-3-

ASSE BLY INSTRUCTIONS

INTRODUCTION

Assembly of your SM-9600K Function Generator Kit

will prove to be an exciting project and give much

satisfaction and personal achievement. If you have

experience in soldering and wiring technique, you

should have no problem with the assembly of this kit.

Care must be given to identifying the proper

components and in good soldering habits. Above all,

take your time and follow the easy step-by-step

instructions. Remember, “an ounce of prevention is

worth a pound of cure”. Avoid making mistakes and

no problems will occur.

PARTS VERIFICATION

Before beginning the assembly process, familiarize

yourself with the components and this instruction

book. Verify that all parts are present. This is best

done by checking off each item against the parts list.

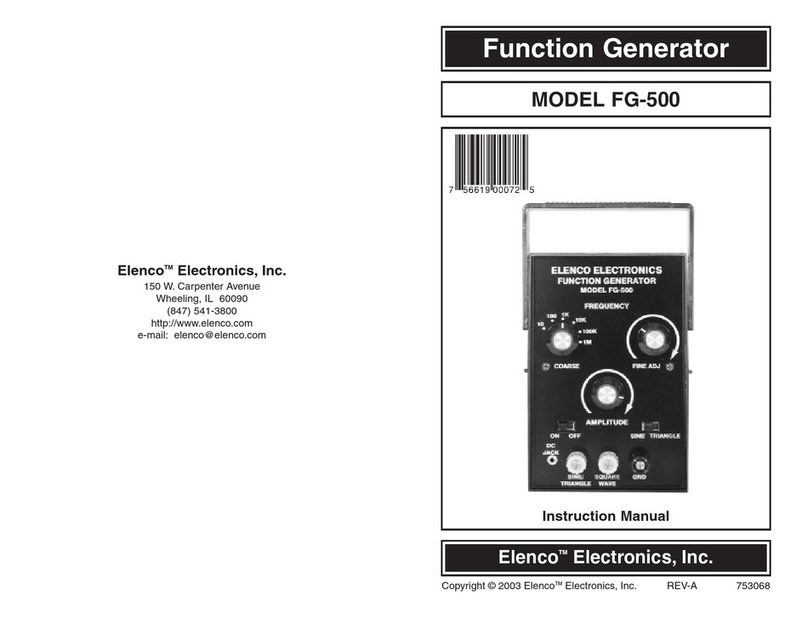

Care must be taken when handling the chip resistors

and capacitors. They are very small and are easily

lost. Chip resistors are marked with their component

value. The first two digits are the first two digits of the

resistance in ohms. The last digit gives the number

of zeros following the first two digits. The resistor

shown below is therefore 3,900Ω.

The values of the chip capacitors are not marked

on the component. To avoid mixing these parts

up, they should not be taken out of their

packages until just before they are soldered to

the PC board. The 0.01µF capacitors are packaged

three to a pack, as shown below. The 0.1µF

capacitors are in similar packaging with two to a

pack. The 820pF capacitor is the unmarked

component packaged one to a pack.

SAFETY PROCEDURES

• Wear eye protection when soldering.

•

Locate soldering iron in an area where you do not

have to go around it or reach over it.

•Do not hold solder in your mouth. Solder

contains lead and is a toxic substance. Wash your

hands thoroughly after handling solder.

• Be sure that there is adequate ventilation present.

SOLDERING TIPS

The most important factor in assembling your new

SM-9600K Function Generator Kit is good soldering

techniques. Using the proper soldering iron is of

prime importance. A small pencil type iron of 10-15

watts is recommended. A sharply pointed tip is

essential when soldering surface mount

components. The tip of the iron should be kept clean

and well-tinned at all times. Many areas on the

printed circuit board are close together and care

must be given not to form solder shorts. Solder

shorts may occur if you accidentally touch an

adjacent foil, particularly a previously soldered

connection, using too much solder, or dragging the

iron across adjacent foils. If a solder short occurs,

remove it with your hot iron. Use only rosin core

solder of 63/37 or 60/40 alloy.

Before soldering, the SM-9600K board should be

taped to the workbench to keep it from moving when

touched with the soldering iron. For a good soldering

job, the areas being soldered must be heated

sufficiently so that the solder flows freely. When

soldering surface mount resistors and capacitors, the

following procedure may be used:

1. Using tweezers, place the surface mount

component on the PC board pads and secure in

place with tape.

2. Apply a small amount of solder to the soldering

iron tip. This allows the heat to leave the iron and

flow onto the foil.

3. Place the iron in contact with the PC board foil.

Apply a small amount of solder simultaneously to

the foil and the component and allow them to

melt the solder.

4. Remove the iron and allow the solder to cool.

The solder should have flowed freely and not

lump up around the component.