Elektromaten TS 981 User manual

Electrical operating instructions

Door control panel TS 981

Software 2.6 (Design and functions subject to change)

51171314 -l 02.2013

en

Page 2

Page

OPERATING INSTRUCTIONS

SAFETY DIRECTIONS.................................................................................................4

INSTALLATION ADVICE ..............................................................................................6

INSTALLATION OVERVIEW ........................................................................................7

ENCLOSURE INSTALLATION ....................................................................................8

CONNECTING THE CONTROL AND THE ELEKTROMATEN®..........................................................8

MAINS SUPPLY............................................................................................................9

PHASE ROTATION.......................................................................................................10

MOTOR CONNECTION (internal wiring) ....................................................................10

RAPID ADJUSTMENT OF THE LIMITS.......................................................................11

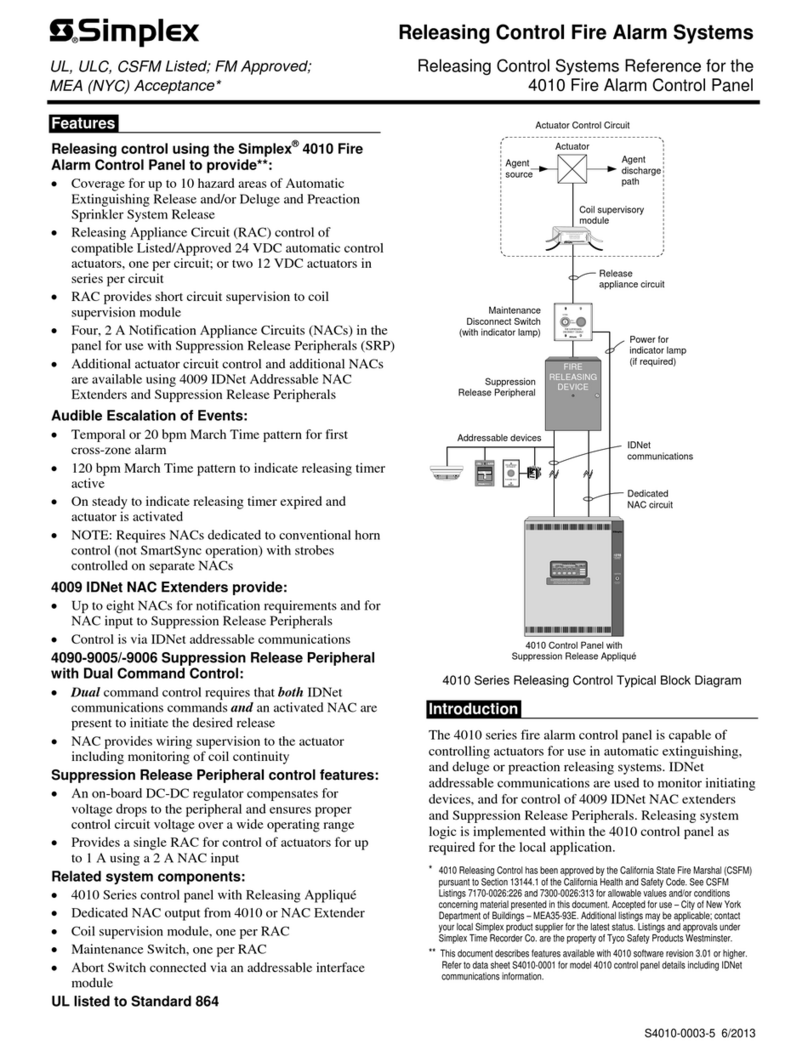

HARDWARE OVERVIEW.............................................................................................12

WIRING DIAGRAM .......................................................................................................14

CONTROL PROGRAMMING........................................................................................18

Operatingmode.............................................................................................................19

Door position .................................................................................................................19

Functions .......................................................................................................................20

Safetyfunctions..............................................................................................................21

SettingsonlyforELEKTROMATEN®withdirect/frequency inverterDU/FI ......................23

Extendeddoorfunctions.................................................................................................24

Maintenancecyclecounter .............................................................................................25

MEMORY CHECK ........................................................................................................25

RESET..........................................................................................................................26

SOFTWARE..................................................................................................................26

SAFETY DEVICES .......................................................................................................27

DoorsafetyswitchX2 ....................................................................................................27

Safetyedgesystemwithoptionalconnectionforshutterpass-doororslackwireswitchcontact.X2 ...27

Typ1: Resistanceevaluation 1K2 with normally closed safety edge contact...................27

Typ2: Resistanceevaluation 8K2 with normally opensafetyedgecontact .....................28

Typ3: Opticalsafety edge (Vitector) ..............................................................................28

Mountingthespiralcable................................................................................................28

Functionofthesafetyedgesystem.................................................................................29

Page 3

Page

Pass door / slack rope switch input X2 ...........................................................................30

Emergency stop X3.......................................................................................................30

FUNCTION DESCRIPTION..........................................................................................31

Internalpushbutton/Threepush button / Key switch X5 / X15.......................................31

Automaticclosing...........................................................................................................31

Automaticclosinginterruption.........................................................................................31

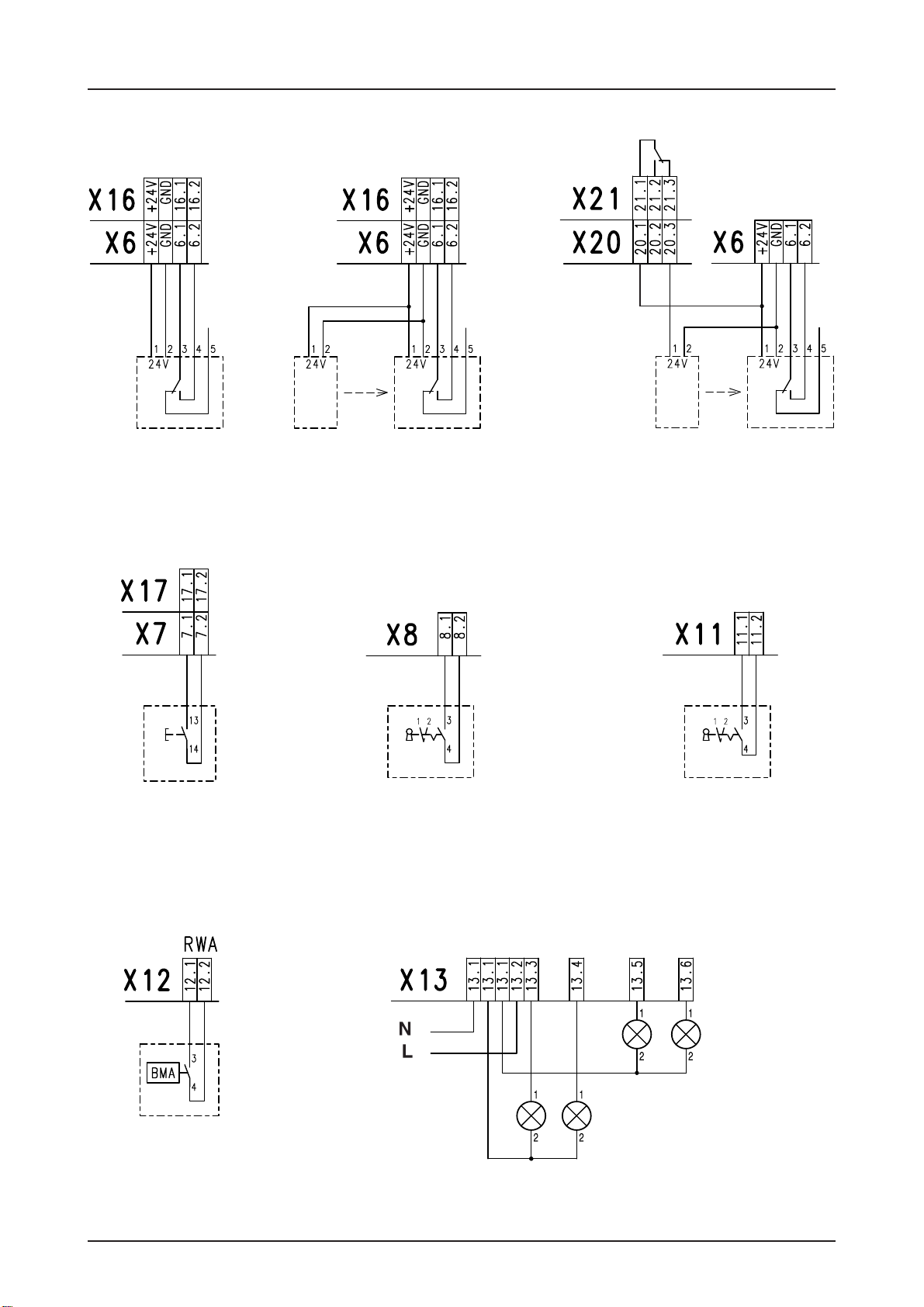

Through/Reflectivephoto cell X6 / X16 or Light curtain X6 ............................................32

Ceiling pull switch / Radio control X7 / X17 ....................................................................34

Key switch – intermediate stop X8 ................................................................................34

Keyswitch(latching)interruptautomaticclosingX11 ......................................................35

Smokedraining - Function (RWA) X12 ..........................................................................35

Lightindicatorfortraffic control X13 ...............................................................................35

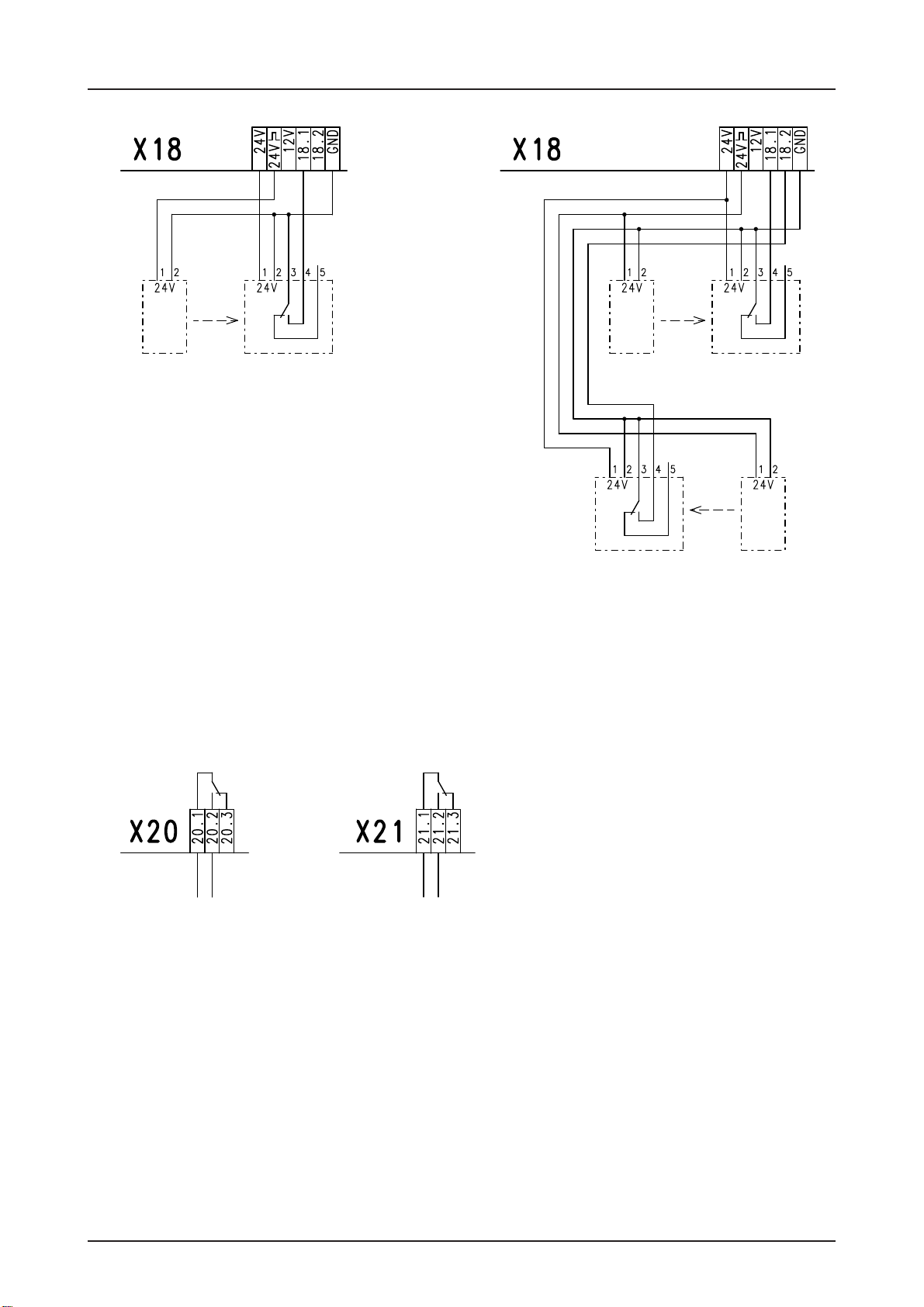

SafetyagainstentrampmentX18 ...................................................................................37

Potentialfree changeover contact X20 /X21 .................................................................37

Overruncorrection..........................................................................................................37

Dooroverloadmonitor ...................................................................................................38

AIRlook SLF..................................................................................................................39

StatusmonitoringfunctionSMF ......................................................................................39

Maintenancecyclecounter .............................................................................................39

SoftwareUpdate ............................................................................................................40

Shortcircuit/overloadmonitor .......................................................................................40

OPERATING STATUS DISPLAY ..................................................................................41

TECHNICAL DATA.......................................................................................................46

LIFETIME / DOORCYKLES..........................................................................................47

DECLARATION OF INCORPORATION .......................................................................48

FUNCTION OVERVIEW ...............................................................................................49

Page 4

SAFETY DIRECTIONS

Safety Regulations

During the installation, initial operation, maintenance and testing of the Control Panel, it is

necessary to observe the safety and accident-prevention regulations valid for the specific

application.

In particular, you should observe the following regulations (this list is not exhaustive):

European normative

- EN 12445

Safety in use of power operated doors - Test methods

- EN 12453

Safety in use of power operated doors - Requirements

-EN 12978

Industrial, commercial and garage doors and gates -

Safety devices for power operated doors - Requirements and Test methods

Please check normative´s bellow.

VDE-regulations

- EN 418

Safety machinery

Emergency stop equipment functional aspects

Principles for design

- EN 60204-1 / VDE 0113-1

Safety of machinery - Electrical equipment of machines - Part 1:

Prescriptions générales

- EN 60335-1 / VDE 0700-1

Safety of household and similar electrical appliances - Part 1:

General requirements

Basic Directions

This control has been built in accordance with EN 12453 Industrial, commercial and garage

doors and gates - Safety in use of power operated doors - Requirements and EN

12978 Industrial, commercial and garage doors and gates - Safety devices for power

operated doors - Requirements and Test methods; and leftthe factory in perfect condition

fromthepointofviewofsafety. Tomaintainthisconditionand toensuresafeoperation,the user

mustobserveallthedirectionsandwarningscontainedintheseoperating instructions.

Inprinciple,onlytrainedelectricalcraftsmenshouldworkonelectricalequipment.Theymustassess

the work which has been assigned to them, identify potential danger sources and take suitable

safetyprecautions.

Reconstructionoforchangesto TS 981areonlypermissiblewiththeapprovalofthemanufacturer.

Original replacement parts and accessories authorised by the manufacturer guarantee safety.

Liability ceases to apply if other parts are used.

The operational safety of an TS 981 is only guaranteed if it is used in accordance with the

regulations. The limiting values stated in the technical data should not be exceeded under any

circumstances (see corresponding sections of the operating instructions).

Regulations

- Please ensure that the local regulations relating to the Safety of Opera-

tions of Doors are followed

Page 5

SAFETY DIRECTIONS

Explanation of warnings

These operating instructions contain directions which are important for using the ELEKTRO-

MATEN®appropriately and safely.

The individual directions have the following meaning:

DANGER

This indicates danger to the life and health of the user if the appropriate

precautions are not taken.

Please observe the safety and accident prevention regulations valid for

the specific application.

The ELEKTROMATEN®must be installed with the authorised coverings

and protective devices. Care should be taken that any seals are fitted

correctly and screw couplings are tightened correctly.

In the case of ELEKTROMATEN®with a permanent mains connection, an

all-pole main switch with appropriate back-up fuse must be provided.

Check live cables and conductors regularly for insulation faults or

breakages. When a fault is detected in the cabling, the defective cabling

should be replaced after immediately switching off the mains supply.

Before starting operation, check whether the permissible mains voltage

range of the devices corresponds to the local mains voltage.

With three – phase motor connection it must have right phase rotation

The following warnings are to be understood as a general guideline for working with the

ELEKTROMATEN®in conjunction with other devices. These directions must be observed

strictly during installation and operation.

General warnings and safety precautions

CAUTION

This warns that the ELEKTROMATEN®or other materials may be damaged if

the appropriate precautions are not taken.

Check that all screw connections are secure before operating the control

and adjusting the limit switches.

Page 6

INSTALLATION ADVICE

After the ELEKTROMATEN®is fitted we recommend the following procedure to rapidly reach

a fully functioning door.

• Installation Enclosure installation page 8

• Installation Wiring the Drive to the Control page 8

• Check Mains supply page 9

• Check Phase rotation page 10

• Programming Rapid limit adjustment page 11

The door is ready to work in Dead man mode.

• Installation Safety devices page 14, 27

• Programming Door functions page 18

The door is ready to work in automatic mode.

Check connection of external devices e.g. push button etc.

Overview to connect external devices see diagram (page 14-17).

After the devices are connected the programming of the control panel must be finalised.

(page 18).

Page 7

INSTALLATION OVERVIEW

Mains supply

Photo-beam

Pull switch

Three push button

Key switch (latching) interrupt

automatic closing

Emergency stop

Key switch (latching) inter-

mediate stop

Red / Green Traffic- Light

Connection cable ELEKTROMAT®for

Motor and DES ( electronic limit) 11

5

5

3

5

3

3

3

2x4

Spiral cable for

Safety edge system 4

( ) Number of cores in the cable

Important!

Using the connection cable out side the building is not permitted.

Page 8

3

2

1

4

PE

- 14 -

5 -

6 -

- 2

- 3

PIN

1

2

PE

3

4

- 4

- 5

- 6

2 -

PIN

ENCLOSURE INSTALLATION

Beforemountingtheenclosure,thesurfacehastobecheckedforflatness,slopeandfreedom

from vibrations. Mounting must be vertical. It is important that the door can be clearly seen

from the position of the control through-out its travel.

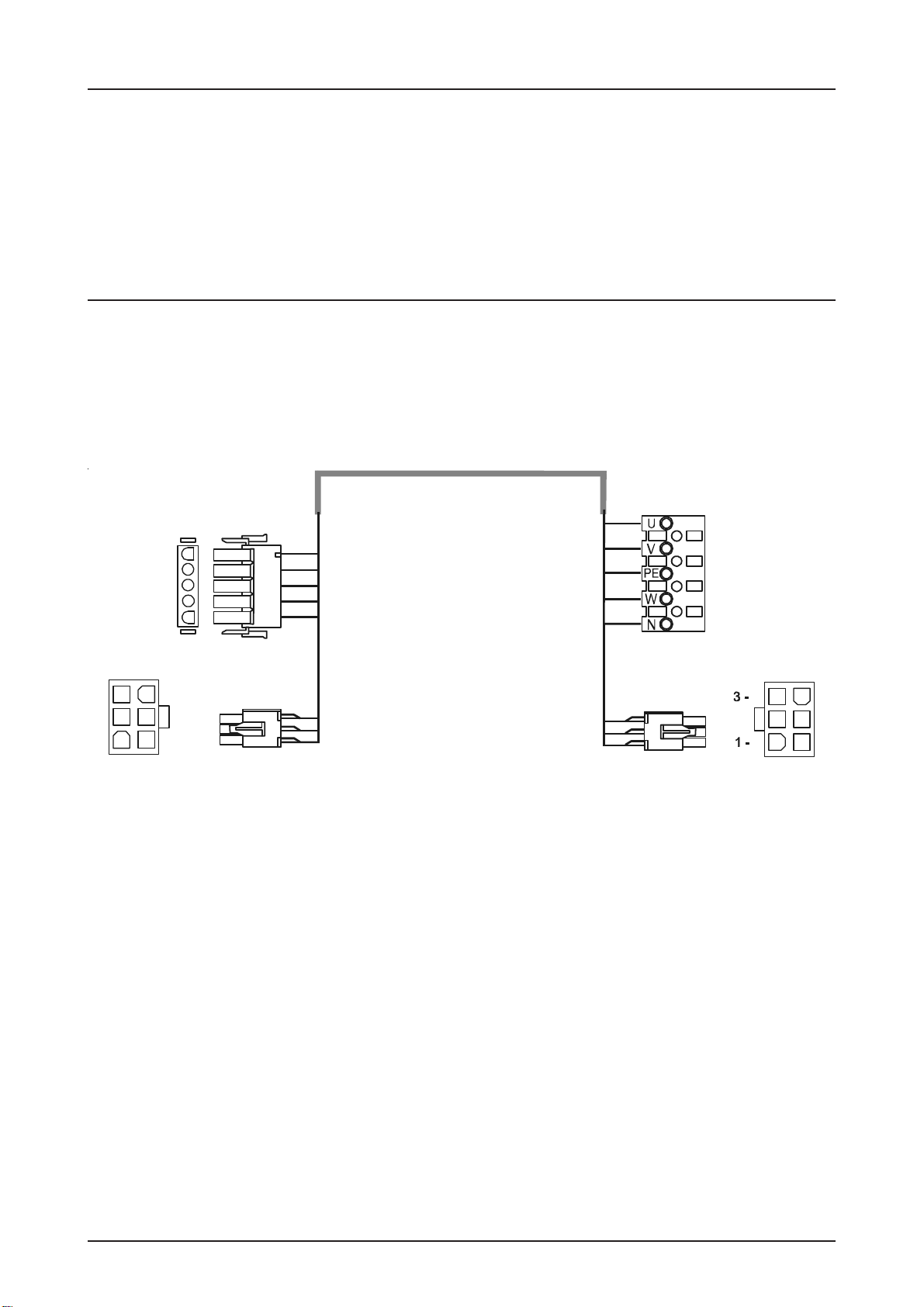

CONNECTING THE CONTROL AND THE ELEKTROMATEN®

After the drive and control are fitted they can be connected with a plug-in cable. The cable

has plugs on each end and for easy fitting. The plugs for motor and control panel are different

and cannot be interchanged.

Connection cable for

digital limit (DES)

Control panel TS 981 ELEKTROMAT®

Cable identification

Motor plug to control unit

PIN -Wire-No. Excution:

1 - 3 Phase W

2 - 2 Phase V

3 - 1 Phase U

4 - 4 Neutral (N) (not used)

5 - PE Earth

Limit plug-in to control panel TS 981 (DES)

PIN - Wire-No. Excution:

1 - 5 Safety chain 24V DC

2 - 6 RS485 B

3 - 7 GND

4 - 8 RS485 A

5 - 9 Safety chain

6 - 10 8V DC

Motor plug-in

Motorconnection (MOT)

Page 9

TheControlpanelTS981hasauniversal electric supplyandworkswiththefollowingsupplies.

(See diagram Fig.1-5)

The supply disconnect device (Main switch or CEE plug) must be installed between 0,6m

and 1,7m above floor level.

Mains supply terminal

Fig.: 1

Fig.: 2

Fig.: 3

Fig.: 5

Fig.: 4

asymmetricwinding

symmetricwinding

MAINS SUPPLY

External fuse!

Control must be saved against short circuit and overload by an external fuse,

max.10Adelayed, in the mains supply.Anautomatic cut offswitchisrequired,

regarding the supply for three-phase or single-phase.

Whenconnectingcontrol tomainssupplya mainsisolatorswitchor(16ACEE–plug)according

EN 12453 is required. The control panel has an integrated auto controlled power unit for

voltages from 230V up to 400V +/- 10%.

DU = 3x400V

FI 1,5KW = 1x230V/N/PE or 3x400V/N/PE

FI 4,5 kW = 3x400V/PE or 3x400V/N/PE

DANGER! To the life and health through electric shock.

IfaGfAfrequencydriveFIisinstalled,itmust be used a class B earth-leakage

circuitbreakerinthemainssupply.Otherswitchescanfailandswitching

unintentionally.

Page 10

PHASE ROTATION

DANGER! To the life and health through electric shock.

Before changing phase rotation the mains supply must be switched OFF.

Three-phase 3 x 400VAC, N, PE

Star connection Three-phase 3 x 230VAC, PE

Delta connection

Single-phase 1 x 230VAC, N, PE

symmetrical winding Single-phase 1 x 230VAC, N, PE

asymmetrical winding

Important note!

For3x400VACPEno

neutral, the brake

rectifier must be

connected between

terminal V and star-

point terminal.

brown brown

supply for

brake

rectifier

blue supply for

brake

rectifier

MOTOR CONNECTION (internal wiring)

blue

On several ELEKTROMATEN®the connection U1 und V1 on the motor-plug are

interchanged.

Important Notice!

Afterthemainssupplyhas been connected: toconfirmthatthephaserotationof

theelectricalmotoriscorrectthedoorshallmoveUPWARDS if the OPEN push

buttonisoperated.Ifthedoordoesnot OPEN change first phase rotation.

Forallthree phase ELEKTROMATEN® even DU: Change wiring atterminalX1:1.1–1.2.

Forinverterdrives FI-ELEKTROMATEN®seepage13.

ForallsinglephaseELEKTROMATEN®:Changewiringattheconnectioncableplug,

changecoreno.1+3reciprocal.

Page 11

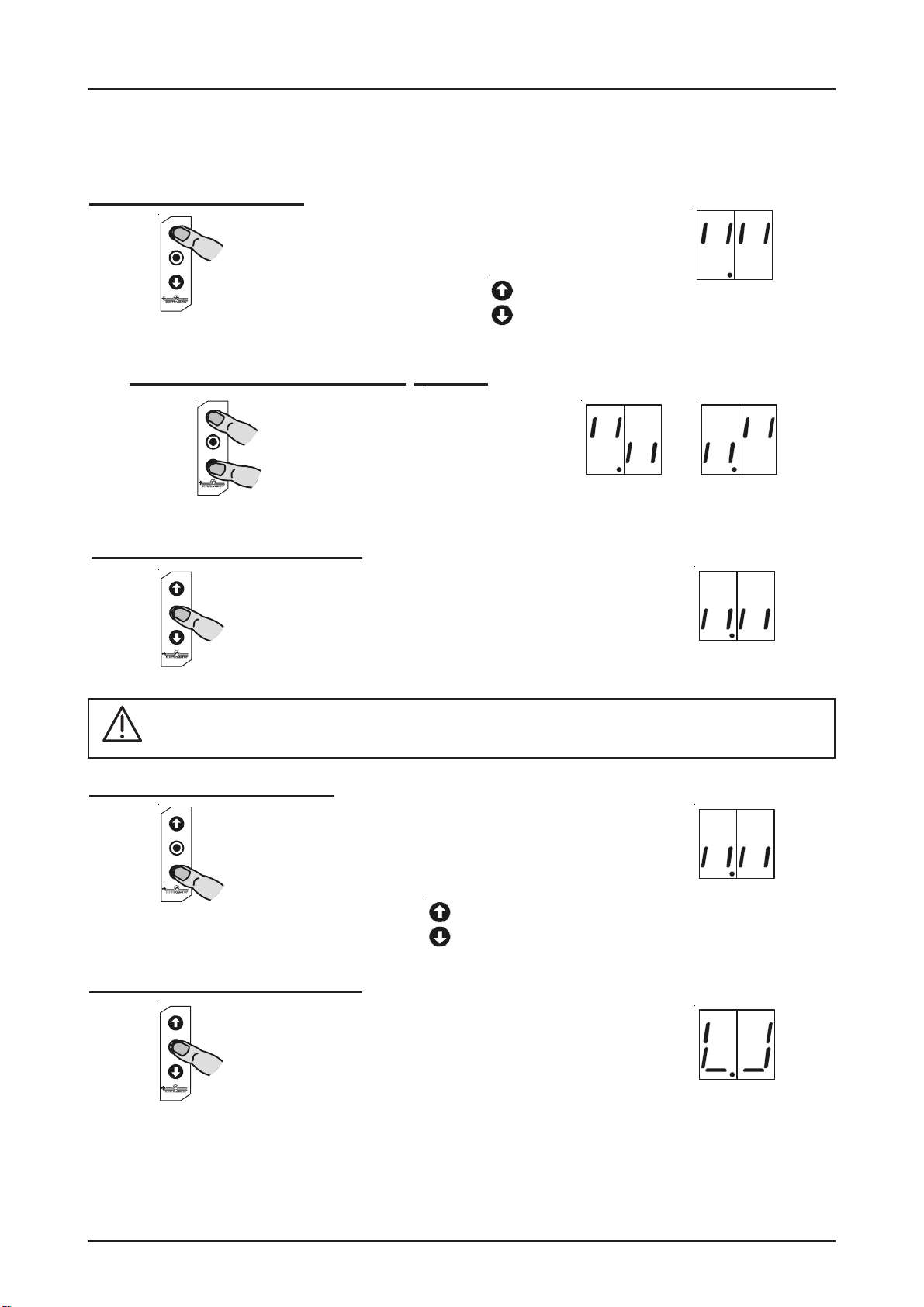

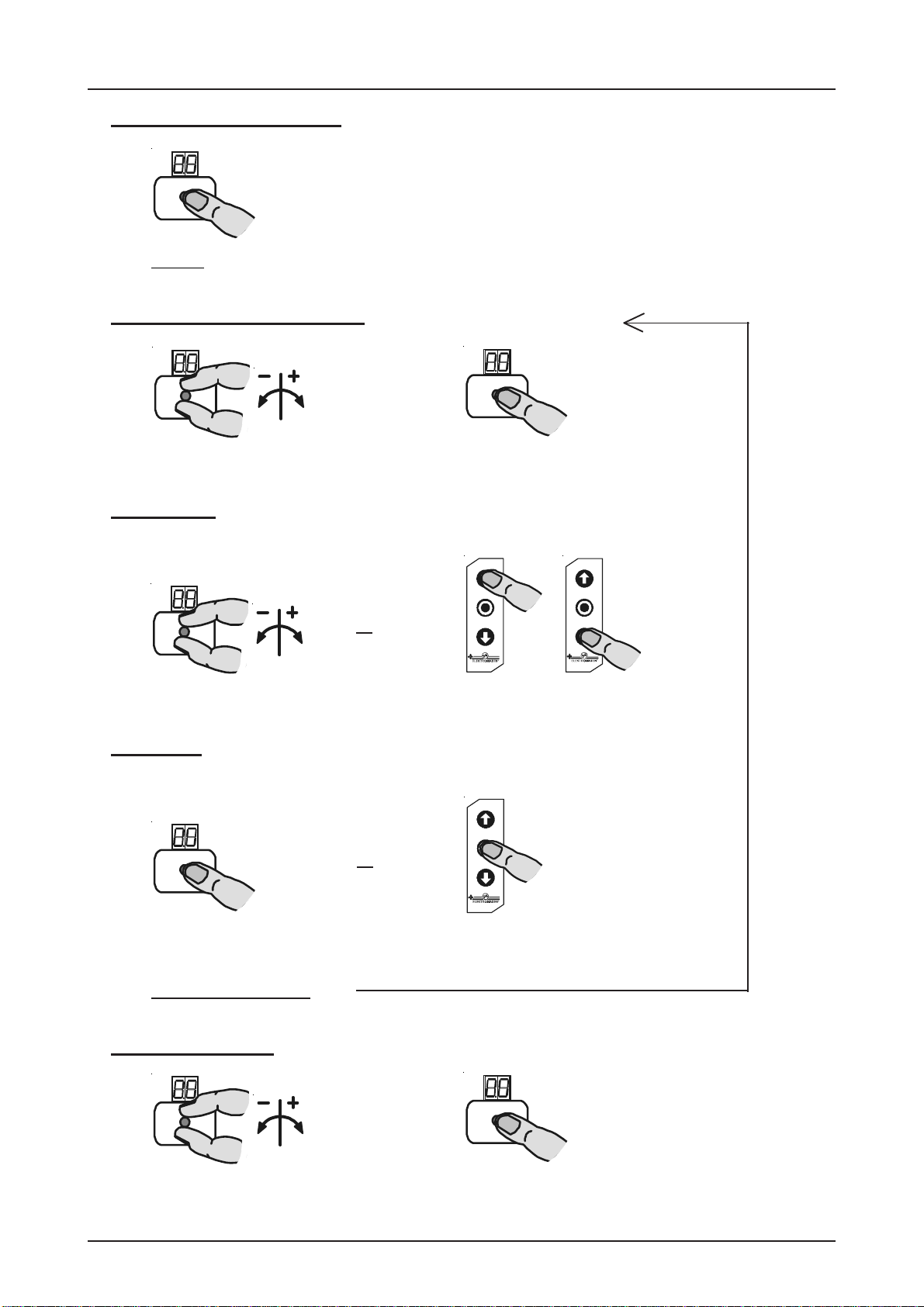

RAPID ADJUSTMENT OF THE LIMITS

The Rapid adjustment is finished

The door could be moved in DEADMAN mode UP/DOWN

Further adjustments see programming mode

1. Setting final limit open

pressbuttontoreachupperlimit

Door open

Display

blinking

2. Memorise the final limit open

Pressstop-buttonfor3sec.until

thedisplaychanges Display

changes

3.Setting the final limit close

press button to reach lower limit Display

blinking

Door close

4. Memorise the final limit close

Pressstop-buttonfor3sec.until

thedisplaychanges Display

changes

When the phase rotation has been checked the Rapid limit adjustment can be made.

The final setting can be made with the fine adjustment (Control Programming page 19).

Safety limits and pre-limits are automatically adjusted.

ThefinallimitOPEN ismemorisedwhenthedoor movesforatleastone secondfrom

closeintotheupper limit position.

1a. Reversing FI-ELEKTROMAT®rotation

Toreversethemotorrotation

keepbothbuttonspressedfor

threesecondsuntilthedisplay

changes Display

blinking Display

changes

Page 12

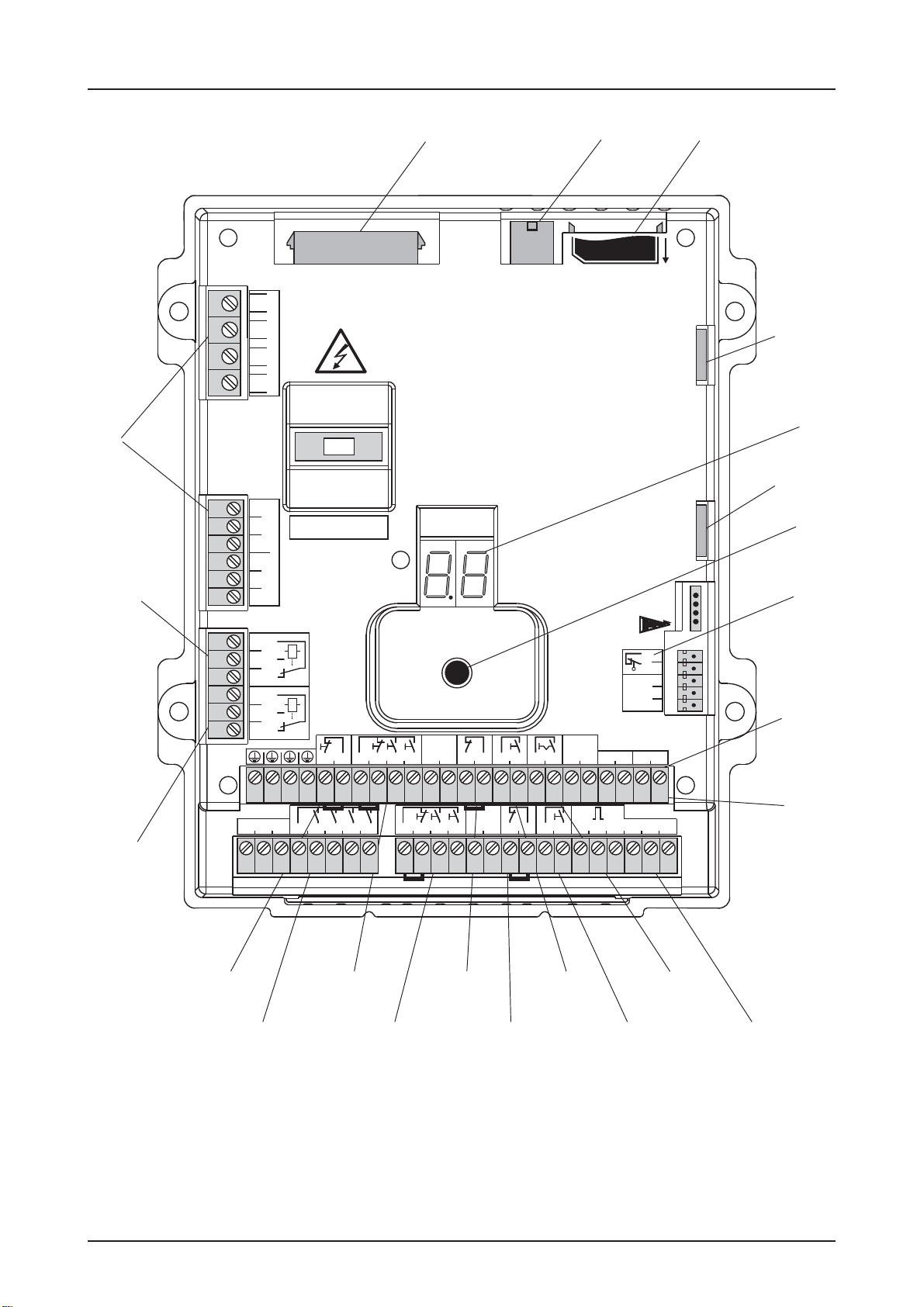

HARDWARE OVERVIEW

X1

X21

X3

X2

X13 X16

X6 X7

X18

S1

V1

X8

X11

X12

X17

X5

X20

X15

SMF

SLF

MOT DES MMC/SD

20.1

20.2

20.3

21.1

21.2

21.3

1.8

1.8

1.8

1.9

1.9

1.9

1.1

1.2

1.3

1.4

F1 = 1,6A t

MOT DES

2.5

2.4

2.3

2.2

2.1

3.1

3.2

5.1

5.2

5.3

5.4

24V

GND

6.1

6.2

7.1

7.2

8.1

8.2

24V

GND

11.1

11.2

12.1

12.2

RWA

13.1

13.1

13.1

13.2

13.3

13.4

13.5

13.6

15.1

15.2

15.3

15.4

24V

GND

16.1

16.2

17.1

17.2

12V24V24V

18.2

18.1

GND

MMC / SD

SMF

SLF

TS 981

40014900

Page 13

Description Print:

X1 Mains supply

externalsupply230V

1.9 = L1 L1 fused with F1 = 1,6A

1.8 = N

(onlywith3 x 400V, N, PE und 1 x 230V, N,PEsymmetricwinding)

X2 Safetyedgesystemandpass-door plug

X3 Emergencypushbutton

X8 Keyswitchforintermediatestop

X11 Key switch ON / OFF forautomaticclosing

X12 Smoke draining

X13 Traffic lights 2x Red / Green

X18 Entrapment safety evaluation

X20 Potential free relay contact 1

X21 Potential free relay contact 2

X5 Three push button / Key switch

X6 Reflective photo-beam / photo-beam

X7 Ceiling pull switch / Radio control

X15 Three push button / Key switch

X16 Reflective photo-beam / photo-beam

X17 Ceiling pull switch / Radio control

Command from inside Commandfromoutside

DES Limit connection

MOT Motor connection

MMC/SD Slot for memory cards

SLF Slot for Air-lock control function

SMF Slot for Status / Information function

S1 Selector switch

V1 7-segment display

Internal push button

HARDWARE OVERVIEW

Page 14

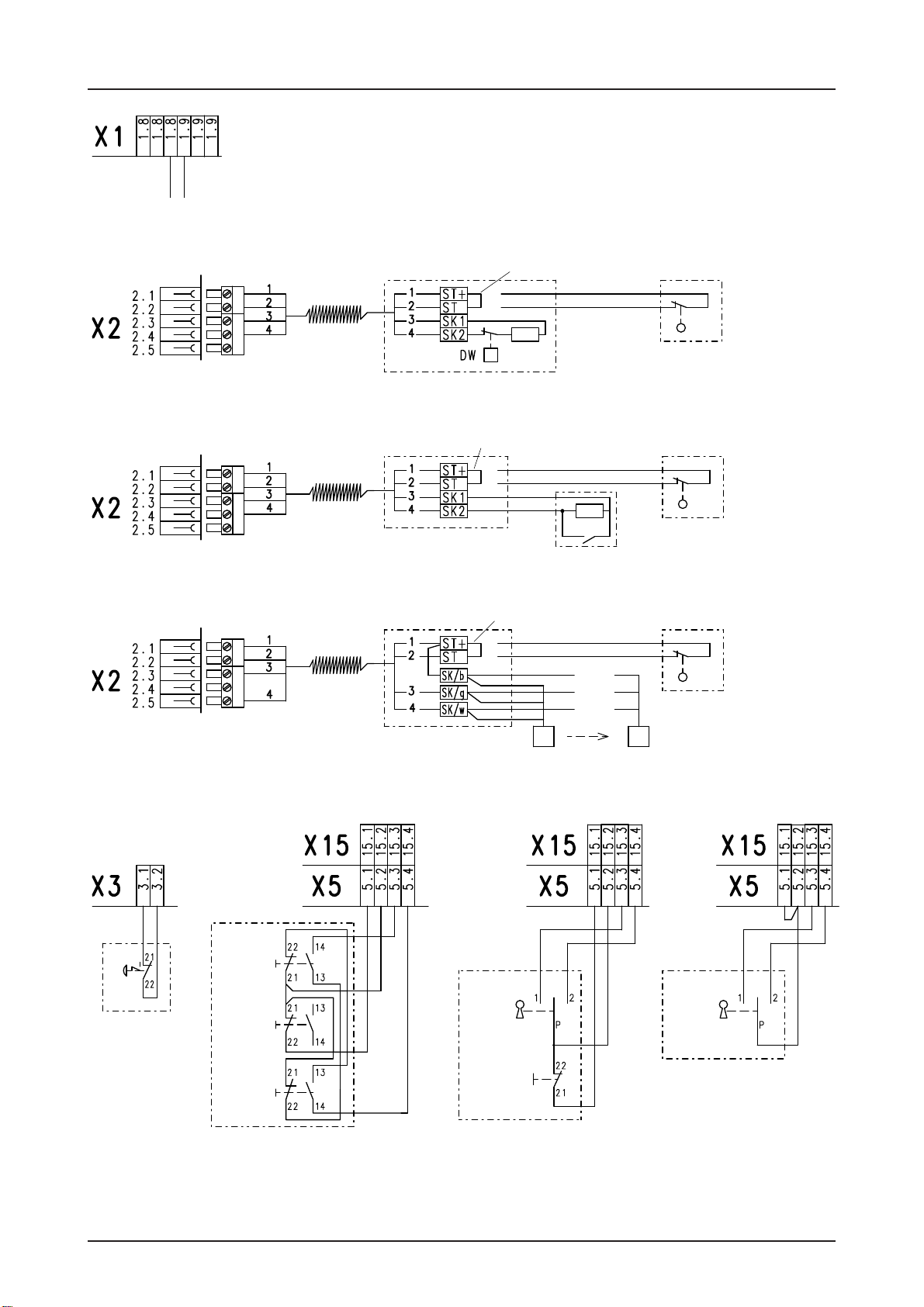

WIRING DIAGRAM

Emergency

stop button

inside

Three push

button station

inside or outside

Key switch with

stop button

inside or outside

CLOSE

STOP

OPEN

STOP

OPEN/

CLOSE

end-of-line

resistor 1K2

end-of-line

resistor 8K2

Bridge

spiral

cable

spiral

cable

Transmitter Receiver

spiral

cable

Normallyclosed contact 1K2

Normallyopen contact 8K2

Optical safety edge system

Key switch

inside or outside

or

plug-in bridge

plug-in bridge

plug-in bridge

N L1

or

br

gr

wh

Terminal box

Bridge

Terminal box

Bridge

Terminal box

L1 fused

via F1 = 1,6At

OPEN/

CLOSE

outside

inside

pass or /

slackwire

switchcontact

orcrash

detector

pass or /

slackwire

switchcontact

orcrash

detector

pass or /

slackwire

switchcontact

orcrash

detector

Page 15

WIRING DIAGRAM

Reflective photo-beam

inside or outside

Ceiling pull switch /

Radiocontrol

inside or outside

Transmitter- Receiver

photo-beam

inside or outside

Red - Green

light

inside

or

Key switch ON / OFF

automaticclosing

Key switch ON / OFF

Intermediatestop

Red - Green

light

outside

Smoke draining

contact RWA

external

or

X1 1.8/1.9

outside

inside

forclosingdirection

Transmitter-Receiver

lightcurtain

inside

Page 16

WIRING DIAGRAM

Raytectorphoto-beamor

Opticalsafetyedge

againstentrapment

single Raytectorphoto-beamor

Opticalsafetyedge

againstentrapment

double(inside- outside)

Transmitter - Receiver

Input for external entrapment

safety device 1K2

single

Input for safety edge 8K2

against entrapment

single

br

gr

wh

Transmitter - Receiver

Input for safety edge 8K2

against entrapment

double

Input for external entrapment

safety device 1K2

double

or

or

or

br

wh

gr

Receiver - Transmitter

br

gr

wh

br

gr 1

wh

br

gr 2

wh

br

gr 1

wh

br

gr 2

wh

br

wh

gr 1

gr 2

Page 17

WIRING DIAGRAM

Potential free

relay contact Potential free

relay contact

photo-beam

single,

againstentrapment

comply EN 12978

Transmitter - Receiver

Receiver - Transmitter

photo-beam

double,

againstentrapment

comply EN 12978

Transmitter - Receiver

or

Page 18

CONTROL PROGRAMMING

5.Exit programming

Turn selector until display = 00 Press selector

and

1.Enter programming Mode

Press selector switch for 3 sec. until display = 00

2.Chose program and confirm

Turn selector Press selector

3.Adjustment

Turn selector Press foil buttons

4.Memorise

Press selector Press stop-button

and

Functionen Door position

or

Functionen Door position

or

further adjustments

Page 19

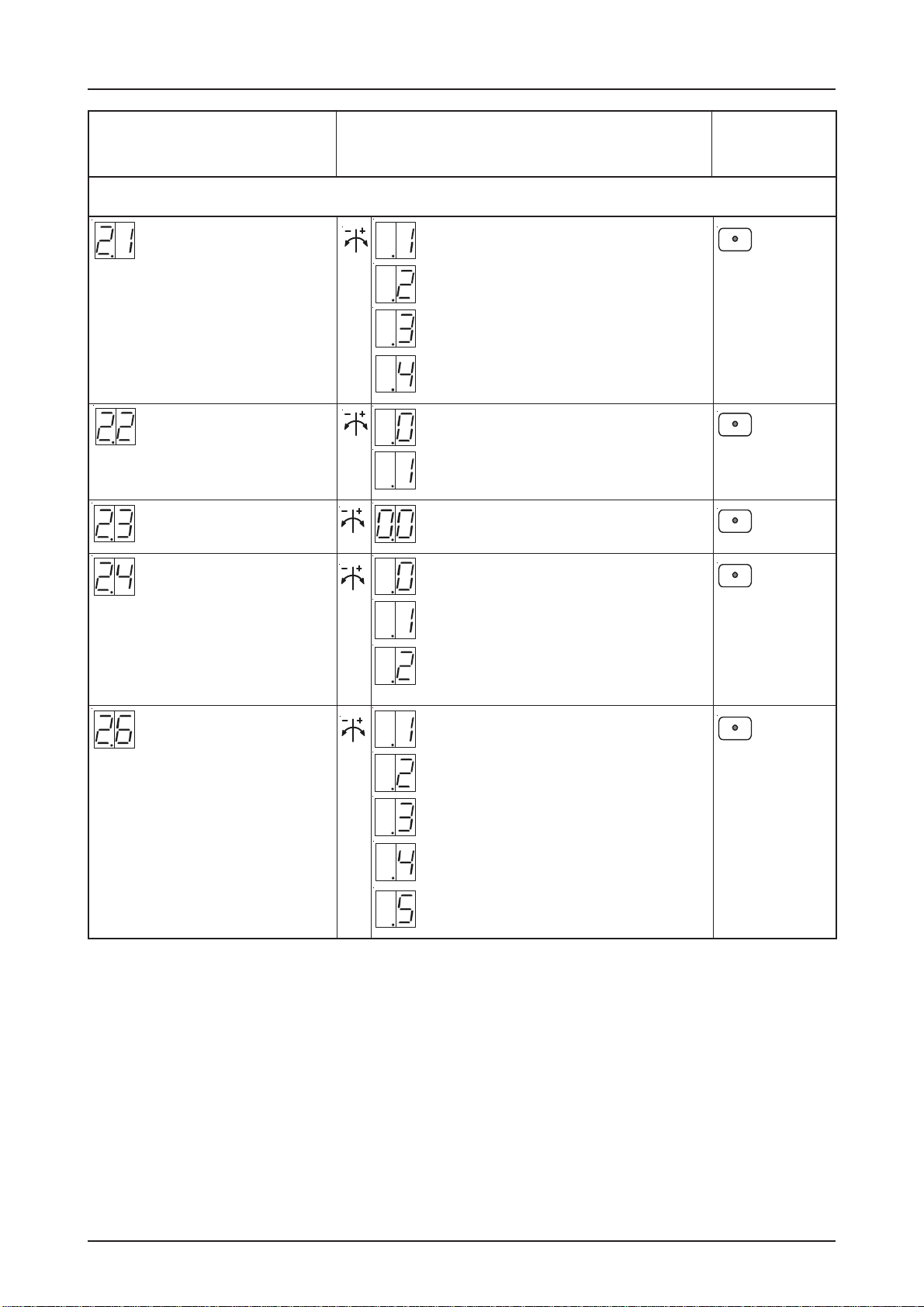

Operating mode

Door position

CONTROL PROGRAMMING

4. Memorise3.Adjustment

2. Choose program and

confirm

Press

selector

Dead man OPEN

Dead man CLOSE

Door function

Self-hold OPEN

Dead man CLOSE

Self-hold OPEN

Self-hold CLOSE

Self-hold OPEN, CLOSE

(X5/X15) release for external

pushbutton function only dead man

close

Press stop

Button

Move door

upwards or downwards

Final limit open

coarse adjustment

Press

selector

Move to intermediate stopIntermediate stop

Move to switching position relay 1

Switching position Relay 1

Press stop

Button

Press stop

Button

Pre-limit safety edge can

change using +/-

Pre-limit safety edge

fine adjustment

Press

selector

Press

selector

Press stop

Button

Move door

upwards or downwards

Final limit close

coarse adjustment

Final limit open can change

without door movement using +/-

Final limit open

fine adjustment

Final limit close can change

without door movement using +/-

Final limit close

fine adjustment

Move to switching position relay 2

Switching position Relay 2Press stop

Button

Page 20

Functions

CONTROL PROGRAMMING

4.Memorise3.Adjustment

2. Choose program and

confirm

Press

selector

time can be set between 1 - 240 sec.

0 = OFF

Automatic closing

feature

Press

selector

OFF

Automatic closing after

photo-beam is interrupted

and re-made ON

Press

selector

Step by Step function

(X7 / X17): only Ceiling

pull switch / Radio

remote control

X7 / X17 = Command 1

X7 = Command 1, X17 = Command 2

X7 = Command 2, X17 = Command 1

X7 / X17 = Command 2

X7 / X17 = Command 3

Vehicle recognition, closes when the

contact is more than 1,5 sec.

triggered

Press

selector

Safety edge is activated

Safety edge function in

Pre - limit area

Safety edge is deactivated

Safety edge is activated

+ automatic ground adjustment

Press

selector

OFF

Overrun correction

ON

Active safety edge

+ re-open

Table of contents

Other Elektromaten Control Panel manuals