Elektromaten TS 961 User manual

Electrical operating instructions

Door control panel TS 961

Software 2.6 (Design and functions subject to change)

51171292 -f 02.2013

en

Page 2

OPERATING INSTRUCTIONS

SAFETY DIRECTIONS .................................................................................................4

INSTALLATION ADVICE ..............................................................................................6

INSTALLATION OVERVIEW ........................................................................................7

ENCLOSURE INSTALLATION ....................................................................................8

CONNECTING THE CONTROL AND THE ELEKTROMATEN®..........................................................8

LIMIT SWITCH CONNECTION

Plug - in system ...........................................................................................................9

Terminalversion(untilyear 1997).................................................................................10

Single-limit-switches....................................................................................................10

MAINS SUPPLY............................................................................................................11

MOTOR CONNECTION (internal wiring) ....................................................................12

PHASE ROTATION.......................................................................................................12

LIMIT SWITCH - ADJUSTMENT ..................................................................................13

HARDWARE OVERVIEW.............................................................................................14

WIRING DIAGRAM .......................................................................................................15

CONTROL PROGRAMMING........................................................................................16

Operating mode ...........................................................................................................17

Functions .....................................................................................................................17

Reset ...........................................................................................................................18

Maintenancecyclecounter ...........................................................................................18

MEMORY CHECK ........................................................................................................18

SAFETY DEVICES .......................................................................................................19

Safety nection forshutter pass - door or slack wire switch contactX2..........................19

Mounting thespiral cable .............................................................................................19

Adjustmentpre-limit S5................................................................................................19

Typ1: Resistanceevaluation1K2with normallyclosed safety edgecontact ................20

Typ2: Resistanceevaluation 8K2 withnormally opensafety edge contact...................20

Typ 3: Optical safety edge (Vitector) ............................................................................20

Function of the safetyedge system ..............................................................................21

Emergency stop X3 ....................................................................................................21

Page

Page 3

FUNCTION DESCRIPTION..........................................................................................22

Key switch (latching) interrupt automaticclosing X4 ....................................................22

Internalpushbutton / Threepushbutton/ Keyswitch X5 ..............................................22

Runtime monitoring......................................................................................................22

Automatic closing ........................................................................................................22

Automatic closinginterruption ......................................................................................22

Photo-beam for Closing Direction X6 .........................................................................23

Ceiling pull switch / Radio control X7 ..........................................................................24

Key switch – intermediate stop X8..............................................................................24

Potential free changeovercontact X9..........................................................................25

Maintenancecyclecounter...........................................................................................25

Short circuit / overloadmonitor ....................................................................................25

OPERATING STATUS DISPLAY ..................................................................................26

TECHNICAL DATA.......................................................................................................29

LIFETIME / DOORCYKLES..........................................................................................30

DECLARATION OF INCORPORATION .......................................................................31

FUNCTION OVERVIEW ...............................................................................................32

Page

Page 4

SAFETY DIRECTIONS

Safety Regulations

During the installation, initial operation, maintenance and testing of the ELEKTROMATEN®,

itis necessary toobserve the safetyand accident-prevention regulationsvalid for thespecific

application.

In particular, you should observe the following regulations (this list is not exhaustive):

European normativ

- EN 12453

Saftey in use of power operated doors - Requirements

- EN 12445

Saftey in use of power operated doors - Test methods

Please check normative´s bellow.

VDE-regulations

- EN 418

Safety machinery

Emergency stop equipment functional aspects

Principles for design

- EN 60204-1 / VDE 0113-1

Safety of machinery - Electrical equipment of machines - Part 1:

General requirements

- EN 60335-1 / VDE 0700-1

Safety of household and similar electrical appliances - Part 1:

General requirements

Basic Directions

This control has been built in accordance with EN 12453 Industrial, commercial and garage

doors and gates - Safety in use of power operated doors - Requirements; and left the

factory in perfect condition from the point of view of safety. To maintain this condition and to

ensure safe operation, the user must observe all the directions and warnings contained in these

operating instructions.

In principle, only trained electrical craftsmen should work on electrical equipment. They must

assess the work which has been assigned to them, identify potential danger sources and take

suitable safety precautions.

Reconstruction of or changes to ELEKTROMATEN®are only permissible with the approval of

the manufacturer. Original replacement parts and accessories authorised by the manufacturer

guarantee safety. Liability ceases to apply if other parts are used.

The operational safety of an ELEKTROMATEN®is only guaranteed if it is used in accordance

with the regulations. The limiting values stated in the technical data should not be exceeded

under any circumstances (see corresponding sections of the operating instructions).

Regulations

- Please ensure that the local regulations relating to the Safety of Opera-

tions of Doors are followed

Page 5

SAFETY DIRECTIONS

Explanation of warnings

These operating instructions contain directions which are important for using the ELEKTRO-

MATEN®appropriately and safely.

The individual directions have the following meaning:

DANGER

This indicates danger to the life and health of the user if the appropriate

precautions are not taken.

Please observe the safety and accident prevention regulations valid for

the specific application. The installation of the ELEKTROMATEN®, the

opening of covers or lids and electrical connection must be carried out

when the supply is switched off.

The ELEKTROMAT®must be installed with the authorised coverings and

protective devices. Care should be taken that any seals are fitted correctly

and screw couplings are tightened correctly.

In the case of ELEKTROMATEN®with a permanent mains connection, an

all-pole main switch with appropriate back-up fuse must be provided.

Check live cables and conductors regularly for insulation faults or

breakages. When a fault is detected in the cabling, the defective cabling

should be replaced after immediately switching off the mains supply.

Before starting operation, check whether the permissible mains voltage

range of the devices corresponds to the local mains voltage.

With three – phase motor connection it must have right phase rotation

The following warnings are to be understood as a general guideline for working with the

ELEKTROMATEN®in conjunction with other devices. These directions must be observed

strictly during installation and operation.

General warnings and safety precautions

CAUTION

This warns that the ELEKTROMATEN®or other materials may be damaged if

the appropriate precautions are not taken.

Check that all screw connections are secure before operating the control

and adjusting the limit switches.

Page 6

INSTALLATION ADVICE

After the ELEKTROMATEN®is fitted we recommend the following procedure to rapidly reach

a fully functioning door.

• Installation Enclosure installation page 8

• Installation Wiring the Drive to the Control page 8

LIMIT SWITCH CONNECTION

Plug - in system page 9

LIMIT SWITCH CONNECTION

Terminal version (until year 1997) page 9

LIMIT SWITCH CONNECTION

Single-limit-switches page 10

• Check Mains supply page 11

• Check Phase rotation page 12

• Adjustmemt Limit switch - adjustment page 13

The door is ready to work in Dead man mode.

• Installation Safety devices page 15, 19, 20

• Programming Door functions page 16

The door is ready to work in automatic mode.

Check connection of external devices e.g. push button etc.

Overview to connect external devices see diagram (page 15).

After the devices are connected the programming of the control panel must be finalised.

(page 16).

Page 7

INSTALLATION OVERVIEW

Mains supply

Photo-beam

Pull switch

Three push button

Key switch (latching) interrupt

automatic closing

Emergency stop

Key switch (latching) inter-

mediate stop

Signal lamp

Connection cable ELEKTROMAT®for

Motor and mechanical limits NES 11

5

5

3

5

3

3

3

3

Spiral cable for

Safety edge system 4

( ) Number of cores in the cable

Important!

Using the connection cable out side the building is not permitted.

Page 8

ENCLOSURE INSTALLATION

Beforemounting the enclosure,the surface hasto becheckedfor flatness,slope and freedom

from vibrations. Mounting must be vertical. It is important that the door can be clearly seen

from the position of the control through-out its travel.

CONNECTING THE CONTROL AND THE ELEKTROMATEN®

After the drive and control are fitted they can be connected with a plug-in cable. The cable

has plugs on each end and for easy fitting. The plugs for motor and control panel are different

and cannot be interchanged.

Cable Description

Motor plug to control Panel

PIN -Wire-No.

1 - 3 Phase W

2 - 2 Phase V

3 - 1 Phase U

4 - 4 Neutral (N)

5 - PE Earth

Limit switch plug to control panel

PIN -Wire-No.

1 - 5 supply + 24V

2 - 6 S 5 aux. limit only for Testing of safety edge system

3 - 7 open - limit

4 - 8 S 6 aux. limit for intermediate Stop or switching contact

5 - 9 close limit

6 - 10 safety circuit common limit

Connection cable

Control panel TS 961 ELEKTROMAT®

1

2

PE

3

4

8

7

10

9

6

5

16

15

14

10

6

5

4

9

17

8

7

13

12

11

3

2

1

4

PE

- 1

- 2

- 3

- 4

- 5

PIN

- 14 -

5 -

6 -

- 2

- 3

PIN

Motor plugLimit switch plug

Page 9

LIMIT SWITCH CONNECTION

Plug - in system

Page 10

LIMIT SWITCH CONNECTION

Terminal version (until year 1997)

LIMIT SWITCH CONNECTION

Single-limit-switches

M

3

M

3

Page 11

The CONTROL PANEL TS 961 has a universal electric supply and works with the following

supplies. (See diagram Fig.1-5)

DANGER! To the life and health thru electric shock.

Before mounting the mains supply must be switched OFF.

The supply disconnect device (Main switch or CEE plug) must be installed between 0,6m

and 1,7m above floor level.

Mains supply terminal

Fig.: 1

Fig.: 2

Fig.: 3

Fig.: 5

Fig.: 4

asymmetric winding

symmetric winding

Important note!

The bridge must be fitted into the right terminal otherwise the print could be

destroyed.

400V – mains supply = 1.5 / 1.6

230V – mains supply = 1.6 / 1.7

MAINS SUPPLY

External fuse!

Control must be saved against short circuit and overload by an external fuse,

max.10Adelayed, in themains supply.Anautomatic cutoffswitchis required,

regarding the supply for three-phase or single-phase.

Whenconnectingcontroltomainssupplyamainsisolatorswitchor(16ACEE–plug)according

EN 12453 is required.

Page 12

Important Notice!

After the Mains supply has been connected by inserting the CEE plug in the

appropriatesocketor turning onthemain switch, confirmthatthe phase rotation

is correct by checking that the door opens when the OPEN push button is

operated.

If the door closes when operating the OPEN push button reverse two phases

at the terminal X1.

PHASE ROTATION

DANGER! To the life and health through electric shock.

Before changing phase rotation the mains supply must be switched OFF.

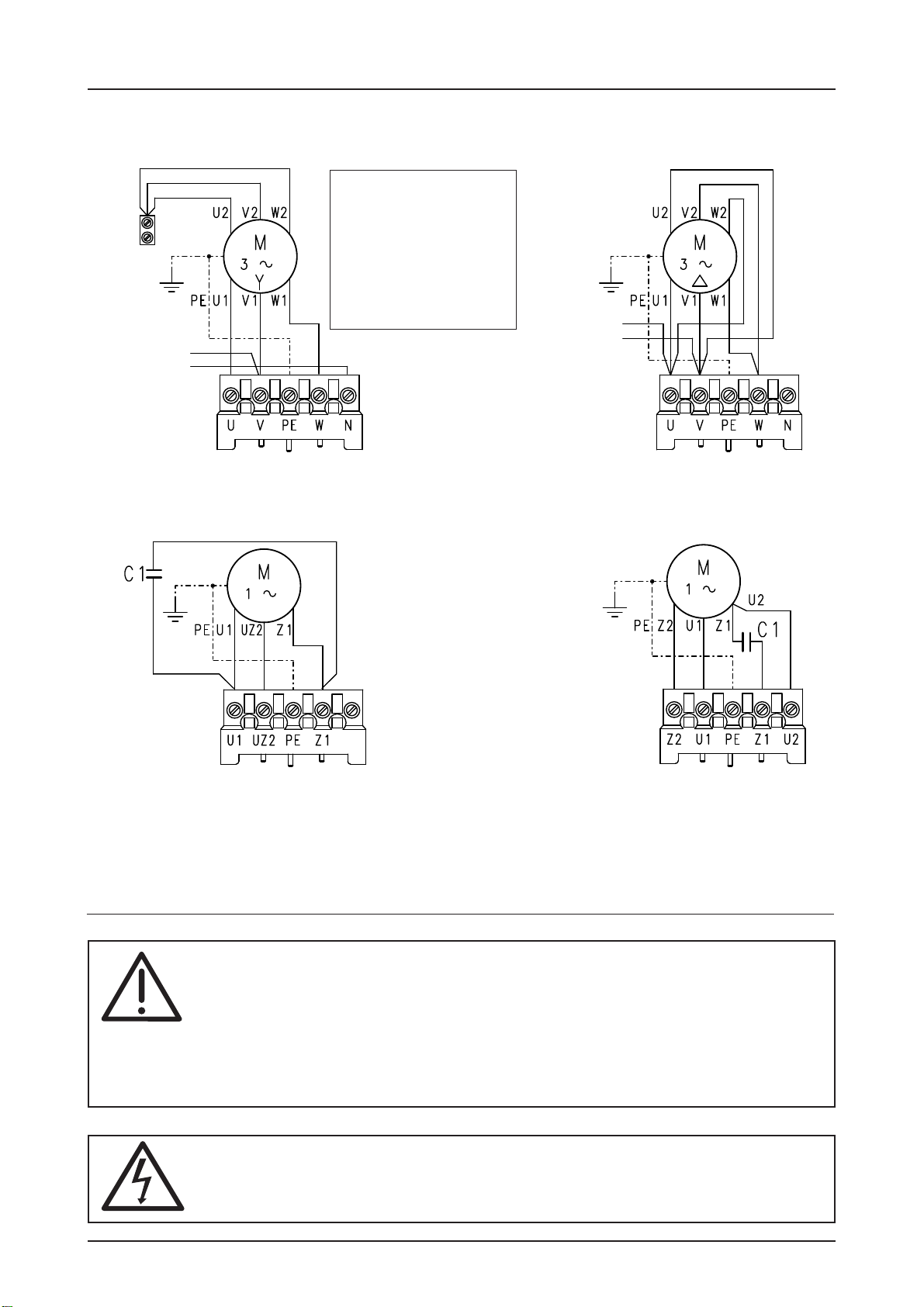

Three-phase 3 x400 V AC, N, PE

Star connection Three-phase 3 x230 V AC, PE

Delta connection

Single-phase 1x230 V AC, N, PE

symmetrical winding Single-phase 1x230 V AC, N, PE

asymmetrical winding

Important note!

For3x400VAC PEno

neutral, the brake

rectifier must be

connected between

terminal V and star-

point terminal.

brown

brown

supply for

brake

rectifier

blue supply for

brake

rectifier

MOTOR CONNECTION (internal wiring)

blue

On several ELEKTROMATEN®the connection U1 und V1 on the motor-plug are

interchanged.

Page 13

LIMIT SWITCH - ADJUSTMENT

Working limit adjustment is complete

The door could be moved in DEADMAN mode UP/DOWN

Further adjustments see programming mode (Page 16)

1. Move the door to final open position

press button to reach upper limit

Door open

2. Adjustment final open limit

3. Move the door to final close position

press button to reach lower limit

Door close

4. Adjustment final close position

After checking the phase rotation, the limit switches must be adjusted in the following steps.

When open and close position limits have been set the safety limits are automatically

pre-adjusted. Eventually fine adjustment could be required. Please see Mechanical

Operating Instruction.

After reaching the final open

position the limit S3 must be

switched with green limit cam S3

and panel display changes to

„Door final open position“

After reaching the final close

position the limit S4 must be

switched with green limit cam S4

panel display changes to „Door

final close position“

Display shown-

door open

Display shown-

door closed

Display flashing

during the door

upwards movement

Display

shown - door

between final

limit positions

Display flashing

during door

downwards

movement

Display shown-

door between

final limit

positions

Page 14

PEPE PE PE

3.1

3.2

4.1

4.2

5.2

5.1

5.3

5.4

6.1

GND

24V

6.2

7.1

7.2

8.1

8.2

2.5

2.4

2.3

2.2

2.1

1.8

1.9

9.1

9.2

9.3

1.1

MOT NES

1.2

1.3

1.4

F1 = 1,0A t

FT

1.5

1.6

1.7

TS 961

HARDWARE OVERVIEW

X1

X9 X3

X2

Description Print:

X1 Mains supply S1 Selector switch

external supply 230V V1 7-segment display

1.9 = L1 fused with F1 = 1A MOT Motor connection

1.8 = N NES Mechanicallimit connection

(only with 3 x 400V, N, PE und 1 x 230V, N, PE) Internal push button

X2 Safety edge system and pass-door plug

X3 Emergency push button

X4 Key switch (latching) interrupt automatic closing

X5 Three push button / key switch

X6 Light barrier reflective or receiver- transmitter type

X7 Ceiling pull switch / Radio control

X8 Key switch for intermediate stop

X9 Potential free relay contact

warning light or annunciator

X4 X5 X6 X7 X8

S1

V1

Page 15

WIRING DIAGRAM

Page 21-25 Page 19, 20

Emergency

stop button

Key switch

(latching) interrupt

automatic closing Three push button

station Key switch with stop

button

Close

Stop

Open

Stop

Open/

Close

Radio receiver

Ceiling pull switch

Transmitter- Receiver

photo-beam

Reflective photo-

beam

Key switch intermediate

stop Warning light Aux. contact

Terminal box Bridge

passor / slack wire

switch contact

passor / slack wire

switch contact

end-of-line

resistor 1K2

end-of-line

resistor 8K2

Terminal box Bridge

Terminal box Bridge

passor / slack wire

switch contact

spiral cable

spiral cable

Transmitter Receiver

brown

green

white

spiral cable

Normallyclosed contact 1K2

Normallyopen contact 8K2

Optical safty edge system

Key switch

Open/

Close

or or

or

N L1

L1 fused via

F1 = 1At

or

plug-in bridge

plug-in bridge

plug-in bridge

or

Page 16

CONTROL PROGRAMMING

5. Exit programming

Turn selector until display = 00 Press selector

and

1. Enter programming Mode

Press selector switch for 3 sec. until display = 00

2. Chose program and confirm

Turn selector press selector

3. Adjustment

Turn selector

4. Memorise

Press selector

and

Functionen

Functionen

further adjustments

Page 17

CONTROL PROGRAMMING

4. Memorise3. Adjustment

2. Choose program and

confirm

Press

selector

Dead man OPEN

Dead man CLOSE

Door function

Self-hold OPEN

Dead man CLOSE

Self-hold OPEN

Self-hold CLOSE

Press

selector

Safety edge is activated

Safety edge function

in Pre - limit area

Safety edge is deactivated

Press

selector

time can be set between 1 - 240 sec.

0 = OFF

Automatic closing

feature

Press

selector

OFF

Automatic closing

after photo-beam is

interrupted

and re-made ON

Press

selector

OFF

Relay function

Switch contact impulse signal

Switch contact continuous

Self - hold OPEN, CLOSE

(X5) release for external pushbutton

function only dead man close

Press

selector

Commands

door travels to Open or Closed position

during closing door Stops and re-opens

Step by Step function

(X7): only Ceiling pull

switch / Radio remote

control Commands

OpenStopCloseStopOpen

Operating mode

Functions

Signal lamp starts flashing with 3 sec. pre-

warning time when door Open’s and Close’s;

Continuous light while the door is moving

Signal lamp starts flashing with 3 sec. pre-

warning time only when door Close’s

direction; Continuous light while the door

is moving

Runtime monitoring

Steady burning light with 3 sec. warning

flashes before the door starts for Opening

or Closing

Press

selector

time can be set between 1 - 90 sec.

0 = OFF

Signal lamp: Continuous red light with 3

sec. pre-warning from open position

Page 18

MEMORY CHECK

Press

selector

Info Cycle counter

7- digit

Last 2 faults would be alternately displayed.

Program version will be displayed

Displayed

Info last 2 faults Press

selector

Info Program changes

7- digit

Info Program version

M HT ZT T H Z E

Press

selector

Press

selector

M HT ZT T H Z E

The cycles would be displayed as follow.

M = 1.000.000 H = 100

HT = 100.000 Z = 10

ZT = 10.000 E = 1

T = 1.000

The Number of program changes would be dis-

played as follow.

M = 1.000.000 H = 100

HT = 100.000 Z = 10

ZT = 10.000 E = 1

T = 1.000

2. Chose program and

confirm

01-99 correspond from 1.000 up to

99.000 Count down cycles

Counter adjustment

Display appears „CS“ and adjusted

number of cycles

Changing to DEADMAN display appears

„CS“ and adjusted number of cycles

Changing to DEADMAN same as 0.2 reset

to about 500 cycles possible, press 3 sec.

Stop – Button

Reaction when

reaching 0

Reset

Maintenance cycle counter

RESET except cycle-

and Program change

counter

Reset Press stop

button

3 sec.

4. Set

3. Adjustment

2. Chose program and

confirm

Press

selector

Press

selector

CONTROL PROGRAMMING

Page 19

SAFETY DEVICES

Safety edge system with optional connection for shutter pass - door or slack

wire switch contact X2

The control recognizes and works with 3 different safety edges.

Each one needs a special 4 core spiral cable and includes an optional shutter pass - door or

slack wire switch contact.

The spiral cable connection must be made on the print with the plug provided. The opposite

side of the cable is connected to a terminal box or a signal (pressure switch) emitter.

Important note!

When connecting a safety edge, take account of EN 12978 for

Industrial, commercial and garage doors and gates - Safety devices for

power operated doors - Requirements and Test methods.

Typ 1: Resistance evaluation 1K2 with normally closed safety edge contact

(safety edge with pressure wave switch and "Testing")

Typ 2: Resistance evaluation 8K2 with normally open safety edge contact

Typ 3: Optical safety edge (Vitector)

Mounting the spiral cable

A bush is provided on both sides of the control box for mounting the spiral cable.

Push the plugs through into the enclosure until there is sufficient cable to allow the (2 and 3

pole) plugs to be connected to the board. The plug with two cores must be connected to the

passdoor or slack wire switch terminals.The three core plug must be connected to the safety

edge terminal.

The control panel TS 961 recognizes on first installation the safety edge system being used.

If passdoor / slack wire switch contact exists, remove bridge at terminal ST and ST+ in

the terminal box. The plug at terminal X2 must be removed.

Adjustment pre-limit S5

The pre-limit switch S5 must be set to avoid a continuously re-opening of the door out of the

final close position, if the safety edge system has been actuated.

Set the S5 limit switch 5 cm before the final close position to interrupt the re-open function.

Page 20

The principle of operation is as a one way light barrier. By activating the safety edge, the

photo-beam will be interrupted.

Typ 3: Optical safety edge (Vitector)

Typ 2: Resistance evaluation 8K2 with normally open safety edge contact

This evaluation system is made for electrical safety edges within an end-of-line resistor of

8K2-+5%0,25W.Theresistormustbeconnectedparallelwiththeswitchinthesafetyedge.

This evaluation system is made for pressure-wave switches (N/C) within an end-of-line

resistor of 1K2 +/- 5% 0,25W.

A pressure wave is generated by compressing the rubber profile, which is conducted to the

pressure-wave switch through the plastic hose.The system should be tested in the CLOSE

position. The pre-limit would be set automatically and activate the "Testing function".

When the shutter runs over the pre-limit door position, a timer of two seconds starts to

countdown at once. If a pressure wave activates the pressure switch in this time the TS

970recognizes the functionof the safety edge. Ifthe pressure switch has notbeen activated,

the control goes into fault mode and the system works only in DEAD MAN function in

downwards direction. Fault information F 2.8 would be displayed.

Typ 1: Resistance evaluation 1K2 with normally closed safety edge contact

Pressure-wave switch - function

The contact between the contact screw and

diaphragm is opened (opening contact). The

pressure-wave switch is set to a release pres-

sure of approx. 1,5 mbar.

The valve screws are set to a throughput of

110 ml/min with a static admission pressure

of 5 mbar. This warrants that a maximum tem-

perature increase of 30° is compensated for in

20 minutes.

The setting of the valve screws may not be

altered. Should the release pressure be insuf-

ficient (pressure wave too insensitive), the

contact screw may be turned counterclock-

wise to the left by 1-2 graduation marks. The

switch's sensitivity is thus increased.

In case of excessive sensitivity, the contact

screw is set clockwise by 1-2 graduation

marks (decreased sensitivity).

Pressure-wave switch

valve screws (may

not be altered)

Hose contact for:

pressure opens

contact screw

SAFETY DEVICES

Table of contents

Other Elektromaten Control Panel manuals

Popular Control Panel manuals by other brands

Mitsubishi Electric

Mitsubishi Electric PANEL_RS2 installation manual

AKO

AKO PROPlus manual

Teletek electronics

Teletek electronics iRIS4 installation manual

Pulsar

Pulsar 17/TRP50/SATEL Assembly instruction

Eight

Eight TouchOne G3 Installation and user manual

Nittan

Nittan CPC-4A-24 Operating instructions manual