–6 –

the condition persists, it may be necessary to select a different transducer (size or

frequency) for the material being measured. See page 15 for information on

Transducer selection.

While the transducer is in contact with the material that is being measured, the

TI-007DL will perform four measurements every second, updating its display as

it does so. When the transducer is removed from the surface, the display will hold

the last measurement made.

IMPORTANT

Occasionally, a small film of couplant will be drawn out between the transducer and

the surface as the transducer is removed. When this happens, the TI-007DL may per-

form a measurement through this couplant film, resulting in a measurement that is

larger or smaller than it should be. This phenomenon is obvious when one thickness

value is observed while the transducer is in place, and another value is observed after

the transducer is removed.

Condition and Preparation of Surfaces

In any ultrasonic measurement scenario, the shape and roughness of the test surface

are of paramount importance. Rough, uneven surfaces may limit the penetration of

ultrasound through the material, and result in unstable, and therefore unreliable, mea-

surements. The surface being measured should be clean, and free of any small particu-

late matter, rust, or scale. The presence of such obstructions will prevent the transducer

from seating properly against the surface. Often, a wire brush or scraper will be help-

ful in cleaning surfaces. In more extreme cases, rotary sanders or grinding wheels may

be used, though care must be taken to prevent surface gouging, which will inhibit

proper transducer coupling.

Extremely rough surfaces, such as the pebble-like finish of some cast iron, will prove

most difficult to measure. These kinds of surfaces act on the sound beam like frosted

glass on light:, the beam becomes diffused and scattered in all directions.

In addition to posing obstacles to measurement, rough surfaces contribute to excessive

wear of the transducer, particularly in situations where the transducer is “scrubbed”

along the surface.

Calibration

In order for the TI-007DL to make accurate measurements, it must be set to the correct

sound-velocity for the material being measured. Different types of material have

different inherent sound-velocities. For example, the velocity of sound through steel is

about 0.233 inches-per-microsecond, versus that of aluminum, which is about 0.248

inches-per-microsecond. If the tool is not set to the correct sound-velocity, all of the

measurements the tool makes will be erroneous by some fixed percentage. The one

point calibration is the simplest and most commonly used calibration procedure for

optimizing linearity over large ranges. The TI-007DL provides two simple methods

for setting the sound-velocity, described in the following pages

–15 –

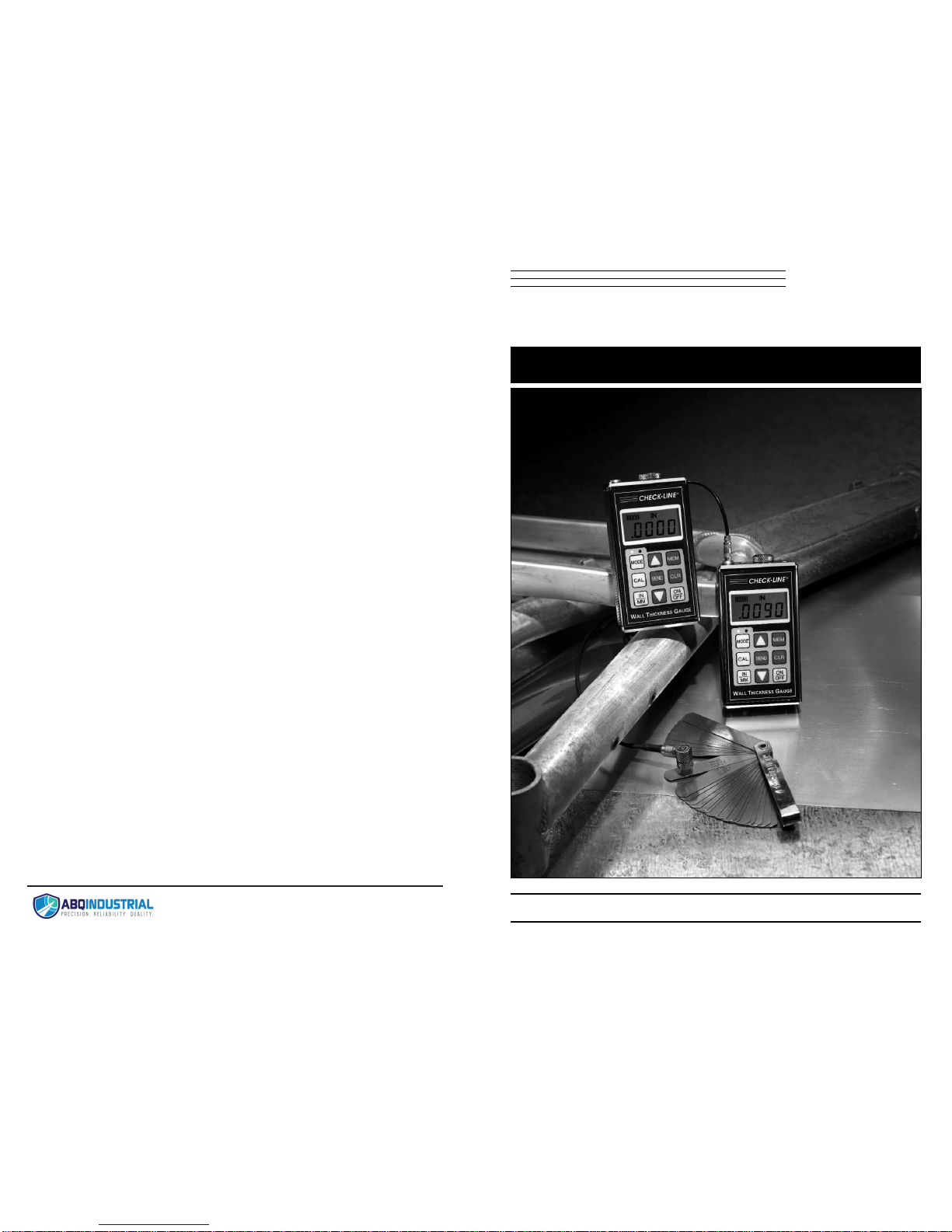

6.0 TRANSDUCER SELECTION

The TI-007DL is inherently capable of performing measurements on a wide range of

materials, from various metals to glass and plastics. Different types of material, how-

ever, will require the use of different transducers. Choosing the correct transducer for a

job is critical to being able to easily perform accurate and reliable measurements. The

following paragraphs highlight the important properties of transducers, which should

be considered when selecting a transducer for a specific job.

Generally speaking, the best transducer for a job is one that sends sufficient ultrasonic

energy into the material being measured such that a strong, stable echo is received by

the TI-007DL. Several factors affect the strength of ultrasound as it travels. These are

outlined below:

Initial Signal Strength

The stronger a signal is to begin with, the stronger its return echo will be. Initial signal

strength is largely a factor of the size of the ultrasound emitter in the transducer. A

large emitting area will send more energy into the material being measured than a

small emitting area. Thus, a so-called “1/4-inch” transducer will emit a stronger signal

than a “1/8-inch” transducer.

Absorption and Scattering

As ultrasound travels through any material, it is partly absorbed. If the material

through which the sound travels has any grain structure, the sound waves will experi-

ence scattering. Both of these effects reduce the strength of the waves, and thus, the

TI-007DL’s ability to detect the returning echo.

Higher frequency ultrasound is absorbed and scattered more than ultrasound of a lower

frequency. While it may seem that using a lower frequency transducer might be better

in every instance, low frequencies are less directional than high frequencies.

Geometry of the Transducer

The physical constraints of the measuring environment sometimes determine a trans-

ducer’s suitability for a given job. Some transducers may simply be too large to be

used in tightly confined areas. Also, the surface area available for contacting with the

transducer may be limited, requiring the use of a transducer with a small cone tipped

delay line. Measuring on a curved surface, may require the use of a transducer with a

matching curved wearface.

Temperature of the Material

When it is necessary to measure on surfaces that are exceedingly hot, special

delay lines may be necessary. Additionally, care must be taken when performing

a “Calibration to Known Thickness” with a high temperature application. See

Appendix B for more information on measuring materials with a high temperatures.

Selection of the proper transducer is often a matter of tradeoffs between various

characteristics. It may be necessary to experiment with a variety of transducers

in order to find one that works well for a given job. ELECTROMATIC can provide

assistance in choosing a transducer, and offers a broad selection of transducers

for evaluation in specialized applications.