Elektromaten TS 980 User manual

Electrical operating instructions

Door control panel TS 980

(Design and functions subject to change)

51171150 -b 07.2007

en

page 2

OPERATING AND INSTALLATION INSTRUCTIONS

PAGE

SAFETY DIRECTIONS .................................................................................................4

ENCLOSURE INSTALLATION....................................................................................6

MAINS SUPPLY ...........................................................................................................7

SAFETY DEVICES .......................................................................................................8

Safety edge system with optional connection for shutter pass-door or slack-wire switch. .8

SAFETY DEVICES .......................................................................................................9

Resistance evaluation 8K2 with normally open safety edge contact ................................9

Resistance evaluation 1K2 with normally open safety edge contact ................................9

Resistance evaluation 1K2 with normally closed safety edge contact ..............................10

Resistance evaluation 8K2 with normally closed safety edge contact ..............................11

Optical safety edge (Fraba Type) ................................................................................... 11

Safety against entrapment .............................................................................................. 12

Slack-wire Switch ...........................................................................................................12

Emergency Stop ............................................................................................................12

Photo-beam ...................................................................................................................13

PUSH BUTTON ............................................................................................................14

Three push button station ............................................................................................... 14

Intermediate stop mode .................................................................................................15

Ceiling pull switch ...........................................................................................................15

RELAY CONTACT ........................................................................................................16

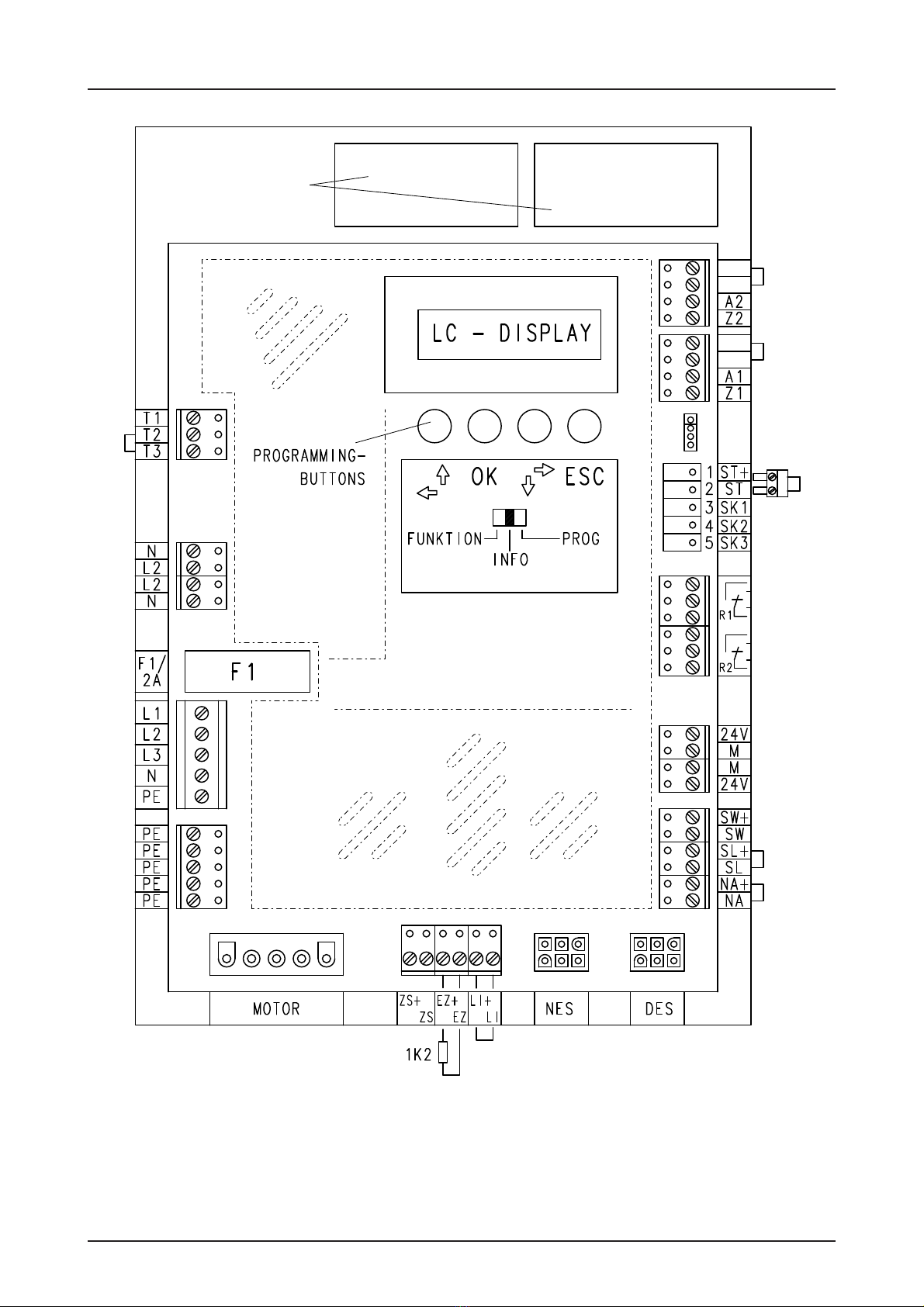

PCB PRINT OVERVIEW ..............................................................................................17

INITIALISATION ............................................................................................................18

Initial installation .............................................................................................................18

Language selection ........................................................................................................19

page 3

PAGE

ADJUSTMENT OF THE LIMITS/ BASIC-FUNCTION ..................................................20

Adjust the mechanical limits NES ...................................................................................20

When control has recognised DES digital limits, adjust limit DES ...................................22

Fine adjustment ..............................................................................................................23

Safety devices ............................................................................................................... 24

Intermediate stop ...........................................................................................................26

Selecting Aux. Function mode ........................................................................................27

Adjusting the automatic close feature .............................................................................27

ADJUSTMENT: AUXILIARY FUNCTIONS ..................................................................27

Adjustment relay contact 1, pre-information mechanical limit NES operation ..................28

Adjustment relay contact 2 .............................................................................................30

Adjustment of pre-limit ....................................................................................................31

Adjustment: Auxiliary Functions ..................................................................................... 32

Automatic ground adjustment .........................................................................................32

Overrun correction should be selected only for rapid doors. ............................................33

Final program ................................................................................................................33

REQUEST INFO MODE ...............................................................................................34

INSTALLATION PLAN .................................................................................................. 35

CONFIGURATION PLAN FOR LIMIT SWITCHES .......................................................36

FAULT REPORT .......................................................................................................... 37

TECHNICAL DATA .......................................................................................................38

page 4

SAFETY DIRECTIONS

Safety Regulations

During the installation, initial operation, maintenance and testing of the ELEKTROMATEN, it is

necessary to observe the safety and accident-prevention regulations valid for the specific

application.

In particular, you should observe the following regulations (this list is not exhaustive):

European normativ

- DIN EN 12453

Saftey in use of power operated doors - Requirements

- DIN EN 12445

Saftey in use of power operated doors - Test methods

- DIN EN 12978 Industrial, commercial and garage doors and gates -

Safety devices for power operated doors - Requirements and Test methods

Please check normative´s bellow.

VDE-regulations

- DIN EN 418

Safety machinery

Emergency stop equipment functional aspects

Principles for design

- DIN EN 60204-1 / VDE 0113-1

Safety of machinery - Electrical equipment of machines - Part 1:

Prescriptions générales

- DIN EN 60335-1 / VDE 0700-1

Safety of household and similar electrical appliances - Part 1:

General requirements

Basic Directions

This control has been built in accordance with DIN EN 12453 Industrial, commercial and garage

doors and gates - Safety in use of power operated doors - Requirements; DIN EN 12978

Industrial, commercial and garage doors and gates - Safety devices for power operated

doors - Requirements and Test methods - and left the factory in perfect condition from the point

of view of safety. To maintain this condition and to ensure safe operation, the user must observe all

the directions and warnings contained in these operating instructions.

In principle, only trained electrical craftsmen should work on electrical equipment. They must assess

the work which has been assigned to them, identify potential danger sources and take suitable

safety precautions.

Reconstruction of or changes of this control Panel TS 980 is only permissible with the approval of the

manufacturer. Original replacement parts and accessories authorised by the manufacturer guarantee

safety. Liability ceases to apply if other parts are used.

The operational safety of this control Panel TS 980 is only guaranteed if it is used in accordance with

the regulations. The limiting values stated in the technical data should not be exceeded under any

circumstances (see corresponding sections of the operating instructions).

Regulations

- Please ensure that the local regulations relating to the Safety of Opera-

tions of Doors are followed

page 5

SAFETY DIRECTIONS

Explanation of warnings

These operating instructions contain directions which are important for using the ELEKTROMATEN

appropriately and safely.

The individual directions have the following meaning:

DANGER

This indicates danger to the life and health of the user if the appropriate precautions

are not taken.

Please observe the safety and accident prevention regulations valid for the

specific application.

The ELEKTROMATEN must be installed with the authorised coverings and

protective devices. Care should be taken that any seals are fitted correctly

and screw couplings are tightened correctly.

In the case of ELEKTROMATEN with a permanent mains connection, an all-

pole main switch with appropriate back-up fuse must be provided.

Check live cables and conductors regularly for insulation faults or breakages.

When a fault is detected in the cabling, the defective cabling should be

replaced after immediately switching off the mains supply.

Before starting operation, check whether the permissible mains voltage range

of the devices corresponds to the local mains voltage.

With three – phase motor connection it must have right phase rotation

The following warnings are to be understood as a general guideline for working with the

ELEKTROMATEN in conjunction with other devices. These directions must be observed strictly

during installation and operation.

General warnings and safety precautions

CAUTION

This warns that the ELEKTROMATEN or other materials may be damaged if the

appropriate precautions are not taken.

page 6

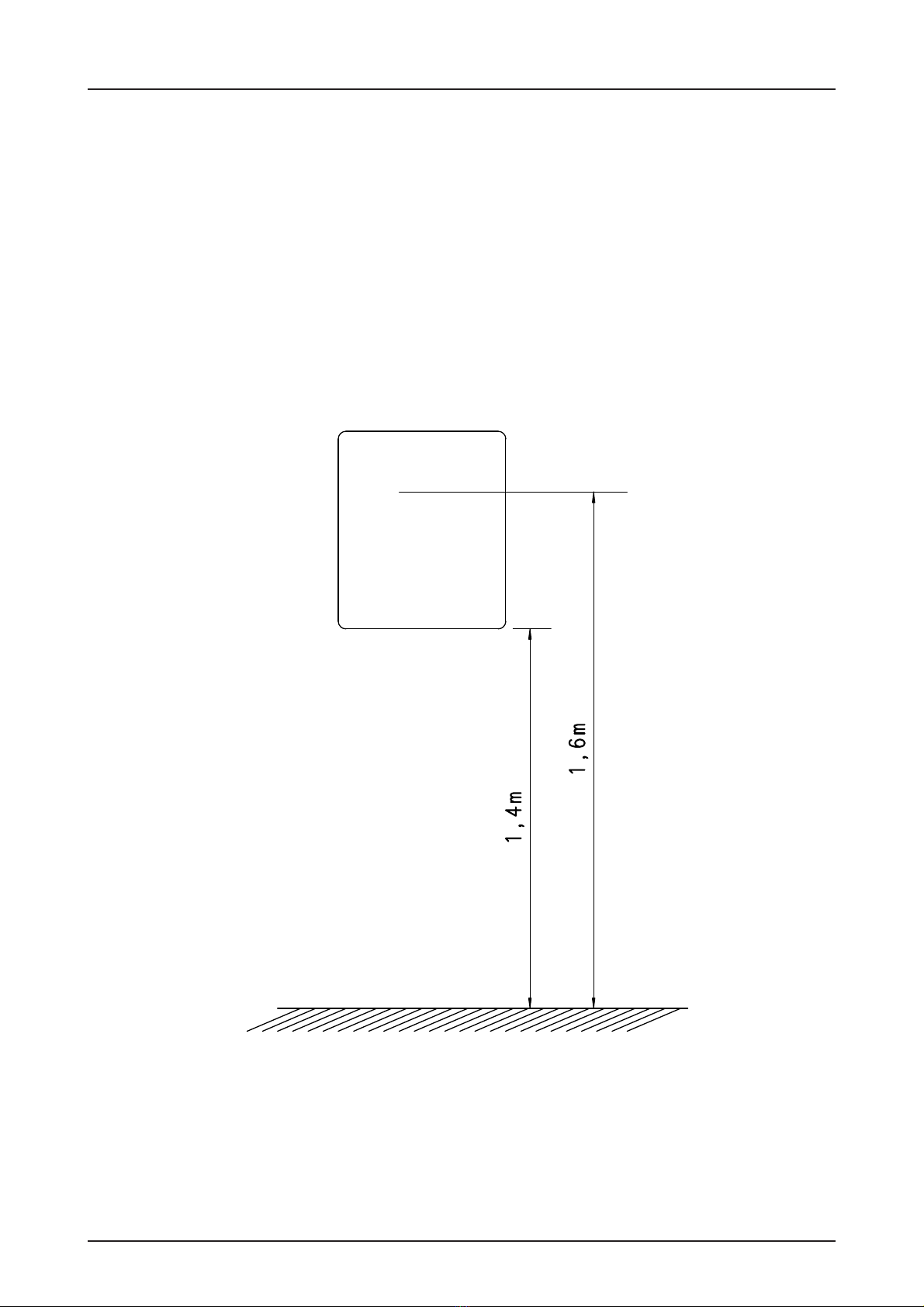

ENCLOSURE INSTALLATION

Before mounting the enclosure the surface has to be checked for flatness, slope and freedom

from vibrations. For installation we recommend to use the template supplied. Mounting must

be vertical.

Mounting, see drawing.

page 7

MAINS SUPPLY

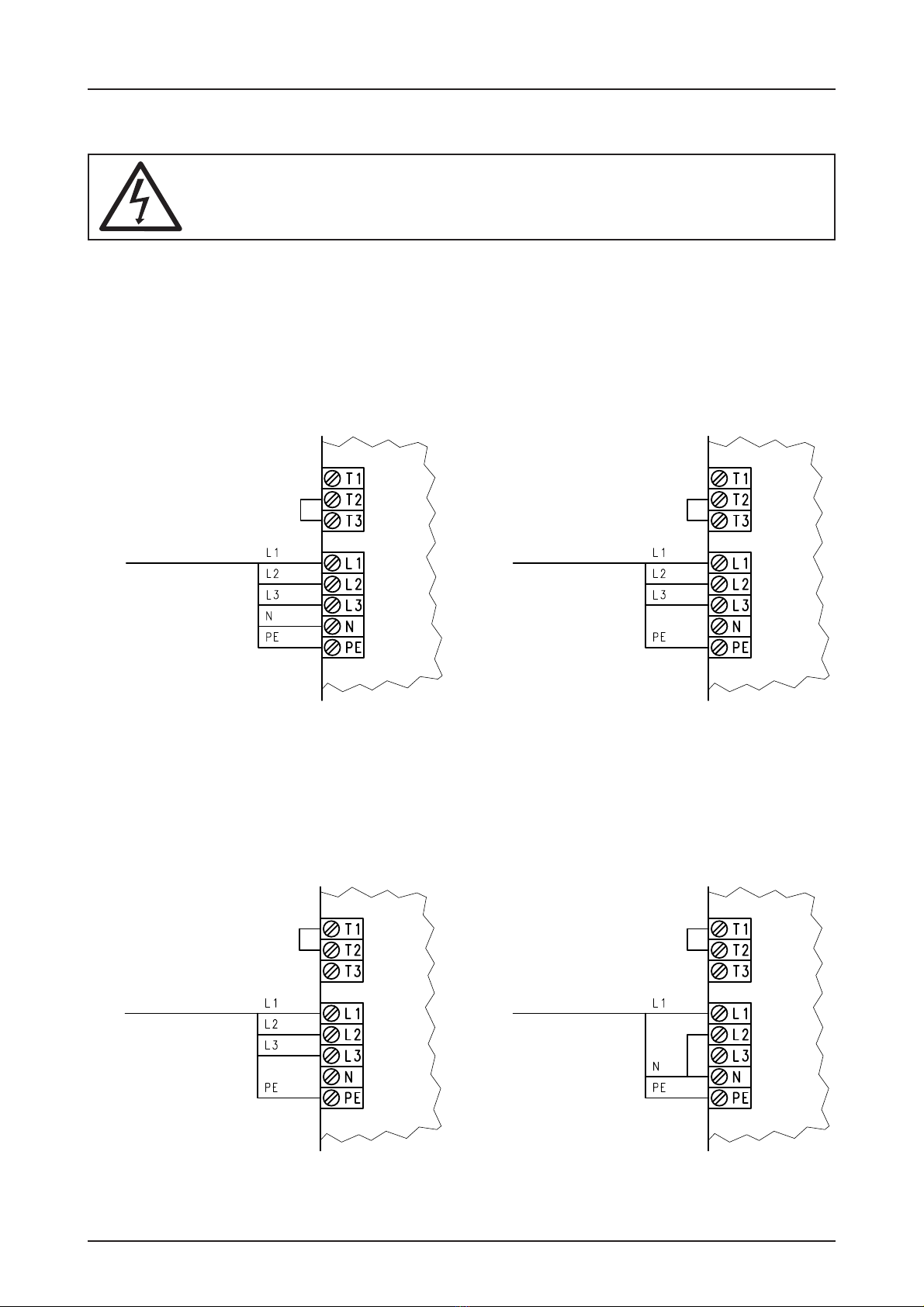

Fig. 1 Mains supply 3x 400V,N,PE

Fig. 3 Mains supply 3x 230V,PE

Fig. 2 Mains supply 3x 400V,PE

Fig. 4 Mains supply 1x 230V,N,PE

3 x 400V, N, PE 3 x 400V, PE

3 x 230V, PE 1 x 230V, N, PE

Warning! This indicates danger to the life through electric shock.

Before starting assembly, disconnect the equipment from the electricity supply.

The control panel TS 980 works with the following supplies. ( See diagrams)

Fig.1 to Fig.4 mains supply

The TS 980 control can be used with all GfA ELEKTROMATEN up to 2,2KW

page 8

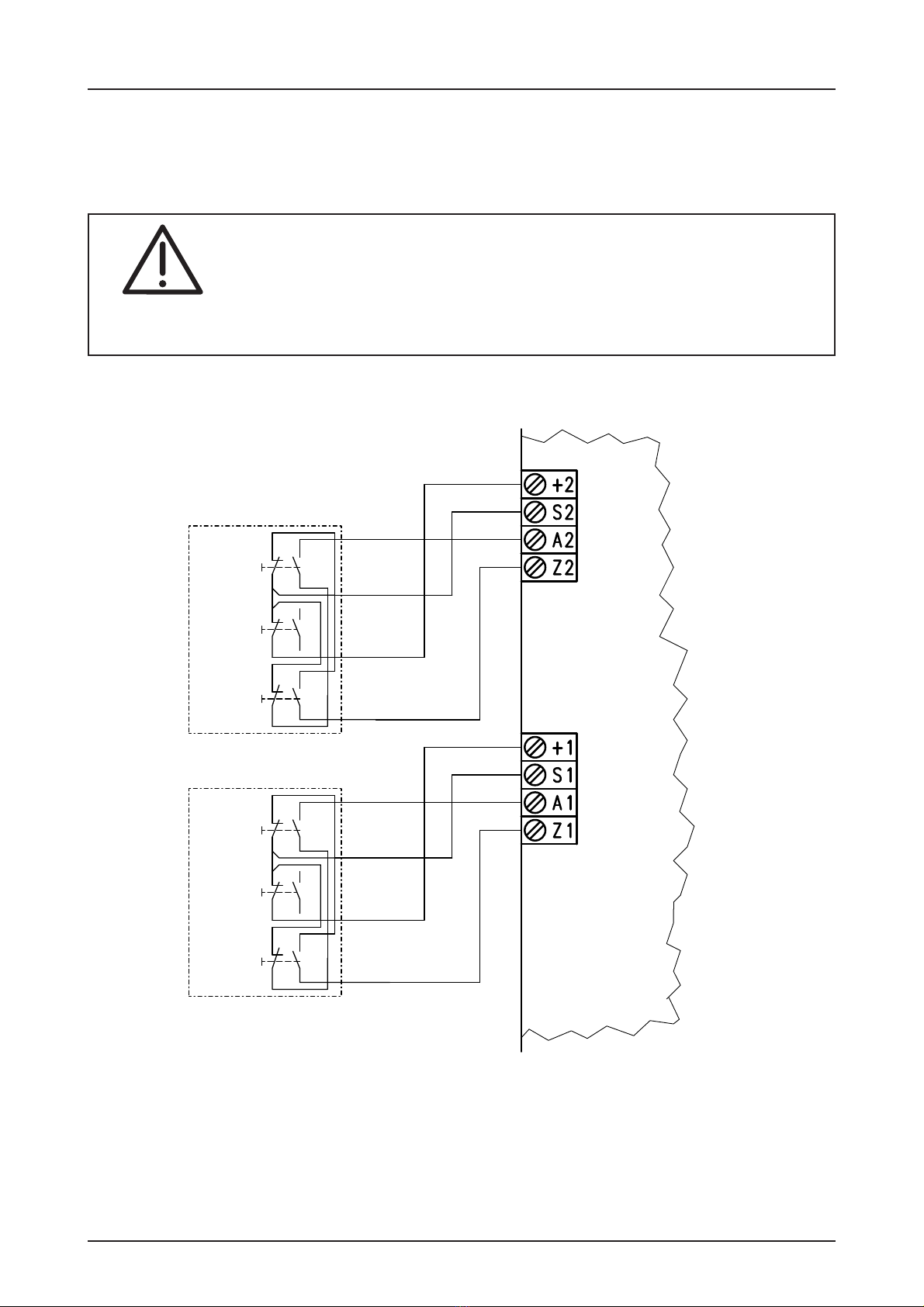

Safety edge system with optional connection for shutter pass-door or

slack-wire switch.

The control recognises and works with 5 different safety edges.

Each one needs a special 4 core spiral cable and includes an optional shutter pass-door or

slack-wire switch contact.

The spiral cable connection must be made on the print with the plug provided. The other end is

connected to a terminal box or a signal emitter, such as a pressure switch.

-Resistance evaluation 8K2 with normally open safety edge contact (page 9)

-Resistance evaluation 1K2 with normally open safety edge contact (page 9)

-Resistance evaluation 1K2 with normally closed safety edge contact (page 10)

(pressure switch with "Pressure Wave Testing")

-Resistance evaluation 8K2 with normally closed safety edge contact (page 11)

-Optical safety edge system (Fraba type) (page 11)

Important note!

When connecting a safety edge, make sure of compliance with DIN EN 12978

Industrial, commercial and garage doors and gates - Safety devices for

power operated doors - Requirements and Test methods.

Mounting the spiral cable

A bush is provided on both sides of the control box for mounting the spiral cable.

Push the blue plugs through into the enclosure until there is sufficient cable to allow them to be

connected to the board. The plug with two cores must be connected

to the pass-door and slack-wire switch terminals. The three core plug must be connected to

the safety edge terminals.

The control panel TS 980 recognises automatically the type of safety edge used.

Please check after installation all terminal screws are tight to ensure they are finger

safe.

SAFETY DEVICES

page 9

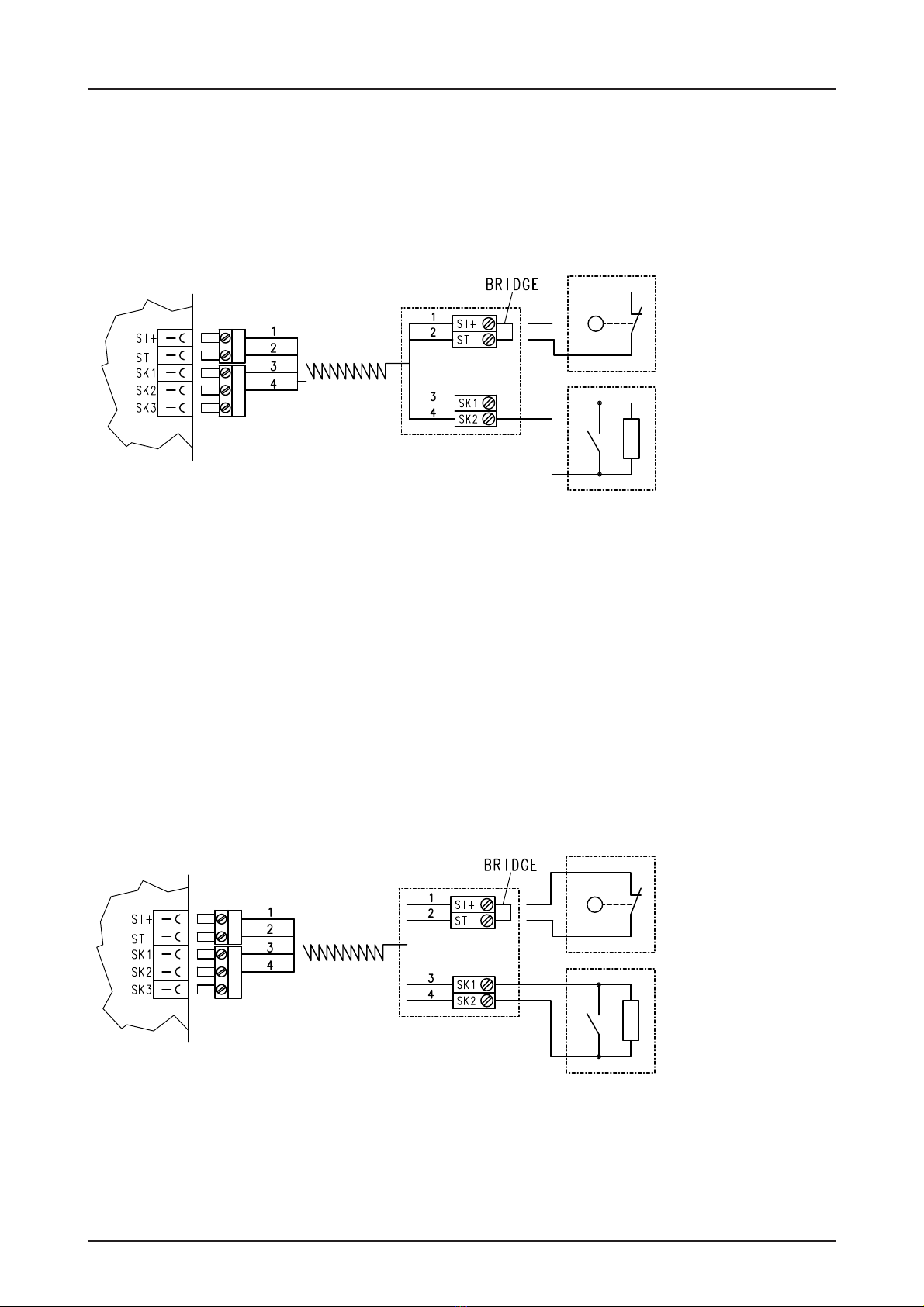

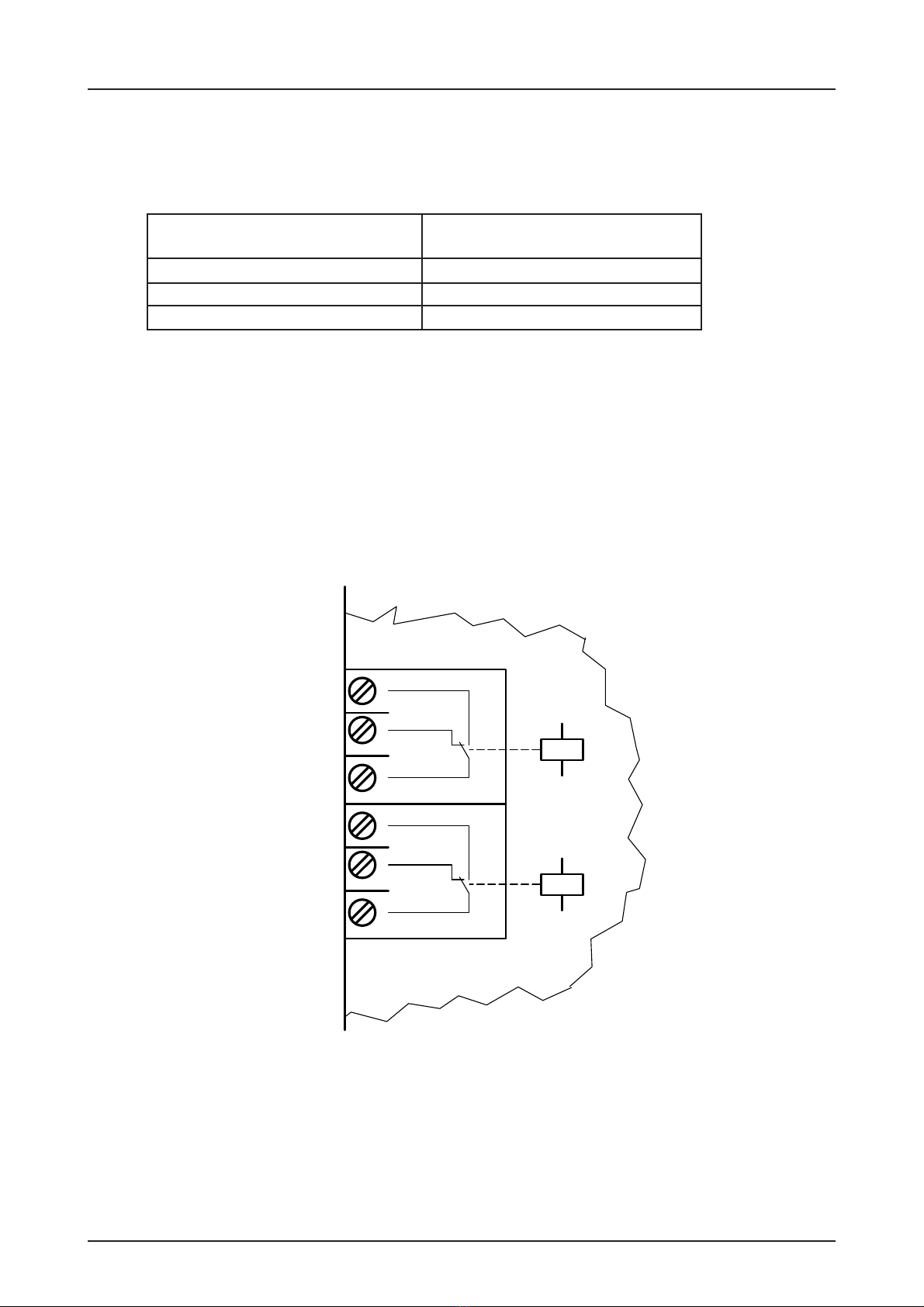

Resistance evaluation 8K2 with normally open safety edge contact

This evaluation system is made for electrical safety edges within an end-of-line resistor of 8K2.

The resistor must be connected in series with the switch in the safety edge.

If a pass-door or slack-wire switch is to be connected, remove the bridge at terminals ST and

ST+ in the terminal box

SAFETY DEVICES

fig. 1 wiring diagram electrical safety edge with 8K2 resistor and normally open contact

This evaluation system is made for electrical safety edges within an end-of-line resistor of 1K2.

The resistor must be connected in series with the switch in the safety edge.

If a pass-door or slack-wire switch is to be connected, remove the bridge at terminals ST and

ST+ in the terminal box.

Resistance evaluation 1K2 with normally open safety edge contact

fig. 2 wiring diagram electrical safety edge with 1K2 resistor and normally open contact

pass-door/slack-

wire switch contact

end-of-line

resistor 8K2

end-of-line

resistor 1K2

pass-door/slack-

wire switch contact

page 10

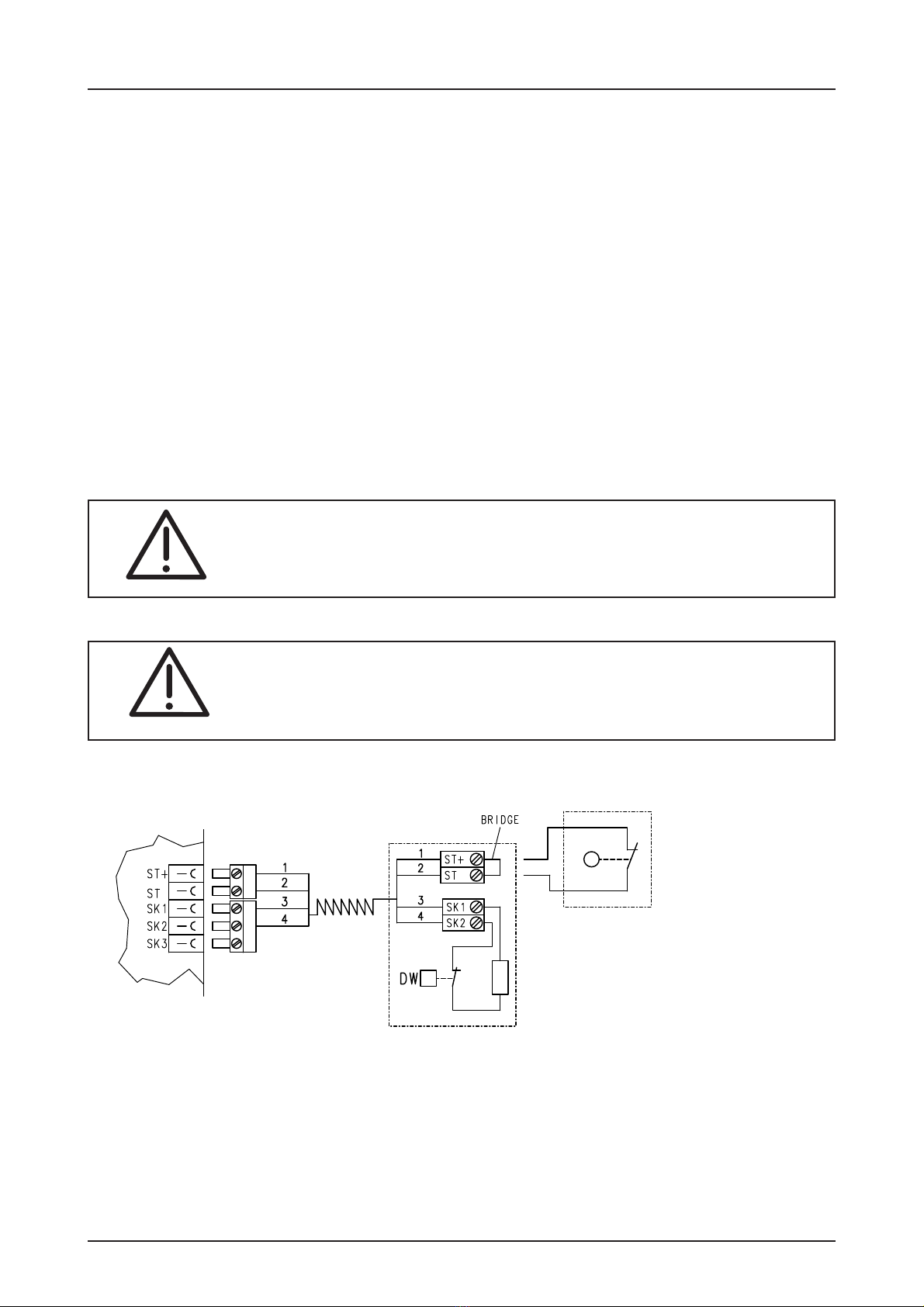

Resistance evaluation 1K2 with normally closed safety edge contact

This evaluation system is made for pressure-wave switches ( N/C ) with an end-of-line resistor

of 1K2.

A pressure wave is generated by compressing the rubber profile, which is conducted to the

pressure-wave switch through the plastic hose. The system should be tested as the door

closes. The limit S5 must be set to activate the "Testing function" (when using mechanical

limit switches). For adjusting the testing function, close the shutter and stop it max. 5 cm

before the closed position, now set limit S5.

When the shutter runs over the limit S 5, a timer of two seconds starts to countdown.

If a pressure wave activates the pressure switch in this time the TS 980 recognises the function

of the safety edge. If the pressure switch has not been activated, the control goes into fault

mode and the system will only work in DEAD MAN mode in the close direction.

If pass-door or slack-wire switch contact is to be connected, remove the bridge at terminal ST

and ST+ in the terminal box.

Important note!

When setting the closed position the rubber edge has to send out a

pressure wave sufficient to operate the pressure switch.

Important note!

When using a safety edge system the limit S5 must be set when using

mechanical limits.

Close the shutter and stop 5 cm before the end position, now set limit S5.

SAFETY DEVICES

Fig.3: Wiring diagram resistance evaluation 1K2 normally closed contact

(pressure - wave switch)

end-of-line

resistor 1K2

pass-door/slack-

wire switch contact

page 11

The principle of operation is similar to a through-beam light barrier with self testing. By activating

the safety edge, the light beam is interrupted. If a pass-door or slack-wire switch is to be

connected, remove the bridge at terminals ST and ST+ in the terminal box.

Optical safety edge (Fraba Type)

The fig. 5 wiring diagram optical safety edge system (Fraba type)

Resistance evaluation 8K2 with normally closed safety edge contact

This evaluation system is made for safety edges within an end-of-line resistor of 8K2. When a

normally closed safety edge system which works in quiescent current mode is connected, a

separate safety edge control has to be connected. The resistor must be connected in series

with the switch in the safety edge.

If pass- door or slack-wire switch is to be connected, remove bridge at terminals ST and ST+

in the terminal box.

SAFETY DEVICES

fig. 4 wiring diagram electrical safety edge with 8K2 resistor and normally open contact

Transmitter Receiver

pass-door/slack-

wire switch contact

end-of-line

resistor 8K2

pass-door/slack-

wire switch contact

To monitor the end of line safety edge system correctly, the resistor should be mounted

close to the switching unit. l. e. pressure switch.

page 12

Emergency Stop

In accordance DIN EN 418 the emergency Stop

button has to meet category 0.

Slack-wire Switch

For doors with a cable or chain drive, in

accordance DIN EN 12453 slackness must

be monitored. The control can be done with a

slack-wire switch which can be connected

directly on TS 980 terminals SL+/SL the

reaction is just STOP.

Fig. 2: Slack-wire switch wiring Fig. 3: EMERGENCY STOP wiring

This is an additional safety system ( e.g. self-testing light barrier) which shall prevent trapping a

person or obstacle in the door. In accordance with EN 12453 monitoring is required of each

door or shutter where lifting of people or obstacles cannot be prevented (e.g. Grilles).

A separate control system within an end-

of-line resistor of 1K2 should be

connected. TS 980 recognises various

faults - short circuit, contact or supply

interruption.

This safety system is only in effect in the

upwards direction.

When recognising a contact the door

movement upwards Stops and returns

downwards for only 2 sec.. Then the door

Stops until a new command is received.

At the same time the control-display

displays Emergency Stop Entrapment.

Important note

In accordance with EN 954 -1 the safety edge control of the

entrapment device has to meet category 2.

Safety against entrapment

SAFETY DEVICES

EMERGENCY

STOP

Slack-wire

Switch

Fig. 1: Wiring diagram of indicator with a monitoring

resistor.

monitoring

resistor

end-of-line

resistor 1K2

page 13

Photo-beam

One external photo-beam (through-beam or reflex type) can be connected.

If the beam is interrupted while the shutter is closing, it will STOP and move BACK UP. The

beam is only operational in the closing direction.

Supply for the beam is 230V AC or 24V DC. A timed return after interruption in the automatic

closing mode can be programmed only when a beam is connected (see program).

In accordance with EN 954 -1 the beam has to meet category B.

Fig. 4: Wiring diagram for reflective photo-beam

Important note!

Photo beam on the 24 V DC power supply may not exceed 60 mA.

SAFETY DEVICES

Fig. 5: Wiring diagram for thro-beam-photo-beam

1

2

3

4

(1)

(2)

1234

1

2

3

4

(1)

(2)

123412

Reflektor

Transmitter/

Receiver connection 24V

connec-

tion 230V

switching contact

Transmitter Receiver connection 24V

connec-

tion 230V

switching contact

page 14

PUSH BUTTON

Terminals are provided for two three button stations

Important Note

The first push button station has to be installed where the door movement

can be seen through-out its travel for dead-man mode control.

The Second push button can be installed at any other place and the door

movement has not to be controlled. When the control goes into fault mode

the second pushbutton will be disabled.

Three push button station

Fig. 1: Wiring diagram three button station

22

21

21

22

21

22

14

13

13

14

13

14

OPEN

STOP

CLOSE

22

21

21

22

21

22

14

13

13

14

13

14

OPEN

STOP

CLOSE

Push button 2

Push button 1

page 15

Intermediate Stop mode can be activated with a key switch (latching - ON-OFF) and setting the

limit S6 at the required intermediate position when using mechanical limits (see page 26).

The intermediate shutter position "PART-OPEN" is only in effect in the upwards direction and is

the new OPEN position. By turning the key switch to the OFF position, the shutter works in

standard mode.

With each command (impulse) the shutter responds as follows:

Shutter position Shutter mode

Shutter closed Shutter moves to open position

Shutter moving open No reaction

Shutter open Shutter moves to close position

Shutter intermediate position open Shutter moves to close position

Shutter moving closed Shutter will STOP and move BACK UP

Intermediate stop mode

Ceiling pull switch

PUSH BUTTON

Fig. 1 wiring key switch (latching)

Fig. 2: wiring ceiling pull switch

12

Key - switch

ceiling pull switch

page 16

The control provides two potential free relay contacts, which can be used for several functions.

Functions can be programmed:

Relay contact 1 Relay contact 2

Fore-warning signal light Signal light green

no function Switch contact*

no function

* only possible when the intermediate stop is not required when using a mechanical limit.

When using DES all functions are available.

The relay contact will be supplied with no function programmed. The switch contact can be

loaded max.: Voltage 230V current 1A.

RELAY CONTACT

Fig. 1: Wiring diagram relay contact´s

R1

R2

Relais 2

Relais 1

page 17

PCB PRINT OVERVIEW

S1

+1

S2

+2

<1

MODULE

POCKETS

FOIL-

KEYPAD

page 18

INITIALISATION

The control panel TS 980 is delivered with a 5 pole CEE plug and a foil keypad Open - Stop -

Close. The SELECTOR SWITCH is set in the position "Function".

After installation, during the set-up, an initialising program starts running, which recognises

DES (digital limits) or NES ( mechanical limits), this needs max 5 sec.

adjust limit

FUNCTION

INFO

PROG

FUNCTION

INFO

PROG

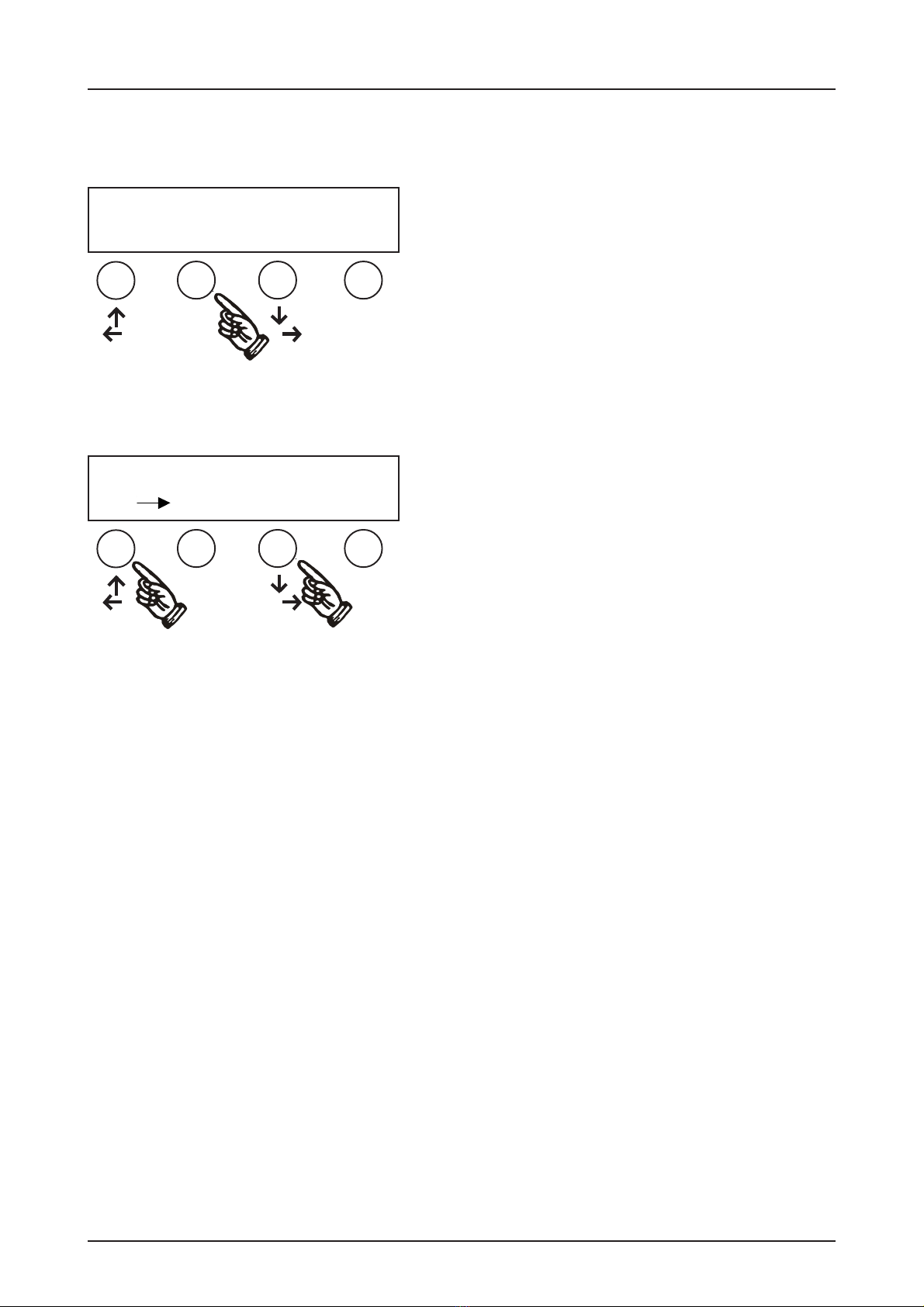

On initial installation the SELECTOR SWITCH must

be set to PROG

To move UP and DOWN in the program press

the arrowed button, language, door position or addi-

tional adjustment can be selected. Confirm selected

function with OK.

ÏÐ

Doorposition OK ?

Aux. Functions

ESCOK

ESCOK

Initial installation

display appears: Adjust limits

page 19

add. adjustments

Select Language OK?

ESCOK

Language selection

Select Language

D GB F

ESCOK

INITIALISATION

Selection of 3 languages integrated.

Set SELECTOR SWITCH to PROG, now using the

arrow buttons UP and DOWN choose SELECT

LANGUAGE and confirm with OK.

The display will show

D = German

GB = English

F = French

Move UP and DOWN with the arrowed buttons and

confirm the required language with OK.

The standard language delivered is GERMAN.

From now on:

To move UP and DOWN in the program press the arrowed buttons.

After each successful function is programmed, the display shows SET!

page 20

Doorposition OK ?

Aux. Functions

After PROG has been selected, the limits should be

adjusted. Confirm door position OK

Select with arrowbutton ÏÐ

Final open

adjust OK ?

Display appears, confirm OK?

To exit use ESC

Door OPEN >

Door CLOSE < OK ?

The control is now in the menu for setting the limits.

The arrow buttons UP and DOWN are used to move

the shutter in DEAD MAN MODE to the final open

position to set the limit S3. See mechanical

instruction, setting the limits. The final open

position must be confirmed by pressing the OK

button after S3 has been operated when the door

is moving.

To exit use ESC

Adjust the mechanical limits NES

ADJUSTMENT OF THE LIMITS/ BASIC-FUNCTION

ESCOK

ESCOK

ESCOK

Table of contents

Other Elektromaten Control Panel manuals

Popular Control Panel manuals by other brands

PS Engineering

PS Engineering PMA8000BT System installation and operation manual

Bosch

Bosch B5512 reference guide

Mitsubishi

Mitsubishi GT2715XTBA installation manual

versa

versa IUI-SOL- VT5 Series quick start guide

SANJIANG

SANJIANG SEC3002 Installation & commissioning manual

Chamberlain

Chamberlain 41A6345-1 owner's manual