ELGO Electric P8511 Series User manual

SERIES P8511-000-P

P8511-000-P-E_25-04.doc Doku Art. Nr. 799000133

Single Axis Position Controller

for regulated (PID) positioning

• PID – regulated analogue positioning with +/- 10 VDC

• Integrated power pack (115/230 VAC)

• Single set operation

• Up to three different speeds

• Manual (inching) operation

• Extensive functions and parameters

2

1. SHORT DESCRIPTION 3

2. FUNCTIONS 4

2.2 Two speed operation 4

2.2 Three speed operation 4

2.3 PID - Analogue +/- 10 V regulation (optional) 4

2.3 Setting Datum 5

2.4 Encoder Monitoring 5

2.5 Quantity Counter 6

2.6 Fault Monitoring 6

3. FRONT PANEL 7

3.1 Functions of Display 7

3.2. Function of the Keypad 7

4. CONTROLLER IN OPERATION 8

4.1 Position to new value 8

4.2 Manual operation (Hand) 8

5. SETTING OF REGISTERS 9

5.1 Register Input 9

6. REGISTER LIST 10

7. DESCRIPTION OF REGISTERS 12

9. SETTING OF ANALOGUE PARAMETERS 26

10. FUNCTIONS OF THE INPUTS (CONNECTOR ST3) 27

11. FUNCTIONS OF THE OUTPUTS 28

12. CONNECTIONS 29

13. TECHNICAL DATA 31

14. INSTALLATION HINTS 32

15. TYPE DESIGNATION 33

LIABILITY EXCLUSION / GUARANTEE 34

3

1. Short Description

Whilst the P8511-000-P with option Analogue-output is specifically designed to provide closed

loop (Proportional, Integral, Differential) analogue control of 4 quadrant drives, it also serves

the purpose of operating as a 2 or 3 speed controller, as the P8511-000-R.

When used as a closed loop controller, it is essential that: -

1. A 4 quadrant drive – usually a high dynamic servo drive, is used.

2. The drive is capable of accepting a +/- reference signal for direction, without a dead-

band.

3. The Encoder is torsional rigidly coupled to motor.

4. The mechanics of the machine are backlash-free.

Whilst it is possible to use lower specification drives and mechanics, it may then not always

be possible to achieve the performance and accuracy which is commonly expected of a

closed loop system. When using a simple Inverter driven AC motor, it is essential to use the

drive in F/V or FCC mode, rather than the full Flux Vector (which tends to fight the position

controller at low speeds).

• 2 or 3 speed positioning

• Absolute and incremental positioning modes

• Operation in Single positioning mode

• Operation in manual, slow and fast mode

• Quantity counting with completed output

• Flexible multiplier for Display calibration

• Datum setting routines

• Tool offset compensation in incremental mode

• Incremental error compensation

• Backlash compensation

• Tolerance window blanking

• Encoder and drive failure detection

• Maximum Encoder frequency 20 kHz

The unit is suitable for operation with any type of 2 or 3 speed bi-directional drive or any

variable speed drive with 1, 2 or 4 quadrant of control. The performance and accuracy

obtained is dependent on the type of drive chosen. The outputs for stepped speed drives are

transistors.

These outputs can be configured in a number of ways to suit all types of control circuits.

The actual position is monitored by an incremental encoder. The power supply unit can be

integrated. The controller can be used to position machinery to any desired absolute position.

Alternatively, the controller can be used to feed material through a process.

As an Analogue closed loop controller, it has the additional features of :

• Analogue output +/- 10 VDC

• Top speed setting

• Acceleration/Deceleration rate settings

• PID term optimisation

• Go to Datum routines

4

2. Functions

2.2 Two speed operation

NB: R1 = R2 > R3 The value in Register 1 must be the same value as Register 2

2.2 Three speed operation

NB: R1 > R2 > R3 The value in Register 1 must be larger than Register 2

NB: The stop offset is only effective when R8 = 1xxxxx.

2.3 PID - Analogue +/- 10 V regulation (optional)

The setting is effected using Registers R50 to R66

Creep

point

F

ast (and slow)

creep

D

emand position

S

top Offset P

3

P

2

Fast

slow

creep

Slow point

P 1

Demand position

Creep point

P 2

Stop Offset

P 3

D

P

Speed

Time

I – Limit or

Target speed

I

5

2.3 Setting Datum

Datum can be set in a variety of ways. The method is selected in Register R8/3

R8 = xx0xxx Datum to R7

Closing input St 3 / 4 transfers the value set in R7

into Actual Value Display

R8 = xx1xxx Setting to Preset

Closing input St 3 / 4 transfers the Target display

value into Actual Value Display

R8 = xx2xxx Automatic Datum setting - direction positive

R8 = xx3xxx Automatic Datum setting - direction negative

R8 = xx4xxx Datum with keypad alone

The value of R7 is transferred to Actual Display by

accessing R7, typing in value and then pressing E.

Operation of “Go to Datum”

After “power on”, initiating “Start” or “Datum” will cause the Axis to move in the direction

set in R8/3. The output “Going to datum” St5/7 is active.

When the Axis activates the respective end limit switch, it will stop for a time as set in

R10. It will then move slowly in the opposite direction. When it crosses off the limit

switch, the Encoder marker input St1/8 is enabled. When the next marker pulse is

detected, the Axis stops and value of R7 is loaded into actual window.

The going to datum output is now turned off.

The speeds for going to Datum are set as follows ;-

1. Analogue control

First phase (from start to hitting end limit)

Speed set in R67 (rpm)

Second phase (from reversal to marker pulse)

Speed set in R68 (rpm)

2. Switched speed control

First phase (from start to hitting end limit)

Speed set in R69

For Creep speed R69 = xxxxx0

For Slow speed R69 = xxxxx1

For Fast speed R69 = xxxxx2

Second phase (from reversal to marker pulse)

Speed is always equal

2.4 Encoder Monitoring

If, after positioning is activated, no Encoder pulses are received after a time set in R19

(0.1 to 9.9 sec), positioning will be aborted and fault 01 will be displayed.

Setting R19 to 0.0 sec, disables this feature.

6

2.5 Quantity Counter

Register R18/6 sets the method of counting whether adding or subtracting

R18 = xxxxx1 Automatic subtracting

R18 = xxxxx2 Automatic adding

R18 = xxxxx3 Manual subtracting (external input signal)

R18 = xxxxx4 Manual adding (external input signal)

R18 = xxxxx5 Automatic add/subtract (Single only)

R18 = xxxxx6 Manual add/subtract (Single only)

With adding function, the counter starts from zero. When the set quantity is reached, the

quantity complete output will be pulsed. With subtracting function, counting from preset

to zero takes place. When zero is reached, the quantity complete output will be pulsed.

With add/subtract function, subtracting will take place if a preset value is entered. On

reaching zero, adding will ensue. When the quantity counter goes from 1 to 0, a pulse

output is given.

The length of this pulse is set in P11. Setting 0.0 gives a maintained output.

2.6 Fault Monitoring

When a fault occurs, it’s number flashes in Actual Value Display

Fault number 01 = Encoder

02 = End Limit minimum

03 = End Limit maximum

04 = Actual Position < min software limit (R13) Hand

Target Position < min software limit (R13) Single

05 = Actual Position > max software limit (R14) Hand

Target Position > max software limit (R14) Single

* 07 = External stop activated or wire break

The fault message is cleared by pressing any button.

“07” also flashes if Stop on front panel is activated in middle of any move.

*NB: External stop input must be linked before system can operate. Therefore, if

external n/c pushbutton is not fitted, then insert a permanent wire link.

7

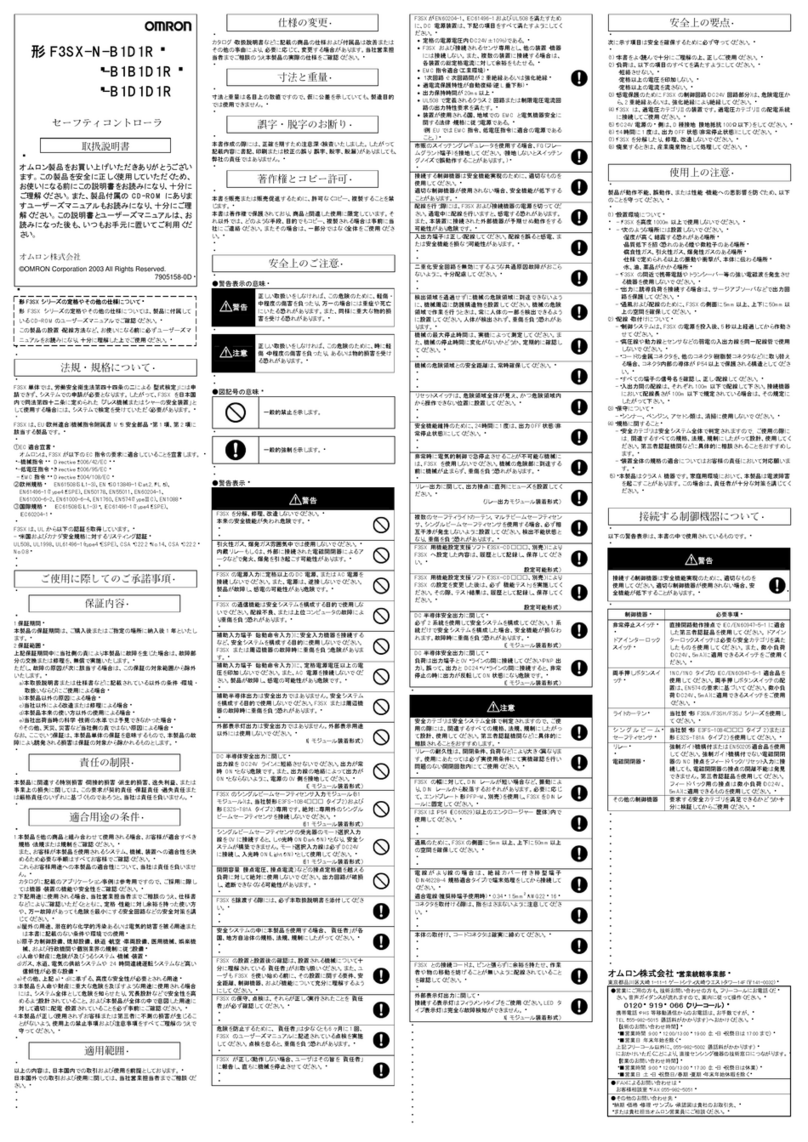

3. Front Panel

Cursor Button

Clear Button

Minus Symbol

Demand

Position

Actual

Position

Quantity

Select single position

or Hand operation

Function button

Start Positioning

Stop Positioning

LED 1-2

5

12

0

m

m

Start

Stop

897

4

C

Hand

Single

TYP

P8511

ELECTRIC

ELGO

>

6

3

>

F

Select

3.1 Functions of Display

Actual PositionShows the Actual Position of the axis

Target Position Here you can enter the required position (or Register value)

Quantity Window Shows how many pieces are left to be cut (or have been cut)

or

How many incremental moves yet to be completed.

LED “Hand” Illuminates when button “Select” is pressed

LED “Single” Illuminates when button “Select” is pressed

LED 1 - 2 Indicate which input window is being used selected by button >

3.2. Function of the Keypad

Select Selecting Single enables operator to enter a position Target value. Pressing > enables

quantity value to be entered. Pressing "Select“ again enables Hand operation.

Using Buttons 7 & 9 the Operator can move the axis manually

FSelects the Register setting mode (only active in Single)

Start Start positioning action. Start is inactive in Register setting mode and Hand mode

Stop Stops positioning action. Also clears error code. Stop is inactive in Register mode and

Hand mode.

> Sequentially selects Dimension or Quantity window. In Register setting mode selects

alternatively:- Register number and Register value.

C Clears the selected window to zero

0-9 Numerical Keypad for entry of values at all times

8

4. Controller in Operation

Switch on conditions is programmable in register R33:

R33 = xxxxx0 same conditions as at time of switch off

R33 = xxxxx1 Single mode

R33 = xxxxx3 Hand mode

The Actual position is memorised. In “Hand” the Target window line is switched off.

In “Single” the Target value is memorised

4.1 Position to new value

Press C : Clear Target position value

Press 0-9 : To enter desired position

Press > : Select quantity demand

Press C : Clear quantity value

Press 0-9 : To enter desired quantity

Press > : To ensure correct window selected

Press start : The axis moves to desired position

4.2 Manual operation (Hand)

Use the button "Select“ to select Hand (LED illuminates).

Use button 7 (forwards) & 9 (backwards) to move axis

The direction of rotation can be selected in P64

The buttons 7 & 9 have twin functions :-

Initially the axis moves at slow speed. When the time set in P32 has elapsed, the axis

changes into high speed. This condition continues till button is released.

In high speed, when the Actual position reaches preset software limits (P13 + P1) or

(P14 - P1), the speed automatically drops to creep.

9

5. Setting of Registers

5.1 Register Input

Press F for 2 sec The digits in Actual value display flash.

98 is displayed when Registers are protected by security code.

To unlock Registers :-

Press > Select Target window

Enter 250565 The security code

Thereafter, the required Register is displayed. To alter value of Register proceed as follows:-

Press > The Actual value display reads 01 for Register 1

Use keypad 0 to 9 To enter desired Register number

Press > The value of that Register is displayed in Target Window

Press C To clear old value

Use keypad 0 to 9 To enter desired Register value

Press > The Register value is stored in memory. The Actual Value display indicates

next Register number

A number of Registers may be set sequentially.

Press F for 2 sec The Register entry is ended. Actual position is again displayed

Registers without function cannot be accessed.

Once Registers have been unlocked, you may alternate between operation and Register entry

mode without the need for further security code entry.

The Registers can be locked away, by either

Powering down, or

Selecting Register 98; press > ; press F for 2 sec.

10

6. Register List

Register Function Resolution Suggested

initial setting

Custome

r

01 Slow speed distance 0.1 mm 200

02 Creep speed distance 0.1 mm 100

03 Stop offset 0.1 mm 0

04 Backlash compensation 0.1 mm 50

05 Retract distance 0.1 mm 500

06 * Tool Width 0.1 mm 0

07 Datum value 0.1 m 1000

08 System Register 1 See para 7.8 000000

09 Position reached pulse 0.1 s 10

10 Backlash dwell time 0.1 s 10

11 Quantity reached pulse 0.1 s 10

12 Tolerance window 0.1 mm 0

13 Min software limit 0.1 mm 0

14 Max software limit 0.1 mm 500000

15 Software limit selection See para 7.15 000000

17 Display brightness 0-15 10

18 System Register 2 See para 7.16 000001

19 Encoder pulse monitor time 0.1 s 0

20 Decimal point See para 7.17 0

24 Backlash distance 2 0.1 mm 0

25 Fixed Position 0.1 mm 1000

28 System Register 3 000000

29 Time delay for Drive inhibit 0,1 sec 10

30 Programme end pulse 0,1 sec 10

31 Closed loop inhibit time in Hand 0,1 sec 10

33 Controller switch on condition 0,1 sec 0-2

34 Start time delay time 0,1 sec 10

40* Programme Block selection See para 7.22 1

41 Number of lines in Prog Block 1-99 20

50 Speed UPM 1-10000 10

51 Acceleration/Deceleration revs/sec2 10

52 P term 1-3000 100

53 I term 1-1000 1

54 D term 1-1000 1

55 I limit 1-1000 1

56 Encoder edge multiplier 1,2,4 1

57 Encoder pulses per rev 1-10000 100

58 Stop-ramp selection 1-3 000000

60 Speed back hand slow Rpm 100

61 Speed back hand fast Rpm 1000

11

62 Speed forward hand fast Rpm 1000

63 Speed forward hand slow Rpm 100

64 Direction of manual buttons 0.1 0

65 Speed to fixed position Rpm 500

66 Acceleration for fixed position revs/sec2 5

67 Speed datum sequence phase 1 Rpm 100

68 Speed datum sequence phase 2 Rpm 10

69 Speed datum sequence with

relays phase 1

0,1,2 0

88 System Register 4 See para 7.42 000000

90 Button enable in service mode 0,1,2 0

94 Inch / factor multiplier 0.0to 9.99999 0

96 Encoder pulse multiplication

0.00001 to 9.99999

100000

97 Inch / mm selection 0,1,2,3 0

98 Security code 250565

99 Service - -

*Logical sequence values such as these must always be present, regardless whether

3 speed, 2 speed or 1 speed drive is used.

P1 > P2 > P3 for 3 speed drive P1 = P2 > P3 for 2 speed or 1 speed drive.

Registers R06 and R07 can be accessed and changed without need for the Security Code.

The Registers R50 to 55, 57 to 63 and 65 to 68 are for analogue output only.

12

7. Description of Registers

R01 Slow speed distance forward/reverse or forward only (see R28/2)

Distance at which the controller switches from high speed to slow speed. The output high

speed will be switched off.

R02 Creep speed distance forward/reverse or forward only (see R28/2)

Distance to demand position at which the controller switches from slow to creep speed

R03 Stop offset distance forward/reverse or forward only (see R28/2)

The overrun distance can be programmed to compensate for distance from the switch-off

point of the motor to standstill. For exact positioning, the overrun distance should be very

small (0.0 to 0.5 mm). Therefore the mechanical friction should be steady and the creep

speed should be very slow.

During commissioning, first set R12 to zero (to eliminate Tolerance window blanking),

then set the value of R03 to 0.0 and execute a number of moves in both directions. Note

the average overrun distance and then set R03 to that value. Then set R12 to suit.

R04 Backlash overrun

To correct for screw or pinion backlash, the Target position should be approached from

one direction only. In positive direction therefore, the Target position will be overrun by

the value of R4 and driven back at creep speed after a time delay of R10, to the Demand

position.

R05 Retract distance

There are different modes available in the P8511, selectable by Register R18/2.

If R18/2 = 0 Retract Position = Actual + R5

If R18/2 = 1 Retract Position = Value of R5

Whilst the input St3/6 is held on, the slide will move to the “Retract” position. On release

of input, slide will return to the original position. (Value 0)

When input St3/6 is activated, the slide moves to position as set in R5 but will not return

to original position on release of input. (Value 1)

R06 Tool offset compensation

This Register can be accessed without Security Code. When moving in incremental, it is

often the case that the subsequent function is a cut that removes part of the material.

Thus to cut the correct preset lengths, it is necessary to move the demanded distance

plus the “Tool Offset”. This feature is active in incremental mode.

13

R07 Datum

The Datum value is stored in this Register. The value is used in different ways, in

accordance with setting of P8/3. Input St3/8 initiates loading. This Register can be

accessed without Security Code.

R08 System Register 1

This Register sets the basic operating functions of the unit.

Backlash

0 = no backlash compensation

1 = negative backlash comp

2 = positive backlash comp

3 = negative backlash on start in R24 window

4 = positive backlash on start in R24 window

Output Relay Configuration

0 = 3 speed operation - Fast, Slow and Creep

1 = 2 speed operation - Forwards & Backwards

2 = 2 speed operation - Run & Reverse

3 = Separate outputs - Fast & Slow forwards, Fast & Slow reverse.

4 = 3 speed operation forwards - Reverse direction is Fast only.

5 = 3 speed Binary coded - Forwards & Backwards

6 = 3 speed operation - Forwards & Backwards

Option

Datum

0 = Datum to R7 with external pulse by key-switch

1 = Datum to Target position window with external key-switch

2 = Automatic datum to positive direction limit

3 = Automatic datum to negative direction limit

4 = Datum to R7 by key-board only

Option

Type of positioning

0 = Analogue positioning

1 = Fast/slow/stop

14

Output Configurations

These depend on setting of Register R8/5

Value 0 3 speed operation (Elgo standard default)

3 speeds selected by relays 1,2 & 3

output 4 sets direction reverse

OUTPUT ST5/ 1 2 3 4

Creep forwards X

Slow forwards X X

Fast forwards X X X

Creep reverse X X

Slow reverse X X X

Fast reverse X X X X

R1 = Run, R2 = Slow & R3 = Fast combined with Run.

If used with 2 speed, R2 or R3 = Fast.

Can also be used with single speed.

Value 1 2 speed operation

Independent outputs forward and reverse

Independent outputs fast and slow

OUTPUT ST5/ 1 2 3 4

Creep forwards X X

Slow forwards

Fast forwards X X

Creep reverse X X

Slow reverse

Fast reverse X X

R1 = Run forwards, R4 = Run reverse, R2 = Creep, R3 = Fast

Value 2 2 speed operation

Speed set by Relays 2 & 3

Direction set by Relay 4

OUTPUT ST5/ 1 2 3 4

Creep forwards X X

Slow forwards

Fast forwards X X

Creep reverse X X X

Slow reverse

Fast reverse X X X

R1 = Positioning (drive inhibit or brake)

R2 = Creep, R3 = Fast (both independent)

15

Value 3 2 speed operation

Independent outputs for direction and speed

OUTPUT ST5/ 1 2 3 4

Creep forwards X

Slow forwards

Fast forwards X

Creep reverse X

Slow reverse

Fast reverse X

Value 4 3 speed operation

Forwards – 3 Outputs set speeds

Reverse – always fast

Output 4 = reverse

OUTPUT ST5/ 1 2 3 4

Creep forwards X

Slow forwards X X

Fast forwards X X X

Creep reverse X X X X

Slow reverse X X X X

Fast reverse X X X X

Value 5 3 speed operation

Binary coded Outputs 2 & 3 for speed

Output 1 = Forwards, Output 4 = Reverse

OUTPUT ST5/ 1 2 3 4

Creep forwards X X

Slow forwards X X

Fast forwards X X X

Creep reverse X X

Slow reverse X X

Fast reverse X X X

Value 6 3 speed operation

Output 1 = Run forwards, Output 4 = Run reverse

OUTPUT ST5/ 1 2 3 4

Creep forwards X

Slow forwards X X

Fast forwards X X X

Creep reverse X

Slow reverse X X

Fast reverse X X X

16

R09 Time position reached

During each move the controller gives an output to signal “positioning”. When 'in position'

the output is deactivated for the length of this pulse set in R9. Setting 0.0 gives a

maintained output. This output St5/14 is inactive when Actual position = Target position

+/- Tolerance window R12

R10 Backlash dwell time

When the machine stops at the end of the overrun, it is usually desirable to have a short

delay. The time is set in this Register.

R11 Pulse “Quantity complete”

When the quantity counter goes from 1 to 0, a pulse output at St5/16 is given. The

length of this pulse is set in R11. Setting 0.0 gives a maintained output.

R12 Tolerance window

It is possible to enter a value in Register R12 that represents an acceptable tolerance e.g.

0.1 mm. When the Actual Position is within the Tolerance window, the Actual position

displayed is made equal to the Target position. The actual error is not lost, as the

controller knows the true position.

Example: R12 = 0.2 Therefore tolerance window is +/- 0.2mm

Display without Tolerance set Display with tolerance set

R13/R14 Min/Max software limits

Fault Message

Target < Limit R13 = 04

Target > Limit R14 = 05

Single Operation

Immediately after start signal, the controller checks the software limits. If the Target

position is greater or smaller than the corresponding limit, the controller will stop and

show the error message on the display. The backlash distance in R4 is considered at the

check of the Max software limit, if the backlash is activated in R8/6.

Hand Operation

The movement will stop when software limits are reached. If moving at high speed, the

drive will drop to creep speed at a distance set in R1 from this limit. This prevents

Actual Display

Demand Display

17

running into the ends of the machine. The end limit values are modified by backlash value

as set in R4, if R8/6 is selected.

R15 Software Limit / End Limits Selection

Software limits (R13 & R14) are active in accordance with the setting of R15/6

xxxxx0 Both software limits active

xxxxx1 Min software limit (R13) inhibited

xxxxx2 Max software limit (R14) inhibited

xxxxx3 Both software limits (R13&R14) inhibited

External limit switches can be connected to the St3/3 negative direction and at St3/7 for

positive direction.

xxxx0x Both limits inputs active

xxxx1x Min limit input (St3/3) inhibited

xxxx2x Max limit input (St3/7) inhibited

xxxx3x Both software limit inputs (St3/3 St3/7) inhibited

N.B If these are not connected to limit switches they need to be connected Normally

closed (i.e. linked out).

R17 Display Brightness

Setting this parameter changes the brightness of the display.

0 = dark, and 15 = maximum brightness.

18

R18 System Register 2

This Register also sets the functions of the controller.

Demand Window

Quantity Counter

0 = no quantity counter

1 = automatic subtracting

2 = automatic adding

3 = manual subtracting (external input St3/7)

4 = manual adding (external input St3/7)

5 = automatic add/sub (in Single only)

6 = manual add/sub for (in Single only)

7 = automatic subtracting, STOP when “zero”

8 = manual subtracting, STOP when “zero”

Option

Option

Positioning in single

0 = Absolute

1 = Incremental + ve

2 = Incremental – ve

3 = Incremental from zero

4 = Incremental from zero with saw-blade in negative

Retract mode

0 = retract to Actual + P5 return on deactivation

1 = retract to P5 setting return on deactivation

2 = retract whilst input active return on deactivation

3 = retract to Actual + P5 without return

4 = retract to P5 without return

5 = retract whilst time in R 10 in positive direction, no return

6 = retract to Actual –P5 in negative direction, return on deactivation

7 = retract whilst time in R 10 in negative direction, return on

deactivation.

8 = retract to Actual –P5 in negative direction, no return.

9 = retract whilst time in R 10 in negative direction, no return.

Serial link

0 = none

1 = with RS232

19

R19 Encoder monitoring

If after positioning is initiated, no Encoder pulses are sensed after a time set in R19,

positioning will be aborted and Fault 01 will be displayed. Setting R19 to 0.0, disables

Encoder pulse monitoring.

R20 Decimal Point

The decimal point is placed in a fixed position and is optional only. It does not change the

resolution of the system. The position is dependent on setting of Register R97.

With R97 = xxxxx0 = mm mode

R20 = xxxxx0 = without

R20 = xxxxx1 = 1/10

R20 = xxxxx2 = 1/100

R20 = xxxxx3 = 1/1000

With R97 = xxxxx1 = Inch mode 1/100

Decimal point is fixed at 1/100

With R97 = xxxxx2 = Inch mode 1/1000

Decimal point is fixed at 1/1000

With R97 = xxxxx3 = “Inch” factor freely programmable in R94

R20 =xxxx0x = without R20 =xxxx1x = 1/10

R20 =xxxx2x = 1/100 R20 =xxxx3x = 1/1000

R21 Slow speed distance in negative direction

This parameter is important for application with different load conditions on forward or

backward if no use of automatic backlash compensation is desired. The Parameter R28/2

has to be set to 1 for activation.

Distance at which the controller switches from high speed to slow speed in negative

direction (the output high speed will be switched off).

R22 Creep speed distance in negative direction

Distance to Target position in negative direction can be set in this parameter at which the

controller switches from slow to creep speed

R23 Stop offset distance in negative direction

The overrun distance in negative direction can be programmed in this parameter to

compensate for distance from the switch-off point of the motor to standstill.

R25 Home Position

Activating the input St3/19 will send the Axis to a prefixed position as set in R25.

20

R28 System Register 3

This Register also sets the functions of the controller.

Target Window

Display windows in single mode

1 = Target Alone

2 = All Windows in use

START/STOP button inhibit

0 = both activated

1 = STOP disabled

2 = START disabled

3 = both disabled

START inhibit in the tolerance window

0 = Start in the tolerance window enabled

1 = Start input in the tolerance window disabled

External STOP logic

0 = Stop is activated when input is at low level

1 = Stop is activated when input is at high level

Separate slowdown parameter selection

0 = Slowdown in both direction set by R1, R2, R3

1 = Slowdown forward R1, R2, R3, reverse R21, R22, R23

R29 Time Delay for Drive inhibit (Positioning)

On activating start, output St5/15 is activated. On arriving in position, after a time delay

of R29 this output deactivates.

R32 Start delay time

When in Hand mode and the delay time set in this parameter has elapsed, the controller

will move from slow speed to fast speed operation.

R33 Power on mode

This parameter sets the switch on conditions of the unit.

R33 = xxxxx0 same conditions as at time of switch off

R33 = xxxxx1 Single mode

R33 = xxxxx3 Hand mode

The Actual position is memorised. In “Hand” the Target window line is swiched off. In

“Single” the Target value is memorised

This manual suits for next models

2

Table of contents

Other ELGO Electric Controllers manuals