Nic PE-1 User manual

Automatic Petro Pyrolysis Mercury

Analyzer

PE-1

PE-1000

Instruction Manual

NIC-600-2266-03

Nippon Instruments Corporation

NIC-600-2266-03

Table of Contents

2

Automatic Petro Pyrolysis Mercury Analyzer

PE-1000 Instruction Manual

Table of Contents

1. READ FIRST! .....................................................................................................................7

1.1 SAFETY PRECAUTIONS.....................................................................................................7

1.1.1 Safety symbols .......................................................................................................7

1.1.2 Installation precautions...........................................................................................7

1.1.3 Maintenance precautions .......................................................................................7

1.2ABOUT THE PE-1000.......................................................................................................8

2. SPECIFICATIONS..............................................................................................................9

2.1 STANDARD CONFIGURATION .............................................................................................9

2.2 UNIT SPECIFICATIONS ......................................................................................................9

3. EQUIPMENT OVERVIEW................................................................................................10

3.1 MEASUREMENT PRINCIPLE .............................................................................................10

3.2NAMES OF PARTS...........................................................................................................11

3.2.1 PE-1 (Front cover removed).................................................................................11

3.2.2 PE-1 (Rear panel).................................................................................................12

3.2.3 PE-1 (Inside).........................................................................................................13

3.2.4 PE-1 (Right panel)................................................................................................14

3.2.5 HT-300A (Option)..................................................................................................15

4. EQUIPMENT INSTALLATION..........................................................................................16

4.1 INSTALLATION CONDITIONS.............................................................................................16

4.1.1 Installation environment........................................................................................16

4.1.2 Power requirements..............................................................................................16

4.2 INSTALLATION AND CONNECTIONS...................................................................................17

4.2.1 PE-1......................................................................................................................17

4.2.2 Mounting the sample changer (HT-300A)............................................................18

4.3 SOFTWARE INSTALLATION AND SETUP.............................................................................21

4.3.1 PE1000Win installation.........................................................................................21

4.3.2 Flash Player installation........................................................................................22

4.3.3 USB-Serial Converter installation.........................................................................23

4.3.4 Setting the communication port............................................................................24

4.3.5 Environmental settings.........................................................................................25

NIC-600-2266-03

Table of Contents

3

4.3.6 Uninstalling PE1000Win ...................................................................................... 26

4.3.7 Upgrading PE1000Win ........................................................................................ 26

5. PE-1000WIN..................................................................................................................... 27

5.1 MAIN WINDOW............................................................................................................... 27

5.1.1 Main window ........................................................................................................ 27

5.1.2 Analysis window................................................................................................... 28

5.1.3 Common elements............................................................................................... 29

5.2TABLE PANE .................................................................................................................. 30

5.2.1 Common elements of Standard Sample and Unknown Sample panes.............. 30

5.2.2 Standard Sample table ........................................................................................ 33

5.2.3 Unknown Sample table........................................................................................ 35

5.3 MENUS ......................................................................................................................... 38

5.3.1 File (F).................................................................................................................. 38

5.3.2 Edit (E) ................................................................................................................. 38

5.3.3 Run (R)................................................................................................................. 39

5.3.4 Table (T)............................................................................................................... 39

5.3.5 System (S)............................................................................................................ 39

5.3.6 Window (W).......................................................................................................... 40

5.3.7 Help (H)................................................................................................................ 40

5.4 FILE (F) MENU COMMANDS ............................................................................................ 41

5.4.1 New (N)................................................................................................................ 41

5.4.2 Open (O) / Save (A)............................................................................................. 41

5.4.3 Page Setup (U) .................................................................................................... 42

5.4.4 Print Preview (V).................................................................................................. 42

5.4.5 Print (P)................................................................................................................ 43

5.5 EDIT (E) MENU COMMANDS............................................................................................ 44

5.2.1.1 Meas. (Displayed only on the control window).........................................30

5.2.1.2 Vial Number (Displayed only on the control window)...............................31

5.2.1.3 Method Number ......................................................................................31

5.2.1.4 Multiple Injection (Displayed only on the control window)........................31

5.2.1.5 Meas. Range.............................................................................................32

5.2.2.1 STD Wt......................................................................................................33

5.2.2.2 Other .........................................................................................................33

5.2.3.1 Sample Name ...........................................................................................35

5.2.3.2 Table headers by type of sample..............................................................36

5.2.3.3 Other .........................................................................................................37

NIC-600-2266-03

Table of Contents

4

5.6 RUN (R) MENU COMMANDS ............................................................................................45

5.6.1 Set Method............................................................................................................45

Sample changer conditions in measurement protocol setup........................................46

5.6.2 Meas. Range ........................................................................................................48

5.6.3 Control ..................................................................................................................49

5.6.5 Blank sample check..............................................................................................50

5.6.6 Leak Check...........................................................................................................51

5.6.7 Maintenance.........................................................................................................51

5.6.8 Wash Syringe........................................................................................................55

5.6.9 Heater Shutoff at Measurement End....................................................................55

5.7TABLE (T) MENU COMMANDS ..........................................................................................56

5.7.1 Annotate Print (M).................................................................................................56

5.7.2 Table Conditions (C).............................................................................................56

5.7.3 Get Statistics (S)................................................................................................58

5.7.4 Register Sample (N).............................................................................................58

5.7.5 Delete Purge / Blank Data....................................................................................59

5.8 SYSTEM (S)...................................................................................................................60

5.8.1 Set Com Port........................................................................................................60

5.8.2 Environmental settings.........................................................................................60

5.8.3 Set Chart Colors...................................................................................................62

5.8.4 View HT300 Parameters (Only when the sample changer is mounted and

connected to the PE-1)..................................................................................................63

5.9 HOW CALIBRATION CURVES ARE PLOTTED.......................................................................64

5.10 FORMULAS FOR CALCULATING THE WEIGHTAND CONCENTRATION OF MERCURY.............64

6. MEASUREMENT..............................................................................................................66

6.1 MEASUREMENT PROCESS FLOWCHART WHEN USING THE SAMPLE CHANGER....................66

6.2 SAMPLES.......................................................................................................................67

6.3ACCESSORIES REQUIRED FOR MEASUREMENT ................................................................67

5.6.7.1 Main (1)..................................................................................................... 51

5.6.7.2 Main (2)..................................................................................................... 52

5.6.7.3 Heaters..................................................................................................... 53

5.6.7.4 Counters................................................................................................... 54

5.6.7.5 Parameters............................................................................................... 55

5.8.2.1 Environmental Settings............................................................................. 60

5.8.2.2 Warning Criteria........................................................................................ 61

5.8.2.3 Maintenance Menu................................................................................... 62

NIC-600-2266-03

Table of Contents

5

6.4 PREPARATION FOR MEASUREMENT ................................................................................ 69

6.4.1 Supply carrier gas................................................................................................ 69

6.4.2 Drain the gas-liquid separation bottle.................................................................. 69

6.4.3 Start up the PE1000Win application.................................................................... 70

6.4.4 Power up the PE-1............................................................................................... 70

6.4.5 Self-checks........................................................................................................... 70

6.4.6 Set the syringe wash solution.............................................................................. 71

6.5 SET MEASUREMENT CONDITIONS................................................................................... 72

6.5.1 Set measurement conditions ............................................................................... 72

6.5.2 Set table conditions.............................................................................................. 74

6.6 MEASUREMENTS........................................................................................................... 75

6.6.1 Perform a purge measurement............................................................................ 75

6.6.2 Set samples.......................................................................................................... 75

6.6.3 Select a measurement protocol........................................................................... 76

6.6.4 Set the number of injections................................................................................ 76

6.6.5 Select a measurement range............................................................................... 76

6.6.6 Register the mercury weight of the standard sample and unknown sample name............... 77

6.6.7 Start measurement............................................................................................... 78

6.6.8 Measurement end................................................................................................ 79

6.6.9 Aborting measurements....................................................................................... 79

6.6.10 Viewing measurement results............................................................................ 80

6.7 PRINTING REPORTS....................................................................................................... 81

6.8AFTER MEASUREMENT ENDS.......................................................................................... 81

7. MAINTENANCE............................................................................................................... 82

7.1 EQUIPMENT CHECKS ..................................................................................................... 82

7.1.1 Daily checks......................................................................................................... 82

7.1.2 Yearly checks ....................................................................................................... 84

7.2 ERRORS AND WARNINGS................................................................................................ 85

7.3 TROUBLESHOOTING ...................................................................................................... 87

7.3.1 If peak sensitivity decreases................................................................................ 87

7.3.2 Blank sample reading error.................................................................................. 88

7.3.3 Flowchart.............................................................................................................. 89

7.4 MAINTENANCE .............................................................................................................. 89

6.5.1.1 Mode.........................................................................................................72

6.5.1.2 Set up standard sample checks................................................................72

6.5.1.3 Set up blank sample checks.....................................................................73

NIC-600-2266-03

Table of Contents

6

7.4.1 Leak check............................................................................................................89

7.4.2 Replacing the syringe...........................................................................................91

7.4.3 Setting the sample injection position....................................................................94

7.4.4 Replacing the septum...........................................................................................96

7.4.5 Detaching the mercury collection tube and joints.................................................97

7.4.6 Removing the trapping agent from the mercury collection tube ........................100

7.4.7 Cleaning the atomic fluorescence cell................................................................101

7.4.8 Washing the mercury collection tube and joints.................................................102

7.4.9 Replacing the sample heating tube....................................................................103

7.4.10 Manually operating the syringe ........................................................................106

7.4.11 Positioning the sample changer........................................................................107

7.4.12 Replacing drainage pump tubes.......................................................................110

8. USER SUPPORT............................................................................................................ 111

NIC-600-2266-03

1. Read First!

7

1. Read First!

1.1 Safety precautions

1.1.1 Safety symbols

Indicates that improper handling may result in serious injury or

even death to the user.

Indicates that improper handling may result in minor or moderate

injury to the user and/or property damage.

1.1.2 Installation precautions

Ground the analyzer to prevent electric shock.

1.1.3 Maintenance precautions

Shut OFF power supply to the analyzer before performing maintenance on it.

Working with the power ON may result in electric shock.

Set the power switch in the OFF position and allow the heater to cool down before

performing maintenance on or around the heater. Working with the power ON and

the heater hot runs the risk of burns.

Use caution when touching glass parts. Rough handling may break the parts.

WARNING

CAUTION

CAUTION

WARNING

WARNING

NIC-600-2266-03

1. Read First!

8

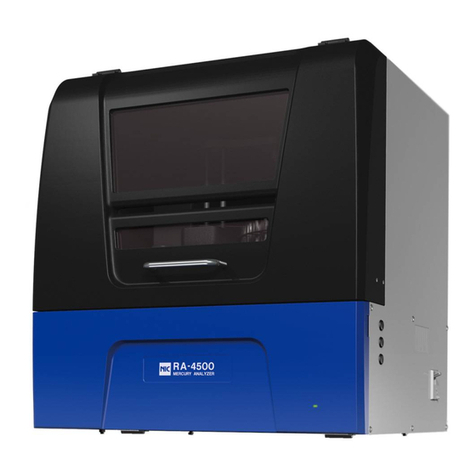

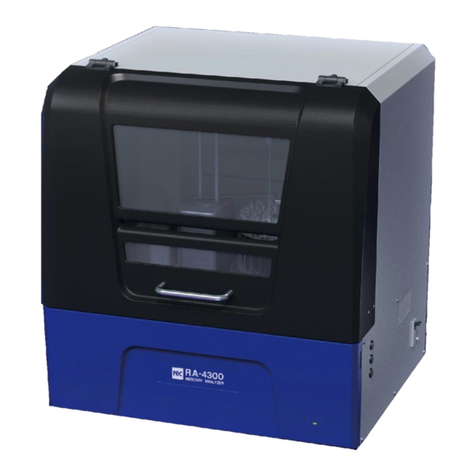

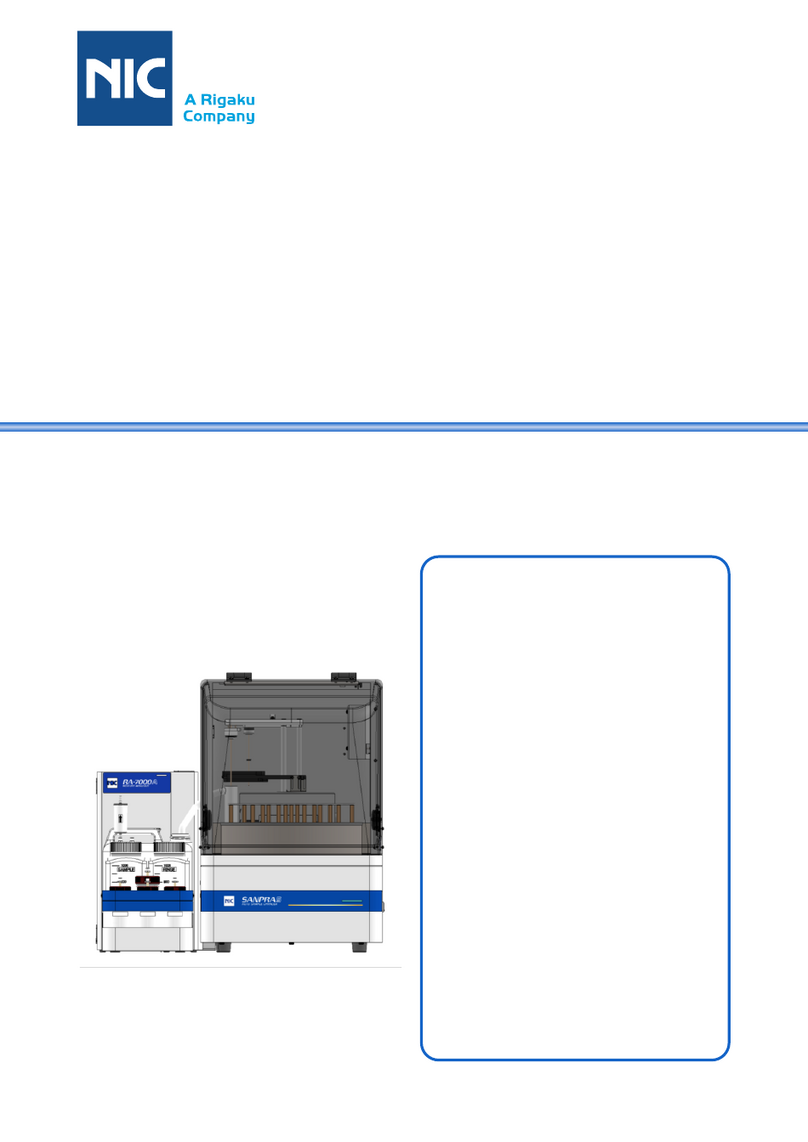

1.2 About the PE-1000

The PE-1000 is an automatic mercury analysis system that easily and quickly measures

the amount of mercury contained in petroleum and natural gas (RH-PE required) to high

degrees of sensitivity and accuracy. The system is composed of a mercury measuring unit

(PE-1), automatic sample changer (HT-300A) and computer (hereinafter, "PC").

Once a sample has been set in the sample changer, it is automatically loaded into the

measuring cell and measured. Measurement results can be analyzed by statistical

processing and other methods, on PC.

To use this analyzer to its full potential, read this Instruction Manual prior to use.

PE-1000 system

PE-1

Mercury measuring unit

HT-300A

Sample changer

NIC-600-2266-03

2. Specifications

9

2. Specifications

2.1 Standard configuration

Mercury measuring unit PE-1

Sample changer HT-300A

Data analysis and equipment control software PE1000Win

Standard accessories

PC

2.2 Unit specifications

Mercury measuring unit (PE-1)

Operating principle :Cold vapor atomic fluorescence spectrometry

Light source :Low pressure mercury discharge tube

Detector :Photomultiplier, Photoelectric tube

Carrier gas :Purified air, Argon (Pressure: 0.3 - 0.5 MPa each)

Flowrate control :Precision needle valve

Flowrate sensor :Electronic sensor

Measurable samples :Liquids, Gas (RH-PE required)

Detection limit :0.003 ng

Measurement range :0 - 100 ng

Data communication :RS-232C cable

Dimensions, Weight :505W × 380D × 510H, 40 kg

Sample changer (HT-300A)

Number of samples :110

Sample container :1.5 mL vial

Dimensions, Weight :420W×400D×520H, 9 kg

Data analysis and equipment control software (PE1000Win)

OS :Windows 7, Windows 8/8.1, Windows 10

Equipment control :Measurement starting and stopping, Heater shutoff

at measurement end, Heater power a activation at a set time

setting of measurement protocol and sample charger sample

position

Data processing :Measurement conditions setup, calibration curve

setup, unknown sample setup, concentration calculation, statistical processing

NIC-600-2266-03

3. Equipment overview

10

3. Equipment overview

3.1 Measurement principle

Sample is injected into a heating cell with a syringe, where components of low boiling

point are volatized and removed, and the remaining mercury compounds are heated until

gasifying. The mercury compounds are then decomposed in the catalytic cell to remove

any organic matter and to atomize the mercury. The atomized mercury is collected and

thickened as gold amalgam and any interfering substances are removed using

temperature control in the mercury collection cell. Argon gas is then injected into the

mercury collection tube and heated, and the fluorescence intensity of the excited mercury

gas is measured by atomic fluorescence spectrometry at a wavelength of 253.7 nm.

Sample injection and measurement flow

Atomic fluorescence cell

Sample

Volatile organic matter

Heating cell

Mercury collection cell

Mercury lamp

Photomultiplier

Photoelectric tube

Activated carbon filter

Carrier gas

Argon gas

Catalytic cell

NIC-600-2266-03

3. Equipment overview

11

3.2 Names of parts

3.2.1 PE-1 (Front cover removed)

No.

Part

Function

Remarks

①

Sample inlet

Sample inlet port

Built-in septum

②

Holding plate

Securing the sample

heating tube

③

Sample heater H1

Catalytic cell

heaters H2, H3

Heating the sample and

catalytic cells

④

Jacketed heater H4

Keeping the joint to the

mercury collection tube

warm

⑤

Sub-power switch

Turning power to heaters

ON/OFF

Equipped with

automatic heater

shutoff in the event of

overheating

⑥

Mercury collection

tube heater H5

Collecting mercury in

combustion product gas

⑦

Photoelectric tube

Quartz fluorescence cell

⑧

Optical circuit

Mercury lamp and

photoelectric tube

⑨

Gas-Liquid

separation bottle

Separating liquid from

combustion product gas

④

⑨

⑤

③

①

⑥

⑧

⑦

②

NIC-600-2266-03

3. Equipment overview

12

3.2.2 PE-1 (Rear panel)

No.

Part

Function

Remarks

①

Argon pressure regulator

Regulating the pressure

of argon gas

0.2 MPa (Max. 1.0 MPa)

②

Air pressure regulator

Regulating the pressure of

compressed air

0.2 MPa (Max. 1.0 MPa)

③

Exhaust port

Releasing exhausted gas

after measurement

Release gas outdoors

④

RH-PE terminal

Connecting a collection

tube heater

Option

⑤

Fuse

Protecting electrical

circuits against

overcurrent

⑥

RS232C port

Connecting to a PC

⑦

Power cable socket

Connecting a power cable

1 kWA. Selected for use

with 100, 110, 120, 220,

230 or 240V supplies

prior to shipping

⑧

Main power switch

Turning power to the

analyzer ON/OFF

Equipped with a built-in

circuit breaker.

⑨

Mercury collection tubes

Removing mercury from

argon gas and air

Contain activated carbon

①

②

③

⑤

④

⑥

⑦

⑧

⑨

NIC-600-2266-03

3. Equipment overview

13

3.2.3 PE-1 (Inside)

No.

Part

Function

Remarks

①

Activated carbon filter

Absorbing mercury after

measurement

②

Solenoid valve V5

Switching gas path

Used only with the

RH-PE

③

Photomultiplier

Measuring fluorescence

intensity

④

Solenoid valve V1

Switching gas path

⑤

Solenoid valve V2

Switching gas path

⑥

Solenoid valve V3

Switching gas path

⑦

Solenoid valve V4

Switching gas path

ON only during leak

checks

⑧

Flowrate sensor

Measuring the flowrate of the

carrier gas

②

①

④

③

⑤

⑥

⑦

⑧

NIC-600-2266-03

3. Equipment overview

15

3.2.5 HT-300A (Option)

No.

Part

Function

Remarks

①

Syringe

Dispensing sample

100 μL

②

Wash bottles

Holding syringe wash solution (x 4)

Bottle slot can be

selected according to

measurement protocol

③

Waste bottle

Collecting wash solution after

washing the syringe

④

Sample tray

Holding sample vials

Accommodates 1.5 mL

vials

⑤

Fuse

Protecting electrical circuits

against overcurrent

0.5 A

⑥

Power switch

Turning power to the sample

changer ON/OFF

Leave in the ON position

as power is drawn from

the PE-1

⑦

Power cable

socket

Connecting the power cable to the

PE-1

230 V

⑧

Signal cable ports

Connecting signal cables to the

PE-1

②

①

④

③

⑤

⑥

⑦

⑧

NIC-600-2266-03 4. Equipment installation

16

4. Equipment installation

4.1 Installation conditions

4.1.1 Installation environment

Room temperature :15 –35ºC

Room humidity :80% or less

Vibrations :Avoid strong vibrations perceivable by the human

body

Dust and dirt :Keep the air clean and free of smoke, dust and

other factors that can adversely affect

measurements

Installation space :Ensure W1,000 x D800 mm or more of space,

and a level foundation that can withstand about

60 kg of weight

Note (Under ordinary conditions):Avoid direct exposure to

sunlight and air drafts from air conditioners, fans,

etc.

Note (Under special conditions):Do not locate the analyzer

anywhere volatile halogen reagents such as

organochlorine solvents are used or their gases

may be present

4.1.2 Power requirements

Power supply :Single-phase 100, 110, 120, 220, 230, 240 VAC

50/60 Hz

*Voltage is selected prior to shipping.

Voltage fluctuation :Within ±5%

Capacity :1.0 kVA (3-pin socket)

Fuse :250 V:3.15 A, 100 V:5 A

Supply quality :No surges, harmonics, noise, etc.

Distance between source and analyzer:Max. 2 m. Equipment must be

grounded.

NIC-600-2266-03 4. Equipment installation

17

4.2 Installation and connections

The equipment is arranged as shown below when used. Locate the PC as explained in

its user manual.

4.2.1 PE-1

(1) Set the PE-1 in the installation site.

If wobbly, stabilize the PE-1 from the level adjusters at the bottom.

(2) Connect the PE-1 to the PC over a RS-232C cross-cable.

(3) Connect the power cable to the PE-1 and the power source.

(4) Connect the argon gas and compressed air to the PE-1. (Set pressure at the source to

0.3 - 0.5 MPa.)

* Use resin tubes of 6 mm in outer diameter. (Tubes must be procured by the user.)

(5) Connect an exhaust tube to the PE-1 and run the tube so that exhausted gases are

released outdoors.

* Use a resin tube of 6 mm in outer diameter. (The tube must be procured by the user.)

(6) Attach the sample heating tube. (See "7.4.9 Replacing the sample heating tube.")

Argon gas tube

Air tube

Exhaust tube

RS-232C cable

Power cable

RH connection

cable (Option)

Level adjuster (x 6)

NIC-600-2266-03 4. Equipment installation

18

4.2.2 Mounting the sample changer (HT-300A)

(1) Open the front cover of the PE-1 and remove the 2 screws

on the left to open the panel that the heaters are installed on.

(2) Remove the 2 screws that lock the left-side cover down

at the top and bottom, and open the cover. Then, disconnect

the yellow tube.

(3) Place the sample changer mounting plate on the PE-1 and tighten the screws enough

to hold it safely in place. There are 4 screws inside the PE-1 and 2 screws at the front.

Inside Front

(4) Tighten the screw so that the mounting plate does not move. (The mounting plate

extends slightly to the right on the front end.)

NIC-600-2266-03 4. Equipment installation

19

(5) Connect the drainage pump.

①Insert the Teflon tube into the waste bottle.

②Fit the waste bottle into the slot and run the tube in

the drainage pump's direction.

③Immobilize the 3 mm tube in the clamps on the

right side of the PE-1, and connect it to the 4 mm

tube at the top of the drainage pump via the

converter joint (3, 4).

④Connect the 4 mm tube to the bottom tube of the

drainage pump and run the open end into a

suitable container.

* A container is not included in the product package,

therefore prepare a suitable container for collecting

wash solution.

NIC-600-2266-03 4. Equipment installation

20

(6) Detach the cable cover from the rear of the HT-300Aand connect the power cable and

2 signal cables from the inside of the PE-1 to the HT-300A.

(7) Check that the power switch is to the

-

(ON)

side, and reattach the cable cover.

* Leave the power switch of the HT-300A in the ON

position so that it can draw power from the PE-1.

(8) Close the left-side cover, tighten the screws to lock it in place and close the front

panel.

(9) Turn ON power to the PE-1, and position the sample changer syringe.

* See "7.4.2 Replacing the syringe" and "7.4.3 Setting the sample injection position."

* If the plunger guide does not line up with the sample inlet port, slide the heater unit

to the left-right until it does. Once the syringe is properly positioned, lock the

positioning plate down.

(10) Once the syringe is properly positioned, open the

front cover and the left-side panel again, and tighten

the screws to the sample changer mounting plate so

that it is firmly locked down.

* Tighten the screws in the opposite order that they

were opened when first mounting the sample

changer.

(11) Lock the HT-300A to the mounting plate with the 4

screws.

Power switch

Other manuals for PE-1

1

This manual suits for next models

1

Table of contents

Other Nic Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Kongsberg

Kongsberg Simrad TV80 quick start guide

Avlite

Avlite AV-RMU Installation & service manual

Honeywell

Honeywell enCore FC Series operating instructions

ELGO Electronic

ELGO Electronic LIMAX02 M Serie operating manual

Leutert

Leutert MSI-3 operating instructions

Badger Meter

Badger Meter M5000 user manual