ELECTROMATIC CHECK-LINE MTG User manual

MATE IAL THICKNESS

GAUGES

CHECK

•LINE®

BY ELECTROMATIC

Model MTG and MTG-DX

OPERATING MANUAL

– 1 –

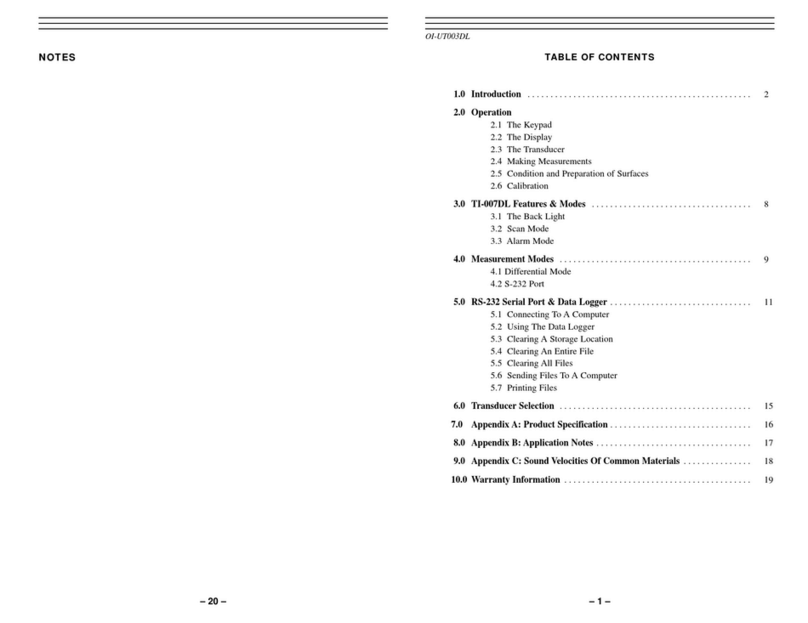

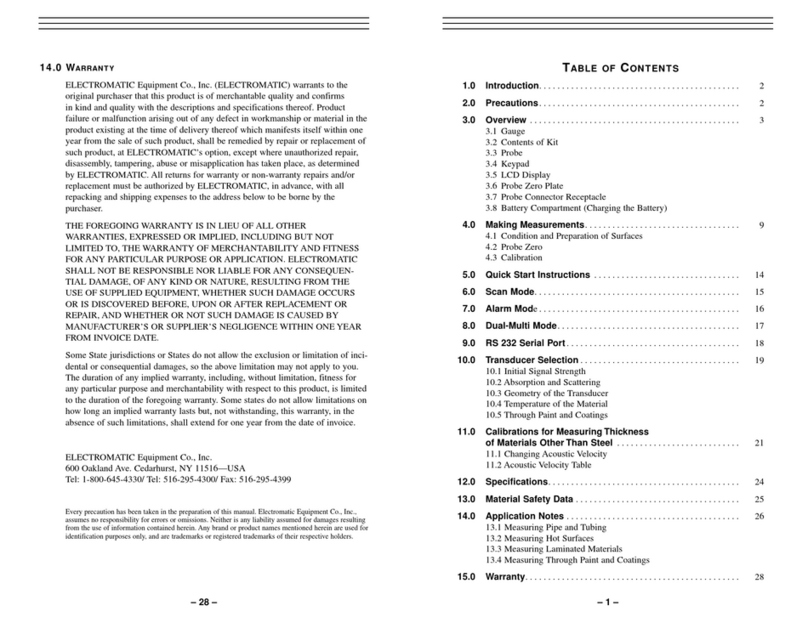

TABLE OF CONTENTS

1.0 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 02

2.0 Unpacking and Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 03

3.0 Installing Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 04

4.0 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0 04

5.0 Using Indicator Function Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0 05

6.0 Operating Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0 07

6.1 Checking Thick aterials

6.2 Data Port

7.0 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 09

8.0 Specifications and Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

9.0 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

– 2 –

1.0 INT ODUCTION

odels TG and TG-DX benchtop contact thickness gauges accurately and

conveniently perform geometric dimensional testing (thickness measurement) on

rubber, fabrics, foams, tapes/films and a wide assortment of other soft materials.

They employs specified presser foot (feeler) of a specific diameter/area, combined

with a predetermined mass (weight) as noted in the AST D 3767 standard.

The TG odel is supplied with a unique air damping feature which ensures that

the presser foot descends at the same rate for each test. This eliminates human

error resulting in superior repeatability. If required, the rate of descent can be user-

adjusted.

For those requiring data output for recording and quality documentation

purposes, a serial output cable and Windows-based software program is

optionally available.

The TG-DX model is supplied without the air dampener option.

– 3 –

2.0 UNPACKING AND SET-UP

Your TG system is packaged completely assembled and tested at our plant to en-

sure a quality product. However, there are some basic steps that must be

performed before using your TG for the first time.

1. Carefully unpack the TG or TG-DX. Take special care when lifting to

support the unit from the granite base when unpacking and

whenever moving the unit.

2. If additional presser feet and weights (mass) have been ordered be

sure to also unpack those items, which are wrapped separately.

3. After the unit is unpacked, it can be cleaned with alcohol,

WITH EXCEPTION OF THE ELECTRONIC INDICATOR.

4. The TG or TG-DX should then be placed on a clean, flat vibration-free

surface for use.

3.0 INSTALLING BATTE IES

1. Using a narrow edge, flathead screwdriver, gently pry

under the tab on the left side of the indicator bezel and

slide out the battery tray as you turn the indicator face

down.

2. Insert two CR 2450 Lithium batteries (3V) into the

tray cavities, positive (+) side up. Now slide the tray

back into its slot, taking care that the batteries stay in

proper position.

– 4 –

4.0 OVE VIEW

Function Keys

Lifting Arm

Column

Air Dampener Knob*

Air Dampener*

Adjustment Knob

Granite Base

Presser Foot

Swivel Connector

Indicator Spindle

Stem Mount Arm

Indicator

Mass (Weight)

*Air Dampe er is ot supplied with Model MTG-DX.

– 5 –

5.0 USING THE INDICATO FUNCTION KEYS

To turn the indi ator ON.

1. Press and hold the ON/ lr key

until lr appears on the indicator

display, then release.

To turn the indi ator OFF.

1. Press and release the OFF/MODE key.

To lear the indi ator display to zero.

1. Press and release ON/ lr key

until .0000 appears on the display.

To turn MAX HOLD on and off.

1. Press and release the HOLD key. MAX will appear on the screen

when this function is active. Repeat to turn this function off.

To hange the indi ator units from in h to millimeter or millimeter to in h.

1. Press the IN/MM Key. Each time the key

is pressed the units will toggle between

Inch (IN) and .

2. The units indicator will be shown on the

right side of the display

To turn AUTO OFF on and off

1. Press and hold 2ND key.

2ND appears at the top of display,

2. Press and release the OFF/MODE

key within three seconds to activate

your selection. An hourglass will

appear on the left side of the display

when the AUTO OFF feature is active

NOTE: AUTO OFF is activated after 10 minutes of non-use.

– 6 –

To Clear All Settings And Return To Fa tory Set Defaults:

1. Press the 2ND key.

2ND icon will appear at the top of the display.

2. Press the ON/ lr.

3. Press and release the IN/MM key.

6.0 OPE ATING POCEDU ES

The TG system can be used to check the thickness of rubber and rubber type

materials.

Note: The TG System is supplied with a 16mm diameter presser foot

and 212 gram mass. This configuration is commonly used for measurement of all

rubber materials with a hardness of 35 IRHD or below

Optional presser feet and mass combinations are available to check

a wide assortment of other material such as: foams, tapes, films, textiles, felts,

sheet metal, foils, fabrics, cloth, leather, fiberboard,

plywood, paper, etc.

1. Use the Adjustment Knob (1)

to position the Indicator so that the

the presser foot is resting freely on

granite base.

2. Clear indicator display to zero by

pressing and releasing the ON/ lr

key.

3. Use the Lifting Lever (2) mechanism

to raise the presser foot.

4. Place the material to be tested

under the Presser Foot (3) and

release the lifting lever.

Note: odel TG is supplied with a unique air-damping feature that controls the

rate of decent of the presser foot (not supplied with odel TG-DX). This allows

the presser foot to descend at the same rate for each test, thus eliminating human

error resulting in superior repeatability.

5. If required, the rate of descent can be user-adjusted by carefully

turning the knurled knob located at the top of the air dampener

(turn clockwise to slow the rate, counter-clockwise to speed up

the rate). Care should be taken to not over adjust the dampener

by over-rotating the adjustment knob.

6. Read and record the thickness of the material immediately after

the presser foot makes full contact with the material.

Note: The pressure being applied by the instrument has a significant effect on the

results obtained. The weight (mass) and presser foot diameter should be specified.

– 7 –

1

3

2

6.1 Checking Thick Materials

For checking materials over 1 inch in thickness, use precision ground gage

blocks in conjunction with the TG.

Example: If you are checking a 2 inch thick part you can use a

1 inch gage block positioned under the sample to obtain the

thickness values.

The maximum sample height capacity of the TG is 5 inches.

6.2 Data Port

For those requiring data output for recording

and quality documentation purposes, a serial

output cable and Windows-based software

program is optionally available.

NOTE: For complete detailed instructions on operation of the Electronic

Indicator, refer to separate Indicator anual supplied or download

from webpage http://www.checkline.com/product/ TG

– 8 –

Data Port

– 9 –

7.0 ACCESSO IES

The TG / TG-DX can be used to check the thickness of rubber and rubber

type materials. Use the optional presser feet and mass combinations to check

a wide assortment of other materials, such as foams, tapes, films, textiles, felts,

sheetmetal, foils, fabrics, cloth, leather, fiberboard, plywood, paper, etc.

Foot Model Foot Dia. (mm) Mass Model Mass (g)

MTG-01-1 10.0 MTG-03-1 176

MTG-01-2 8.0 MTG-03-2 113

MTG-01-3 6.3 MTG-03-3 70

MTG-01-4 6.0 MTG-03-4 63

MTG-01-5 5.0 MTG-03-5 44

MTG-01-6 4.0 MTG-03-6 28

MTG-01-7 3.2 MTG-03-7 18

MTG-01-8 1 6.0 MTG-03-8 452

MTG-01-9 25.0 MTG-03-9 1104

For Materials Equal to or Above 35 IRHD

Presser Foot/Mass Combinations

Foot Model Foot Dia. (mm) Mass Model Mass (g)

MTG-01-1 10.0 MTG-04-1 80

MTG-01-2 8.0 MTG-04-2 52

MTG-01-3 6.3 MTG-04-3 32

MTG-01-4 6.0 MTG-04-4 29

MTG-01-5 5.0 MTG-04-5 20

MTG-01-6 4.0 MTG-04-6 13

MTG-01-7 3.2 MTG-04-7 8

MTG-01-8 1 6.0 MTG-04-8 212

MTG-01-9 25.0 MTG-04-9 518

For Materials Below 35 IRHD

Presser Foot/Mass Combinations

Note: Custom sized presser feet and weights (mass) to fit specific needs or

applications are also available.

– 10 –

Presser Foot “A” Dim. (mm)

MTG-01-1 10.0

MTG-01-2 8.0

MTG-01-3 6.3

MTG-01-4 6.0

MTG-01-5 5.0

MTG-01-6 4.0

MTG-01-7 3.2

MTG-01-8 16.0

MTG-01-9 25.0

Optional Presser Foot

(Feeler / Anvil)

8.0 SPECIFICATIONS AND DIMENSIONS

Certified Electronic Indicator

Ra ge 0–1" (0–25mm)

Resolutio .0001" (0.001mm)

Power CR 2450 Lithium batteries (2)

Units Inch or metric. perator selectable

Data Output RS-232, Mitutoyo (MTI) , BCD

Certified Granite Base 6" x 6" x 2" (152.4 x 152.4 x 50.8mm)

Grade AA

Presser Foot 0.63" (16mm)

ystem Pressure (MTG) With Dampe er: 51-55 g (depending on

dampener adjustment) without weight or

foot*

ystem Pressure (MTG-DX) Without Dampe er: 16 g without weight or

foot*

Mass (Weight) 6.82 oz (212 g)

Lifting Lever left hand

Maximum Height 5 inches

Warranty 1 year

* Keep in mind when calculating pressure.

– 11 –

– 12 –

9.0 WA ANTY

The manufacturer warrants to the original purchaser that this product is of

merchantable quality and confirms in kind and quality with the descriptions and

specifications thereof. Product failure or malfunction arising out of any defect in

workmanship or material in the product existing at the time of delivery thereof

which manifests itself within one year from the sale of such product, shall be

remedied by repair or replacement of such product, at the manufacturer’s

option, except where unauthorized repair, disassembly, tampering, abuse or

misapplication has taken place, as determined by the manufacturer. All returns

for warranty or non-warranty repairs and/or replacement must be authorized

by the manufacturer, in advance, with all repacking and shipping expenses to

the address below to be borne by the purchaser.

THE FOREGOING WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR I PLIED, INCLUDING BUT NOT LI ITED TO, THE

WARRANTY OF ERCHANTABILITY AND FITNESS FOR ANY PARTICU-

LAR PURPOSE OR APPLICATION.ELECTRO ATIC SHALL NOT BE RE-

SPONSIBLE NOR LIABLE FOR ANY CONSEQUENTIAL DA AGE, OF

ANY KIND OR NATURE, RESULTING FRO THE USE OF SUPPLIED

EQUIP ENT, WHETHER SUCH DA AGE OCCURS OR IS DISCOVERED

BEFORE, UPON OR AFTER REPLACE ENT OR REPAIR, AND WHETHER

OR NOT SUCH DA AGE IS CAUSED BY ANUFACTURER’S OR SUP-

PLIER’S NEGLIGENCE WITHIN ONE YEAR FRO INVOICE DATE.

Some State jurisdictions or States do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation may not apply to you.

The duration of any implied warranty, including, without limitation, fitness for any

particular purpose and merchantability with respect to this product, is limited to

the duration of the foregoing warranty. Some states do not allow limitations on

how long an implied warranty lasts but, not withstanding, this warranty, in the ab-

sence of such limitations, shall extend for one year from the date of invoice.

Every precaution has been taken in the preparation of this manual. The manufacturer, assumes no respon-

sibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of in-

formation contained herein. Any brand or product names mentioned herein are used for identification

purposes only, and are trademarks or registered trademarks of their respective holders.

ELECTROMATIC

E Q U I P M E N T C O., I N C.

600 akland Ave., Cedarhurst, NY 11516–U.S.A.

TEL: 516-295-4300 • FAX: 516-295-4399

CHECK

•LINE ®

IN TRUMENT

This manual suits for next models

29

Table of contents

Other ELECTROMATIC Measuring Instrument manuals

ELECTROMATIC

ELECTROMATIC TI-007DL User manual

ELECTROMATIC

ELECTROMATIC STM-50 User manual

ELECTROMATIC

ELECTROMATIC Check-line DT-205LR User manual

ELECTROMATIC

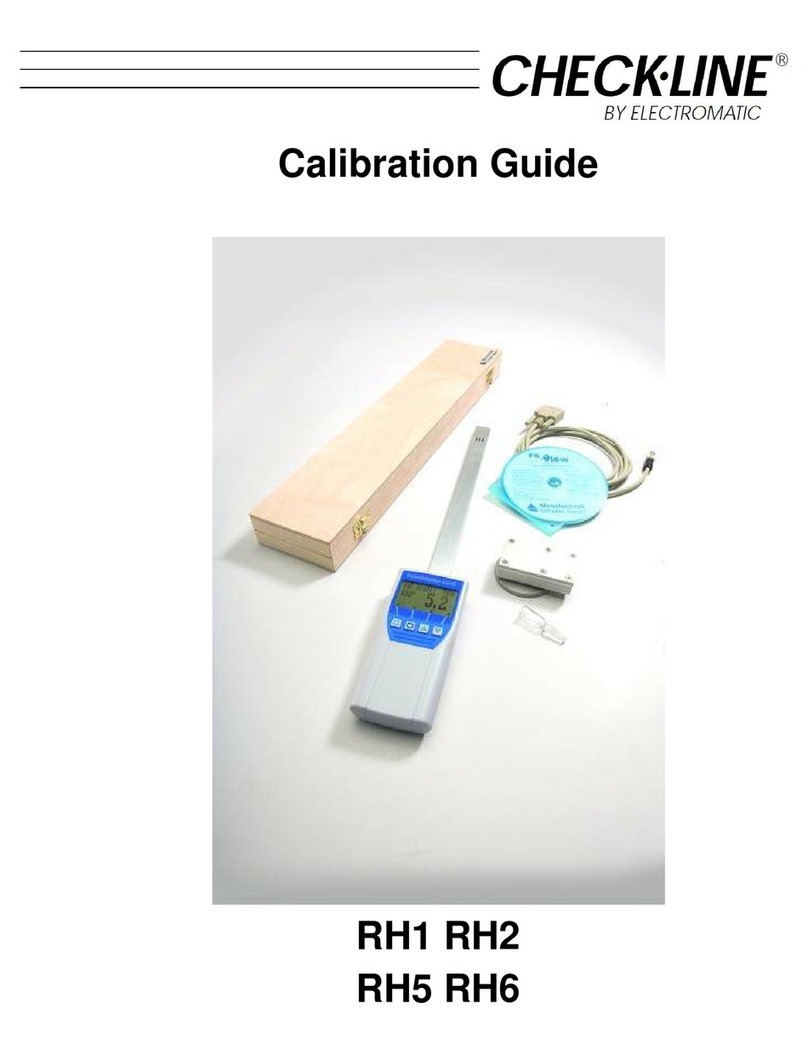

ELECTROMATIC Check-Line RH1 Use and care manual

ELECTROMATIC

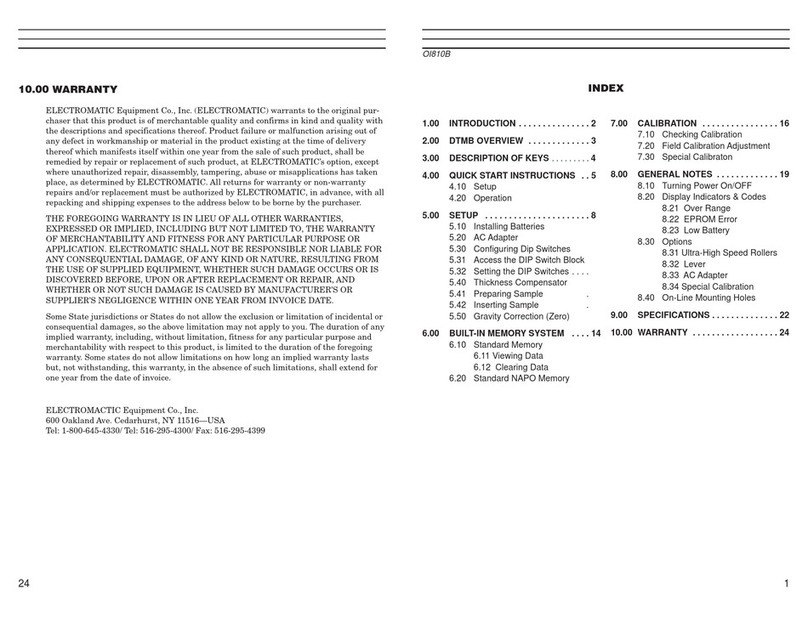

ELECTROMATIC CHECK LINE DTMB-200 User manual

ELECTROMATIC

ELECTROMATIC PosiTector 6000 User manual

ELECTROMATIC

ELECTROMATIC FS2 User manual

ELECTROMATIC

ELECTROMATIC TI-25M-MMX User manual