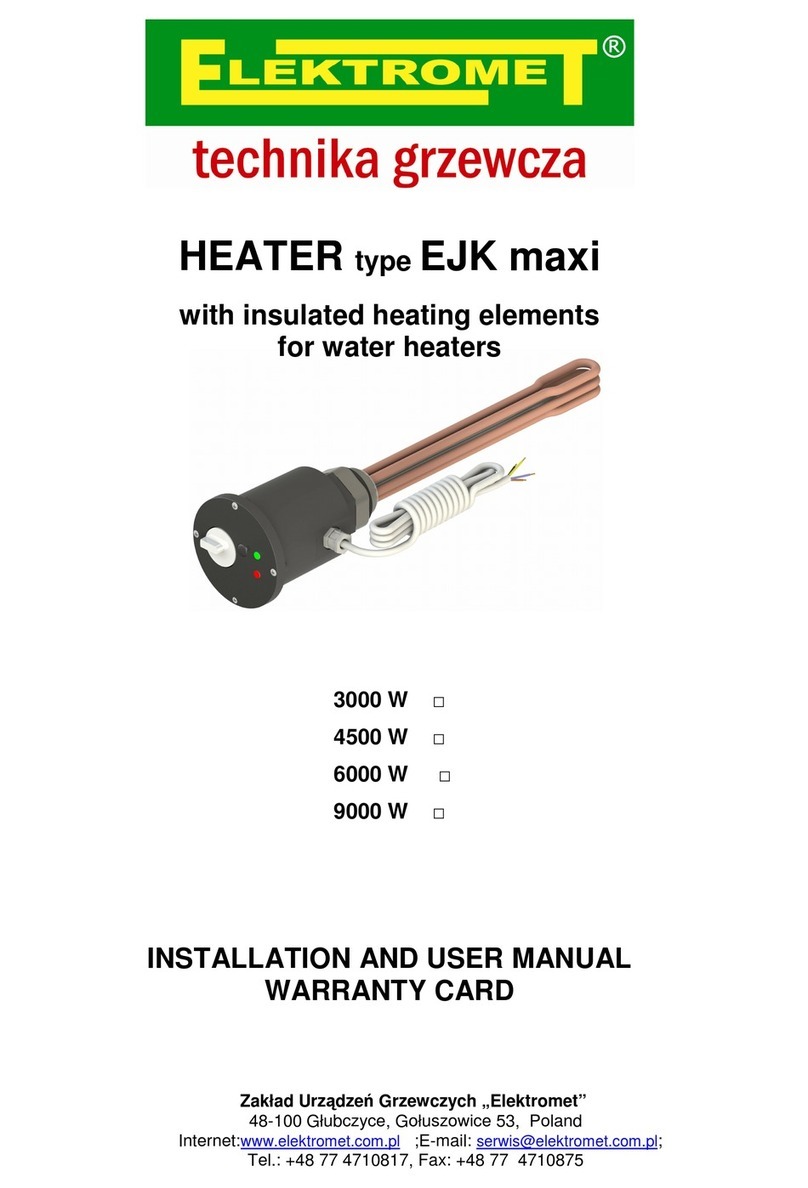

25.07.2014 ZUG ELEKTROMET

3. Heater Installation

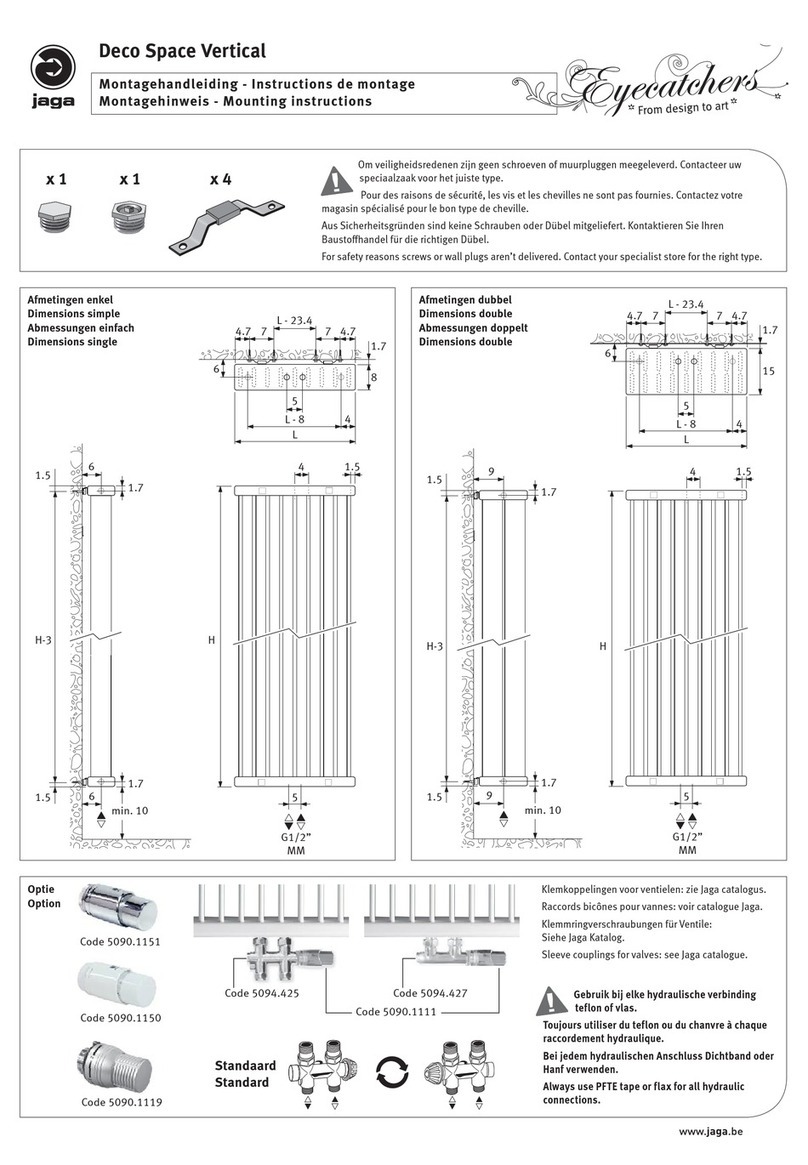

3.1 Assembly in tank

A. Type of tank

he tank and its connections must be made of metal. The structure of the heater provides

a protective circuit connecting protective conductor of the power cord with a metal head. This

connection is made in a sustainable way inside the body of the heater.

B. Working position

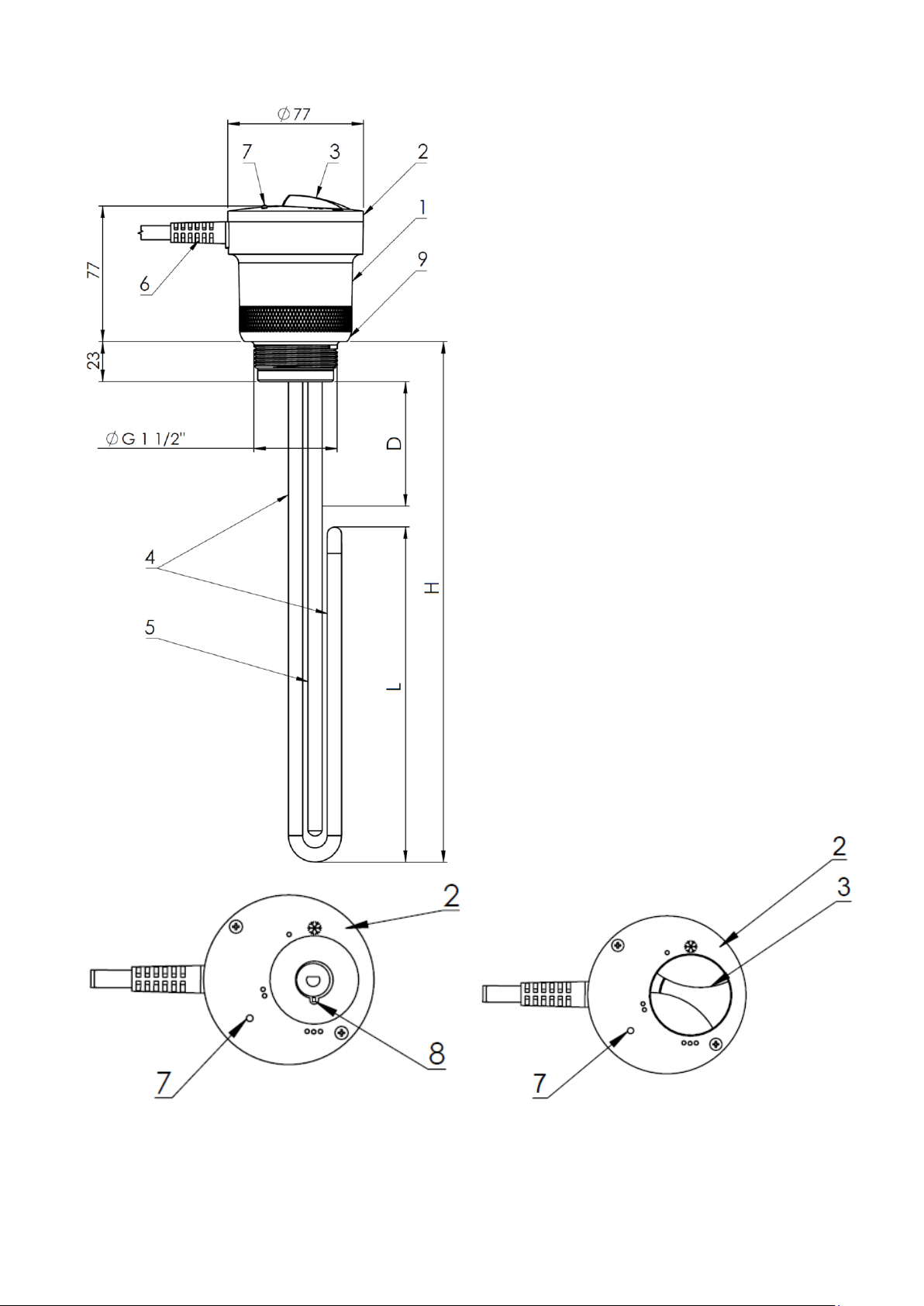

The heater may only operate in horizontal or semi horizontal position.

During operation heating element and the sensor protection must be totally immersed in

water and free thermally forced water circulation must be ensured. The length of the coupling

for assembling the heater shall not exceed circa 70 mm so that it does not stand out from the

heating elements dead zone (unheated zone). Heater casing must not be covered nor thermally

insulated as it would disturb normal operation of the temperature controller and of the

temperature limiter installed in the casing. When assembling the heater make sure that heating

elements length fits into the tank and that they do not touch any internal parts of the tank, such

as heat exchangers or thermometric pipes.

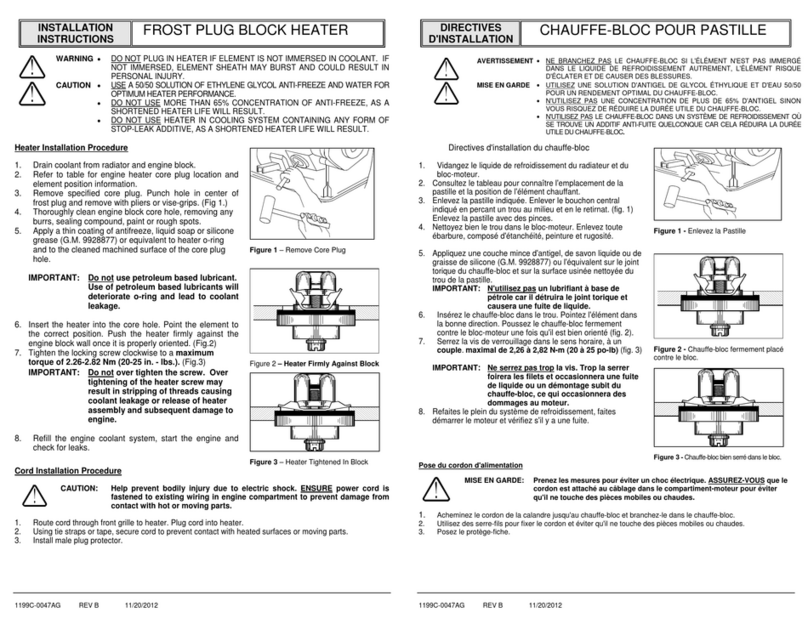

C. Pressure tanks

The heater is adapted for installation in pressure tanks of an admissible pressure not

higher than 10 bar. All the assembly, installation and service conditions for these tanks (boilers)

must be observed. It is also absolutely obligatory to install a safety valve with the opening

pressure not higher than indicated in the tank operating parameters. Valve flow capacity should

be chosen taking into account the power of all heaters and heat exchangers which heat water in

tank, as regulated by the Office of Technical Inspection, using the technical data published by

particular safety valves manufacturers.

Safety valve opening pressure when heater type EJK mini is used must not exceed 10 bar.

When installing an electric heater in a pressure tank it must be also remembered that the

operation of these devices is subject to various kinds of technical inspection, particularly in

accordance with the Regulation of the Minister of Economy, Labour and Social Policy dated

9.07.2003. Among other things, it stipulates that:

1. 1. Electric storage water heaters for domestic water of working temperature not higher

than 100ºC and capacity not larger than 300 l as well as tanks filled with water (heat exchangers

included) of working temperature not higher than 100ºC and capacity not larger than 500 l are

subject to simplified inspection, and therefore do not need to be reported to the Office of

Technical Inspection.

2. Electric water heaters of capacity larger than 300 l as well as tanks filled with water

(heat exchangers included) of capacity larger than 500 l are subject to limited inspection and

need to be reported to the Office of Technical Inspection.