ELEY 1041 Programming manual

Wall Mount Garden Hose Reel

Model 1041

Assembly & Installation Instructions

Page 2

Reel Specications

Max. Temperature....140° F (60° C)

Max. Pressure.............150 PSI (10 Bar)

CONTENTS

Please DO NOT contact or return this

item to the retailer. Seek assistance

directly from ELEY Corporaon using

the informaon below.

PHONE:

1-866-523-2363 (toll free)

MON- FRI, 8am to 5pm (CST)

E-MAIL:

MON- FRI, 8am to 5pm (CST)

ONLINE:

The SUPPORT secon on our website

www.eleyhosereels.com is available

24/7/365 and contains assembly

videos, repair instrucons and FAQ’s.

QUESTIONS?

PROBLEMS?

123

4 5 6

7

89

10

11

12

13 14

15

10 16

17

Page 3

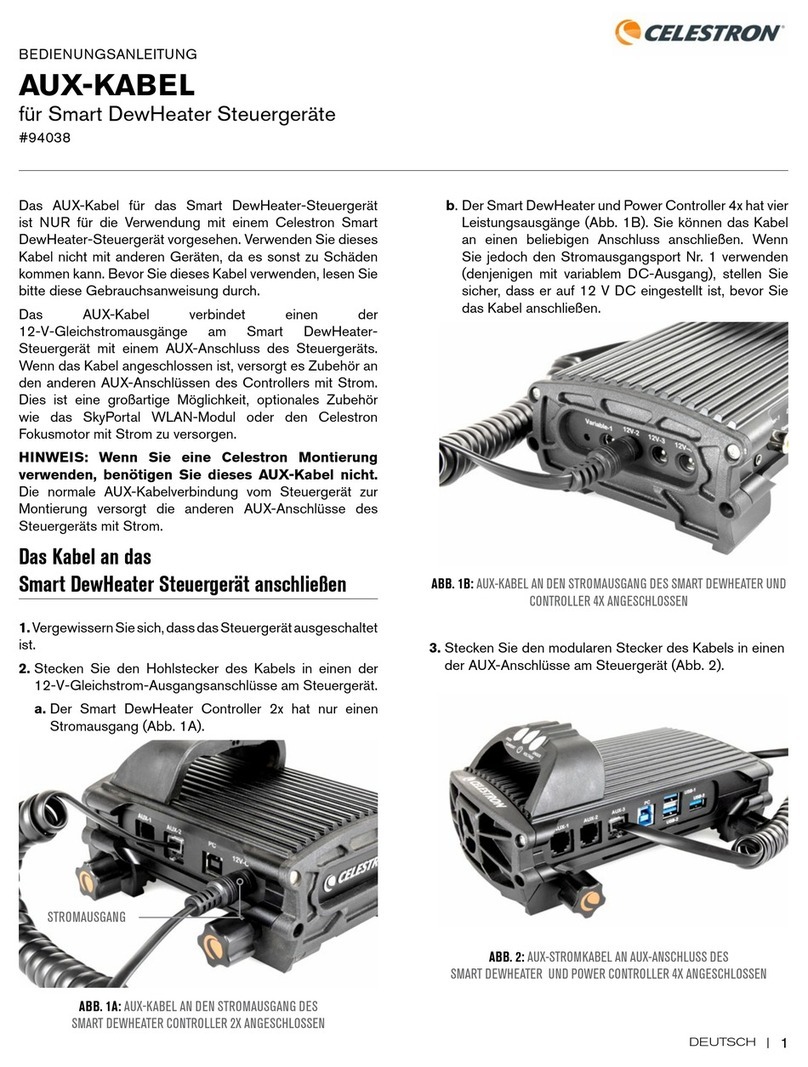

STEP 1

Place the Front

Flange (4027) on

top of the Back

Flange (4028).

Pins and sockets on

the anges will aid in

proper alignment.

IMPORTANT!

If you purchased an Extra-Capacity Kit

(Item# 1044) with your reel, please refer

to the assembly instructions included

with the Extra-Capacity Kit now. When

you have completed those instructions,

then proceed to Step 3 of this manual.

Standard Reel

Upgraded with

Extra-Capacity Kit

Page 4

STEP 2

Fasten anges together using the three

M6 x 20 Hex Socket Head Cap Screws

(4006) and the small hex end of the

Hex Key Wrench (4003).

STEP 3

Remove the screw from the

Handle Assembly (2654).

STEP 4

Install Handle Assembly

into Front Flange.

Page 5

STEP 5

Remove the two M10 x 25 Hex Socket Head Cap Screws

(4013) and 3/8” Flat Washers (2520) from the Garden

Hose Reel Arm (3071).

STEP 6

Determine which direction you want the reel to operate.

Parallel Perpendicular

STEP 7

Attach the Garden Hose Reel Arm (3071) securely to the Wall Mount Base (2558) using the two

previously removed M10 x 25 Hex Socket Head Cap Screws (4013) and 3/8” Flat Washers (2520).

Parallel Perpendicular

Page 6

Parallel Perpendicular

Step 8

Locate the reel base within 5 feet of your faucet. Note: Be certain there are no other

objects that may interfere with the proper operation of your reel.

Installation Option A - Masonry Walls

(For Option B, stud-wall installation, skip ahead to page 8)

Parallel Perpendicular

Step A9

Use a marker or pencil to mark the location of the four mounting holes on your wall.

Page 7

Step A10

Use a 5/16 inch masonry

bit (not included) and drill

1-1/2 inch deep holes at

the 4 marked locations.

Helpful hints:

Measure and then mark

the masonry bit with

masking tape to ensure

you drill at the proper

depth. Clean the holes

with a shop vacuum.

Wear eye and dust

protection.

Step A11

Position the Wall Mounting Base over the drilled holes and tap the four 5/16” x 1-3/4” Sleeve

Anchor Bolts (2598) through the base and into the holes in the wall.

Step A12

Tighten the four sleeve anchor bolts with a 7/16 inch wrench. Do not over tighten.

PerpendicularParallel

PerpendicularParallel

Proceed to step 13

on page 10.

Page 9

Installation Option B - Stud Walls

Parallel Perpendicular

Step B10

Use a 1/8 inch drill bit (not included) and drill 1-1/2 inch deep holes at the four marked locations.

Helpful hint: Measure and then mark the drill bit with masking tape to ensure you drill at the

proper depth. Wear eye protection.

Step B9

Use a marker or pencil to mark the location of the four mounting holes on your wall.

Note: Locate studs prior to drilling. The reel must be fastened to 2 studs.

Page 8

Perpendicular

Step B12

Tighten the four 1/4 x 2-1/2 inch Hex Head Lag Screws (2319) with a 7/16 inch wrench.

Do not over tighten.

Page 9

Perpendicular

Parallel

Step B11

If you are fastening to lap siding, use the four Standoffs (2510) between the Wall Mounting base

and the siding. Fasten the base to the wall with the four 1/4 x 2-1/2 inch Hex Head Lag Screws

(2319) and 1/4 inch Flat Washers (2331).

Parallel

Page 10

PerpendicularParallel

Step 13 - Insert the externally threaded (male) end of the Inlet hose (1087) into the axle tube

until it is accessible from the other side.

Step 14 - Install the Flange Assembly onto the axle with the crank handle to the outside.

Step 15 - Install the Cam-lever Brake (2587) onto the axle.

Note: Align the tab on the brake with the notch in the ange.

PerpendicularParallel

PerpendicularParallel

Page 11

Step 16

Attach the Swivel (2914) to the inlet hose.

Step 17 - Attach the Swivel to the axle. Hand tighten rmly.

Parallel Perpendicular

Parallel Perpendicular

Step 18

Position the Hose Strap

(4045) 32 inches from the

internally threaded (Female)

end of your garden hose.

Page 12

Step 19

Position the Hose Strap

(4045) so the grommets

pass through the small slot

in the ange.

Step 22

Hand tighten your

garden hose to the

brass swivel.

Page 13

Step 20

Tighten the hose

strap. The M6 x 65

Hex Socket Head

Cap Screw (4009)

will pass through the

1/4 inch Flat Washer

(2331) and the two

brass grommets on

the hose strap and

then thread into the

cage nut on the reel

ange assembly.

Do not over tighten.

Step 21

Insert your garden

hose through the

large opening in

the reel ange.

Install the Anti-Kink

Spring (2367) into

the end of your

hose. The small end

rst.

Page 14

How to use the Cam-Lever Brake

As you pull the hose from the reel, our innovative cam-lever brake will

prevent the reel from “free-spinning”, unrolling more hose than you

want. The brake can be turned ON and OFF with the ick of the lever.

BRAKE ON

Pulling the hose out.

BRAKE OFF

Reeling the hose in.

Page 15

How to adjust the Cam-Lever Brake

1. Place the cam-lever in the “ON” position.

2. Pull enough hose off the reel to test the amount of drag created by the Cam-Lever Brake.

a. Too little drag, and the reel will continue to unspool hose after you’ve stop pulling.

i. Tighten the nut on the Cam-Lever Brake using a 3/8” wrench.

ii. Adjust 1/4 turn of the wrench.

ii. Test again.

b. Too much drag and it will be difcult to pull hose off the reel.

i. Loosen the nut on the Cam-Lever Brake using a 3/8” wrench.

ii. Adjust 1/4 turn of the wrench.

ii. Test again.

©2014 Eley Corporation PO Box 22640 Lincoln, NE 68542-2640 Rev. 04/14

Patents and Patents Pending (Manual Part # 4074)

Model: 1041 Serial # ____________________

Purchase Date:_________________________________

Purchased From:________________________________

10 Year Warranty

Coverage

Eley Corporation guarantees this hose reel, components and parts, unless otherwise specied,

to be free from defect, malfunction or failure in material, or workmanship, under normal use

and service, for a period of 10 years(120 months). Warranty period starts from original invoice

date. In the event of a defect or component failure, Eley Corporation will replace the specic

component(s) free of charge.

Exemptions

Warranty does not cover leaking due to damage caused by the use of acid, harsh chemicals

or mineral deposits. Warranty does not apply when products are used in excess of their

rated capacities and design functions or under abnormal conditions. The effects of corrosion,

and normal wear and tear are specically excluded from this warranty. This warranty does

not cover damage which occurs in shipment or failures which are caused by products

not supplied by the warrantor or failures which result from accidents, mishandling, faulty

installation, freezing, misuse or misapplication, abuse or neglect. Warranty is void if the

product or any part thereof has been tampered or altered in any manner, or damage that is

attributable to acts of God. Eley Corporation covers the replacement or credit of defective

parts only and does not allow for eld labor charges for removal, installation, analysis or

travel expenses. In no event shall Eley Corporation or its suppliers be liable for any damages,

whatsoever, arising out of the use of or inability to use this product. (Some states do not

allow the exclusion of limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you). Eley Corporation and its suppliers disclaim all

other expressed or implied warranties. Some states do not allow limitations on how long an

implied warranty lasts, so the above limitation may not apply to you. This warranty gives you

specic legal rights, and you may also have other rights which vary from state to state.

Other manuals for 1041

1

Table of contents

Other ELEY Cables And Connectors manuals

Popular Cables And Connectors manuals by other brands

Cooper Lighting

Cooper Lighting Halo Lazer Track Lighting LZR211 installation instructions

Reelworks

Reelworks SR101.01 instruction manual

Staubli

Staubli CombiTac uniq CT-GOF Assembly instructions

Fischer Connectors

Fischer Connectors FOH Assembly instruction

Redarc

Redarc SRC0001 manual

Philips

Philips SWV3104S/10 user manual