ELEXOL Ether I/O 24 R User manual

Ether I/O 24R Users Manual V1.0

Elexol Pty Ltd Version 1.0 Page 1 http://www.elexol.com

ELEXOL

ELECTRONIC SOL U T I ONS

ELEXOL

Ether I/O 24 R

Users Manual

Version 1.0

For Firmware Release 2.0

Ether I/O 24R Users Manual V1.0

Elexol Pty Ltd Version 1.0 Page 2 http://www.elexol.com

ELEXOL

ELECTRONIC SOL U T I ONS

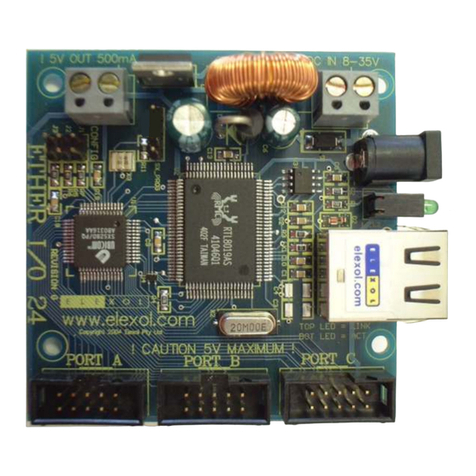

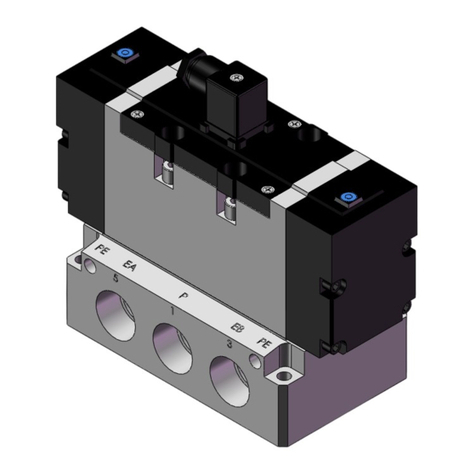

Ether I/O 24 R Module Hardware

I ÆÅD

H Æ

ÅC

ÅB

J Æ

ÅA

E F G

A. Ethernet Connector

B. LED Indicators

C. Power Connector 2.1mm DC Jack Center +

D. Power Connector Screw Terminal

E. Port A Connector

F. Port B Connector

G. Port C Connector

H. CONFIG Jumper Links J1-J4

I. Optional 5V output screw terminal

J. Factory Programming Header

Ether I/O 24R Users Manual V1.0

Elexol Pty Ltd Version 1.0 Page 3 http://www.elexol.com

ELEXOL

ELECTRONIC SOL U T I ONS

Table of Contents

Contents.............................................................................................................................................................. 4

Technical Support and Further Information...................................................................................................... 4

Functional Description....................................................................................................................................... 6

LED Functions ................................................................................................................................................... 6

Accessory Boards............................................................................................................................................... 7

Application Features .......................................................................................................................................... 8

Why should I use Ethernet?.......................................................................................................................... 8

Industrial Automation and Distributed I/O .................................................................................................. 8

Home, Office and Building Automation, Distributed control and Internet Connectivity......................... 10

Network Enabling your PC linked machine or equipment ........................................................................ 11

Electrical Characteristics ................................................................................................................................. 13

Absolute Maximum Ratings ....................................................................................................................... 13

Packet Timing Characteristics .................................................................................................................... 13

Module Connections ........................................................................................................................................ 14

Module I/O Connectors (PORT A, PORT B, PORT C) ............................................................................ 14

Module Configuration Options Connector (CONFIG J1, J2, J3).............................................................. 14

Ether I/O 24 Factory Programming Header (SX_PROG) ......................................................................... 15

Power Connectors ....................................................................................................................................... 15

Ethernet Connector ..................................................................................................................................... 15

Command Set Quick Reference ...................................................................................................................... 19

SPI Mode.......................................................................................................................................................... 30

EEPROM Memory contents............................................................................................................................ 31

Basic Programming.......................................................................................................................................... 32

1. Reading data from the Module ......................................................................................................... 32

2. Working with individual bits ............................................................................................................ 32

3. Finding a module’s IP address.......................................................................................................... 33

4. Basic set up and writing to the ports................................................................................................. 34

5. Reading the Ports .............................................................................................................................. 34

6. Programming the Input options ........................................................................................................ 35

7. Using the EEPROM .......................................................................................................................... 36

Advanced Programming .................................................................................................................................. 37

Programming the module to have a fixed IP address................................................................................. 37

Programming the module’s ports default power up state .......................................................................... 37

Programming the module’s ports default power up state .......................................................................... 38

Programming the AutoScan Mode ............................................................................................................. 38

Resetting the Module .................................................................................................................................. 38

Programmable Port Number ....................................................................................................................... 39

Glossary............................................................................................................................................................ 39

Document Revision History ............................................................................................................................ 40

Firmware Revision History.............................................................................................................................. 40

Ether I/O 24R Users Manual V1.0

Elexol Pty Ltd Version 1.0 Page 4 http://www.elexol.com

ELEXOL

ELECTRONIC SOL U T I ONS

Contents

When your Ether I/O 24 module arrives you should receive the following items.

1The Ether I/O 24 Module in a Protective Anti Static Bag

22 Jumper Links (please note that these links may be factory fitted to the CONFIG

connector on the board)

Please inspect the Module carefully for any damage that may have occurred during shipping or

handling. If you do not receive the module in its protective bag, if the Jumper links are missing,

or your module appears damaged in any way, please contact your place of purchase immediately.

Please be sure to download the latest support tools and datasheets from the ELEXOL

website at www.elexol.com and check that you are using the most up to date versions.

Technical Support and Further Information

For any questions relating to the Ether I/O 24 or if we can assist you with integrating the Ether

Ph: +61 755 031202 Fax: +61 755 031206

Elexol Pty Ltd Elexol Pty Ltd

Unit 1 PO Box 2742

8 Pirelli Street, Southport Southport Business Centre

Queensland 4215 Queensland 4215

Australia Australia

Product Use Limitations, Warranty and Quality Statement

This product is not designed, intended, or recommended for use in systems intended to support or

sustain life, or for any other application in which the failure of the product could create a situation

where personal injury or death may occur and should not be used for those applications.

The Ether I/O 24 is warranted to be free from manufacture defects for a period of 12 months from

the date of purchase. Subjecting the device to conditions beyond the Absolute Maximum Ratings

listed in this document will invalidate this warranty. As the Ether I/O 24 is a static sensitive device,

anti static procedures should be used in its handling.

All Ether I/O 24 units are tested during manufacture and are despatched free of defects.

Elexol is committed to providing products of the highest quality. Should you experience any product

quality issues with this product please contact our quality assurance manager at the above address.

Disclaimer

This product and its documentation are provided as-is and no warranty is made or implied as to

their suitability for any particular purpose. Elexol Pty Ltd will not accept any claim for damages

arising from the use of this product or its documentation. This document provides information on

our product and all efforts are made to ensure the accuracy of the information contained within.

The specifications of the product are subject to change and continual improvement without

notification.

Other than the extent permitted by law and subject to the Trade Practice Act, all and any liability

for consequential loss or damage arising from an ELEXOL Ether I/O24 module is hereby limited,

at ELEXOL’s discretion, to replacement or repair.

Ether I/O 24R Users Manual V1.0

Elexol Pty Ltd Version 1.0 Page 5 http://www.elexol.com

ELEXOL

ELECTRONIC SOL U T I ONS

Introduction

Thank your for purchasing the Ether I/O 24 Module. We trust that programming and using the

Ether I/O 24 will prove to be an ongoing positive experience for you.

Please take a moment to unpack and inspect your module to ensure it is undamaged and is complete

with the items listed in the contents section. As the module has several connectors that are critical to

its correct operation, please take a moment to familiarize yourself with the Module’s layout and

connector locations.

Along with the module itself you will require the following items for its operation.

1. A Power Supply 8 - 34V DC, Minimum 1.2Watts (0.1A@12V / 0.05A@24V)

2. A PC equipped with an Ethernet Network Interface and Software to support the TCP/IP

protocol suite

3. A Network cable for connection of the Module to your networks hub/switch or a crossover

cable for connection directly to the PC

4. One or more 5V operable devices or switches and connecting cables for operation by, or

connection to the module. (A range of accessory devices are available from your ELEXOL

distributor.)

The module’s test and programming software is only operable on a PC with the Windows operating

system. Your own software can be written to operate and program the module from any platform

that has an Ethernet connection. Full details of the programming and operation of the module are

contained in the programming sections of this manual.

UDP/IP packets sent over the network from any device with appropriate software are able to

operate the Ether I/O 24. The module has DHCP support to allow it to automatically obtain its IP

address from a suitable server device. If a DHCP server is not available, the module may be

configured by jumper link to a fixed address to allow for initial programming operations. Once

programmed, the device may have any IP address the user assigns.

Three Ports labeled Port A, Port B and Port C are for connection of the module to external digital

devices operating at 5V levels. These ports are standard 10 way box headers with 0.1” pitch. Each

of these ports has 8 I/O signals and the +5V and Ground lines from the module. As these groups of

8 signals are treated as a single byte for the efficient use of software resources, it is best to connect

devices of the same type to the same port. For Example, If you had LED illuminated switches then

it would be recommended to connect your switches to Port A and your LED’s to Port B, then to

make the switches control the LED’s you could simply read the value from Port A and write that

value to Port B.

Non-volatile memory on the module can be programmed to allow the module to have a fixed, user

assigned, IP address, to each of the ports to power up in a user defined state and/or to allow the

module to automatically scan any of it’s input lines at a user defined rate, filter the signals digitally

and transmit a UDP/IP packet to report any valid input line changes to a user programmed

destination address.

The Ether I/O 24 module has been designed and manufactured as a component of a larger system

that may consist of the module combined with, your own input and/or output devices, any of our

accessory boards connected to other components or modules, other 5V level operated modules and

devices by direct connection.

The Ether I/O and all of the accessory modules are built to a 72 mm standard width thereby

allowing their easy mounting to a DIN rail by means of commonly available DIN rail mounting

hardware. The modules also have mounting holes to allow 3mm or 1/8” mounting hardware to be

used. Care should be taken so as not to damage the printed circuit boards when mounting the

modules.

Ether I/O 24R Users Manual V1.0

Elexol Pty Ltd Version 1.0 Page 6 http://www.elexol.com

ELEXOL

ELECTRONIC SOL U T I ONS

Functional Description

The Ether I/O 24 is an integrated, micro-controller based network interface board with 24 digital

user I/O lines and an on board switch mode voltage regulator. The module’s firmware and

hardware enable your devices or other modules to be connected to a generic Ethernet network and

controlled or sensed using industry standard protocols. Each of the 24 User I/O lines operates at

5V DC maximum levels and can be independently programmed as, an Input whose state can be

remotely sensed via another network device, an Input whose state is internally checked and

transmitted when a change occurs, or an output whose state can be remotely controlled by another

networked device.

The IP Address of the module is determined either automatically by BOOTP protocol from a

DHCP server or is programmed by the user to be at a fixed address. The MAC or Ethernet

address of the module is factory programmed and cannot be altered by the user.

Onboard firmware reads the user configuration stored on the module’s onboard non-volatile

memory and sets the ports to a user configured state at power up. If un-configured, all ports will

be set as inputs with the input thresholds set at TTL levels and the pull-up function disabled.

If configured to do so, the module periodically scans any or all of the digital inputs, filters any

changes to remove noise and signals a remote unit of the changes. The scan rate can be set from

1 millisecond to 65.5 seconds and the filter can be set to discard any number of unstable readings

from 1 up to 255. Each of the 24 signal lines has an independent control bit that controls whether

the module detects changes on that line. Filtering is done on a per port basis with each port

filtered as a group. When any line is set as an output its state is not checked for changes.

If a PC controls the module, the Programmer must have access to an UDP/IP socket in order to

communicate with the module. The Winsock control in MS Windows operating systems provides

for such communication in a simple and easy manner. As other operating systems have different

methods of programming network sockets, please consult your operating system’s specifications,

software and language manuals for details of how to open a UDP/IP socket to communicate with

the module.

The programmer should note that the UDP/IP protocol requires an IP address and a Port Number

to allow communication with the module. The Port number for communication with the module

is 2424 decimal and this port number is used for all UDP/IP communications for module and port

programming. Other port numbers are used for the ICMP and BOOTP protocols, however the

programmer is advised not to use other ports unless they possess an extensive knowledge of these

protocols.

The IP address of the module can be programmed to a fixed address by a windows PC running

the ELEXOL Ether I/O 24 Test and Programming utility software (downloadable from the Elexol

website). Alternately, the user may program the fixed IP address from their own software by

using the EEPROM writing commands. If the Fixed IP address function is not used the module

will have a dynamically assigned IP address from the DHCP server. To find the IP address of any

module, broadcast a special message to port 2424 and each of the Ether I/O 24 modules will

respond, stating their IP address, Ethernet address and firmware version number.

LED Functions

There are 2 LED indicator lights on the Ether I/O 24 module; their operation is as follows.

UPPER LED = NETWORK LINK/ACTIVITY. This LED is illuminated when the module is powered and

the network interface has detected a connection. The LED will blink whenever there is

activity on the network link.

LOWER LED = VALID COMMAND. This LED illuminates for 0.1 second each time the unit processes a

valid command. When the commands are arriving faster than 10 times per second the

LED will be continuously illuminated.

Ether I/O 24R Users Manual V1.0

Elexol Pty Ltd Version 1.0 Page 7 http://www.elexol.com

ELEXOL

ELECTRONIC SOL U T I ONS

Accessory Boards

In order to connect devices that are not 5V operated or require isolation, ELEXOL has pre-built

accessory boards available. All accessory boards are equipped with box headers matching those

on the Ether I/O 24 module and are supplied with 30cm long connecting cables. All external

connections to the input or output channels of the accessory boards are by screw terminals that

will accept cables 0.5 – 2 mm2.

Opto Input Board,8 optically isolated input channels to accept signals from 3-24V AC or DC.

Each channel of the board is electrically isolated from all other channels and the I/O module

thereby preventing incoming signals from interfering with each other or damaging the I/O

module. The board has a box header matching the connector of the I/O module and an indicator

LED for each channel.

Relay Output Board,with both N/O and N/C contacts rated to 250V AC or DC at 5Amps. The

8 relays on the board can drive a multitude of devices. Each of the 8 relays on the board has a

matching LED to indicate its state.

Connector / LED Board, to provide for easy connection of larger wires to the Ether I/O 24

module or to provide a buffered visual indication of the states of all the signals on a port. The

Connector / LED Board can also be used simply as a mimic light board for a remote location or

for system diagnosis and debugging.

Switch / Push Button Board,allowing user inputs to be mounted along side the Ether I/O 24

module or for diagnosis and debugging. The Switch / Push Button Board features 8 miniature

pushbutton switches and 8 slide switches, with each channel having an indicator LED to show

that the board is powered and that the switch or the button is activated.

50 Pin Connector Board, to allow connection of industry standard I/O racks with 50 pin

connectors, this board will adapt the three 10 pin box headers on the Ether I/O 24 module to a

single 50 pin header with industry standard pin configuration.

Please check our website for further details of other accessory boards that may be released from

time to time.

Ether I/O 24R Users Manual V1.0

Elexol Pty Ltd Version 1.0 Page 8 http://www.elexol.com

ELEXOL

ELECTRONIC SOL U T I ONS

Application Features

The Ether I/O 24 has many unique features that enable its use in a great many applications. This

section will describe what makes the module ideal for many real world situations.

Why should I use Ethernet?

Ethernet is the most prolific, most quickly growing and most common network standard in the

world. Over 50 million pieces of equipment are already installed on this network. Ethernet is

most commonly carried over inexpensive CAT-5 UTP cable; for longer runs or where electrical

interference is an issue, fiber optic cable and converters may be used. Electricians and

communication system installers are very familiar with Ethernet cable systems and terminations,

thus making it easy to find an experienced installer. Ethernet infrastructure devices such as

switches, media converters and routers are readily available from numerous manufacturers and

vendors.

Industrial Automation and Distributed I/O

High-speed inputs and outputs. When used with a switched Ethernet network, the module,

with its high-speed inputs and outputs, provides a reliable and deterministic I/O platform. The

latency from command receipt to response transmission is less than 500 microseconds under all

circumstances. If short I/O packets are used, the latency will always be less than 200

microseconds. The high speed of the Ethernet interface to the control system will allow for

160,000 inputs to be read per second or 500,000 outputs to be controlled per second using off-the-

shelf Ethernet switches and Ether I/O 24 modules. Due to the nature of modern switched Ethernet

and full duplex communications the CSMA/CD system that plagued older, non-switched Ethernet

networks with collisions, packet loss and indeterminate transfer times, no longer provides an

obstacle to deterministic Ethernet communications.

AutoScan Mode. The AutoScan mode of the module allows changes of input signals to be sent

to the host without the host having to poll the module. An onboard digital low pass filter allows

the module to screen out noisy electrical signals or switch contact noise thereby removing this

burden from the system controller. Using this mode also allows one Ether I/O 24 to be connected

directly to another Ether I/O 24 module by an Ethernet or Internet link. The states of the ports on

one module can be sent to the other module without the need of a host system. Using this mode

and two or more Ether I/O 24 modules, several or even hundreds of signals can be sent from one

location to another by low cost twisted pair cable up to 100 meters in length. By using readily

available fiber-optic converters this distance can be extended dramatically.

Programmable Power-Up State. The module can be programmed to power up with all its

ports to a programmed state, thus if a machine needs to have certain devices enabled at power up

or if the machine designer desires all lamps to light in a lamp test, it is possible for the module to

accomplish this before the main control system is active.

Ether I/O 24R Users Manual V1.0

Elexol Pty Ltd Version 1.0 Page 9 http://www.elexol.com

ELEXOL

ELECTRONIC SOL U T I ONS

Industrial Automation and Distributed I/O (continued)

Fixed IP. Fixed IP addressing allows each module to be given a specific address that remains

constant throughout the life of the machine thereby simplifying machine software design and

allowing easy diagnosis of machine wiring faults.

Electrical Isolation. Electrical Isolation within the Ether I/O 24 module is provided by the

transformer coupling of the data signals. This means that when the module is used with an

Ethernet switch, a severe fault in one section of a machine resulting in high voltage being applied

to the module is unlikely to damage other parts of the machine. Most common bus systems do

not provide this level of isolation.

In industrial systems there is frequently a need for user controls with indicators to be placed at

several points on a machine and the economical nature of the Ether I/O 24 and other Ethernet

components make its use more affordable and easier to use than most other systems.

The star or multi linked star wiring of Ethernet makes for very easy fault diagnosis and the

onboard LED indicators of the module allow the diagnostician to quickly ascertain whether a

module is powered, active or dormant, and whether any Ethernet signals are reaching the module.

As all Ethernet switches also have link and activity LED indicators, it is easy to see if any parts of

the network are not communicating. This allows for quick diagnosis of any wiring faults in the

Ethernet signaling or power distribution systems. As each module has its own serial number, the

system’s control software is able to verify that all parts of the network and all I/O modules are

correctly communicating and notify the operator of the specific location of any malfunction. The

low cost per I/O line of the module allows for the monitoring of non-signaling inputs such as

power supply rails for advanced diagnostics.

Using Ethernet allows companies to utilize their existing IT infrastructure to convey control

information, messages or process data to various points throughout their facilities. The

economical nature of the Ether I/O 24 makes this an attractive alternative to other systems.

Ether I/O 24R Users Manual V1.0

Elexol Pty Ltd Version 1.0 Page 10 http://www.elexol.com

ELEXOL

ELECTRONIC SOL U T I ONS

Home, Office and Building Automation, Distributed control and Internet

Connectivity

Because of its low cost per I/O line, the Ether I/O 24 module ideally services the budget sensitive

building automation market. Ethernet’s low cost infrastructure, cabling and switching systems

combined with the ability of the Ethernet network to service other systems within a building

make it a single platform multi function network for delivering services throughout a building.

Ethernet networks can be used to deliver Voice Over IP telephony services, Internet and Local

Area Network services, Video and Audio on demand as well as control and monitoring of devices

or services within the building. With IP becoming the new standard for worldwide

communication and most modern buildings being fitted with Ethernet cabling during

construction, the Ether I/O 24 can economically share that infrastructure and optimize

connectivity.

The Ether I/O 24 in conjunction with the accessory boards can be used to control most electrical

devices. Future expansion of the accessory board range will allow additional devices to be

serviced by the module.

The falling costs of PC computing power combined with the fact that most new PC hardware is

equipped with an Ethernet port make the PC platform combined with Ethernet connectivity ideal

for central control of most mid to large scale systems. When linked to the Internet, an automated

building can be controlled and monitored from any Internet terminal; Internet enabled mobile

phone or other device anywhere on the globe. Wireless connectivity will further enable the

occupant to access their entire buildings network facilities without the burden of wires.

The low power consumption of the Ether I/O 24 module will enable the module to reduce the

additional cost burden of building automation on the utility bill. In many cases an automated

building may have a reduced utility bill through more efficient use of power. Load shedding

during peak demand times will allow building designers to purchase energy at lower rates and

electricity supply companies to make more efficient use of their infrastructure.

When connected to a router or if the main control PC has Internet access the system is able to

request its own maintenance or repair when a malfunction occurs. When a unit has run its

scheduled number of hours it can automatically contact the building supervisor or contracted

maintenance organization to arrange for service. By automating these services, the chances of

maintenance being overlooked and expensive malfunctions and downtime resulting will be

minimized. When a fault does occur, downtime can be minimized by prompt, automatic

notification to the correct people.

Ether I/O 24R Users Manual V1.0

Elexol Pty Ltd Version 1.0 Page 11 http://www.elexol.com

ELEXOL

ELECTRONIC SOL U T I ONS

Digital I/O from PCs

Ethernet is now standard on almost all PCs making it an attractive option for the connection of

I/O devices. In the past, using Ethernet for I/O has been too expensive or complicated. The Ether

I/O 24 now changes that situation with the cost of Ethernet I/O now similar to that of USB

solutions. The added advantages of longer cable length, an almost unlimited numbers of nodes,

electrical isolation and Internet connectivity, make Ethernet a very attractive option for I/O

connection.

No matter what you are connecting, if the requirement is for medium to large numbers of I/O

connections the Ether I/O 24 is an ideal solution. Additional modules enable the Ether I/O 24

module to connect to almost any electrical device, and with appropriate sensors or actuators, it

can be used to control or monitor almost any simple or complex system.

With wireless Ethernet now coming as standard on many laptop computers and wireless access

points becoming more economical, the Ether I/O 24 can be linked wirelessly to a laptop computer

by the same hardware that allows that laptop to connect to the Internet or other network services.

By connecting the Ether I/O 24 to a wireless network access point, any device that requires

monitoring by the network can be connected wirelessly.

Whether you are connecting a special function keyboard, indicator lights or a coffee machine, the

Ether I/O 24 will connect your device to your network and from there to your local PC or by

Internet, to the world.

Network Enabling your PC linked machine or equipment

If you’re designing a new PC linked machine or piece of equipment, imagine the end users

delight at finding an Ethernet connection on the back that enables them to place your new device

anywhere in their facility that the network reaches and control or monitor it from right from their

own PC wherever it is located. Multiple users may even be able to share the device or have

scheduled or queued access to it.

The Ether I/O 24 has been designed for easy integration into other equipment. By using the Ether

I/O 24 module as the main interface board in your machine, all control functions can be offloaded

to a host PC, thus eliminating the need to develop and program an embedded machine controller.

The high speed of modern PCs allows complex machine functions to be handled by the PC and

the easy software development environment of the PC enables more sophisticated machine

operations and user interfaces to be provided without the high development costs and unit costs of

embedded controllers. Your new devices’ software can now be easily updated or maintained via

the web. If a fault were to occur you could access all the machine’s functions remotely via the

Internet for instant diagnosis.

If higher speed or real time functions are required these can be implemented on your own boards

with connection back to the Ether I/O module for communication back to the controlling PC. The

Ether I/O 24 can easily communicate with your own boards by synchronous serial or clocked

parallel interface whereby a single packet from the host PC can send up to 250 bytes of data to

your board.

The Ether I/O 24 has been designed and physically laid out to simplify the task of users wishing

to incorporate the Ether I/O 24 as the principal interface element in their product. The Ethernet

and power connectors as well as the status LED indicators are aligned down one edge of the

board and the internal power outlets and I/O connectors aligned down the adjacent edges. The I/O

ports use low cost IDC connection cables and the board provides 500mA at 5V for your own

circuitry as well as access to the main incoming power feed for higher power devices. If your

device has an internal power supply the board can be fed from inside and the external connector

used for powering ancillary external devices or an Ethernet switch.

Ether I/O 24R Users Manual V1.0

Elexol Pty Ltd Version 1.0 Page 12 http://www.elexol.com

ELEXOL

ELECTRONIC SOL U T I ONS

Differences between Ether I/O 24 and Ether I/O 24R

The Ether I/O 24 R is the next version of the Ether I/O 24.

The End of life notice on the SX52 due to Non RoHS compliance / Packaging issues has forced

Elexol to update the Ether I/O 24 to incorporate the Parallax SX48.

The difference between the two versions are as follows

Ether I/O 24 Ether I/O 24R

Ether I/O 24

•Main Controller Ubicom SX52 (52 pin TQFP) End of Life due to Non RoHS

•Mechanicals 72mm x 72mm

•Not RoHS

Ether I/O 24R

Hardware Changes

•Main Controller Parallax SX48 (48 pin TQFP) RoHS Compliant

•Mechanical dimensions identical to Ether I/O 24

•New jumper for fixed IP address of 192.168.0.10

•RoHS Compliant

Firmware Changes

•Added Programmable port number

•Added Programmable subnet mask and gateway address

•Added SPI on PORT A (ability to send multiple bytes)

•Changes in Autoscan feature to perform ARP

•The ‘ , * and % commands are now redundant.

Ether I/O 24R Users Manual V1.0

Elexol Pty Ltd Version 1.0 Page 13 http://www.elexol.com

ELEXOL

ELECTRONIC SOL U T I ONS

Electrical Characteristics

Absolute Maximum Ratings

Warning! Exceeding these ratings may cause irreparable damage to the unit.

Parameter Absolute Maximum Conditions

Storage Temperature -65°C to +150°C

Ambient Temperature (Power Applied) -40°C to + 75°C

Power Input Voltage -1.0v to +35.00v DC

DC Input Voltage – Inputs -0.6v to +5.6v

DC Output Current – Outputs 45mA

DC Output Current – Total all outputs 210mA

Maximum DC current into an input pin ±500uA

Power Dissipation 3W

DC Characteristics (Temperature = 25°C, Power = 24VDC)

Packet Timing Characteristics

Parameter Conditions Min Typ Max Units

Response Time 1 Read Command in Packet 80 100 200 μS

Port Write Time Within one packet 1.5 μS

Port Write Speed 250 writes per packet 500,000 Writes/S

Port Write Time 1 write per packet 100 μS

Port Write Speed 1 write command per packet 10,000 Writes/S

Port Read Speed 1 read per packet 6,500 Reads/S

Port Read Speed 32 reads per packet 160,000 Reads/S

Parameter Conditions Min Typ Max Units

DC Input 8 35 V

Power Consumption 1.1 W

Temperature Range 0 65 ºC

Humidity Range 0 85 %RH

Logic Low

TTL

CMOS

Schmitt Trigger

0

0

0

0.8

1.5

0.75

V

V

V

Logic High

TTL

CMOS

Schmitt Trigger

2.0

3.5

4.25

5.0

5.0

5.0

V

V

V

Input Leakage Current Vin = 0V or 5V -3.0 +3.0 μA

Pull-Up Current 200 400 600 μA

Output High Voltage Load = 14mA 4.3 V

Output Low Voltage Load = 25mA 0.6 V

Ether I/O 24R Users Manual V1.0

Elexol Pty Ltd Version 1.0 Page 14 http://www.elexol.com

ELEXOL

ELECTRONIC SOL U T I ONS

Module Connections

Module I/O Connectors (PORT A, PORT B, PORT C)

All three of the I/O connectors are wired the same

I/O Port Pin Diagram

+5v User Power I/O Bit 7 (128)

I/O Bit 6 (64) I/O Bit 5 (32)

I/O Bit 4 (16) I/O Bit 3 (8)

I/O Bit 2 (4) I/O Bit 1 (2)

I/O Bit 0 (1) Ground

PIN # SIGNAL TYPE DESCRIPTION

1 +5v User PWR +5 Power supply out for user circuits

2 I/O 7 I/O Programmable I/O pin with bit value of 128 or $80

3 I/O 6 I/O Programmable I/O pin with bit value of 64 or $40

4 I/O 5 I/O Programmable I/O pin with bit value of 32 or $20

5 I/O 4 I/O Programmable I/O pin with bit value of 16 or $10

6 I/O 3 I/O Programmable I/O pin with bit value of 8 or $08

7 I/O 2 I/O Programmable I/O pin with bit value of 4 or $04

8 I/O 1 I/O Programmable I/O pin with bit value of 2 or $02

9 I/O 0 I/O Programmable I/O pin with bit value of 1 or $01

10 Ground PWR Ground Pin / Common reference for all signals

Module Configuration Options Connector (CONFIG J1, J2, J3)

The CONFIG connector is a 6 pin arranged as 2 rows of 3 pins. To set an option jumper place

one of the 2 supplied links across the 2 rows next to the corresponding label on the circuit board

overlay.

JUMPER# Function

J1 ON Lock EEPROM, OFF allows EEPROM writes

J2 ON DHCP, OFF LOAD IP FROM EEPROM IF PROGRAMMED else DHCP

J3 Fix IP – The module will operate at fixed IP address 10.10.10.10

J4 Fix IP – The module will operate at fixed IP address 192.168.0.10

Jumper J1, when placed will lock the EEPROM memory from any write or erase procedures.

Jumper J2 when placed, will cause the module to power up ignoring the user settings in the

EEPROM; DHCP will be enabled and port will be set to 2424. When not placed the user settings

will be loaded from the EEPROM if the fixed IP address is enabled this IP address will be loaded

else the unit will DHCP and load the port number programmed into the EEPROM. The unit is

programmed with default Port Number 2424.

Jumper J3, when placed will disable DHCP and override the EEPROM IP address settings and

force the module to used IP address 10.10.10.10 with Port 2424.

Jumper J4, when placed will disable DHCP and override the EEPROM IP address settings and

force the module to used IP address 192.168.0.10 with Port 2424.

Ether I/O 24R Users Manual V1.0

Elexol Pty Ltd Version 1.0 Page 15 http://www.elexol.com

ELEXOL

ELECTRONIC SOL U T I ONS

Module Connections (continued)

Ether I/O 24 Factory Programming Header (SX_PROG)

This header is used for factory programming, DO NOT USE this connector for any other

purpose.

Power Connectors

The Module has 2 types of power in connector; these connectors are connected directly to each

other. The 2.1mm DC jack is mounted overhanging the boards edge in order that the module can

be mounted with the network connector, power connector and status LEDs protruding through a

case. The second power connector or 5V from the module can then be used to power your own

circuitry. If the module is not mounted through a panel either or both of the power in connectors

may be used.

5V Out Screw Terminal Block (optional)

This terminal block, if fitted allows for the 5v supply from the onboard regulator to be used to

power user circuits and sensors. The maximum current that user circuits may draw from the on

board regulator is 500mA; if this current is exceeded then the operation of the board may be

adversely affected.

Ethernet Connector

The module is equipped with a standard RJ45 network socket and conforms to the 10 Base-T

standard. Only 4 of the 8 wires are used for network interface, 2 as a pair for data sent from the

module and 2 as a pair for data being received by the module the other wires are unused at this

time.

18

Ethernet Connector

Pin # Name Description

1 TXD + Transmit Data Positive Signal

2 TXD - Transmit Data Negative Signal

3 RXD + Receive Data Positive Signal

6 RXD - Receive Data Negative Signal

Pins 4, 5, 7 and 8 not used

Ether I/O 24R Users Manual V1.0

Elexol Pty Ltd Version 1.0 Page 16 http://www.elexol.com

ELEXOL

ELECTRONIC SOL U T I ONS

Command Summary

For ease of use we have broken the command set into subgroups based on their function.

All commands are shown as their ASCII characters, text in italics represent binary 1 byte

values.

Values that pertain to port Input, Output or control are shown as data, values that pertain to

address information are shown as address and values that represent 16-bit information are

shown as MSB and LSB. When a byte is required as padding or for future use it is shown as

dummy. Where a specific byte is required its hexadecimal value is shown with a dollar sign

thus $55.

The spaces shown are only for clarity and no actual spaces are used in commands sent to the

module.

Example Code

All example code is written in Visual Basic with the Winsock control named Winsock1. To execute these

commands you will need to Place a Winsock component on your form and set the following option.

Winsock1.Protocol = sckUDPProtocol

Other options will be discussed further in the text

The I/O lines are accessed as 3 ports and each line is controlled by its bit value within the data byte.

Port I/O Commands

Function Command Reply

Write Port A A data

Write Port B B data

Write Port C C data

Read Port A a A data

Read Port B b B data

Read Port C c C data

Port Configuration Commands

For each of the three I/O ports there are 4 commands used to set the ports’ options. First and

most critical of these options is Direction, which can be set as input or output. When set as

output, the I/O line will be driven to the last value written to the port. This value can be pre

set by writing to the port before writing to the direction register. When set as an output, none

of the other configuration commands have any effect. The Pull Up configuration command

applies to those lines that are set as inputs, writing a 0 to the corresponding bit applies a pull

up resistor to the line so that if it is not driven low it will be pulled to a known high state, this

is very useful if sensing contact closures or open collector outputs. The threshold function

sets the threshold at which a line reads as high or low. When the corresponding bit is set as 1

then the threshold is set at 1.4V and any voltage above this reads as a high level. When the

corresponding threshold bit is set to 0 the threshold is set at 2.5V and any voltage above this

reads as a high level. Last of the configuration commands allows the port to read as Schmitt

trigger inputs which means that the input line is compared to 2 voltages, 0.75V and 4.25V.

When the line’s voltage drops below 0.75V it will read as a low until the line’s voltage rises

above 4.25V at which time the line will read as a high. When the lines’ voltage is in between

0.75V and 4.25V, the value will remain stable at its previous level. To enable the Schmitt

trigger on any input a 0 must be written to the corresponding bit.

Write Direction A !A data

Write Direction B !B data

Write Direction C !C data

Write Pull Up A @A data

Write Pull Up B @B data

Write Pull Up C @C data

Ether I/O 24R Users Manual V1.0

Elexol Pty Ltd Version 1.0 Page 18 http://www.elexol.com

ELEXOL

ELECTRONIC SOL U T I ONS

Command Summary (continued)

Write Threshold A #A data

Write Threshold B #B data

Write Threshold C #C data

Write Schmitt A $A data

Write Schmitt B $B data

Write Schmitt C $C data

The EEPROM Reading and Programming Commands

All EEPROM commands must be sent as a single packet with 5 bytes, the module will ignore packets

with a size other than 5 bytes.

Read EEPROM word ‘R address dummy dummy

Write Enable EEPROM ‘1 address $AA $55

Write Disable EEPROM ‘0 address dummy dummy

Write EEPROM word ‘W address MSB LSB

Erase EEPROM word ‘E address $AA $55

Only the Read EEPROM command generates a response in the form of ‘R address MSB LSB

A special EEPROM command is used to reboot the module and cause it to load and activate any new

settings.

Reboot Module ‘@ dummy $AA $55

Identification and Information Commands

The module will always respond to a packet containing IO24, 4 bytes in length sent to port 2424.

The response contains the module’s six-byte MAC address and a two-byte firmware version number.

Ether I/O 24R Users Manual V1.0

Elexol Pty Ltd Version 1.0 Page 19 http://www.elexol.com

ELEXOL

ELECTRONIC SOL U T I ONS

Command Set Quick Reference

.

Table 1, Module Command Set

Bytes values include all Commands and Data sent in the packet

NU represents a value that is Not Used; a dummy byte must be included to ensure correct operation

- Means that there is no data or no response, do not insert data bytes

All hex values represented by $xx represent a single byte having this value

Command

ASCII Command

Hex

Bytes Data Function Response

Bytes Response

Identifier Response Data

A $41 2 Port_Value Write Port A - - -

B $42 2 Port_Value Write Port B - - -

C $43 2 Port_Value Write Port C - - -

a $61 1 - Read Port A 2 A PortA_Value

b $62 1 - Read Port B 2 B PortB_Value

c $63 1 - Read Port C 2 C PortC_Value

!A $21 $41 3 Direction Write Port A Direction Register - - -

!B $21 $42 3 Direction Write Port B Direction Register - - -

!C $21 $43 3 Direction Write Port C Direction Register - - -

IO24 $49 $4F

$32 $34

4 - Identify IO24 Units 12 IO24 6 Byte MAC Address

2 Byte Firmware Version

!a $21 $61 2 - Read Port A Direction Register 3 !A Direction

!b $21 $62 2 - Read Port B Direction Register 3 !B Direction

!c $21 $63 2 - Read Port C Direction Register 3 !C Direction

@A $40 $41 3 Pull_Up Write Port A Pull Up Register - - -

@B $40 $42 3 Pull_Up Write Port B Pull Up Register - - -

@C $40 $43 3 Pull_Up Write Port C Pull Up Register - - -

#A $23 $41 3 Threshold Write Port A Threshold Register - - -

#B $23 $42 3 Threshold Write Port B Threshold Register - - -

#C $23 $43 3 Threshold Write Port C Threshold Register - - -

$A $24 $41 3 Schmitt Write Port A Schmitt Trigger Register - - -

$B $24 $42 3 Schmitt Write Port B Schmitt Trigger Register - - -

$C $24 $43 3 Schmitt Write Port C Schmitt Trigger Register - - -

@a $40 $61 2 - Read Port A Pull Up Register 3 @A Pull_Up

@b $40 $62 2 - Read Port B Pull Up Register 3 @B Pull_Up

@c $40 $63 2 - Read Port C Pull Up Register 3 @C Pull_Up

#a $23 $61 2 - Read Port A Threshold Register 3 #A Threshold

#b $23 $62 2 - Read Port B Threshold Register 3 #B Threshold

#c $23 $63 2 - Read Port C Threshold Register 3 #C Threshold

$a $24 $61 2 - Read Port A Schmitt Trigger Register 3 $A Schmitt

$b $24 $62 2 - Read Port B Schmitt Trigger Register 3 $B Schmitt

$c $24 $63 2 - Read Port C Schmitt Trigger Register 3 $C Schmitt

‘R $27 $52 5 Address NU NU Read EEPROM Word 4 R Address MSB LSB

‘W $27 $57 5 Address MSB LSB Write EEPROM Word - - -

‘E $27 $45 5 Address $AA $55 Erase EEPROM Word - - -

‘0 $27 $30 5 NU NU NU Write Disable EEPROM - - -

‘1 $27 $31 5 NU $AA $55 Write Enable EEPROM - - -

‘@ $27 $40 5 NU $AA $55 Reset Module - - -

S1A $53 $31

$41

3 - Sets up Port A for SPI, sets bits 0-3 to

appropriate directions for SPI

3 S1A -

S0A $53$30$41 3 - Disables SPI on Port A, restores

direction values and port values to

what they were before an S1A

command

3 S0A

SAXX $53$41 X No.

of

bytes

X Data Bytes Sends out the data bytes on Port A via

SPI. The number of response bytes is

dependent on the number of bytes

sent.

SAXX X No. of bytes +

Response Bytes

Ether I/O 24R Users Manual V1.0

Elexol Pty Ltd Version 1.0 Page 20 http://www.elexol.com

ELEXOL

ELECTRONIC SOL U T I ONS

Command Set

Write Port A

ASCII Code Bytes Data Function

A 2 Port-Value Writes data to ports output lines. A bit value of 1 sets the

corresponding line high and a 0 sets it low

The power up default value for this port is 0

Operation: This command affects any of the eight lines of port A that are set as outputs. The port

value is written to the entire port with each of the values bits affecting the corresponding

I/O line. To change a single I/O line without affecting the others it is required to store the

old value of the port or read its current value before writing a new value with only the

corresponding bits changed. This command does not affect any I/O lines that are set as

Inputs.

Example: Winsock1.SendData “A” + Chr$(Value)

Write Port B

ASCII Code Bytes Data Function

B 2 Port-Value Writes data to ports output lines. A bit value of 1 sets the

corresponding line high and a 0 sets it low

The power up default value for this port is 0

Operation: Same as Write Port A

Example: Winsock1.SendData “B” + Chr$(Value)

Write Port C

ASCII Code Bytes Data Function

C 2 Port-Value Writes data to ports output lines. A bit value of 1 sets the

corresponding line high and a 0 sets it low

The power up default value for this port is 0

Operation: Same as Write Port A

Example: Winsock1.SendData “C” + Chr$(Value)

Write Port A Direction Register

ASCII Code Bytes Data Function

!A 3 Direction Writes data to port’s direction register. Lines with a

corresponding bit value of 0 are set as outputs, lines with a bit

value of 1 are set as inputs

The power up default for Direction is 255 setting all lines as inputs

Operation: This command affects all eight lines of port A. The Direction value is written to the entire

port with each of the bits in the byte affecting the corresponding I/O line. To change a

single I/O line without affecting the others it is necessary to store the old value of the port

or read its current value before writing a new value with only the corresponding bits

changed. To set the entire port as outputs use Direction = 0 to set all as inputs use Direction

= 255 to set 0, 1, 2 and 3 as inputs and 4, 5, 6 and 7 as outputs use Direction = 15.

Example: Winsock1.SendData “!A” + Chr$(Direction)

Ether I/O 24R Users Manual V1.0

Elexol Pty Ltd Version 1.0 Page 21 http://www.elexol.com

ELEXOL

ELECTRONIC SOL U T I ONS

Command Set (continued)

Write Port B Direction Register

ASCII Code Bytes Data Function

!B 3 Direction Writes data to ports direction register. Lines with a

corresponding bit value of 0 are set as outputs, lines with a bit

value of 1 are set as inputs

The power up default for Direction is 255 setting all lines as inputs

Operation: Same as Write Port A Direction Register

Example: Winsock1.SendData “!B” + Chr$(Direction)

Write Port C Direction Register

ASCII Code Bytes Data Function

!C 3 Direction Writes data to ports direction register. Lines with a

corresponding bit value of 0 are set as outputs, lines with a bit

value of 1 are set as inputs

The power up default for Direction is 255 setting all lines as inputs

Operation: Same as Write Port A Direction Register

Example: Winsock1.SendData “!C” + Chr$(Direction)

Write Port A Pull Up Register

ASCII Code Bytes Data Function

@A 3 Enable Writes data to port’s direction register. Lines with a

corresponding bit value of 0 have their pull up resistors turned

on, lines with a bit value of 1 have their pull up resistors turned

off

The power up default for Enable is 255; all pull up resistors turned off

Operation: This command affects all eight lines of port A whose direction is set as an input. The

Enable Value is written to the entire port with each of the bits in the byte affecting the

corresponding I/O line. To change a single I/O line’s behaviour without affecting the

others it is necessary to store the old value of the register or read its current value before

writing a new value with only the corresponding bits changed. To set the entire port with

pull up resistors turned on use Enable = 0 to turn all the pull up resistors off use Enable =

255 to set 0, 1, 2 and 3 as on and 4, 5, 6 and 7 as off use Enable = 240.

Example: Winsock1.SendData “@A” + Chr$(Enable)

Write Port B Pull Up Register

ASCII Code Bytes Data Function

@B 3 Enable Writes data to port’s direction register. Lines with a

corresponding bit value of 0 have their pull up resistors turned

on, lines with a bit value of 1 have their pull up resistors turned

off

The power up default for Enable is 255; all pull up resistors turned off

Operation: Same as Write Port A Pull Up Register

Example: Winsock1.SendData “@B” + Chr$(Enable)

Table of contents

Other ELEXOL Control Unit manuals

Popular Control Unit manuals by other brands

Duratrax

Duratrax SPRINT Forward Hardware installation guide

Sun Microsystems

Sun Microsystems Sun Blade X6270 Safety and compliance guide

Zano Controls

Zano Controls GRID 1-10V quick start guide

PC Pelser

PC Pelser SMT340 user manual

Intermatic

Intermatic P1353ME instruction manual

KLC

KLC Disco 240 user manual