General

This function enables an external additional heater, e.g.

an electric boiler, wood boiler, pellet boiler, oil boiler,

gas boiler or district heating, to assist with the heating.

The heat pump/indoor module controls a shunt valve

(QN11) and a circulation pump (GP10) via AXC 40. If the

heat pump/indoor module cannot manage to maintain

the correct supply temperature (BT25), the additional

heat starts. When the temperature on the boiler sensor

(BT52) exceeds the set value, the heat pump transmits

a signal to the shunt (QN11) to open from the additional

heat. The shunt (QN11) is regulated so that the true

supply temperature agrees with the heat pump’s theor-

etically calculated set point value. When the heating

demand drops sufficiently, so additional heat is no longer

required, the shunt (QN11) closes completely.

Factory-set minimum operating time for the boiler is 12

hours.

The function smart energy source can be selected if you

want to prioritise automatically between heat pump

operation and additional heat versus the best price or

environmental impact.

COMPATIBLE PRODUCTS

• S1155

• S1255

• VVM S320

• VVM S325

Pipe connections

The external circulation pump (GP10) is located on the

supply line to the climate system after the temperature

sensor (BT25).

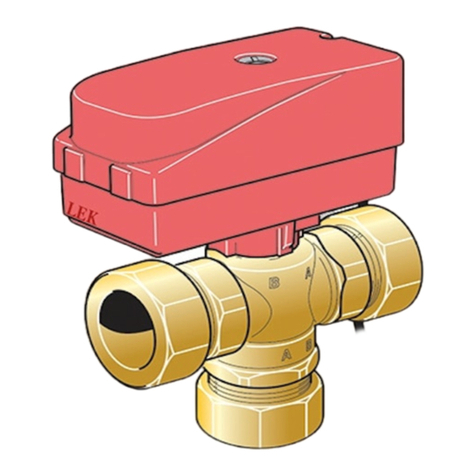

SHUNT VALVE

The shunt valve (QN11) must be placed on the supply

line to the climate system after the heat pump according

to the outline diagram.

• Connect the supply line from the

heat pump to the external heat

source via the T-pipe to port B on

the shunt valve (closes on reduce

signal).

• Connect the supply line to the climate system from

the shunt valve to the common port AB (always open)

• Connect the supply line from the external additional

heat to the shunt valve to port A (opens on increase

signal).

9Chapter 4 | Shunt controlled additional heatAXC 40

Shunt controlled additional heat