ElektroPhysik MiniTest 600 User manual

Bedienungsanleitung MiniTest 600 Version 2.4 Englisch

© 03/2002 B10-N

Subject to change without notice.

ElektroPhysik Dr. Steingroever GmbH & Co. KG

Pasteurstr. 15

50735 Cologne

Germany

Tel.: +49 221 752040

Fax.: +49 221 7520467

web: www.elektrophysik.com

mail: [email protected]

MiniTest 600

Technical Reference and

Operating Manual

Advancing with Technology ElektroPhysik

ElektroPhysik i

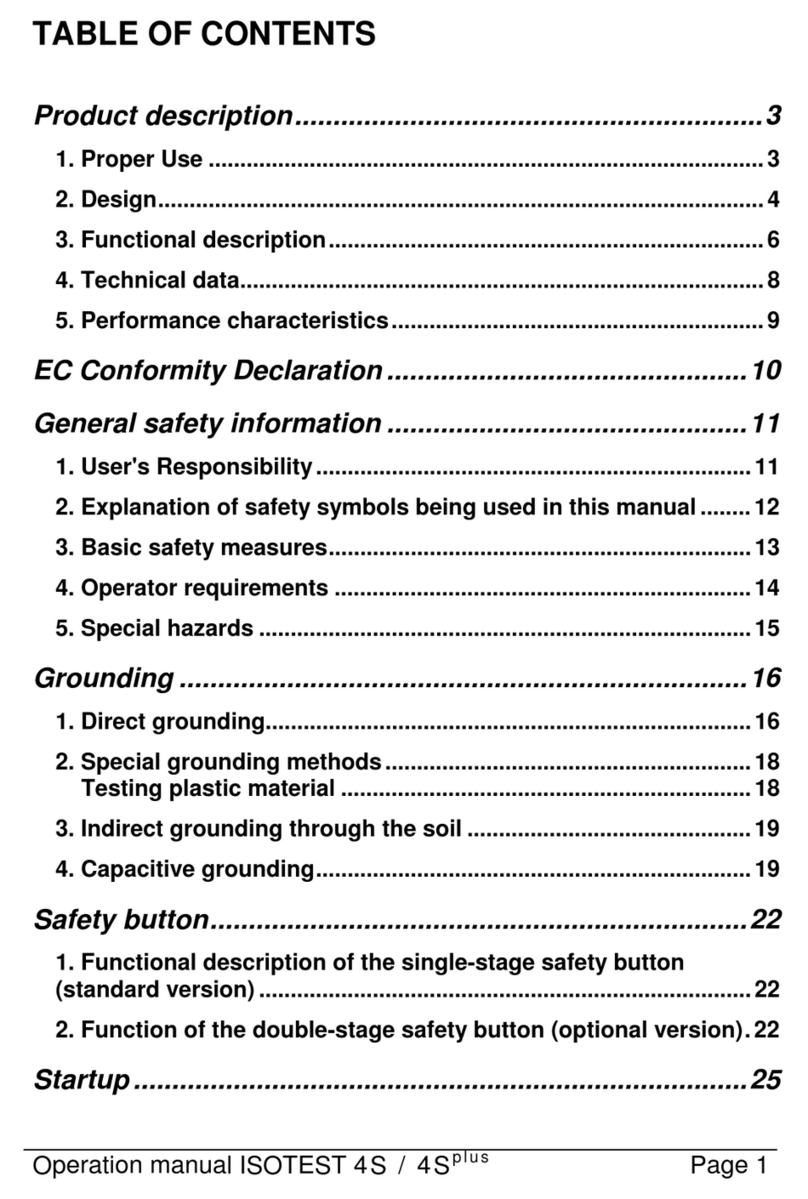

Table of Contents

Table of Contents

1. General Information .................................. 1

1.1 Applications................................................1

1.2 Description of the gauge...........................3

1.3 Equipment...................................................5

1.4 Probe construction ....................................5

2. Preparing the MiniTest 600 gauges ........ 6

2.1 Checking the power supply ......................6

2.2 Replacing the batteries .............................7

2.3 Start-up functions ......................................8

2.3.1 Total reset ....................................................9

2.3.2 LCD segment test........................................9

2.4 Basic gauge settings .............................. 10

2.4.1 Switching between short-term and

long-term modes ...................................... 12

2.4.2 KEYLOCK Function for ZERO- and

CAL-keys (locks calibration keys)............. 12

2.4.3 Activating/deactivating the

LC display light (optional) ......................... 13

2.4.4 Select a measuring unit

‘metric’ - ’inch’ (imperial) ........................... 13

ii ElektroPhysik

Table of Contents

3. Calibration and measurement ............... 14

3.1 General remarks on calibration ............. 14

3.1.1 Methods of calibration .............................. 14

3.1.2 Saving calibration values.......................... 15

3.1.3 Example of calibration .............................. 16

3.1.4 The effects of substrate thickness ............ 17

3.1.5 High-accuracy calibration ......................... 19

3.1.6 Cleaning the measuring point .................. 19

3.1.7 Acoustic signal.......................................... 19

3.1.8 Stabilisation of calibration values. ............ 20

3.2 Points to remember when calibrating ... 20

3.2.1 Activate standard calibration .................... 21

3.2.2 One-point calibration without foil

(zero only)................................................. 22

3.2.3 Two-point calibration

(ZERO with one calibration foil) ................ 24

3.2.4 Calibration and measurement with

MiniTest 600 FN........................................ 27

3.2.5 Calibration and measurement on

shot blasted surfaces................................ 28

3.2.6 Adjusting the basic calibration.................. 31

3.3 General remarks on measurement........ 31

ElektroPhysik iii

Table of Contents

4. Measurement using statistics ............... 32

4.1 Definition of statistical values ............... 33

4.2 Entering a series of measurements

for statistical analysis............................. 34

4.3 Storage capacity overflow ..................... 35

4.4 Display and print-out of the 5

statistical values for a series of

measurements (no single value) ........... 35

5. ‘Delete’ functions .................................... 36

5.1 Deleting the last reading taken.............. 36

5.2 Deleting statistics ................................... 36

7. Interface description............................... 37

8. Accessories ............................................. 38

9. Maintenance............................................. 39

10. Customer service .................................... 39

11. Troubleshooting ...................................... 39

12. Example of how to operate the

MiniTest 600 ............................................. 41

13. Technical Data ......................................... 45

iv ElektroPhysik

Table of Contents

13.1 Technical data (metric system).............. 45

13.2 Technical Data (imperial system) .......... 47

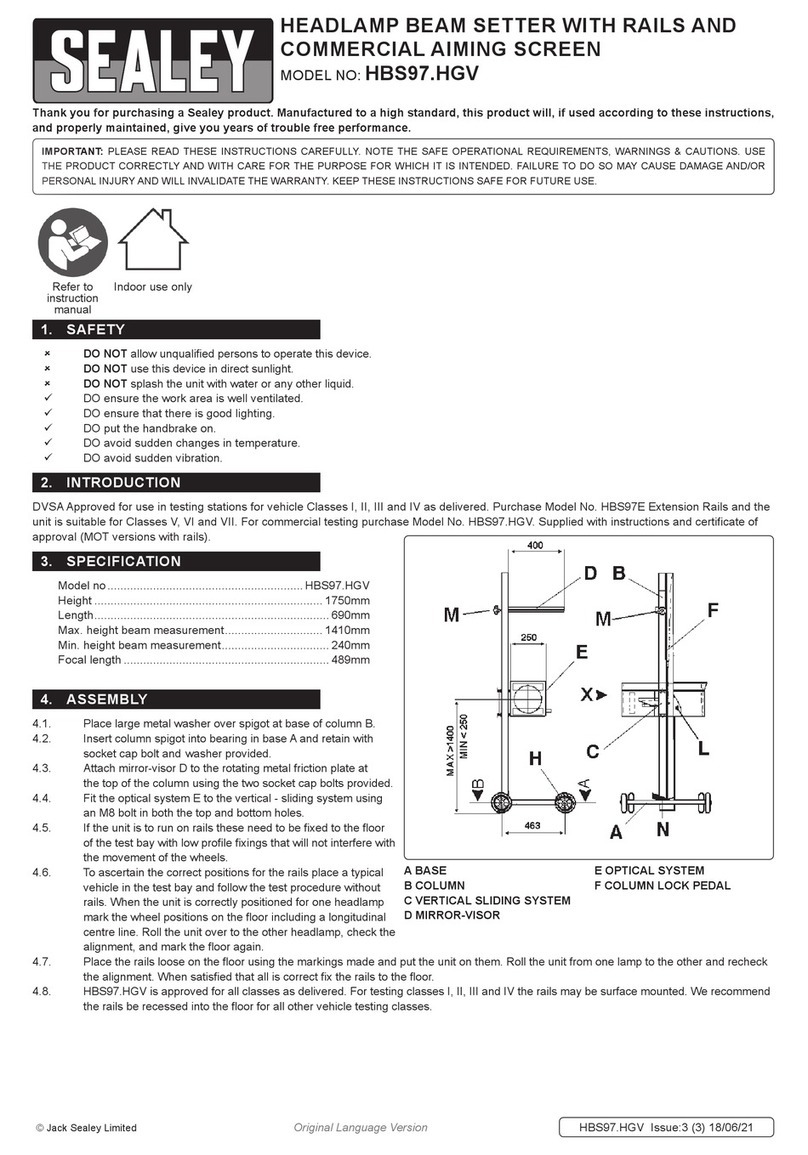

ElektroPhysik 1

1. General Information

1.1 Applications

This compact, handy pocket gauge is designed for

non-destructive, fast and precise coating thickness

measurement. The principal applications lie in the

field of corrosion protection. It is ideal for

manufacturers and their customers, for offices and

specialist advisers, for paint shops and

electroplaters, for the chemical, automobile,

shipbuilding and aircraft industries and for light and

heavy engineering.

The range of applications is indicated by the probes

available.

- F probes work on the magnetic induction

principle and should be used for non-

magnetic coatings such as aluminium,

chrome, copper, zinc, paint and varnish,

enamel, rubber etc., on an iron or steel

substrate; they are also suitable for alloyed

and hardened magnetic steel.

General Information

2 ElektroPhysik

- N probes work on the eddy-current principle

and should be used for insulating coatings

on all non-ferrous metals and on austenitic

stainless steels, e.g. paint, anodising

coatings, ceramics, etc. applied on

aluminium, copper, zinc die-casting, brass,

etc.

- FN probes work on a combination of the

magnetic induction and the eddy-current

principle. One probe only is required for

coating measurement both on ferrous and

non-ferrous metal substrates. When switched

to automatic mode (see 1.2) both principles

are used for coating measurement (the

gauge version MiniTest 600 B is not equipped

with an automatic mode to switch

automatically between the two measuring

principles).

General Information

ElektroPhysik 3

1.2 Description of the gauge

Measured values and user information are shown

on a large, easy-to-read LC display. A display back

light (optional) ensures easy reading of screen data

in poorly-lit conditions. The gauges’ user-friendly

measuring system permits automatic storage of up

to 9 999 readings in one memory matrix for later

statistical evaluation (statistical evaluation is not

possible with MiniTest 600 B).

Note:

- MiniTest 600 FN is equipped with a manual

as well as with an automatic mode.

- The manual mode serves to activate either

the magnetic induction principle (F) or the

eddy-current principle (N) by means of the

arrow keys.

- Owing to a special evaluation algorithm the

correct coating thickness is always shown

after corresponding calibration when the

Description of the gauge

4 ElektroPhysik

gauge is switched to automatic mode working

on ferrous steel as well as on non-ferrous

metal (the gauge version MiniTest 600 B is

not equipped with an automatic mode).

- The statistical values measured on steel or

on nonferrous metal (n, x, s, max, min) are

stored in separate memories.

- All MiniTest 600 gauges are suitable for

particular fields of application, e.g. for

measurement on special geometries. After

storage of the corresponding parameters the

gauge automatically takes them into

consideration.

The portable data printer MiniPrint 4100 allows

immediate printing of measured values and subse-

quent printing of the 5 statistical values. The data

printer is connected to the MiniTest by means of a

cable and is instantly ready for use (printing and

statistical evaluation are not possible with MiniTest

600 B).

Description of the gauge

ElektroPhysik 5

1.3 Equipment

Standard gauge including probe(s), 2 alkaline

batteries, zero standards, calibration foils and

operating instructions.

1.4 Probe construction

All probe systems are spring-mounted in the probe

sleeve. This ensures safe and stable positioning of

the probe and even contact pressure. A V-groove in

the sleeve of the probes facilitates reliable readings

on small cylindrical parts.

The probe should be held by the spring-mounted

sleeve.The hemispherical tip is made of hard and

durable material.

Equipment and probe construction

6 ElektroPhysik

2. Preparing the MiniTest 600

gauges

2.1 Checking the power supply

1. 2 x 1.5 volt alkaline-battery or

2 x 1.2 volt rechargeable battery

2. Check battery condition by pressing ON .

- no LC display:

battery missing or batteries charge too low

to illuminate display

- no BAT display:

batteries is sufficiently charged

- flashing BAT display, gauge switches itself

off after about 1 sec:

replace batteries immediately

Checking the power supply

ElektroPhysik 7

If the BAT display flashes during measurement, the

batteries are running low and should be replaced

before the gauge is switched on again. If not, the LC

display will show the permanent BAT warning and

the gauge will switch itself off after about a second.

Note:

Note that the gauge will not make faulty

measurements even if the voltage is very low.

2.2 Replacing the batteries

1. Place the gauge upside down on a suitable

surface.

2. Push the lid of the battery compartment in

direction of the arrow and raise the lid of the

compartment.

3. Remove batteries.

4. Insert new batteries.

5. Replace the battery compartment lid.

Replacing the batteries

8 ElektroPhysik

Caution:

Make sure that the positive and negative poles are

correctly positioned. If not, all data saved to memory

will be lost.

An interval of more than 10 seconds between

removing the old batteries and inserting the new

one will also result in the loss of data (readings,

calibration values, time and date).

2.3 Start-upfunctions

The MiniTest 600 gauges include a number of

functions that can only be called up or activated

through start-up of the gauge.

Function Key combination

Total reset ZERO + CLEAR + ON

LCD-Test ⇑−key + ON

Set gauge options ZERO + ON

Start-up functions

ElektroPhysik 9

2.3.1 Total reset

A total reset erases all statistical and calibration data

and the gauge will resume the basic MODI-setting

(ZERO - : / 0, see section 2.4).

1. Switch off gauge.

2. Press CLEAR-, ZERO- and ON

simultaneously.

Total reset is confirmed by a long bleep.

2.3.2 LCD segment test

The LCD segment test enables all sections of the

LC display to be inspected and checked.

1. Switch off the gauge.

2. Hold down the ñ-key, press ON and keep

both keys depressed. As long as the arrow

key is depressed, all sections of the LC

display will be shown.

Total reset and LCD segment test

10 ElektroPhysik

2.4 Basic gauge settings

1. Switch off the gauge, hold down the ZERO

key and press ON.

2. Keep both keys pressed until you hear the

signal. The gauge will now display a pair of

numbers: 1:0 or 1:1.

Note:

If you are using a MiniTest 600 FN, use the arrow

keys to activate the F section (ñ) or the N section

(ò) or wait 3 seconds until switching between

sections is performed automatically.

3. Press ZERO to move through each of the

table’s function from 1 to 4. Use the arrow

keys to set the option 0 or 1.

4. Press ZERO again to return to measuring

mode.

Basic gauge settings

ElektroPhysik 11

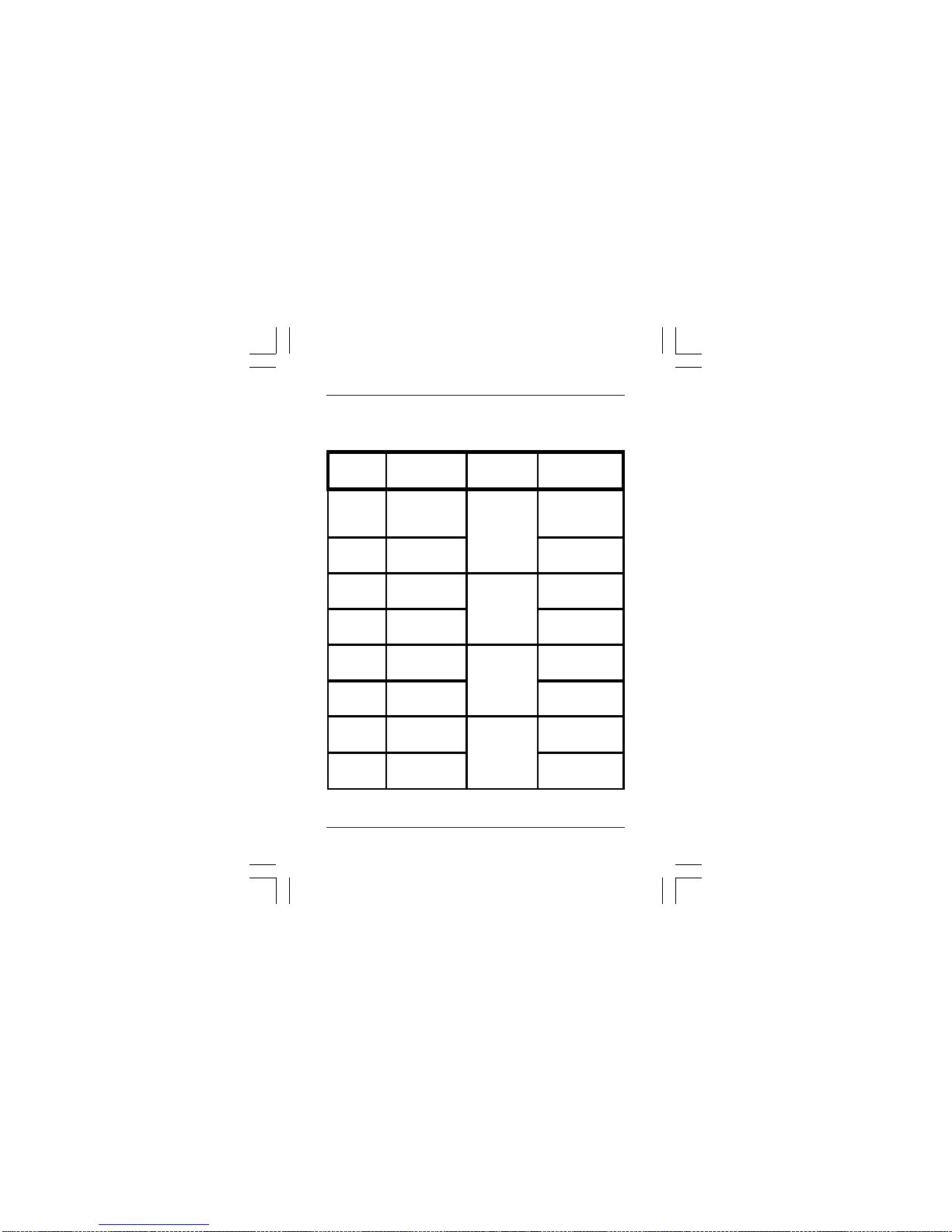

Table of basic settings

Basic gauge settings

Zero-key Arrow-keys↑ ↓ Modi-setting

10wwitch-off

mode short-term

mode

1 long-termmode

2 0 key lock

mode for

ZEROCal

off

1keylock

30displaylight

(option) inactive

1active

4 0 measuring

mode metric/mm

1 imperial/inch

12 ElektroPhysik

2.4.1 Switching between short-term and long-

term modes

The gauge is programd to switch itself off after about

90 seconds of inactivity. This can hinder operations

in certain circumstances. In this case please switch

sto the alternative long-term mode.

To switch the gauge to long-term mode, please refer

to the table of gauge settings in section 2.4.

Adjust to the new mode with the ZERO- and arrow

keys as described.

2.4.2 KEYLOCK Function for ZERO- and CAL-

keys (locks calibration keys)

An accidental recalibration or unintentional offset

input can be prevented by using the KEYLOCK

function.

To activate the KEYLOCK function please refer to

the table of gauge settings in section 2.4. Select

option with the ZERO and arrow keys as described.

Short-term and long-term mode

ElektroPhysik 13

2.4.3 Activating/deactivating the LC display

light(optional)

A switch-on LC display lamp can be supplied as an

optional extra. When activated, it lights the display

for about 2 sec after a reading has been taken.

Please remember that using the lamp requires ex-

tra power.

To activate the display light please refer to the table

of gauge settings in section 2.4. Select option with

the ZERO and arrow keys as described.

2.4.4 Select a measuring unit

‘metric’ - ’inch’ (imperial)

Readings can be taken and displayed in metric and

imperial units. To switch from metric units (µm, mm,

cm) to imperials (mils, inch) or vice versa, please

refer to the table of gauge settings in section 2.4.

Select option with the ZERO and arrow keys as

described.

LC display light and selection of measuring unit

Table of contents

Other ElektroPhysik Test Equipment manuals