-2-

CONSTRUCTION

Introduct on

Assembly of your M-115 Analog Multimeter Kit will prove to be an exciting project and give you much satisfaction and personal

achievement. If you have experience in soldering and wiring techniques, then you should have no problem with the assembly

of this kit. Care must be given to identifying the proper components and in good soldering habits. Above all, take your time

and follow these easy step-by-step instructions. Remember, An ounce of prevention is worth a pound of cure. Avoid making

mistakes and no problems will occur.

CAUTION: WEAR SAFETY GLASSES WHEN ASSEMBLING THIS KIT.

Assemble Components

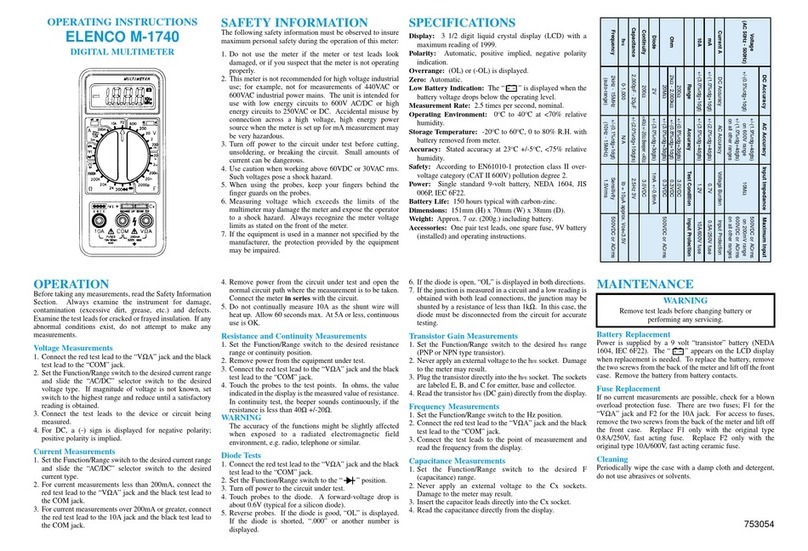

In all of the following assembly steps, the components must be installed on the top side of the PC board unless otherwise indicated. The

top legend shows where each component goes. The leads pass through the corresponding holes and the board is turned to solder the

component leads on the foil side. Solder immediately unless the pad is adjacent to another hole which will interfere with the placement

of the other component. Cut excessive leads with a diagonal cutter. Then, place a check mark in the box provided next to each step to

indicate that the step is completed. Be sure to save the extra leads for use as jumper wires if needed.

Solder ng

The most important factor in assembling your multimeter is good soldering techniques. Using the proper soldering iron is of prime

importance. A small pencil type soldering iron of 25 - 4 watts is recommended. The t p of the ron must be kept clean at all

t mes and well t nned. Many areas on the PC board are close together and care must be given not to form solder shorts. Size

and care of the tip will eliminate problems.

For a good soldering job, the areas being soldered must be heated sufficiently so that the solder flows freely. Apply the solder

simultaneously to the component lead and the component pad on the PC board so that good solder flow will occur. Be sure that

the lead extends through the solder smoothly indicating a good solder joint. Use only ros n core solder of 60/40 alloy. DO NOT

USE ACID CORE SOLDER! Do not blob the solder over the lead because this can result in a cold solder joint.

1. Solder all components from

the copper foil side only.

Push the soldering iron tip

against both the lead and

the circuit board foil.

Component Lead

Soldering Iron

Circuit Board

Foil

2. First apply a small amount

of solder to the iron tip. This

allows the heat to leave the

iron and onto the foil.

Immediately apply solder to

the opposite side of the

connection, away from the

iron. Allow the heated com-

ponent and the circuit foil to

melt the solder.

Solder

Soldering Iron

Foil

Example 1

Poor solder connections occur

when the lead is not heated

sufficiently. The solder will not

flow onto the lead as shown. To

correct. reheat the connection

and, if necessary, apply a small

amount of additional solder to

obtain a good connection.

Solder does not flow onto the

lead. A hard rosin bead sur-

rounds and insulates the con-

nection.

Poor solder

connection

Mount Part

Soldering iron posi-

tioned incorrectly.

Example 2

A solder bridge occurs when

solder runs between circuit

paths and creates a short cir-

cuit. This is usually caused

by using too much solder. To

correct this, simply drag your

soldering iron across the sol-

der bridge as shown.

4. Here is what a good sol-

der connection looks like.

Cut off excess leads.

3. Allow the solder to flow

around the connection.

Then, remove the solder

and the iron and let the con-

nection cool. The solder

should have flowed

smoothly and not lump

around the wire lead.

Solder Soldering Iron

Foil

Bend Leads to Hold Part Solder and Cut Off Leads

Rx - 1 Ω5% 1/4W Resistor

(brown-black-brown-gold)

Foil Side

þ