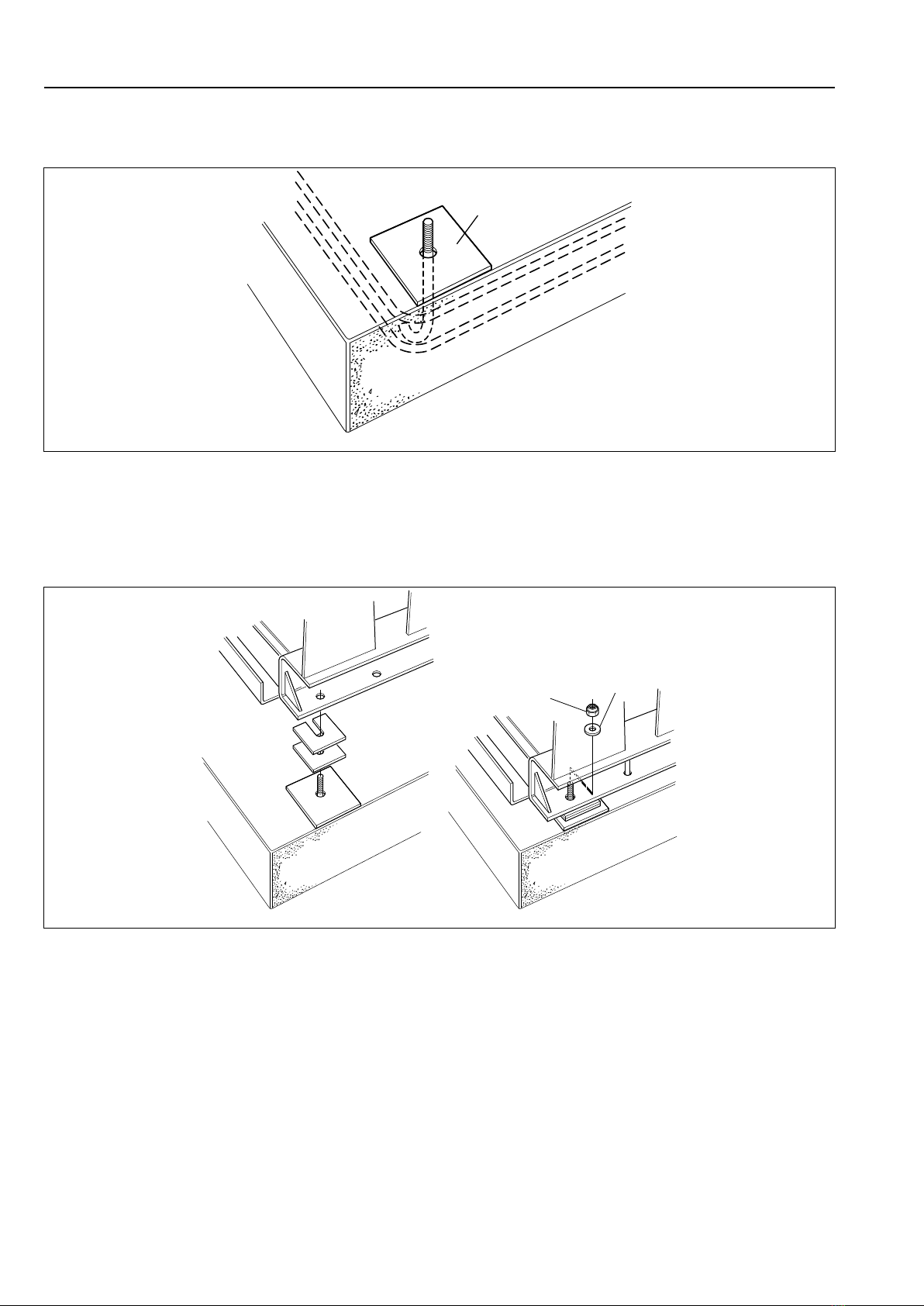

4.3.3 Chemical bolts ...............................................................................................................13

4.3.4 Fastening the machine....................................................................................................14

5 Water connection ..............................................................................................................................15

6 Connection of external dosing systems ...............................................................................................16

6.1 Connection of the hoses...........................................................................................................16

6.2 Electrical connection of external dosing system..........................................................................16

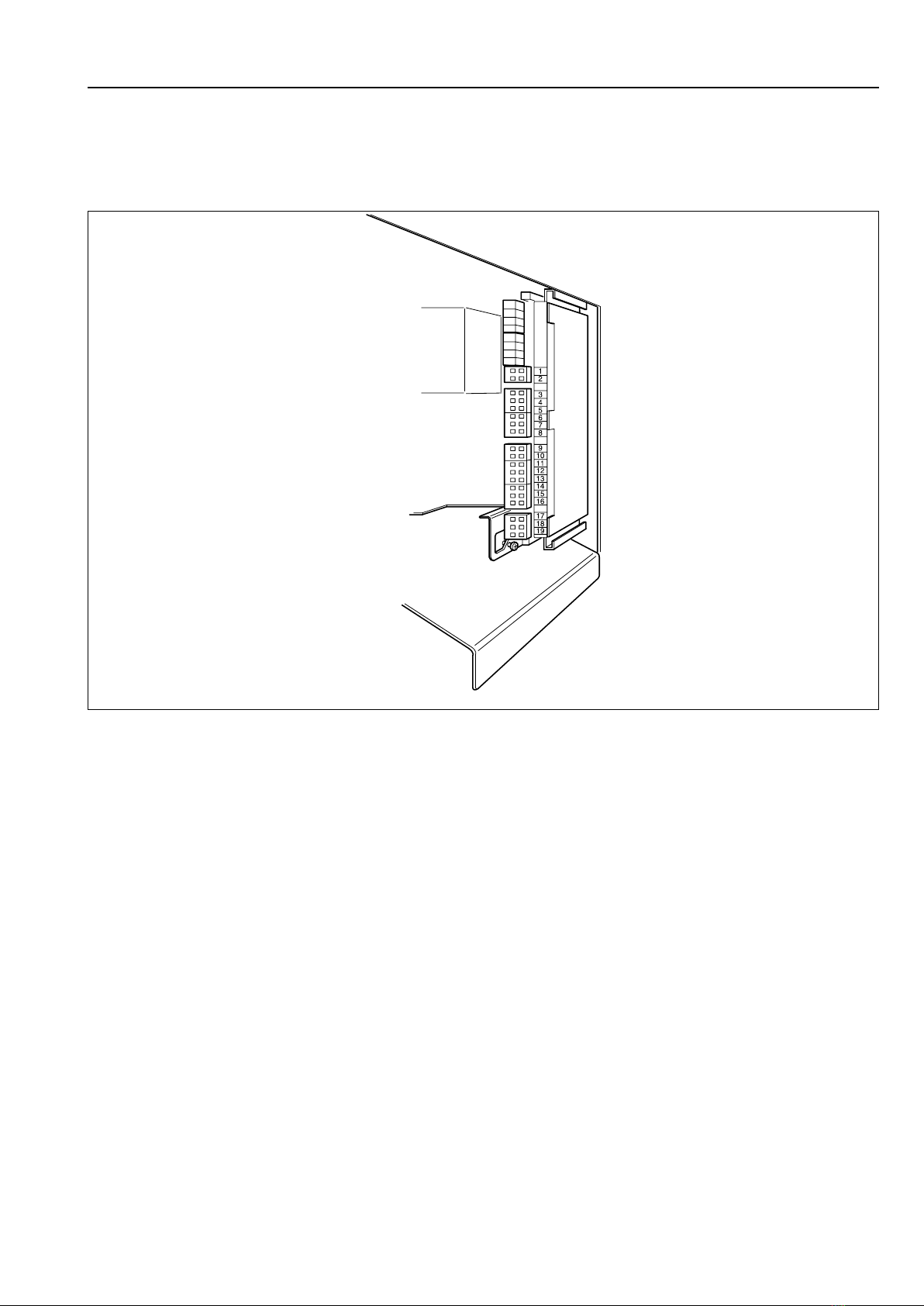

6.2.1 Machine without connectors............................................................................................17

6.2.2 Outputs .........................................................................................................................18

6.2.3 Inputs ............................................................................................................................19

7 Drain connection ...............................................................................................................................20

8 Detergent supply injector ...................................................................................................................20

9 Electrical connection..........................................................................................................................21

9.1 Electrical installation ................................................................................................................21

9.2 Electrical connections ..............................................................................................................21

9.3 Machine connection .................................................................................................................22

9.3.1 Three-phase connection .................................................................................................22

9.4 Functions for I/O-cards.............................................................................................................23

9.4.1 External coin meter/Central payment (2A) ........................................................................23

9.4.2 Central payment (2B)......................................................................................................24

9.4.3 Outputs for detergent signals and inputs for pause signals, "empty" signal and price re-

duction (2D) ...................................................................................................................25

9.4.4 Machines with I/O module type 3 .....................................................................................26

10 Steam connection .............................................................................................................................27

11 At first power up ................................................................................................................................28

11.1 Select language.......................................................................................................................28

11.2 Set time and date.....................................................................................................................28

12 Function check..................................................................................................................................29

13 Disposal information..........................................................................................................................30

13.1 Disposal of appliance at end of life ............................................................................................30

13.2 Disposal of packing..................................................................................................................30

The manufacturer reserves the right to make changes to design and component specifications.